It took much longer than expected, but the new clamp and coupler plates are installed.

Removing the old plates

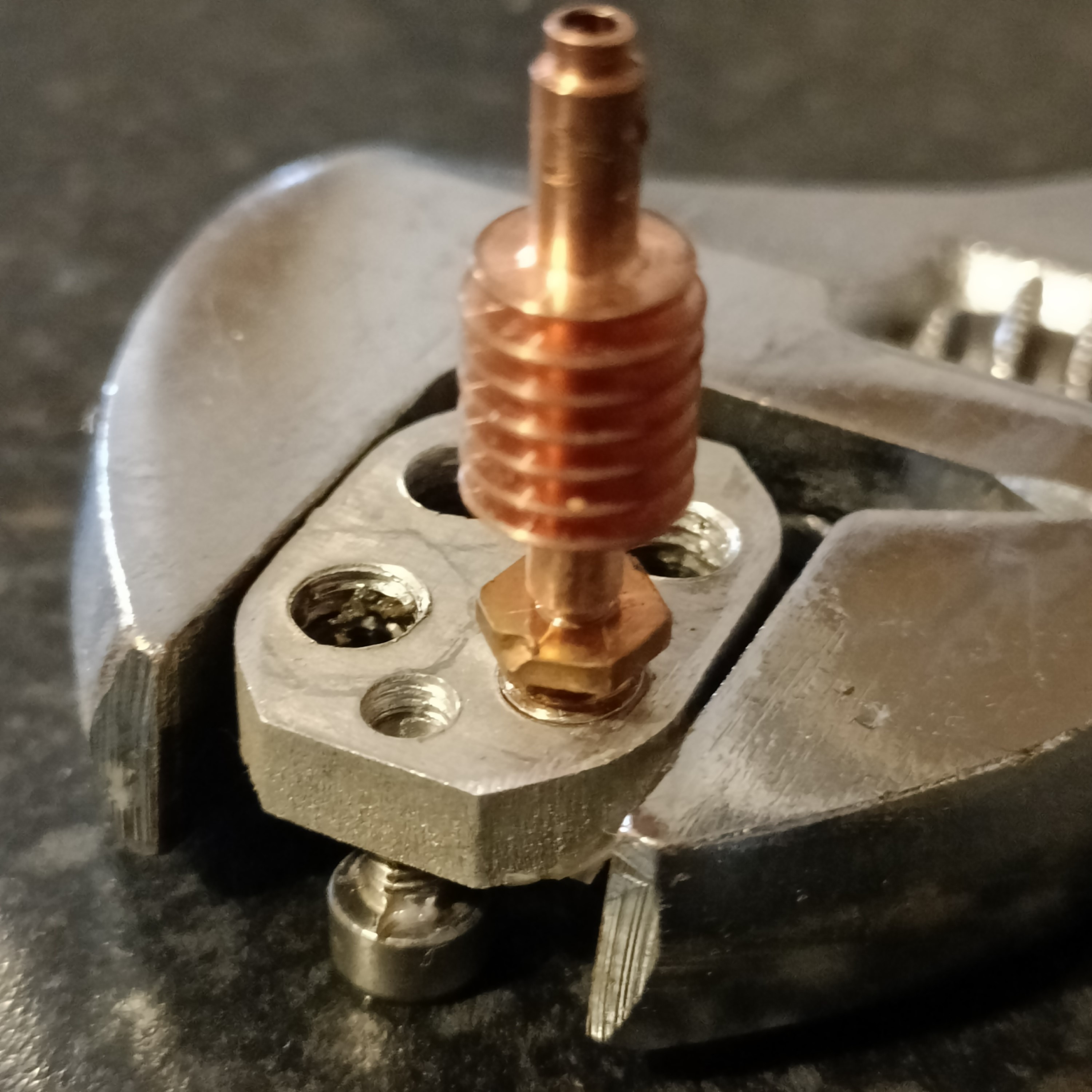

I guess the reason why it took longer was because of all the oozed material, which was notably less in previous revisions. It meant that the filaments didn't pop out of the heatbreaks like I've been able to do in the past. Additionally, the threads were tight in so I had to dip in hot water and then use a large wrench to hold them. I used bolts to prop them up from the table so that I could get the smaller wrench on the heatbreaks:

This is also the first time I've had to install them without unblocking them all, since I wasn't able to get the filament out and the best way really was just clamping them back to the c8or heatblock. The job was made harder because I only have 1pcs needle nose pliers, but because of the gaps in the design, I was able to use it to hold the heatblock while I installed and tightened the heatbreaks in the new stainless steel plates while at 140C.

I first tried 160C but that caused the material still inside the block to expand. Thus, I took the plate off and had to remove material from one channel that had stuck to the underside of the not-yet-tightened heatbreak.

Tightening the heatbrakes to these new stainless clamps feel much stiffer and confidence-inducing.

The coupler plates didn't work due to the FrontBack tabs

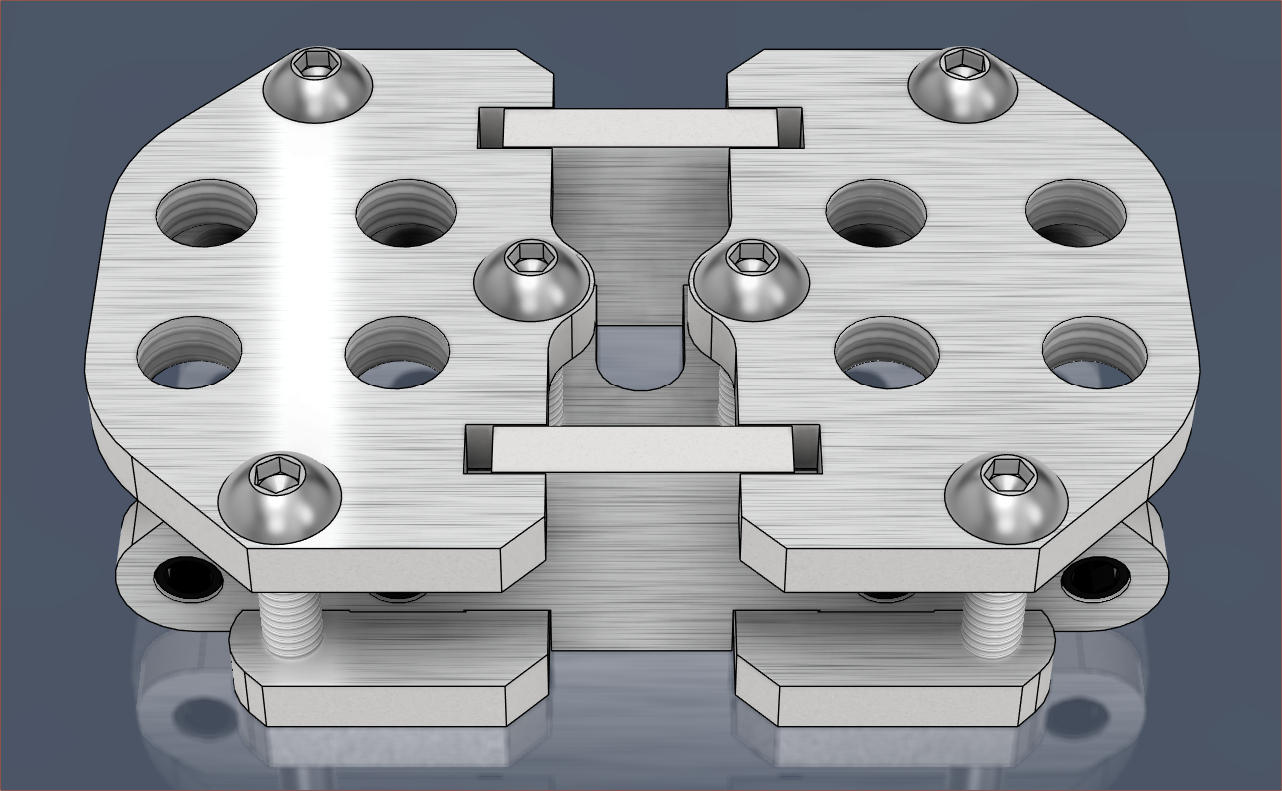

I spent about an hour trying various ways of installing the hotend into the holder before realising that the reason I couldn't was because of the top tabs that don't need to extend all the way. Thus I measured and tried to take about 1 - 2mm off one and then using it as a template for the other:

I then put the hotend together and it was much easier (except that I should've probably put the grub screws in before assembly).

As you can see below, I've added offsets to the CAD as well as changed the grubs to M4 mainly so that I can use a larger hex tool:

Trivia

It takes ages (maybe 2 - 3x longer) for the Coaxial8or to cool down when the heatsinks aren't attached, suggesting that they are dissipating the bulk of the heat power and that a heatblock sock wouldn't help much.

I got 100% initial-filament-load-in success rate for the first time, meaning that the strategies I've been learning during this project are working to streamline the user experience. I think access to E6 is the only main pain point (other than the leaks).

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.