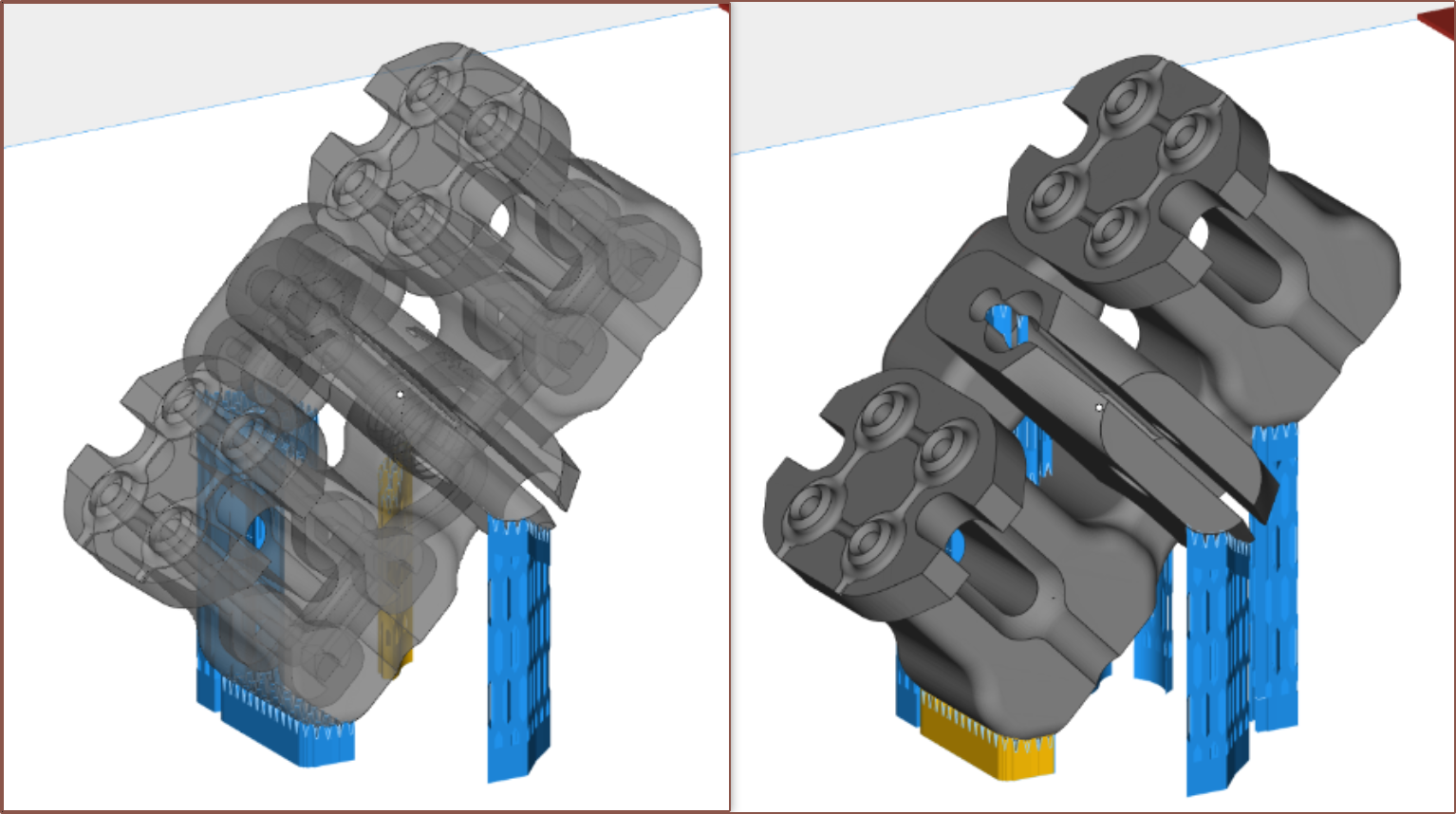

Instead of saying something along the lines of "I expect the part will be printed in X orientation", I instead just specified "There shouldn't be any powder / supports in the internal channels" and the engineer quote was $47.69; almost 10 entire dollars lower than earlier quotes. Obviously, I wanted to find out why and the engineer sent this:

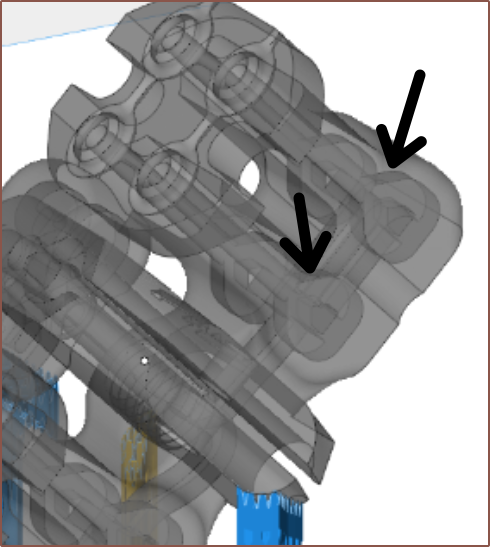

I thought the bridge overhangs (see below) weren't allowed and produce a coarse surface finish but the engineer informed me that it'll be the same as the forward tilt.

The grand total with all the fees and shipping (that didn't budge from $12 regardless on if the part was 30, 29.9, 29.4 or 29mm high) was 4,777 pennies (£47.77) so I'll take that as a sign that I've "hit the jackpot".

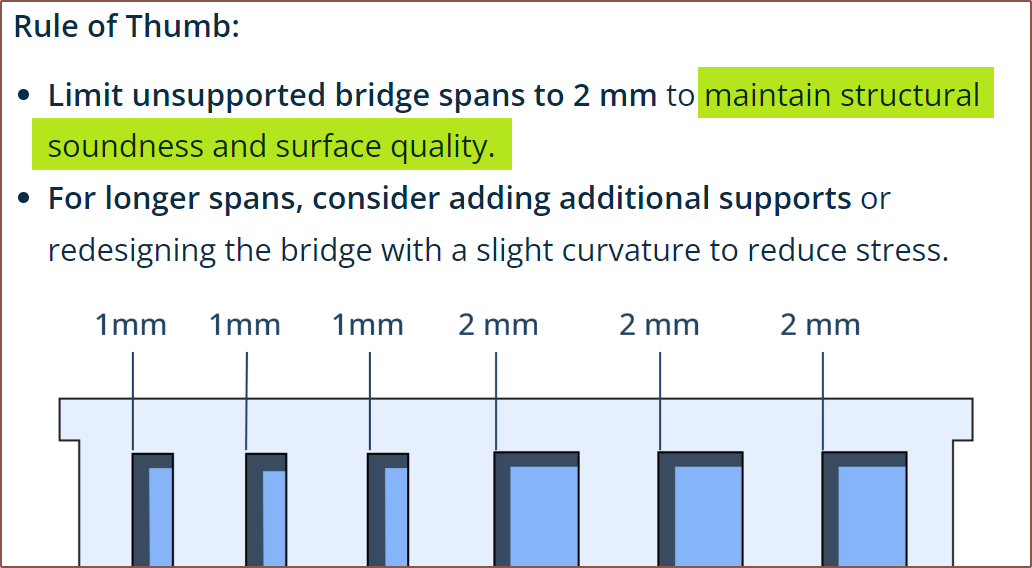

I found Xometry had an article on DLMS design practices and it does mention that "unsupported bridges" can be 2mm long, and the channels are only 10% longer than that:

Essentially, I've been trying to model around a problem that doesn't exist. Thus, the orientation the engineer chose is indeed the better one when also considering the external features like the output port.

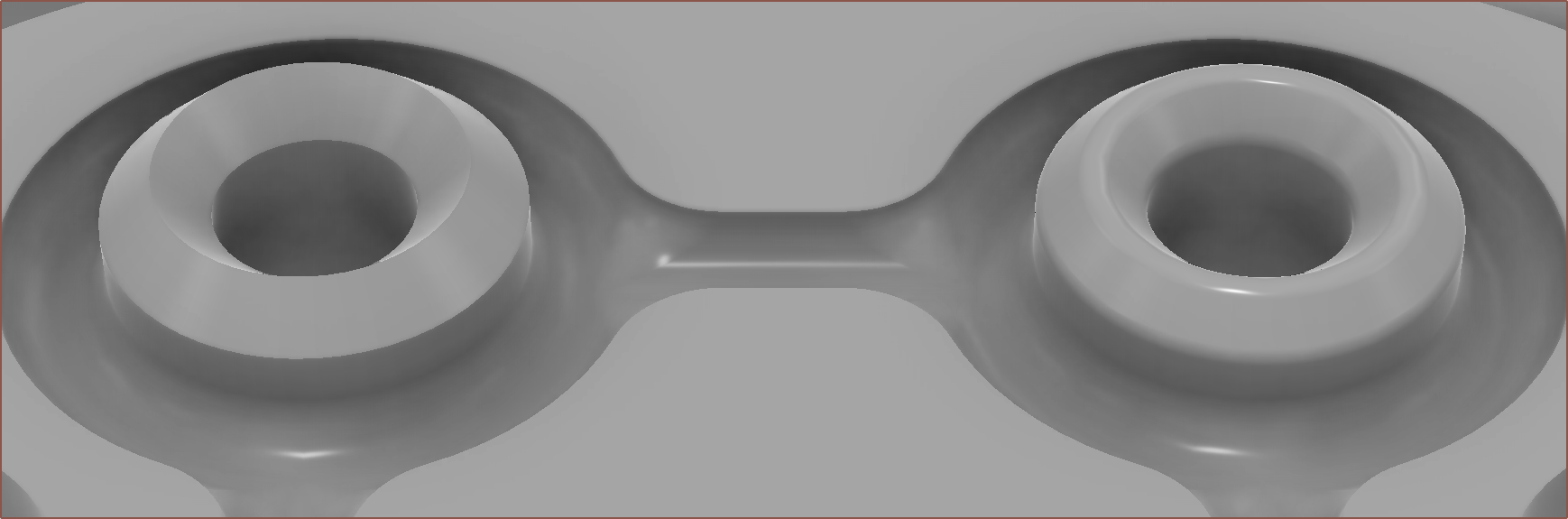

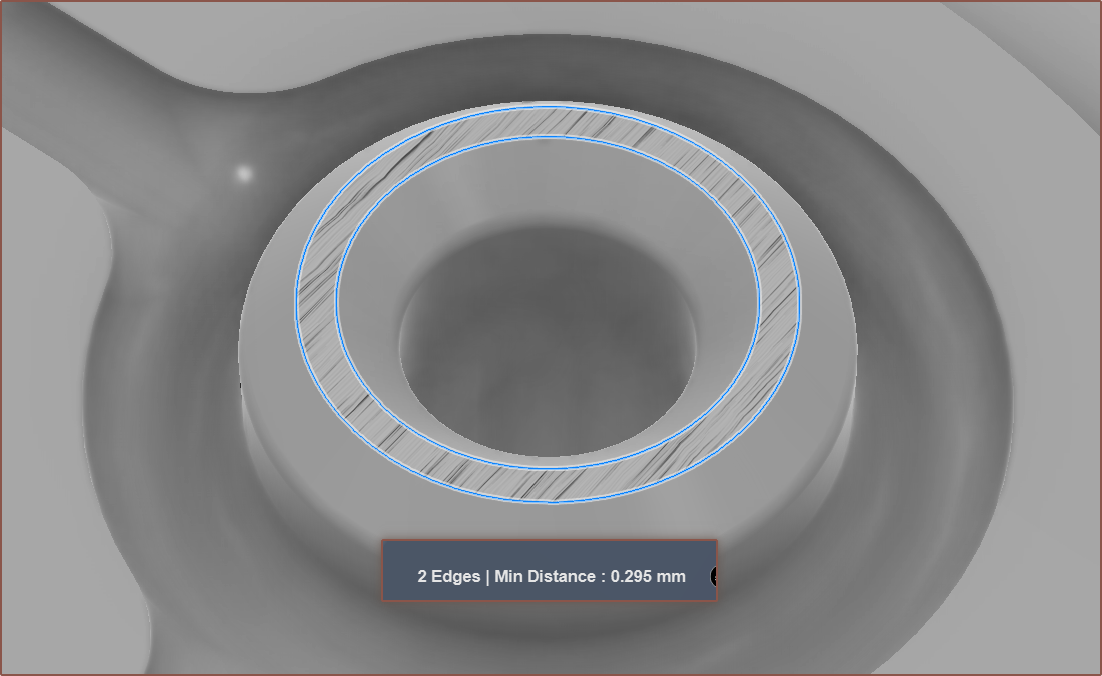

My main hope is that the port rings print correctly. I don't know what the shape would be called, but from looking at past prints, I'd guess that the minimum fillet is 0.25mm radius.

Then, by screwing in the stainless steel nozzle, it'll flatten out to a very narrow surface. This both reduces the chance for defects to allow material to leak through and places much higher pressures on the sealing faces.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.