I reverted the directions of the extruders, now a lot easier without the washers, and printed a pancake with all channels and the print completed!

I finally figured out that 224C is too cold for the PETG to stick on the bed and had more success with 239C. During the print, I did hear filament slipping. I could then feel each of the filaments to find out which channel had the issue.

I wanted to see if the flow issues have been solved so I did another print in white. This had a few problems.

The Z axis sounded like it might have skipped a step, and it showed in the print and had to babystep. I've now increased current from 0.6 -> 0.9A. Now that I'm typing this, I'm also considering increasing the Z_HOLD_MULTIPLIER (the current when the motor is not moving) from 0.5.

Additionally, I had set PrusaSlicer to move at a speed limited by 30mm3/s, but the channel choked and was only stable at around 40%, hence the expectation is 12mm3/s of flow per channel.

I was also doing some in-situ linear advance testing to see if it was working.

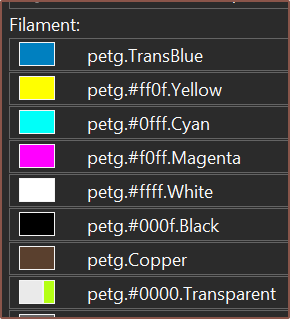

During this print, I could see in the leak detection window some yellow that was coming out, which means that it's channel 2:

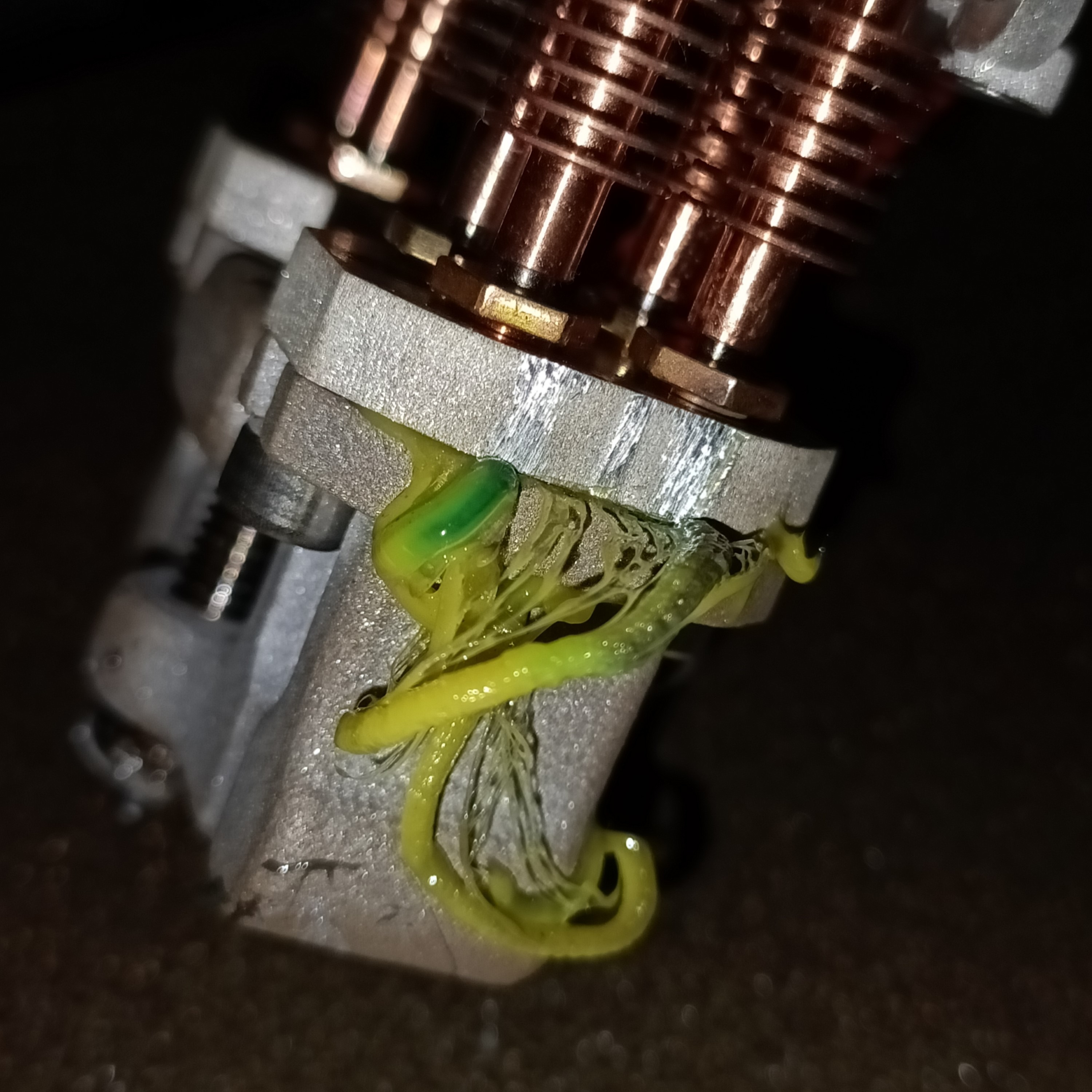

I could also see some transparent blue (and a little bit of white) eeking out of the output channel, so I cleaned this off and tightened at 220C:

I could also see some transparent blue (and a little bit of white) eeking out of the output channel, so I cleaned this off and tightened at 220C: After tightening the nozzle, I unscrewed the hotend and started to clean off the yellow before tightening its channel. It's nice to see that the leak channels work as intended.

After tightening the nozzle, I unscrewed the hotend and started to clean off the yellow before tightening its channel. It's nice to see that the leak channels work as intended.

As you can see, it looks like some transparent blue is also in there so I used needlenose pliers to try and tighten its channel. Unfortunately, the cartridge wire takes up more space than I expected, meaning that 2 of the 8 heatbreaks are unturnable by the wrench, and I'm thinking that a revision to the hotend holder could help fix this issue. It could also be cyan so I've gone around and tighened that too.

As you can see, it looks like some transparent blue is also in there so I used needlenose pliers to try and tighten its channel. Unfortunately, the cartridge wire takes up more space than I expected, meaning that 2 of the 8 heatbreaks are unturnable by the wrench, and I'm thinking that a revision to the hotend holder could help fix this issue. It could also be cyan so I've gone around and tighened that too.Now, since the Coaxial8or is out and in the open, I thought it was a good a time as any to heat to 240C and find the flow limit using this guide with the following changes:

- I used a crocodile clip from my hydra "helping hands" thing (seen in a previous log when it was holding the extruded filament)

- I used 112mm because that's the length of my screwdriver

The feedrate values I tried, in order were:

- 300 (worked, but probably doesn't count since the hotend wasn't fully pressurised)

- 600

- 450

- 360

- 330

- 300 (didn't work this time)

- 240 (worked)

- 270 (didn't work)

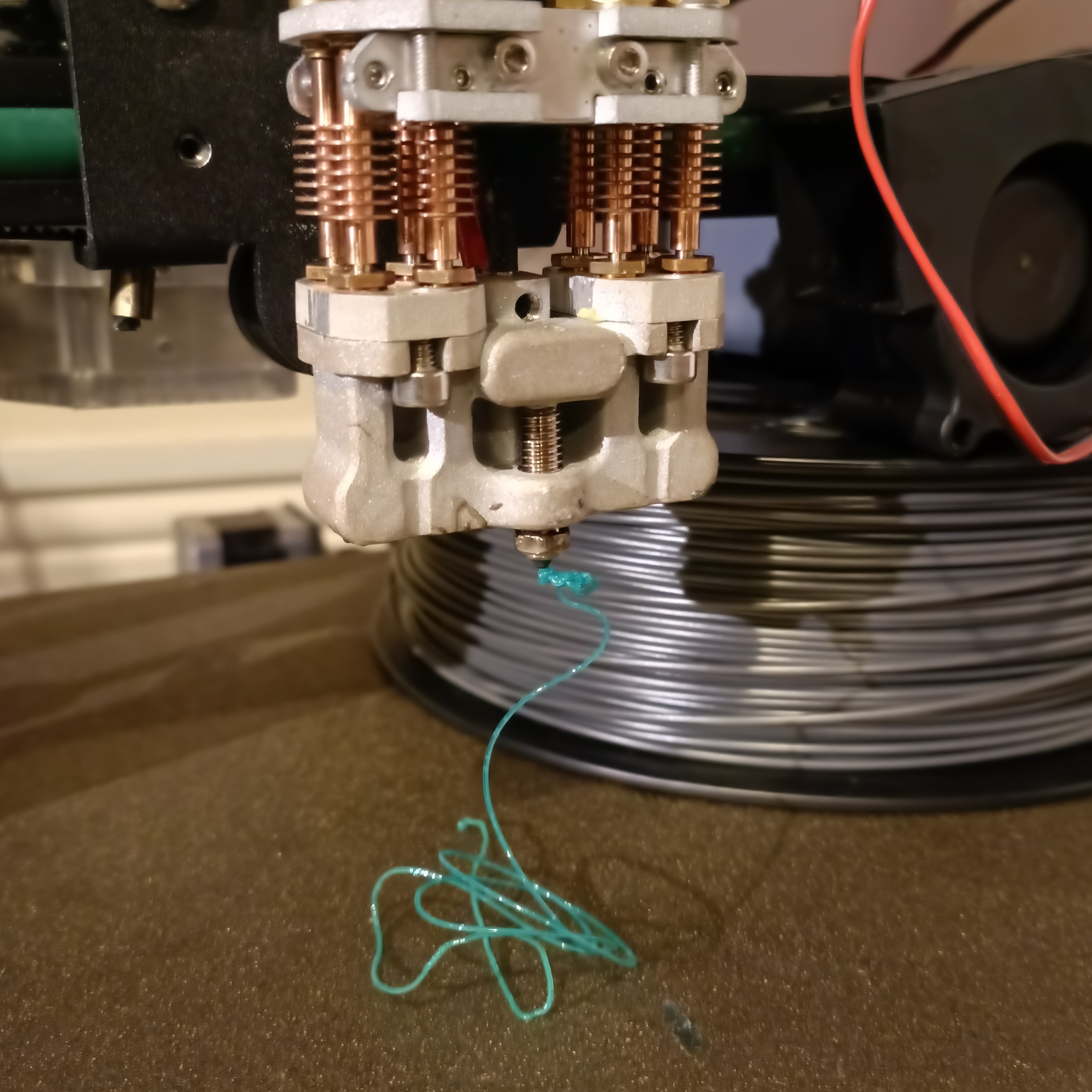

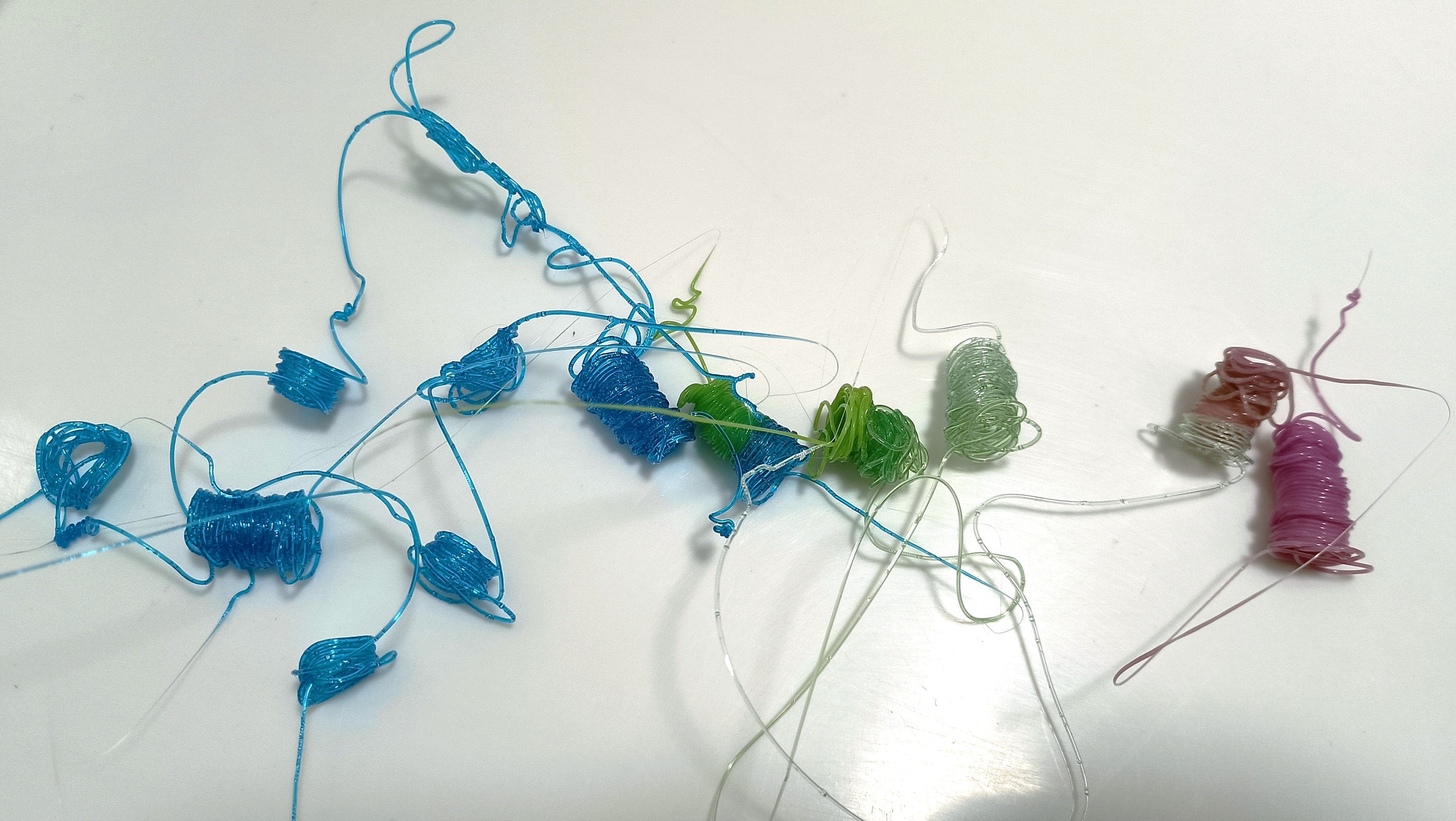

I then extruded 200mm through channels 2 - 8 with F240 as seen below. This corresponds to 240 / 60 * 2.4 = 9.6 cubic millimetres/second/channel.

There were no leaks to be seen.

What's that? Big Leaka's stocks are tanking?

The flow rate is still disappointing though. I don't think there's even been a change over the previous designs.

[Next Day - 14:00]

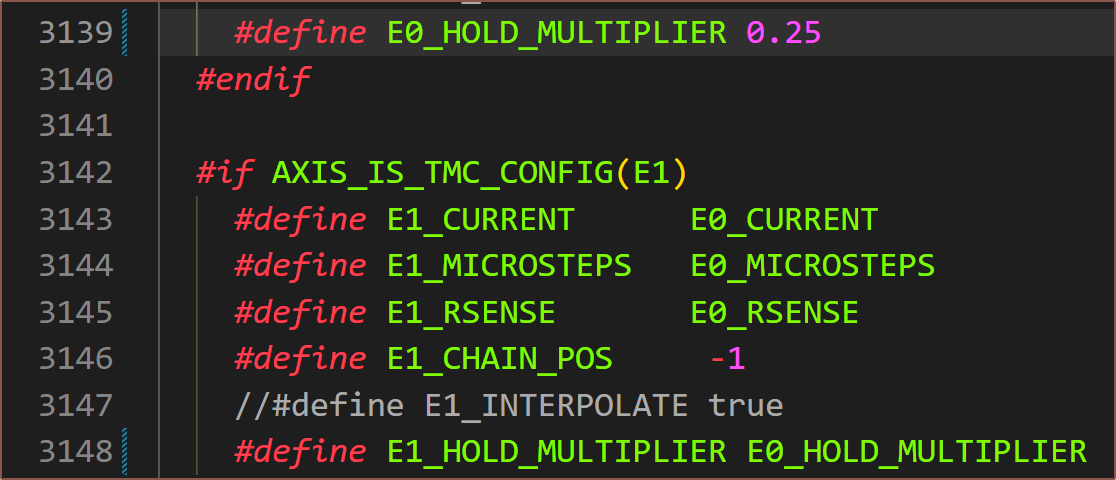

I decided to set all motors to 900mA current, which should be in acceptable limits since the extruder motors are rated for 1000mA. Since non-moving extruders were perfectly fine, even way back at the start of the year when I set the run current to 450mA, I have also halved the default hold multiplier to 0.25:

Redoing the test at 240C, I was able to consistently extrude 300mm at F450 (7.5mm/s) through a 0.6mm nozzle, meaning that the volumetric flow has now increased to a respectable 18mm3/s per channel. The extruder motors are lukewarm.

Redoing the test at 240C, I was able to consistently extrude 300mm at F450 (7.5mm/s) through a 0.6mm nozzle, meaning that the volumetric flow has now increased to a respectable 18mm3/s per channel. The extruder motors are lukewarm.

[16:30]

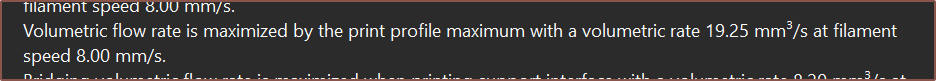

Decided to move past arbitrary limits and set 1A current for all motors. The steppers and the driver heatsinks are still barely warm, but the feedrate has increased to 510mm/min (8.5mm/s) for a volumetric flow rate of 20.4mm3/s. Since filament in some channels started to slip over the gears, I believe it's right on the edge and a flow limit of 19.2mm3/s should be used for printing.

In other words, the Coaxial8or speed limit is 8mm/s with my present setup.

Some yellow is starting to creep out again so I need to further tighten it.

Some yellow is starting to creep out again so I need to further tighten it. kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.