Since this is March -- when most of my university-related StepChanges (deadlines wherby there will be a change in conditions/considerations afterwards) are -- my time utilisaton would probably be seen as >97% if there was a Task Manager for it.

Some nice news is that most of the coaxial8or-specific things have arrived, including the coaxial8or heatblock itself.

Coaxial8or

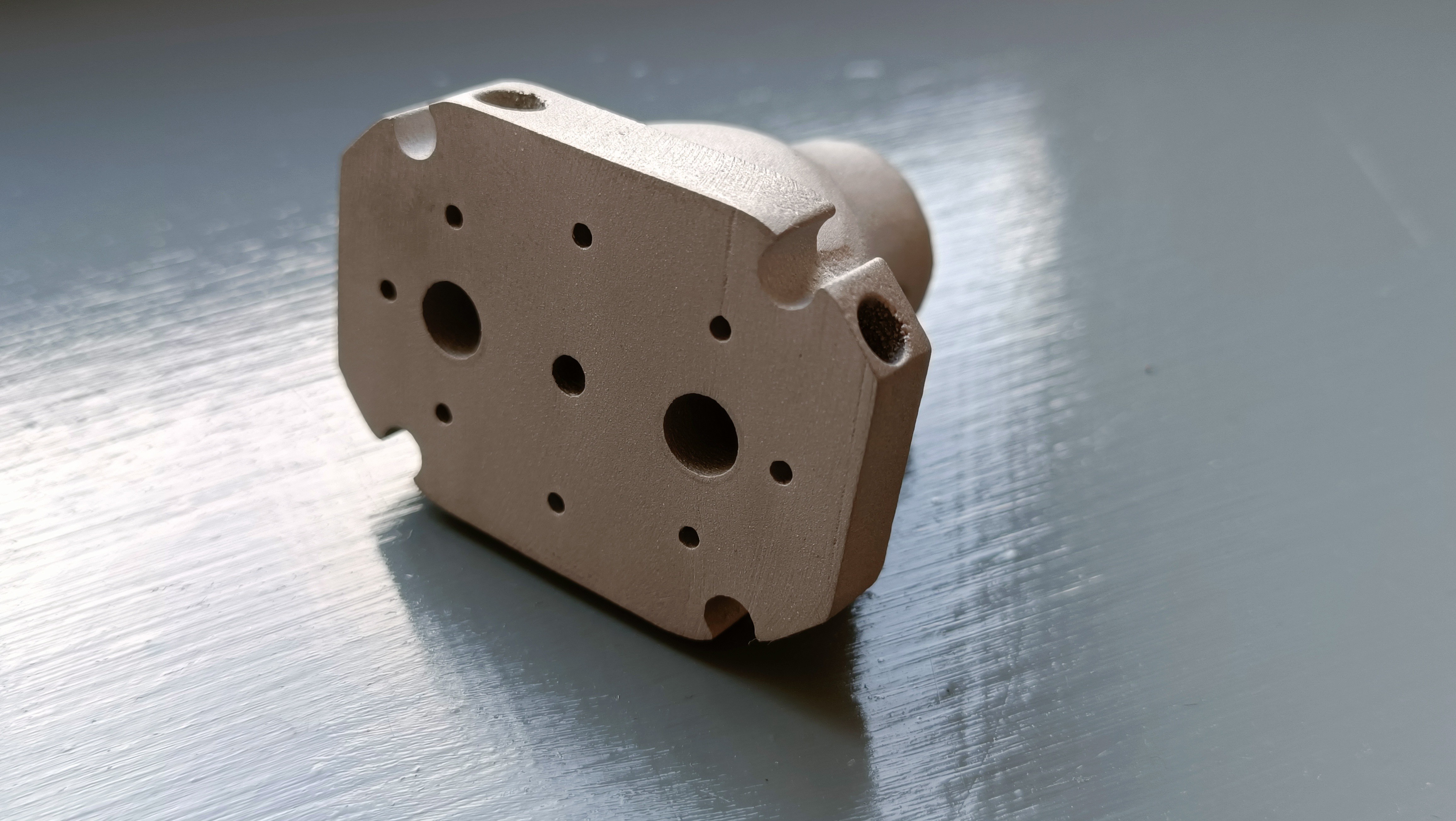

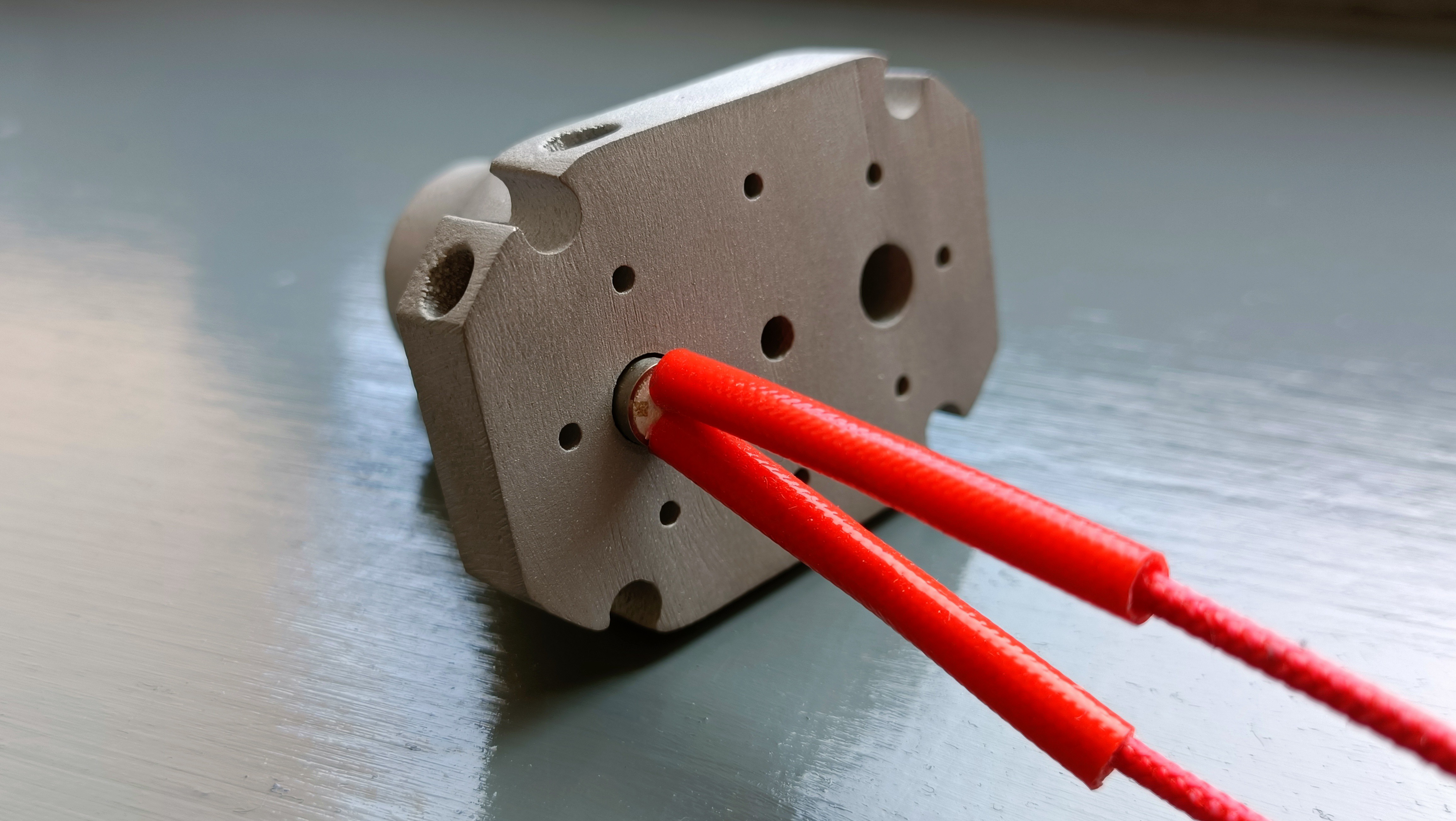

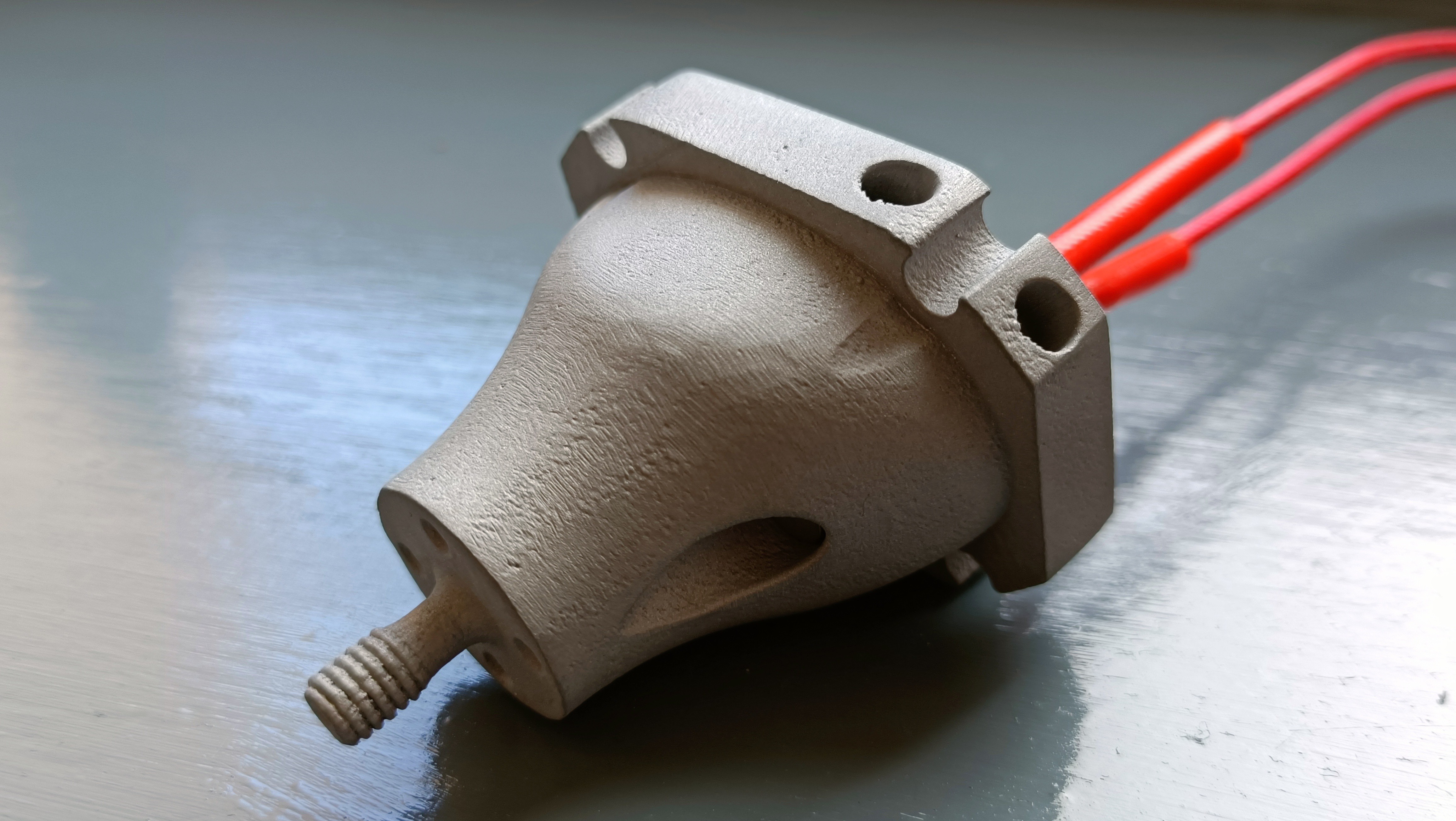

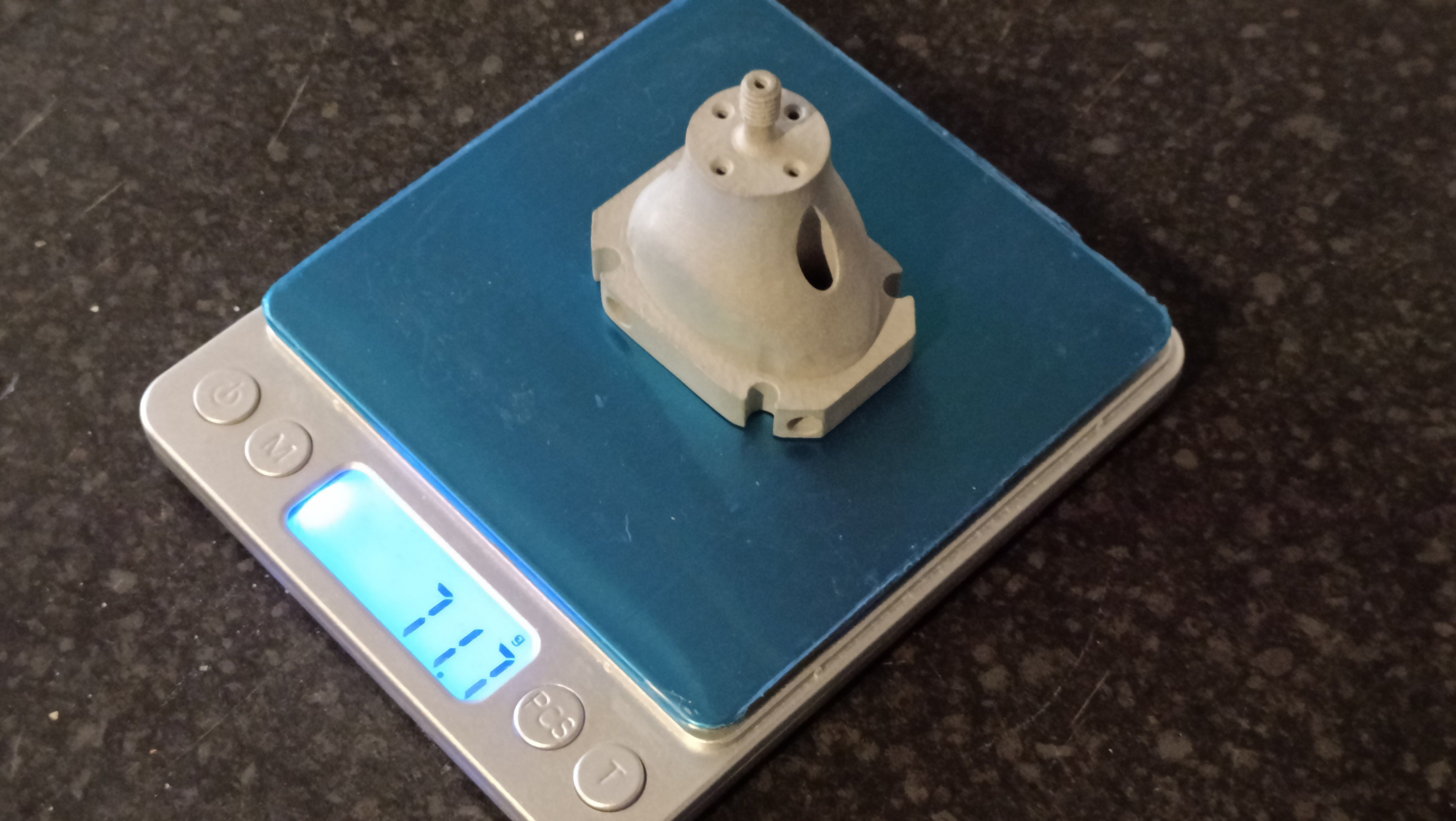

Images of parts 3D printed from PCBWay's aluminium service are few and far between, so here's mine:

Measuring holes, it seems that they're undersized from the CAD by up to 0.2mm. For example, my 1.9mm filament holes are 1.68mm, the 3.3mm thermistor hole is 3.13mm and the 6.3mm cartridge heater holes are 6.13mm at smallest. With this information, I'd like to predict that the gap between the thermistor sleeve and the 360 degree input channels is 0.75mm IRL.

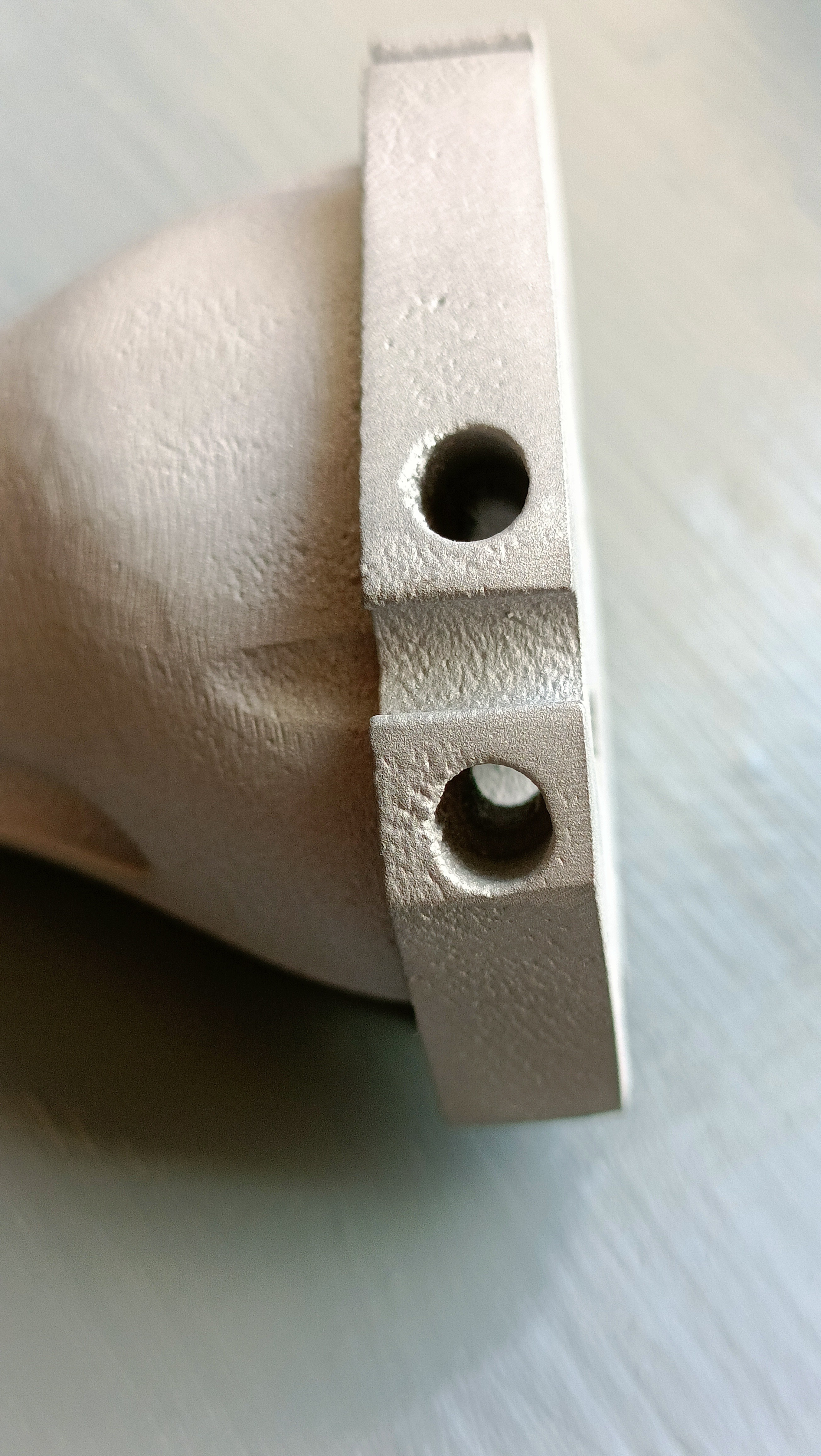

This is the clamp plate, gasket and heatblock all together, and the non-flatness is visible. If the screws are tightened, the 3mm clamp plate understandably bends to conform to the unlevel surface. I'm probably going to play it safe and ask around to see if I can get it lathed / sanded flatter.

This is the clamp plate, gasket and heatblock all together, and the non-flatness is visible. If the screws are tightened, the 3mm clamp plate understandably bends to conform to the unlevel surface. I'm probably going to play it safe and ask around to see if I can get it lathed / sanded flatter.Other parts

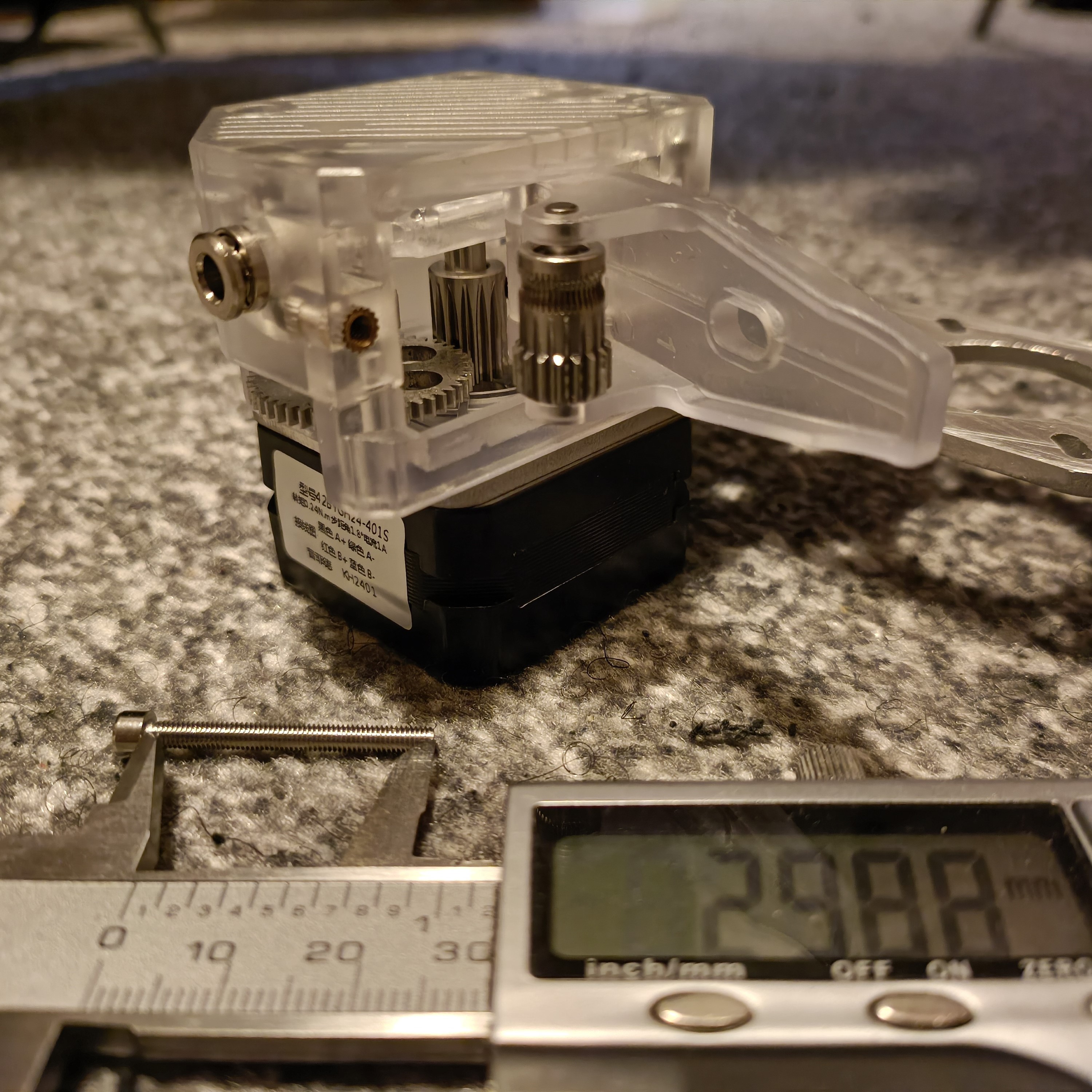

Unfortunately, despite me asking if mounting to a 3mm plate would be fine, the screws that come with the DDE are too short. These screws were flush with the underside of the plate. The max depth of threads on the Nema 17 is 4.95, so it's a close fit with 35mm screws which is the next standard length up.

The thickness of the DDE is 32mm.

As mentioned in one of the reviews, the large metal gear has a small amount of backlash, unlike my clone BMGs that use white plastic gears.

(17 Mar 23 - Turns out that the old ones were also individually colour coded, but the Earth line was a somewhat confusing blue (instead of something resembling the Yellow-Green wire in the UK) and was thinner than the other two wires for some reason.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.