The university technician said that it took 24 hours in total to create this part, and it looks amazing. Thankfully, he sounded like he was enjoying himself. He also milled out both the M6 brass grubs into the inserts, so I've got one spare. If I remember correctly:

- He had to do some operations on the manual tool changing machine because the £80K CNC one didn't have the holders for the tools

- He said those tool holders are £800 and up.

- He drilled the 1mm paths in 0.2mm increments to prevent the flute clogging up and the drillbit breaking.

- These two points contributed to the long working time.

- He liked that this was what us in the 3D printing world would call a torture test because of its complexity, and it was found that some GCODE commands weren't working correctly with the machine and someone else set up a post processing script to remedy the issue.

Also, the thermistor didn't fit and he was like "ah, that's why you specified 3.1. I only had 3mm" and another tech said that a 3.1mm drill bit came in yesterday, conviniently enough. Thus the hole was enlarged and it slides in now.

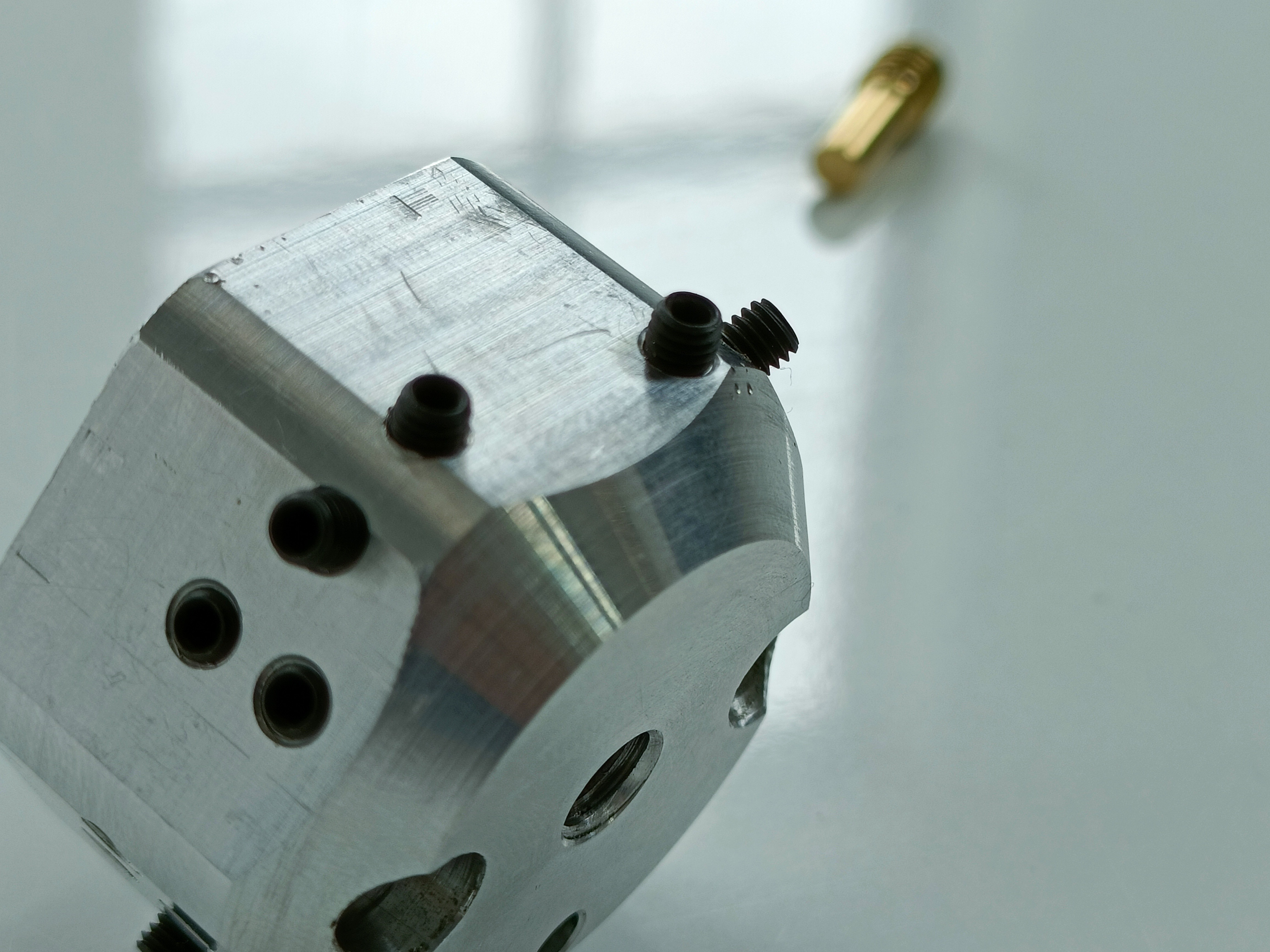

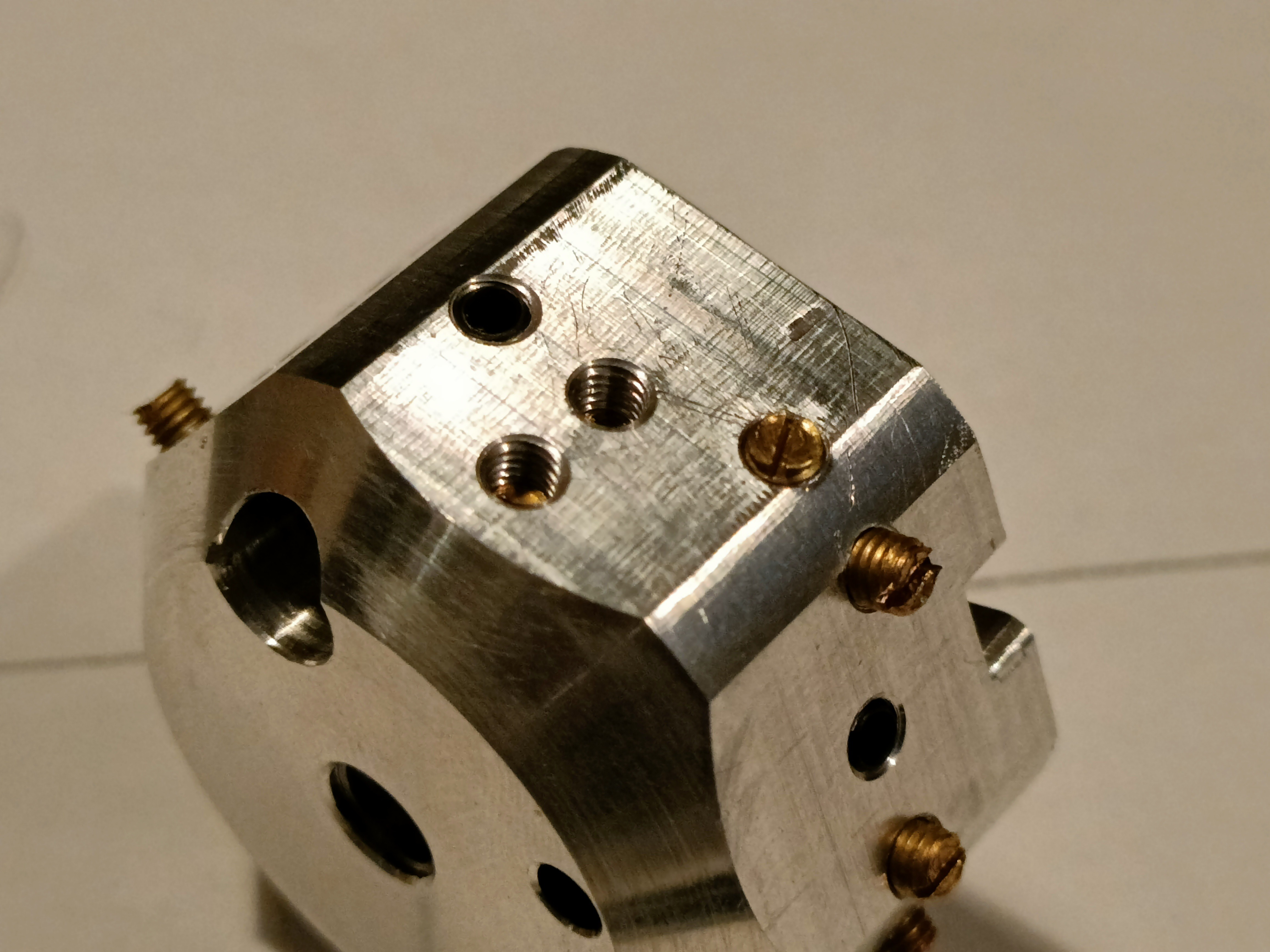

I wasn't expecting him to fill it with grub screws, and all but one were straight, which for a first attempt is rather good. It actually straightened out when I replaced most of them with the brass ones, since, as I feared, these small hex screws are really easy to slip on. I was able to put in more force with the slotted grub screws, and I'd even imagine that if I used stainless or hardened steel grubs, I could use them to self-tap the holes.

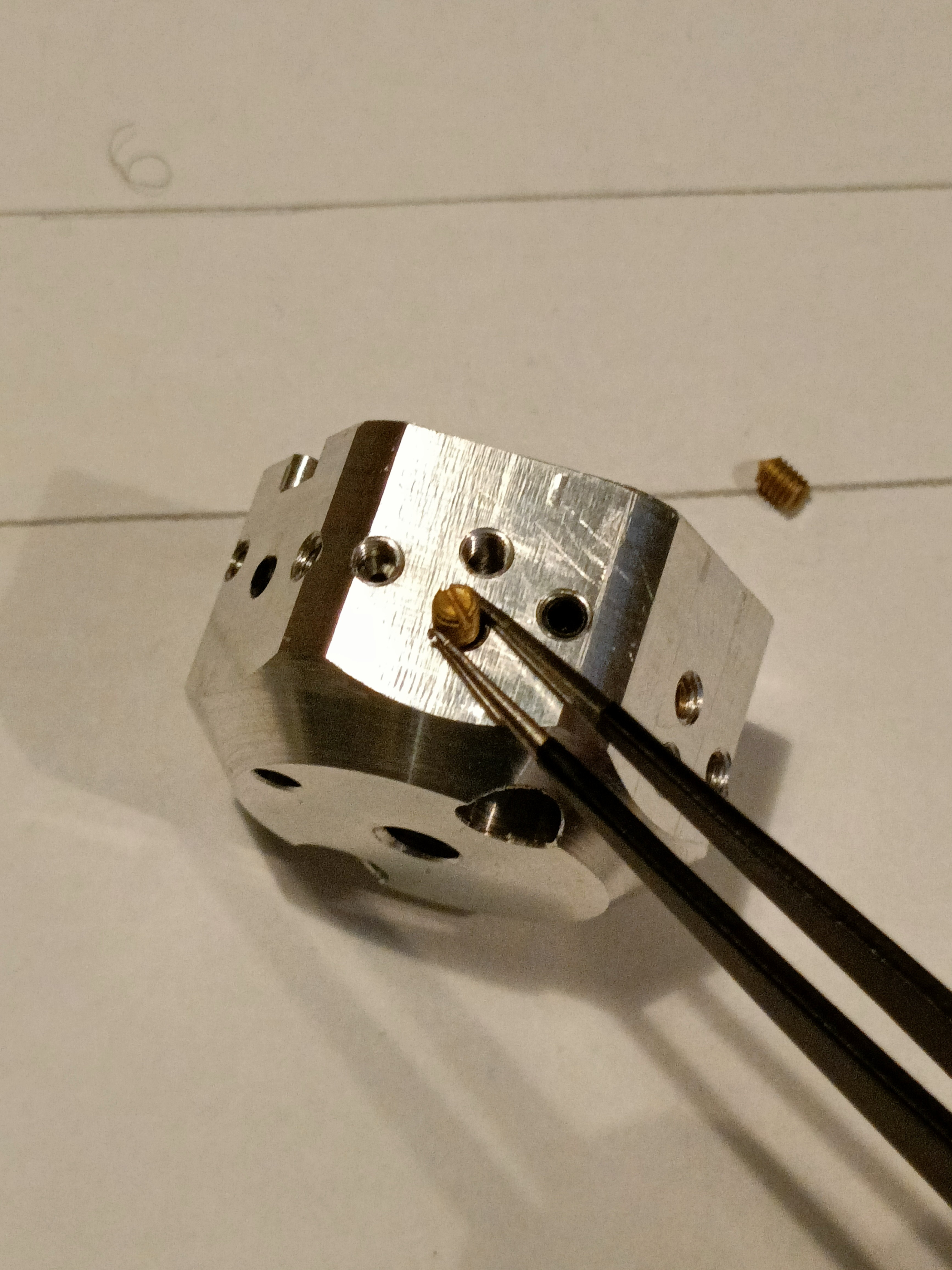

Unlike the black grub screws, brass is non-magnetic, so you'd need to use tweezers to hold them in place.

All the screws went in, but some deeper than others:

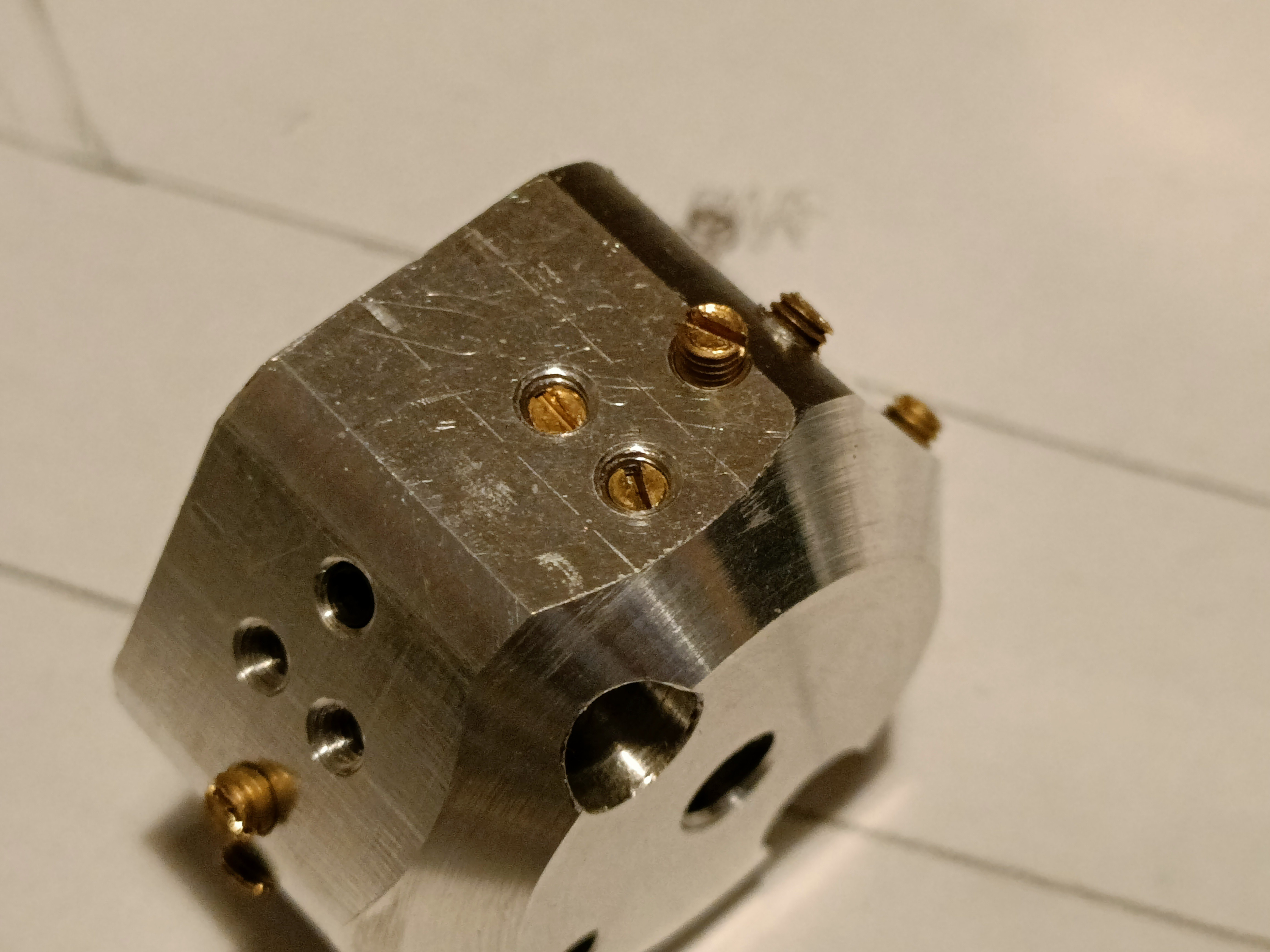

2 heatsinks wouldn't slot in as the heatbreak tilted ever so slightly when it bottomed out, and it was fixed by tightly screwing in an M6 bolt which I assummed cleared out any swarf that might be in the threads.

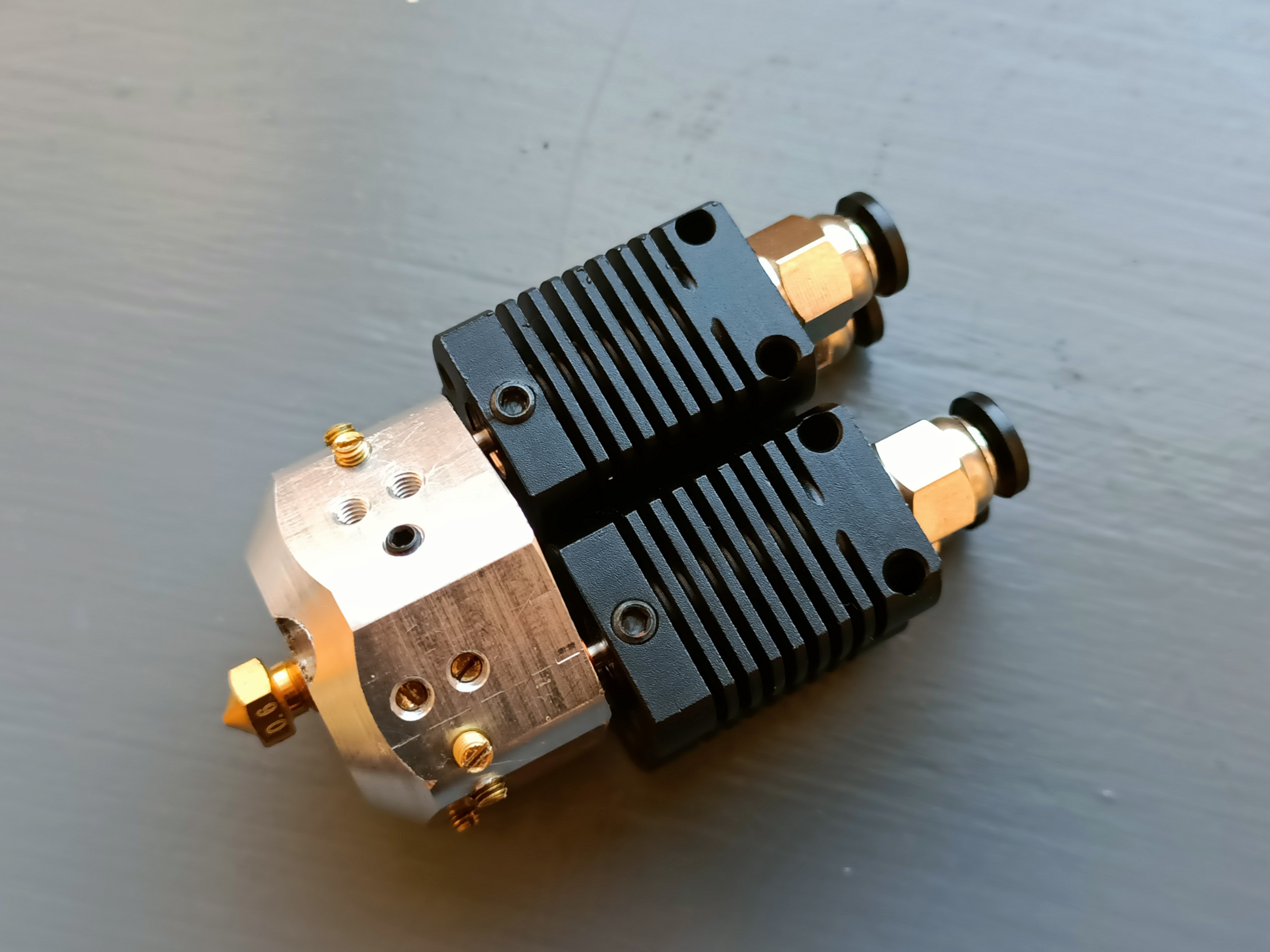

Bamme! Here it is, all together. For some reason, that grub screw on the top left heatsink is really tight compared to the other 3. I might see if an M4 bolt can widen the thread or if I could use an M4 tap at my uni tomorrow. The full weight is 116.5g, excluding the cartridges.

It feels good to get some tangible progress in one of my projects. This feeling of "I'm onto a winner here" is what I needed in my literal dozens of other projects that haven't made it as far. #Tetrinsic [gd0041], I'm looking at you when I say this.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.