So this took 6 hours to do. A long time, yes, but something I wanted to get done since the start of October. At least it's a nice way to start off the year of 2024.

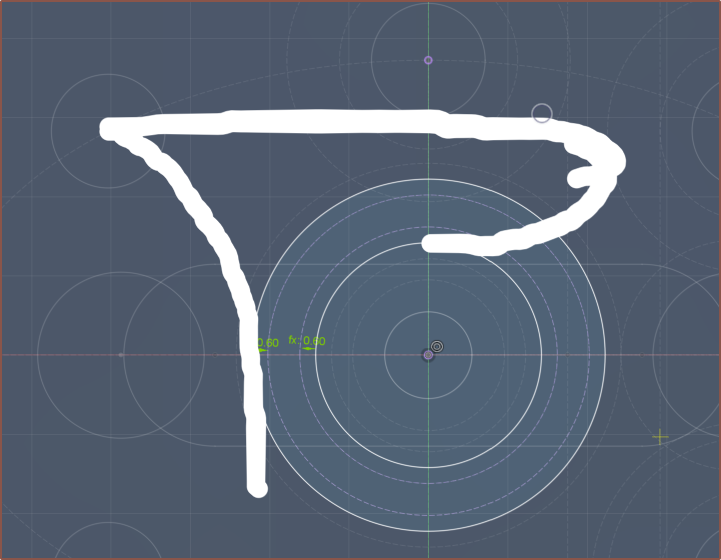

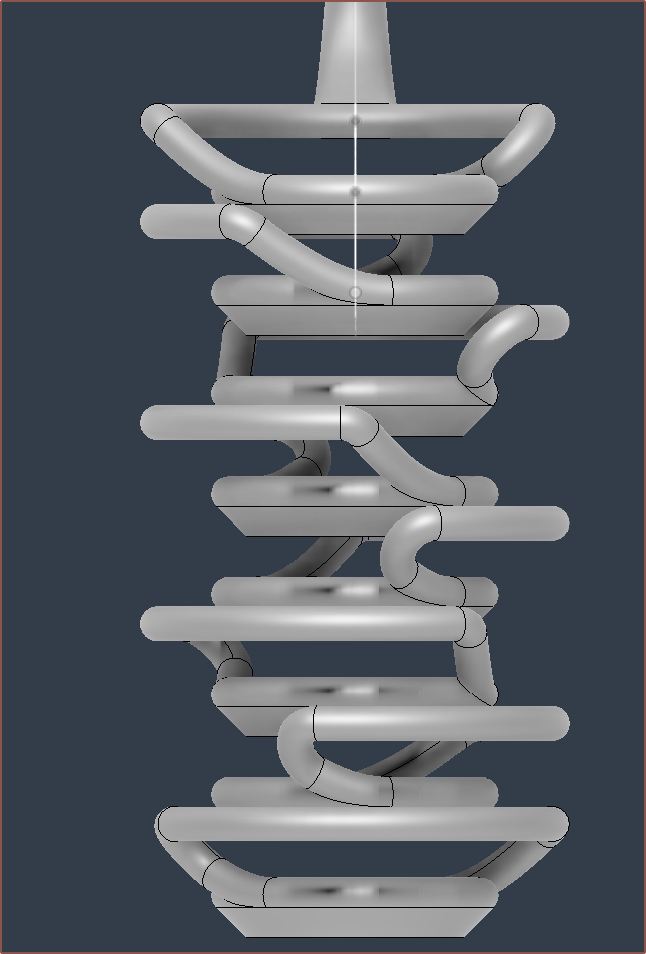

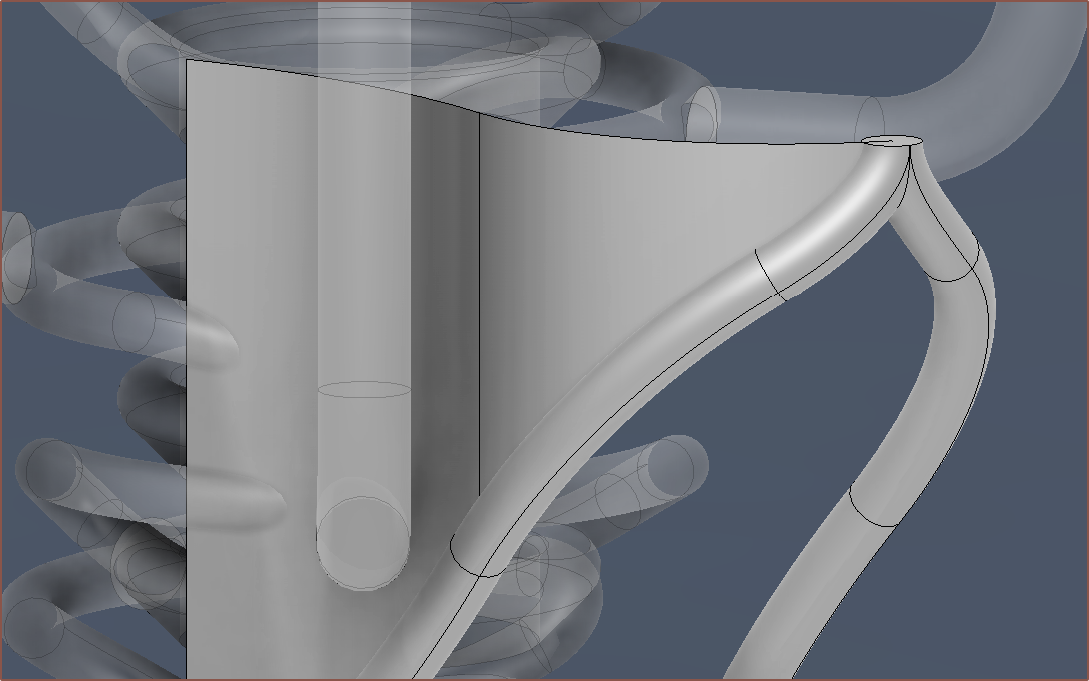

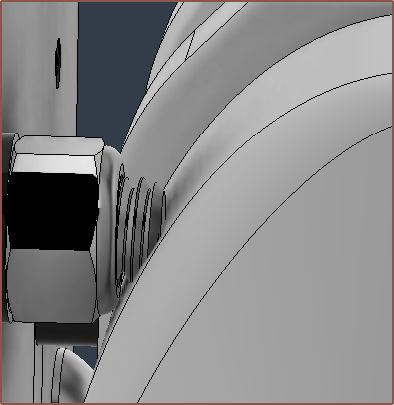

First, I had to figure out how I was actually going to join up the internal channels, and was thinking of things like this:

Then I said "Why am I making things difficult for myself?" and just did this:

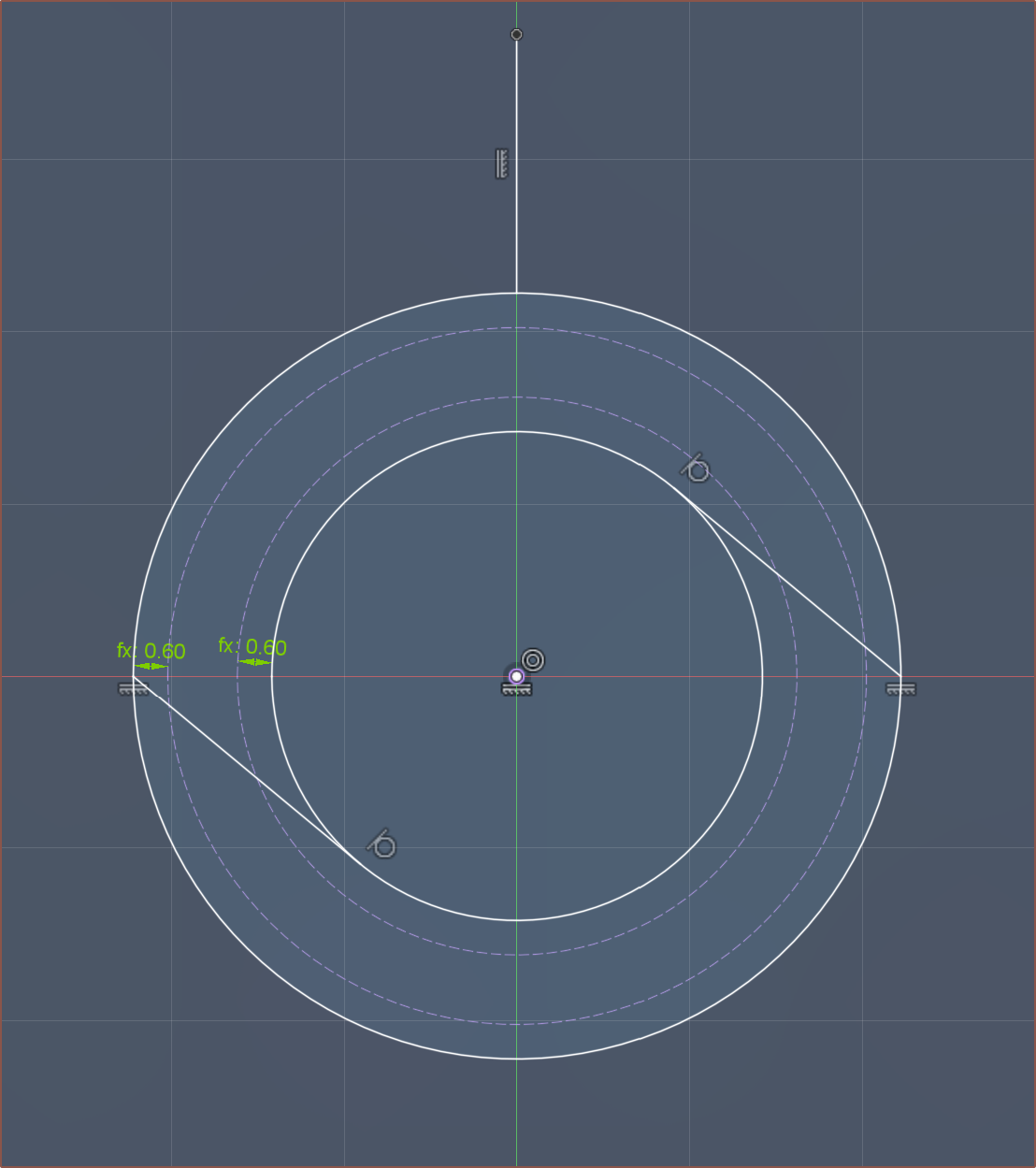

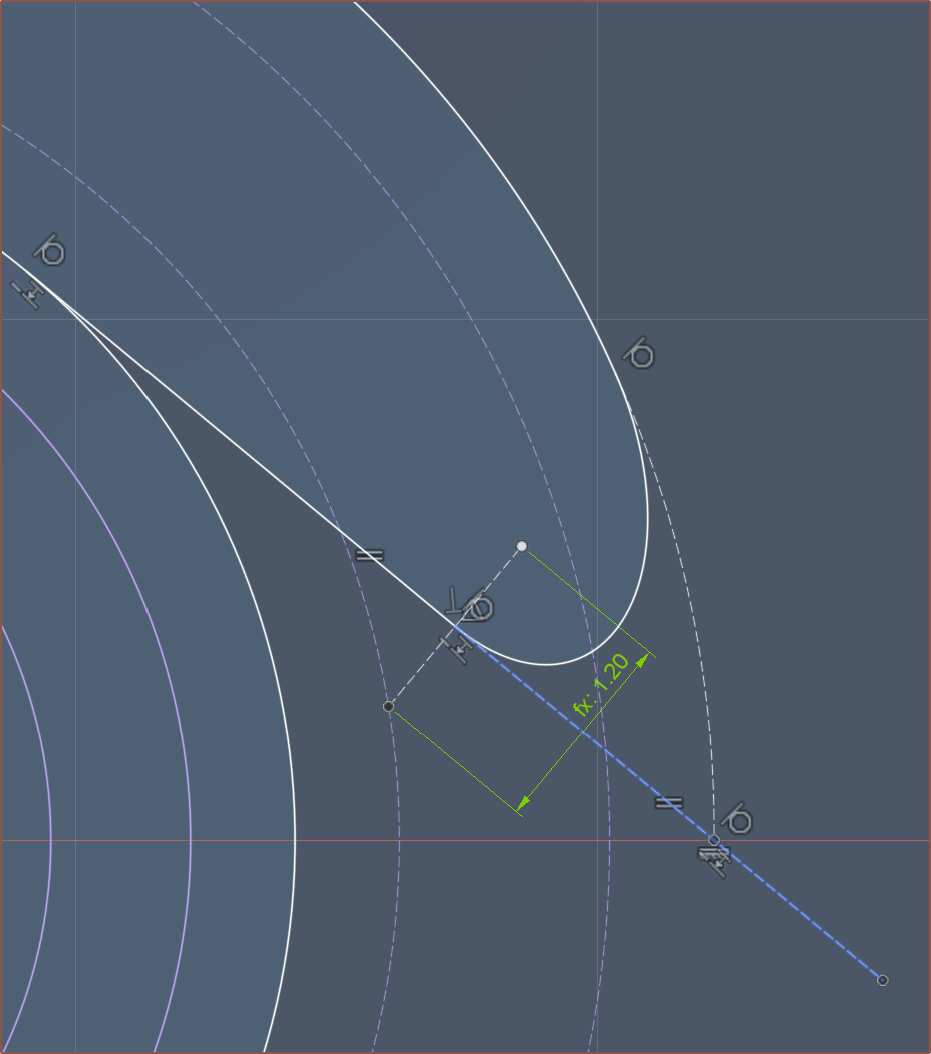

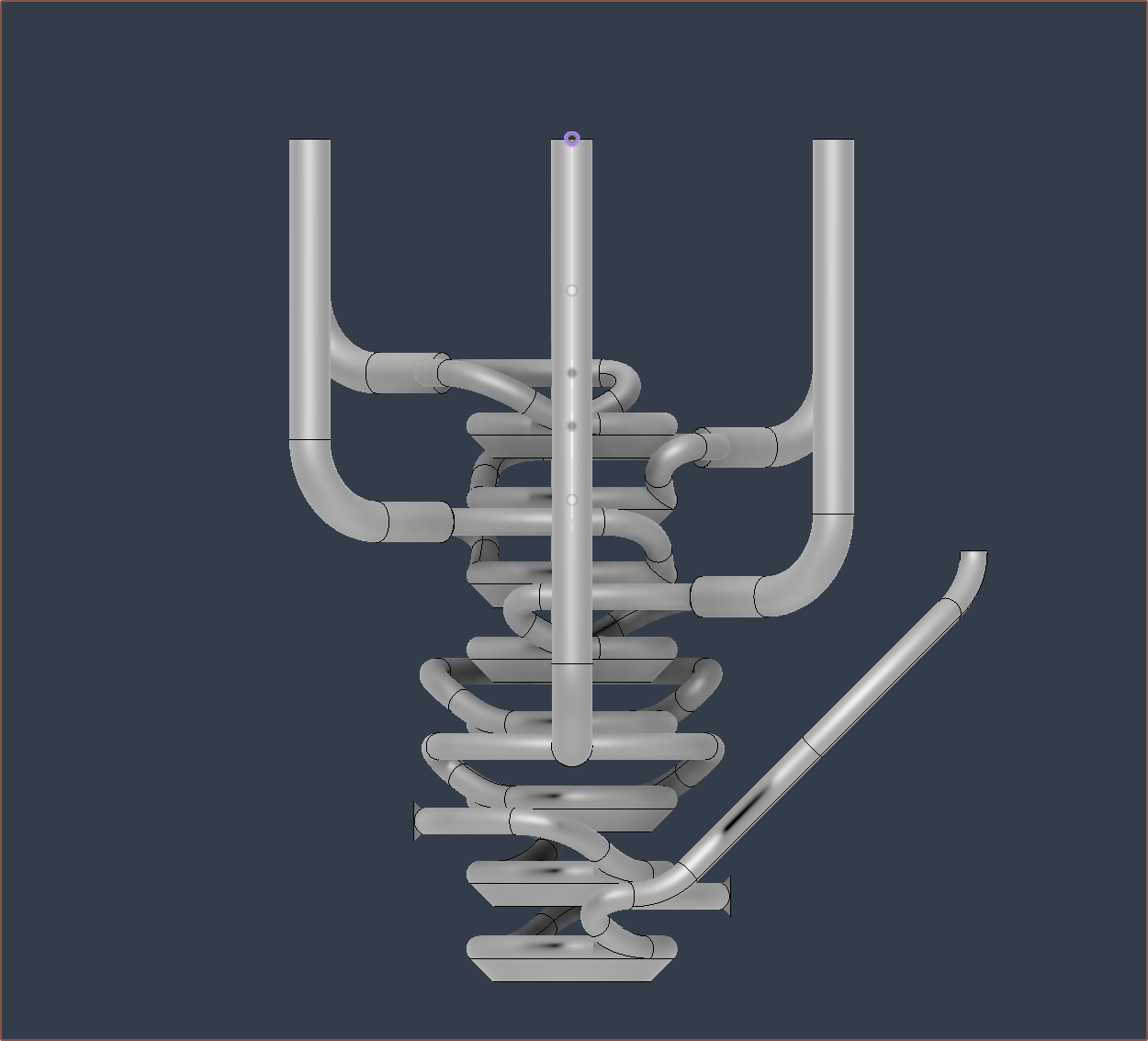

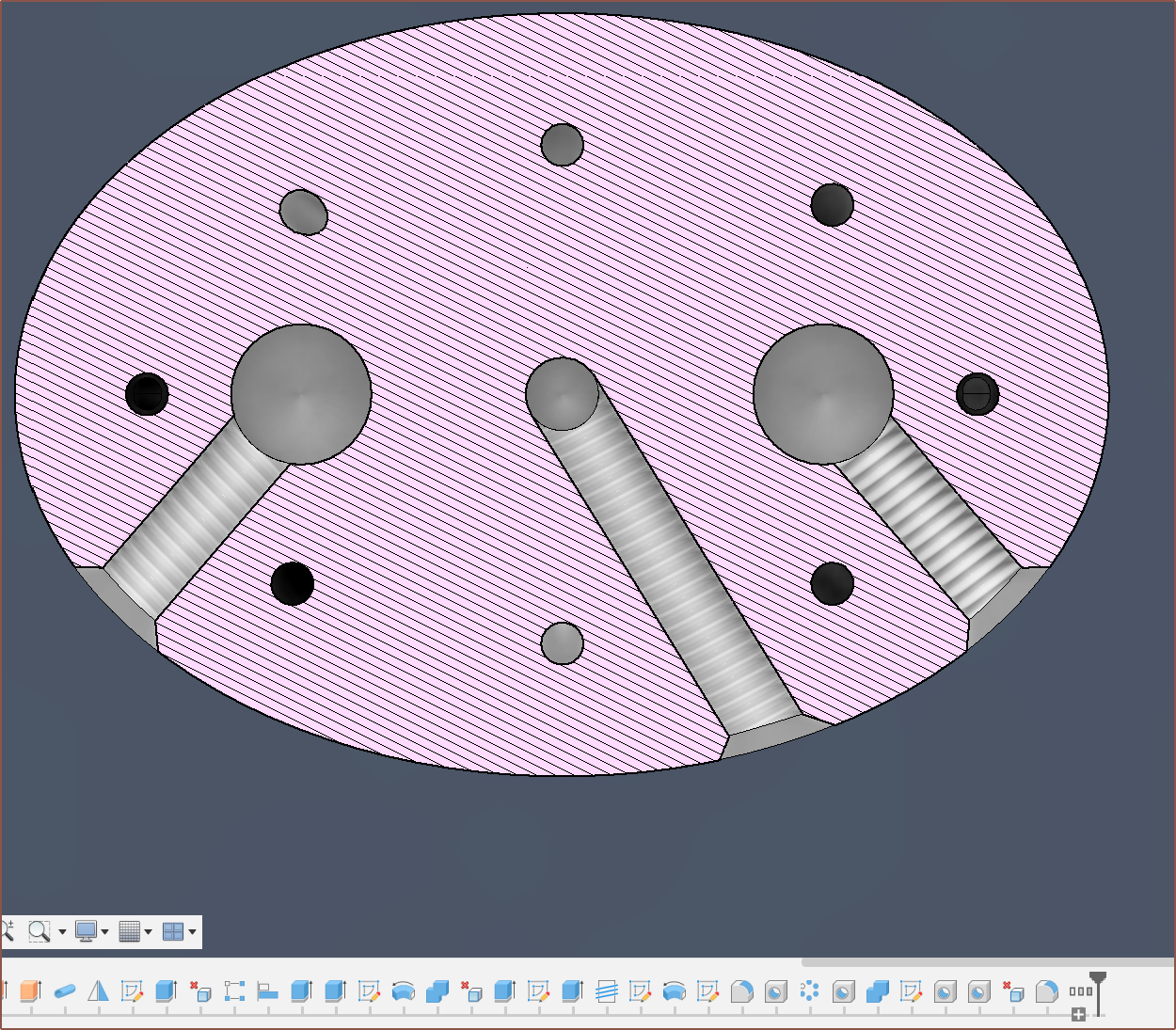

Next, I took advantage of the new Fusion360 feature to use driven dimensions anywhere in the file to make sure all of these 8 bodies were seperated by at least 1.2mm:

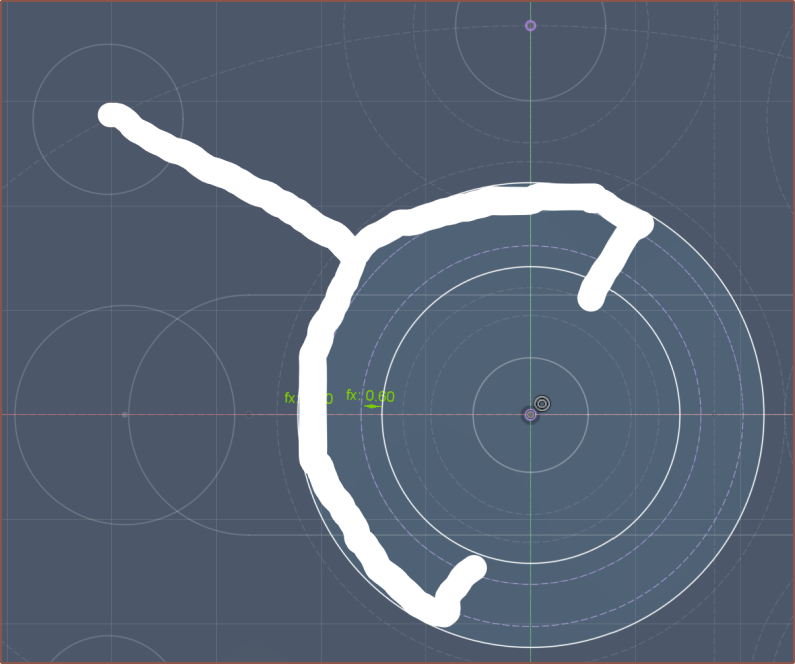

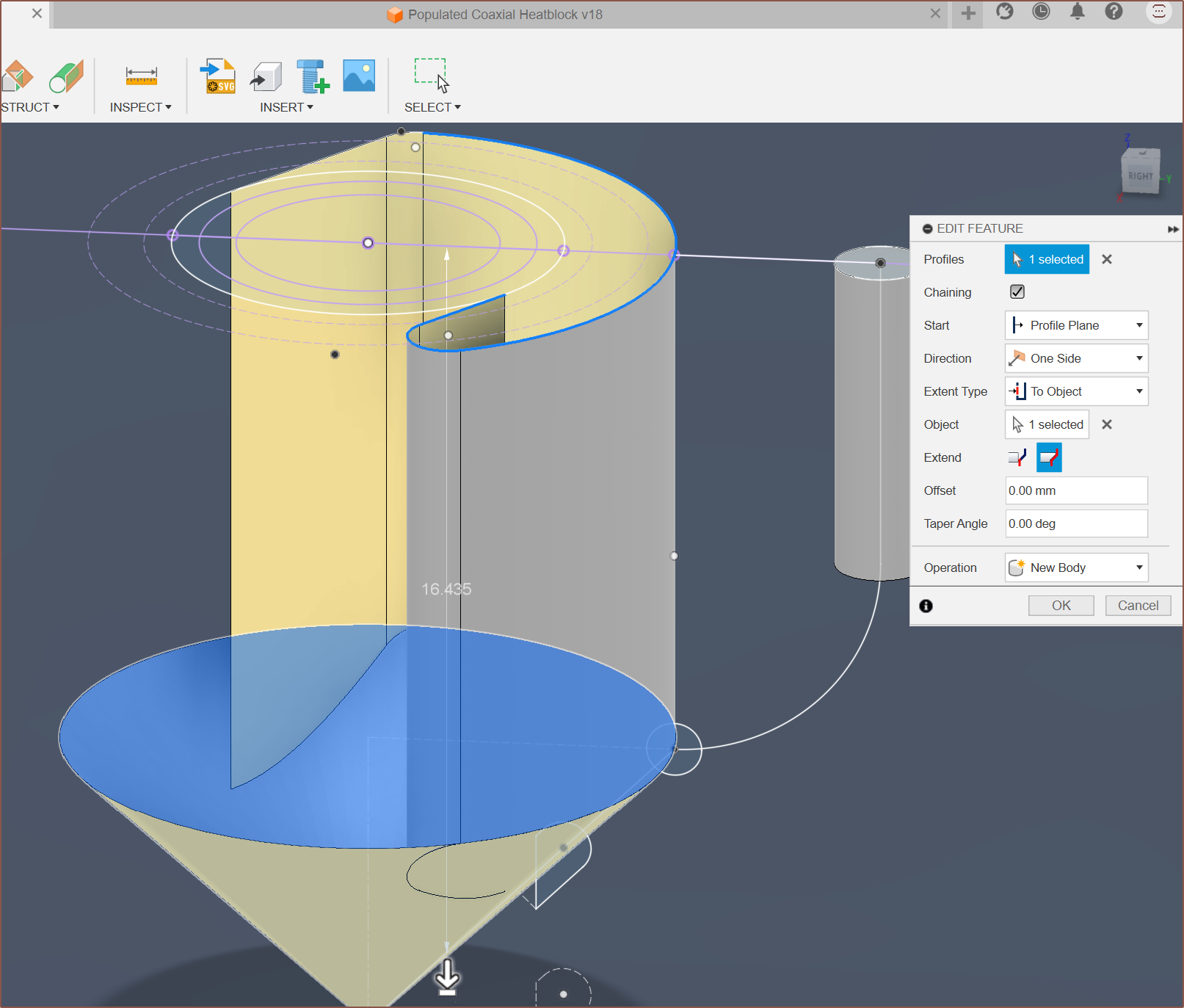

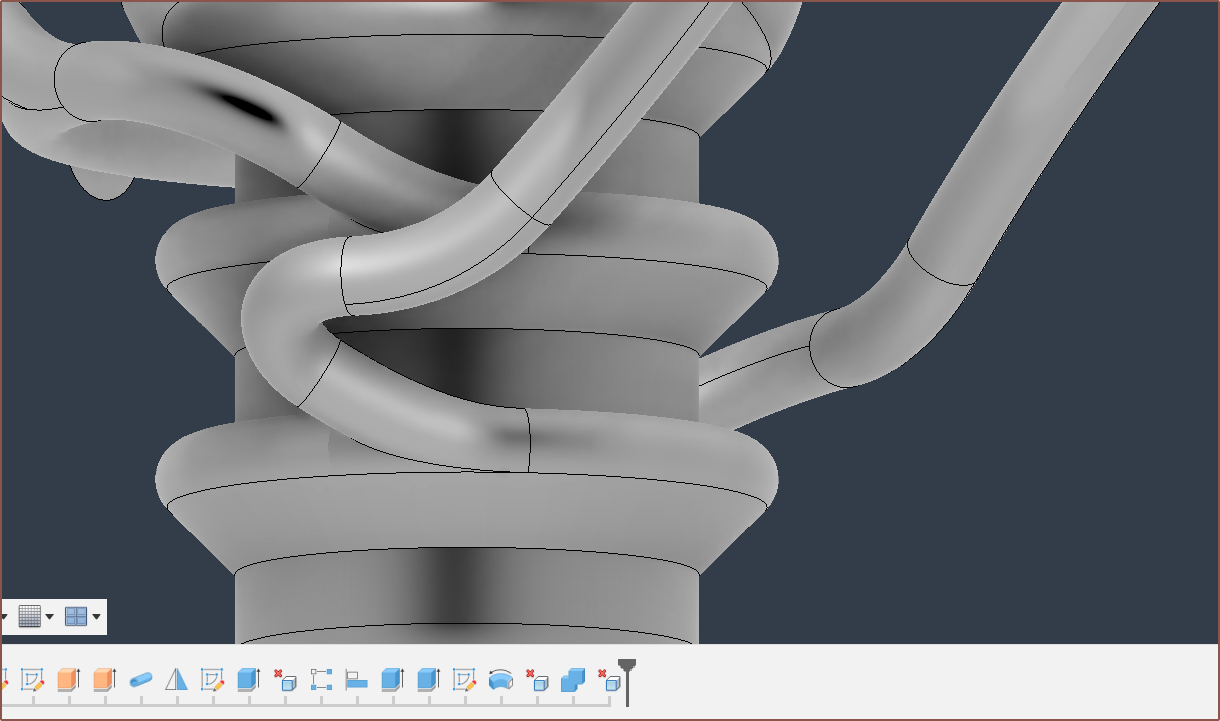

Next, I did the main thing I've been planning to do for weeks, which is a cone-derived path:

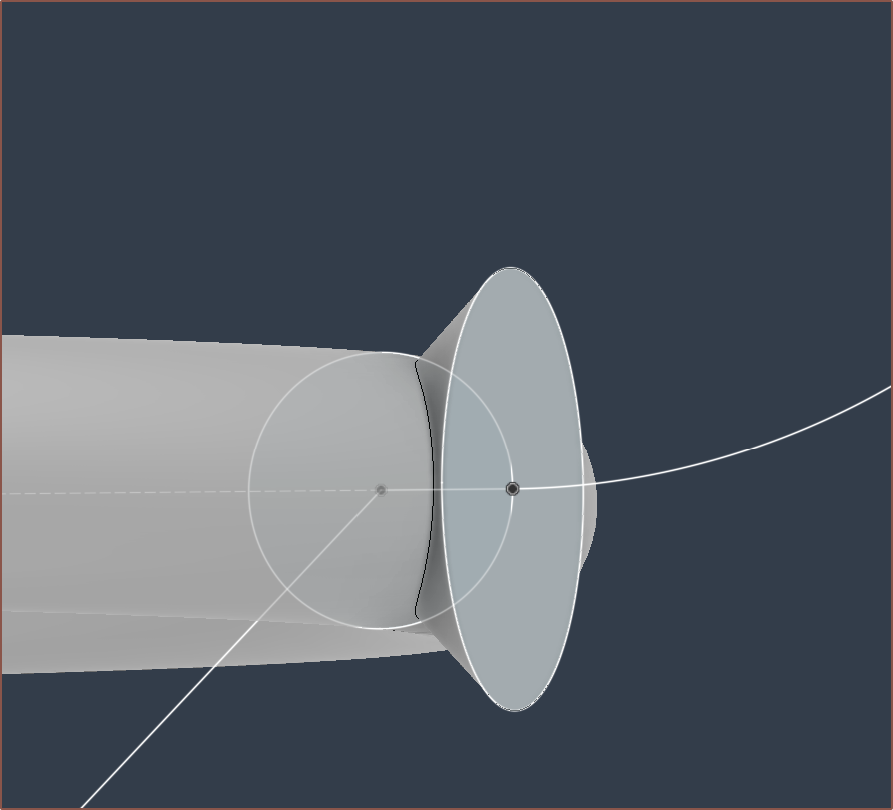

Suprisingly, it actually worked. If you're wondering why I've done this, it's so that there are no internal overhangs to keep print surface quality optimal. Since everything seemed as expected, I went back and replaced the arc with a "conic curve" so that a better 3D bend could be generated:

After that, I added some ports for the "MajorChannels" to tap into:

I kept on adding channels and then I got to the side-most ones and I was so close yet so far:

The solution? I reordered them. I believe it's better now as it's the optimal order for me to model in a large 45 chamfer and allows the filaments on the surface of the extrusion to be thoroughly melted.

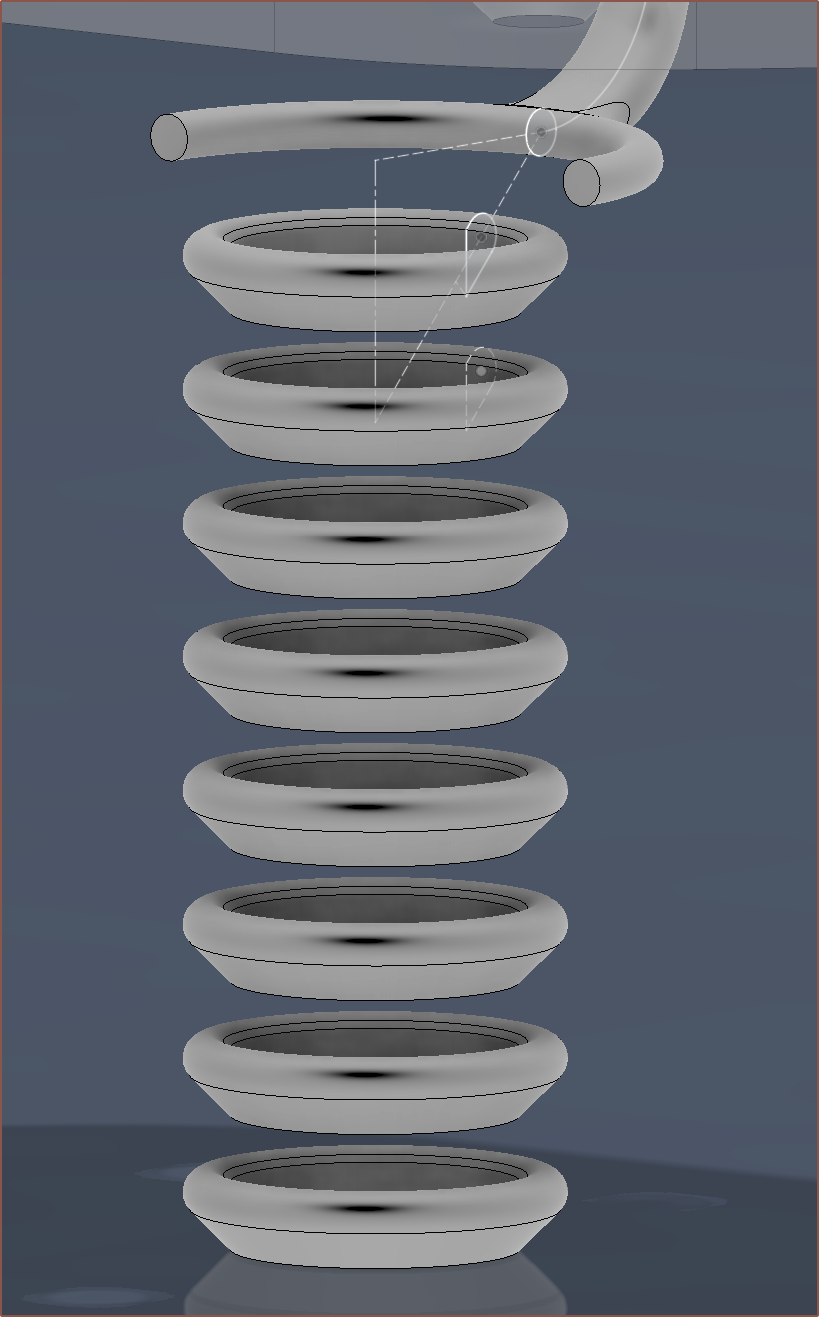

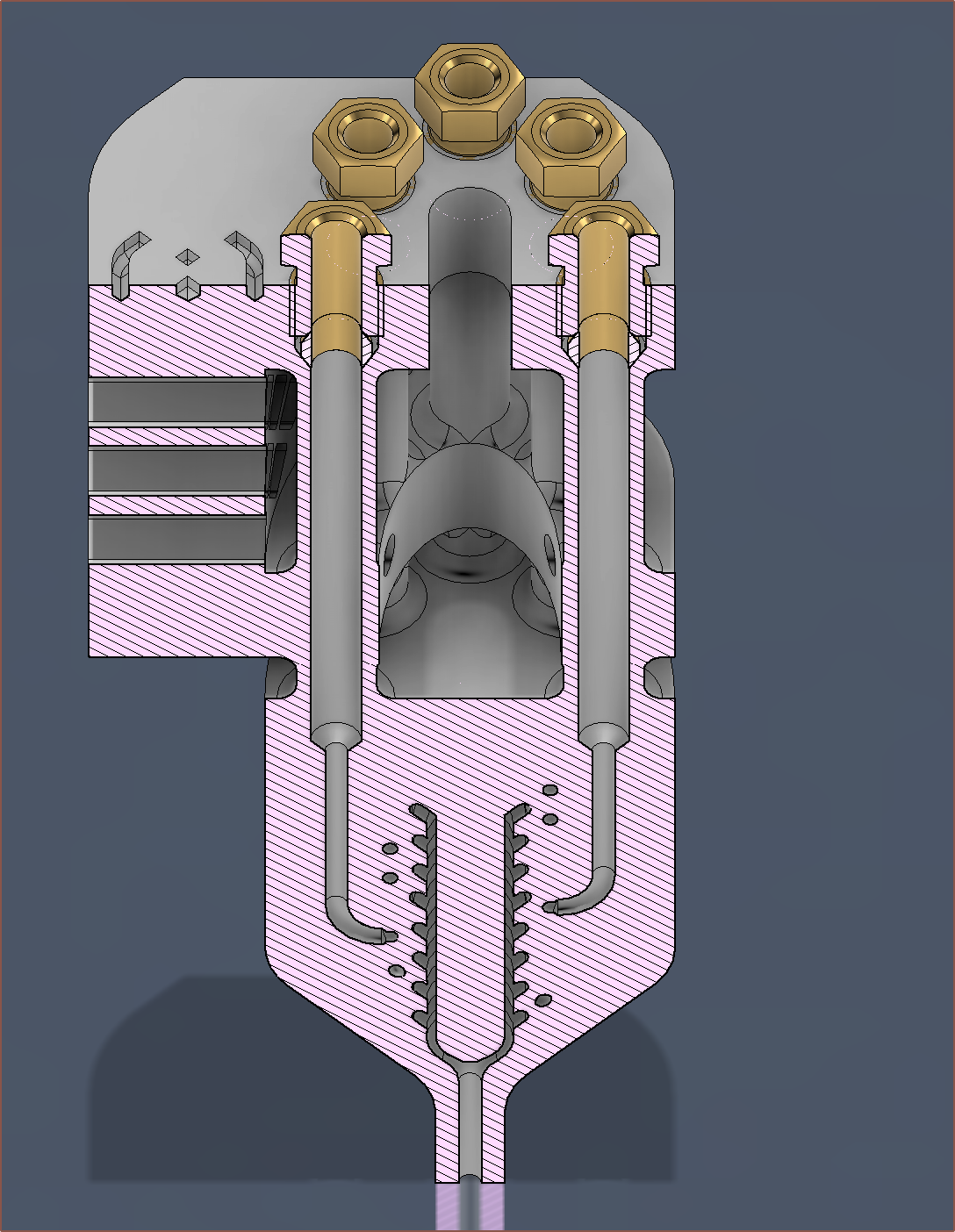

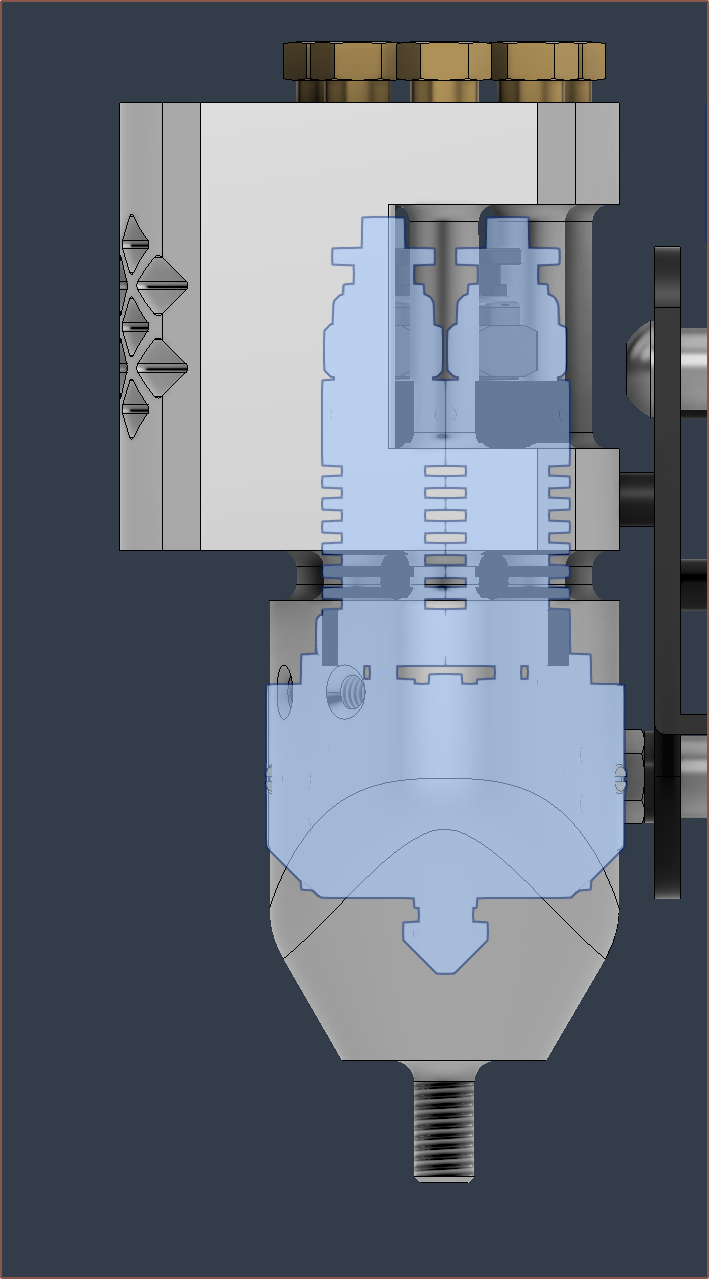

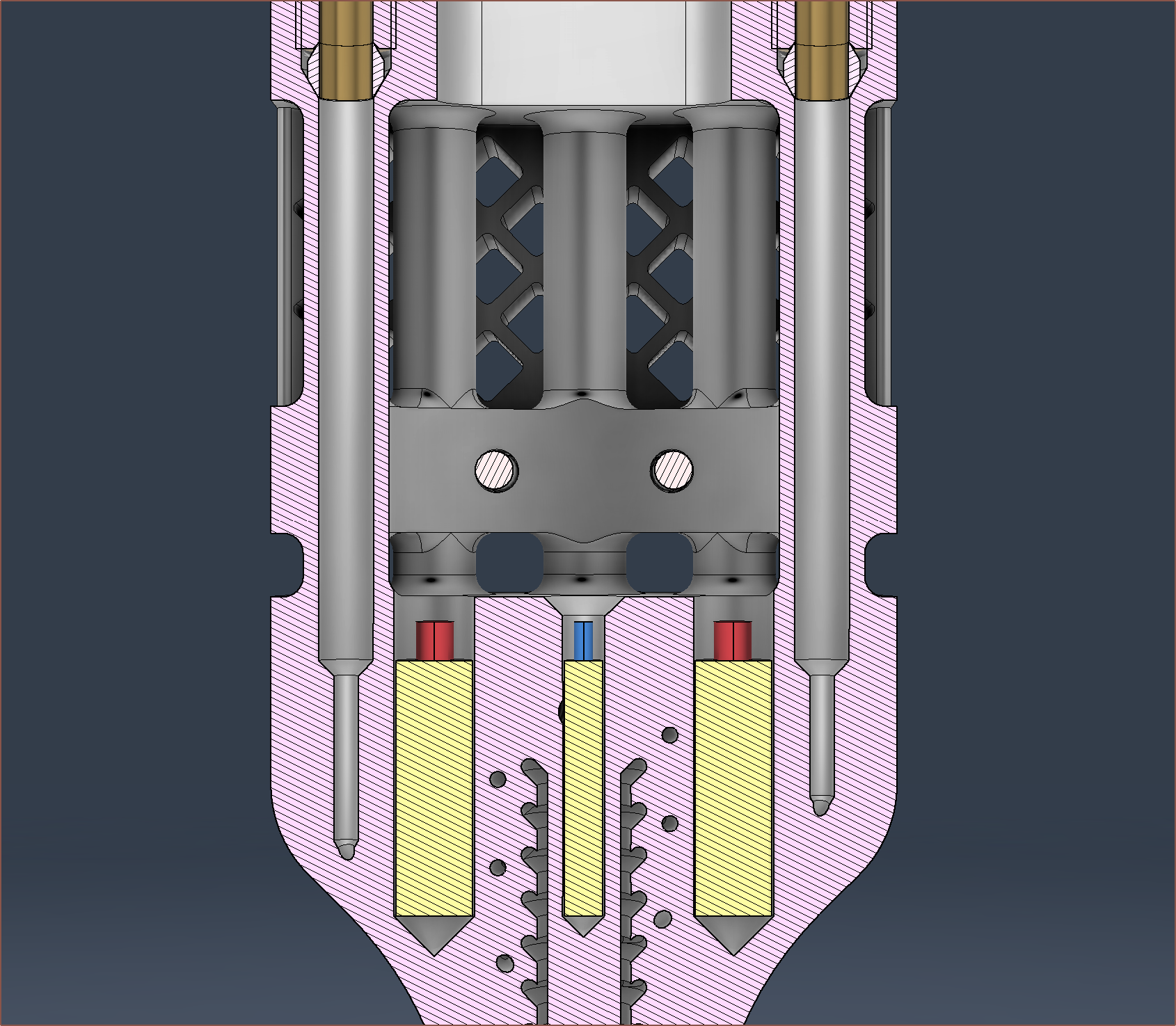

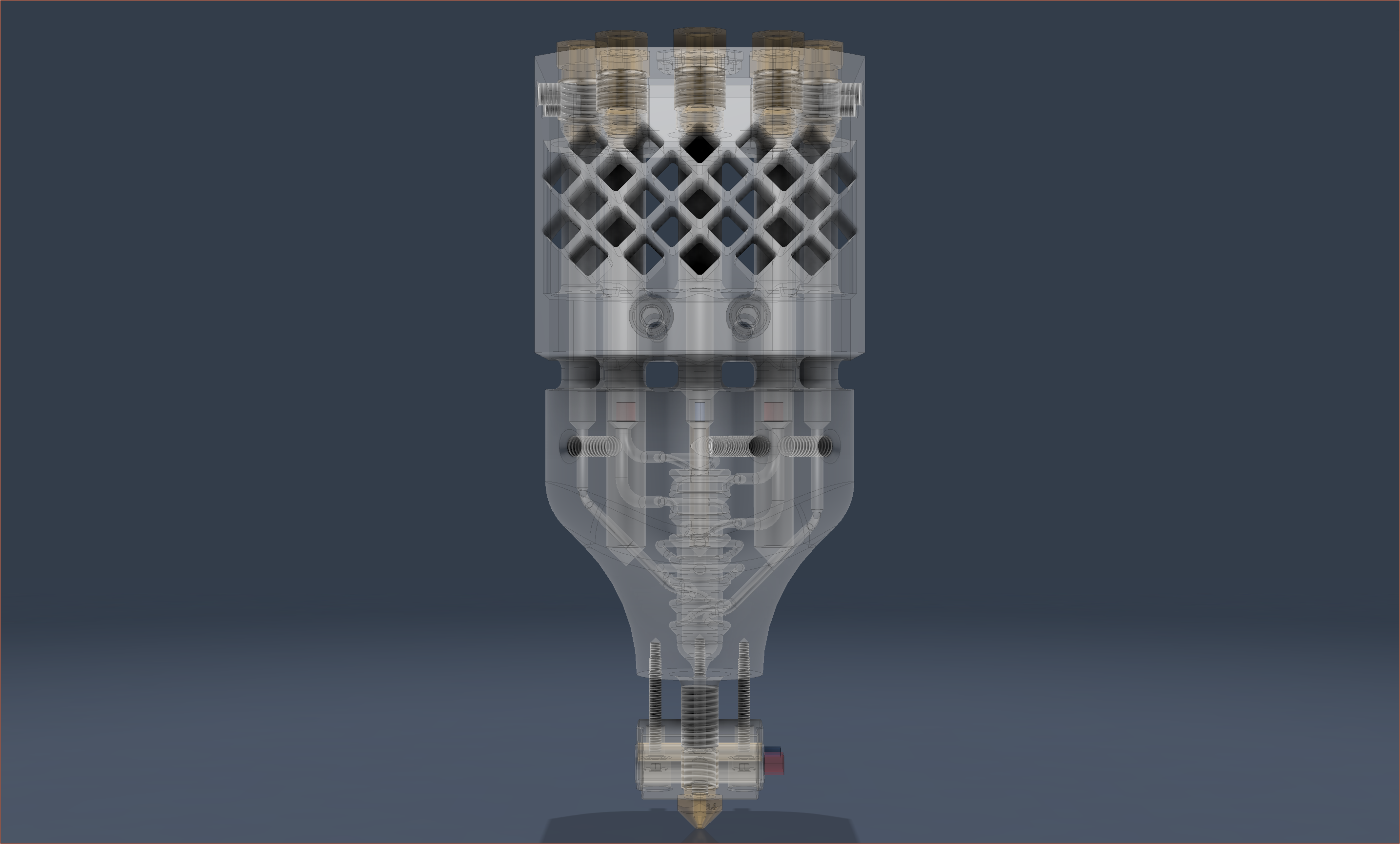

Now it was time to combine cut the internal channels from the main body, and it looked good in the Section View:

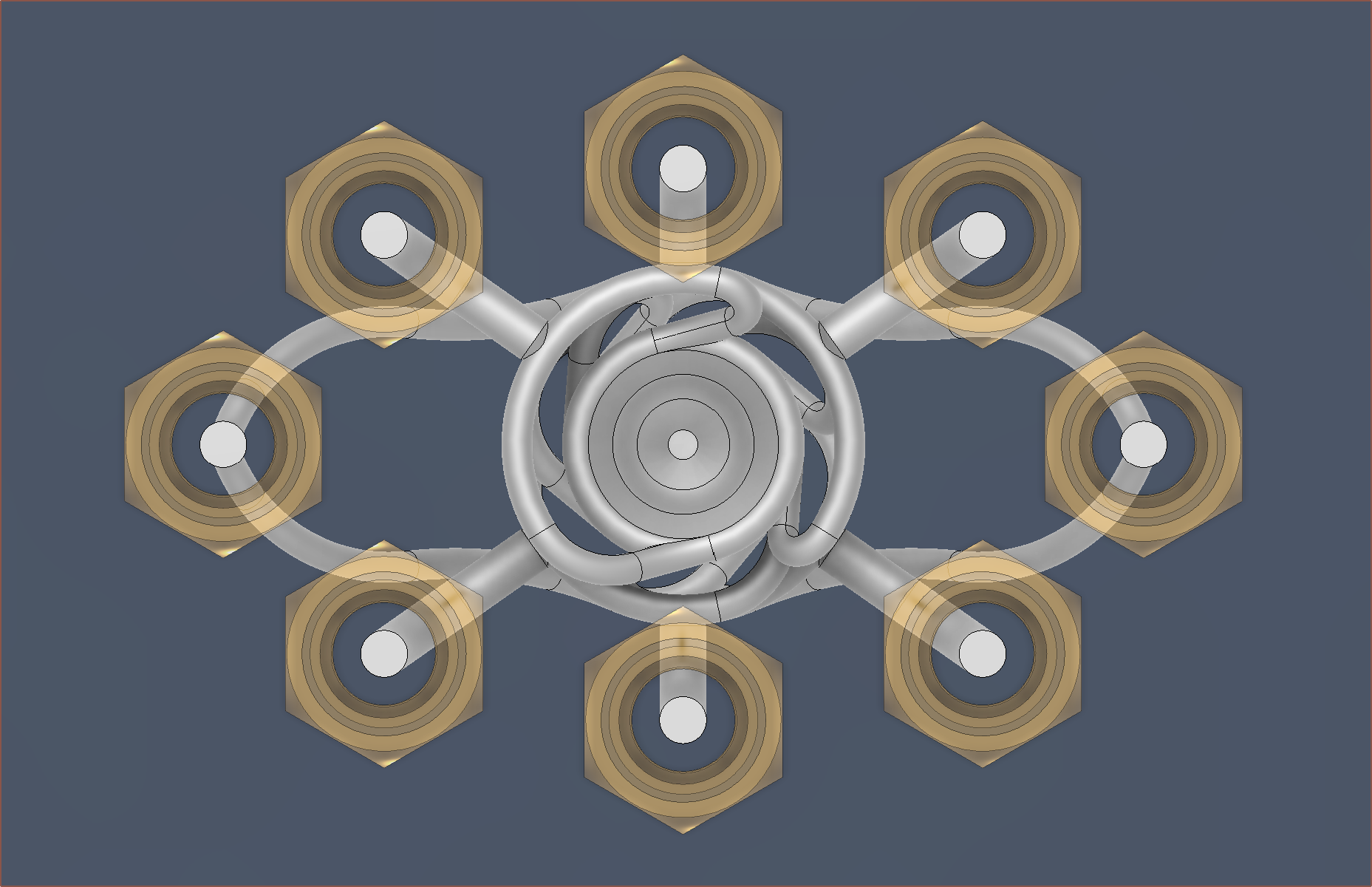

It also looks cool from this top-view:

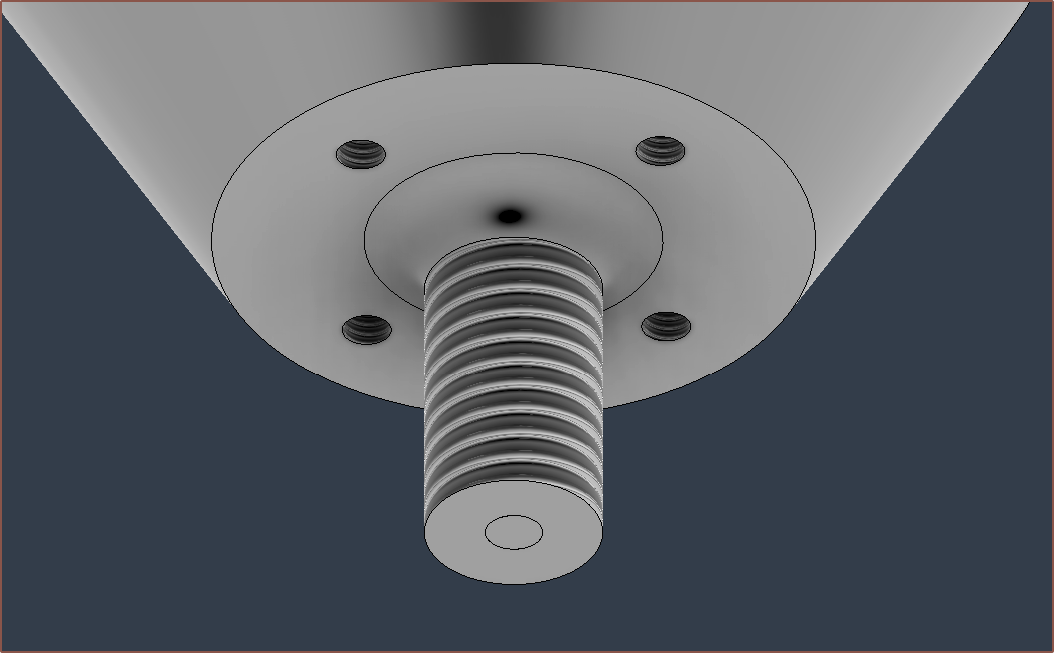

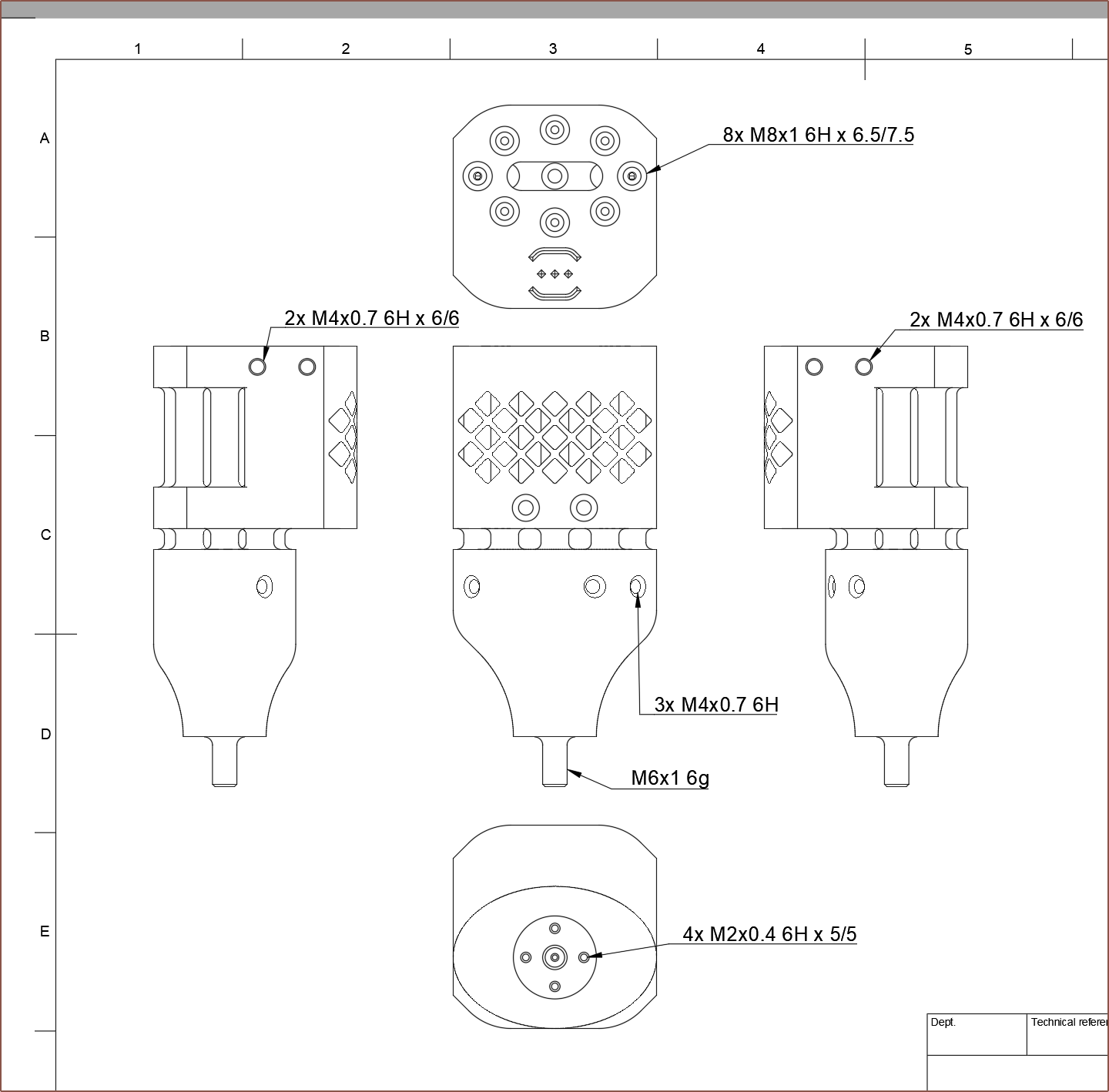

Then remembered that I need the M2 threads so that I can still do 1-handed nozzle changes:

Added the cartridge holes and thread holes, making sure that the thread paths were equidistance from the input channels:

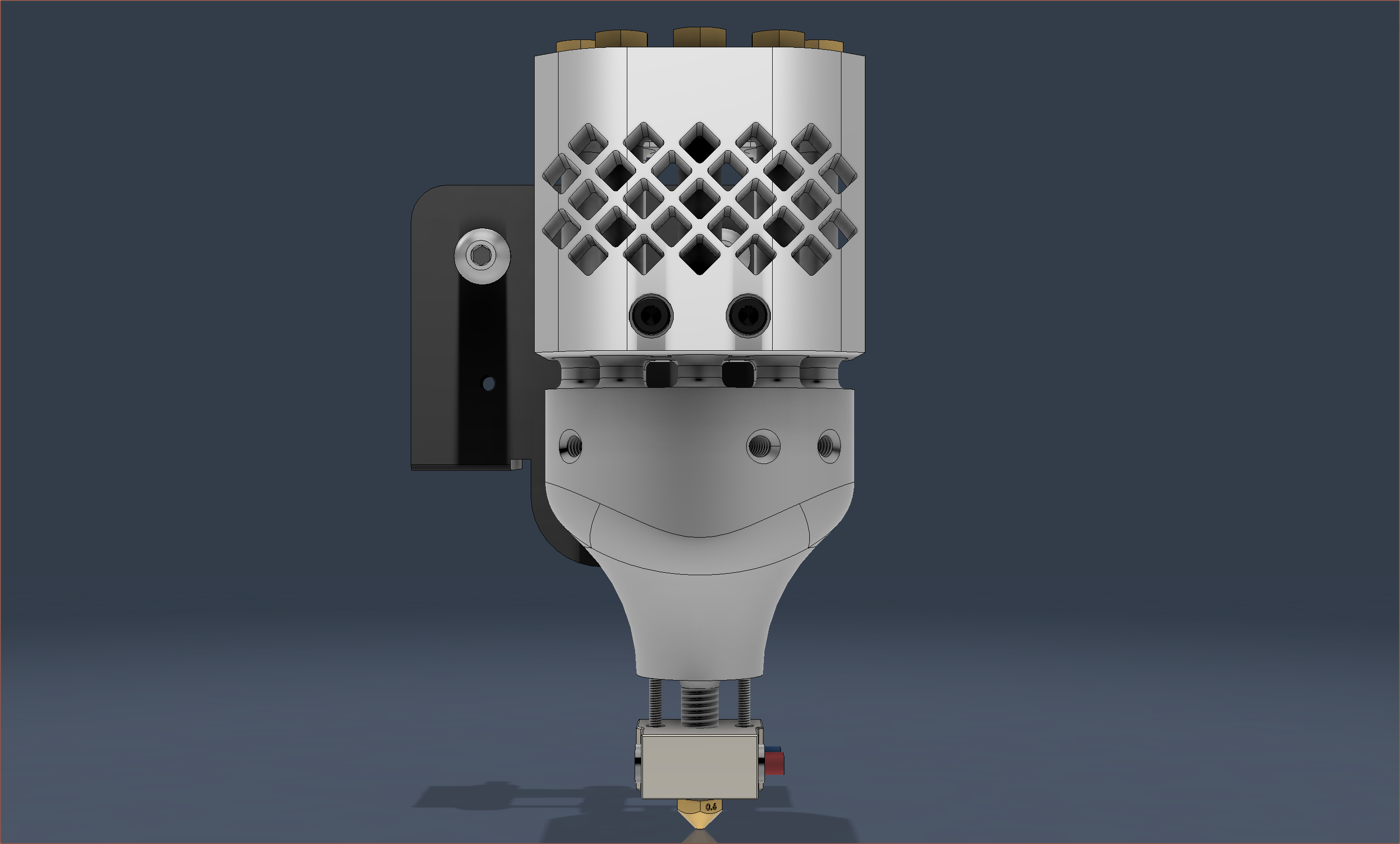

So the design was mostly done and I decided to import it into the larger assembly to compare:

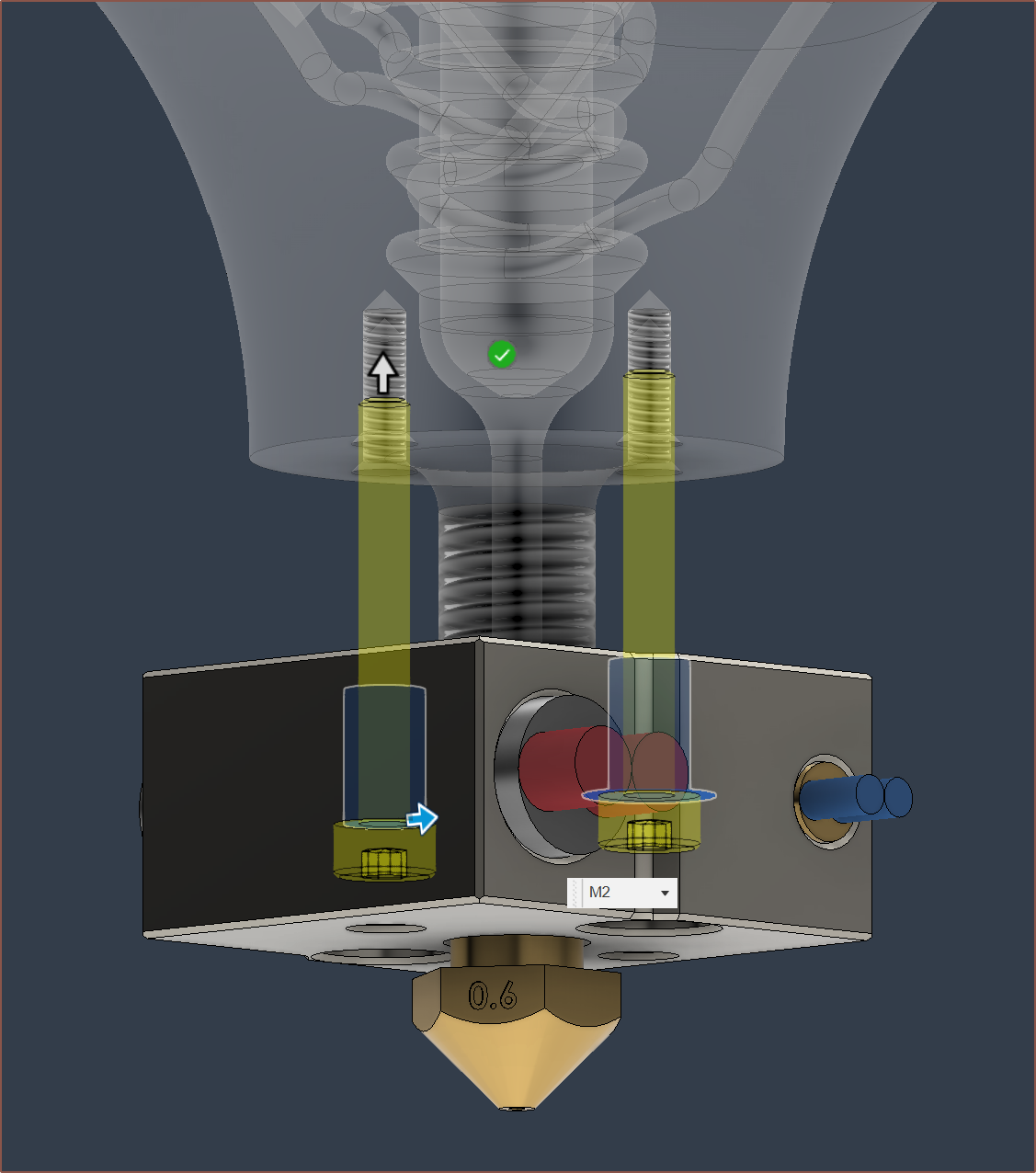

I tried the brand new to Fusion360 feature which brings in fasteners. Allegedly, having to Partpicker everything will be a thing of the past:

However, I'm not so keen on the timeline noise (see below) nor the fact that only things that are in the active component can be fastened (though this is mitigated for the most part as all fasteners go into their own folder).

However, I'm not so keen on the timeline noise (see below) nor the fact that only things that are in the active component can be fastened (though this is mitigated for the most part as all fasteners go into their own folder).

Lastly, I added some M4 threads so that other things, such as the 3D printed cover holding the fans, can be mounted:

Before today, I worried that the thermistor wouldn't be able to get an accurate reading of the cartridges due to a layer of molten plastic inbetween, but I think there's plenty of direct-metal between the two:

And there you have it:

Fusion360 says that all of this is 392g. The brass compression fittings on the top contribute 100g alone. The machined model, without these fittings, was 306g, so the mass is comparable between them.

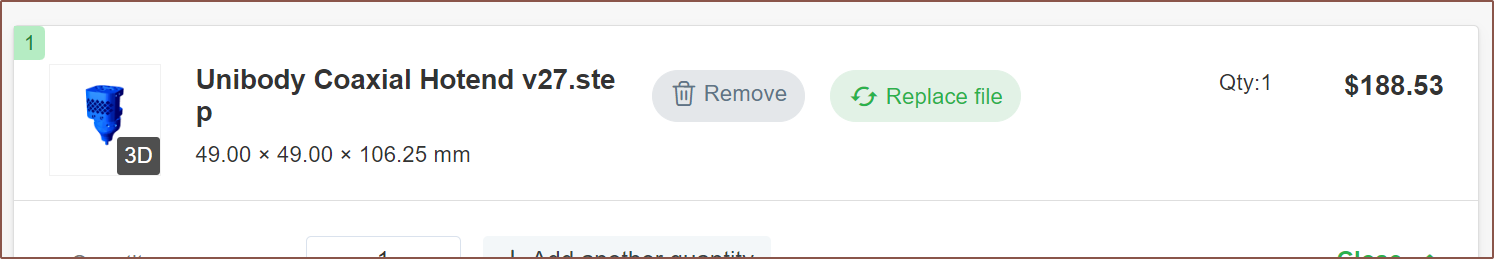

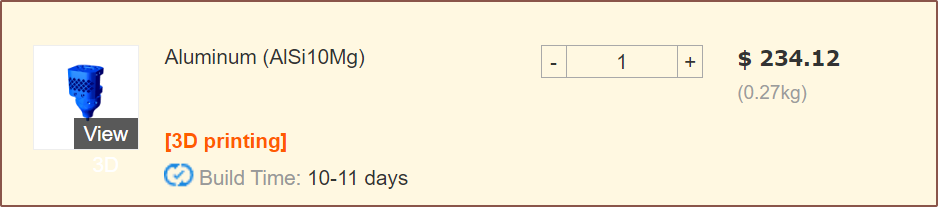

Now to see how much it costs...

At that price, I'm not risking a bent thread. I'll as for that too:

[2 Jan] That increases the price by another $46 and the build time by 6 days:

It's certainly more expensive than I would've liked, but many other strategies for multicolour/multimaterial are around about the same ballpark or higher. I was hoping for sub £100 ideally, but the mass of this hotend was also more than expected.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.