I'm not really sure how I even stumbled on this paper. I was just looking for SLM-printed hotends and learning why the heatbreak length is usually 2mm. I didn't think I'd find a 2020 thesis paper of a guy called Robert trying to make a coaxial hotend. This hotend was just to see if the desired extrusion was possible and wasn't connected to a motion system. Here's what I learned:

- Fabrication: Binder jetting from i.materialse and Shapeways, starting at 60% stainless / 40% bronze and eventually going for 100% stainless due to heat conductivity.

- He had to split up parts a lot because the parts kept coming in with powder! Is SLM less susceptible to this, or has PCBWay just not got that skill issue?

- One of the issues from this is that the "shell" input only came in from one side, causing the extrusion to be pushed

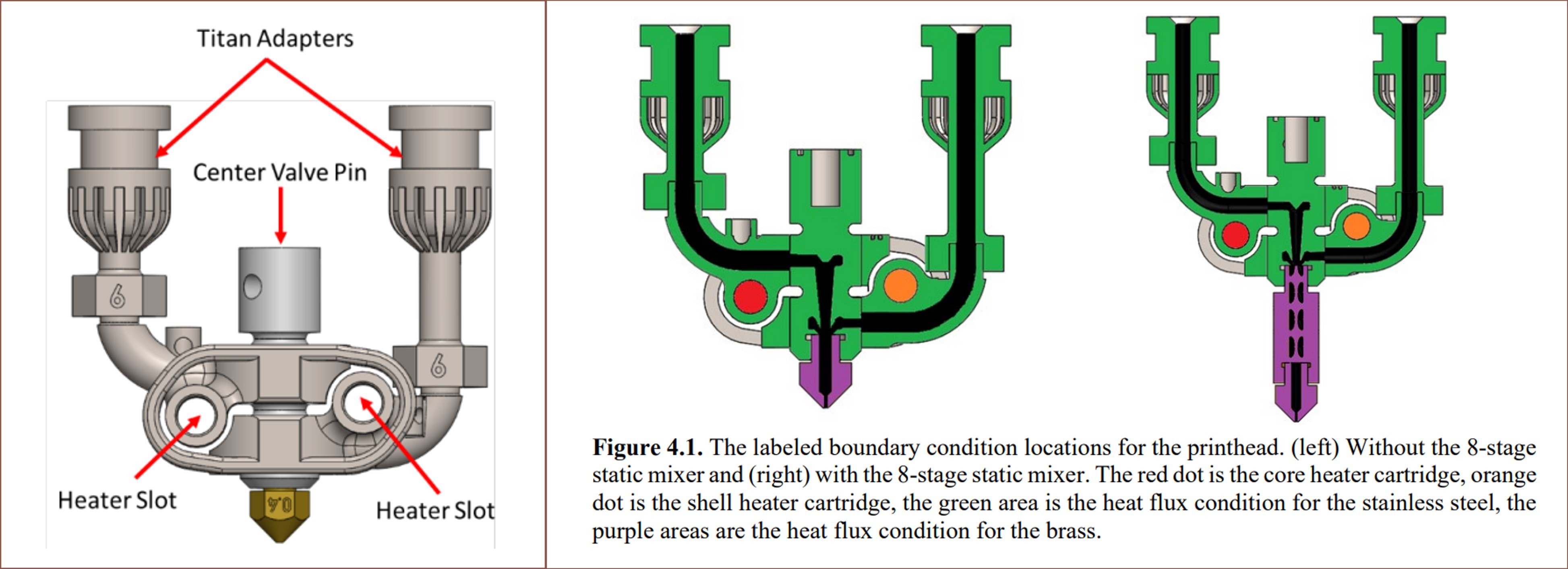

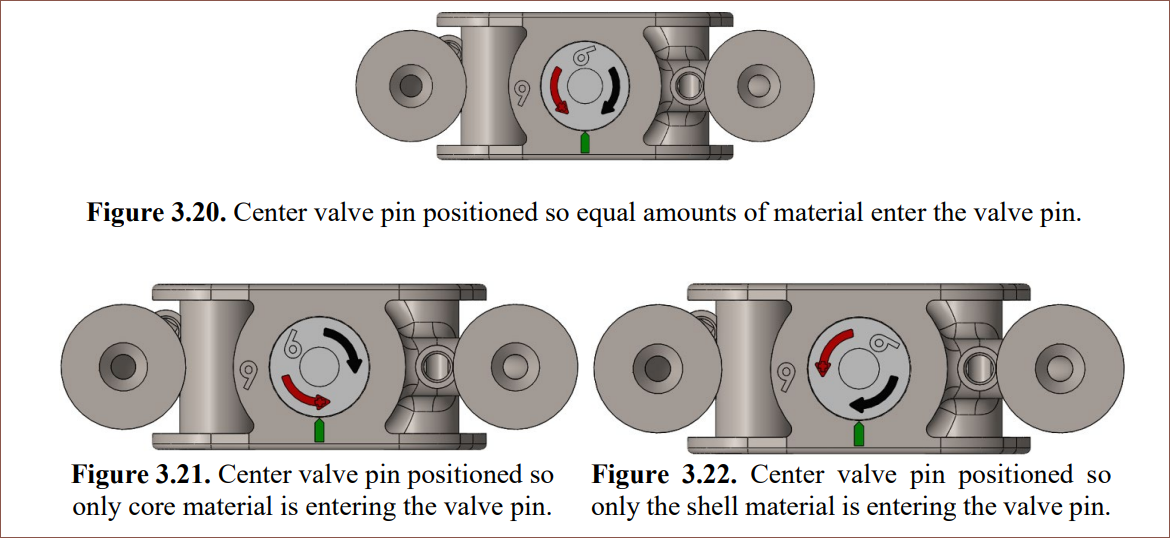

- Design: Essentially all-in-one. Since it wasn't mentioned till rather later, it seems that Robert assumed that each input needs to be thermally isolated for use of materials with different melting temperatures. The center pin generally averages out the temperatures anyway. He had flow issues that he attributed to the complex internal geometry, but I believe it's because he's trying to bend semi-molten filament. Interestingly, the centre valve pin can be rotated:

-

![]()

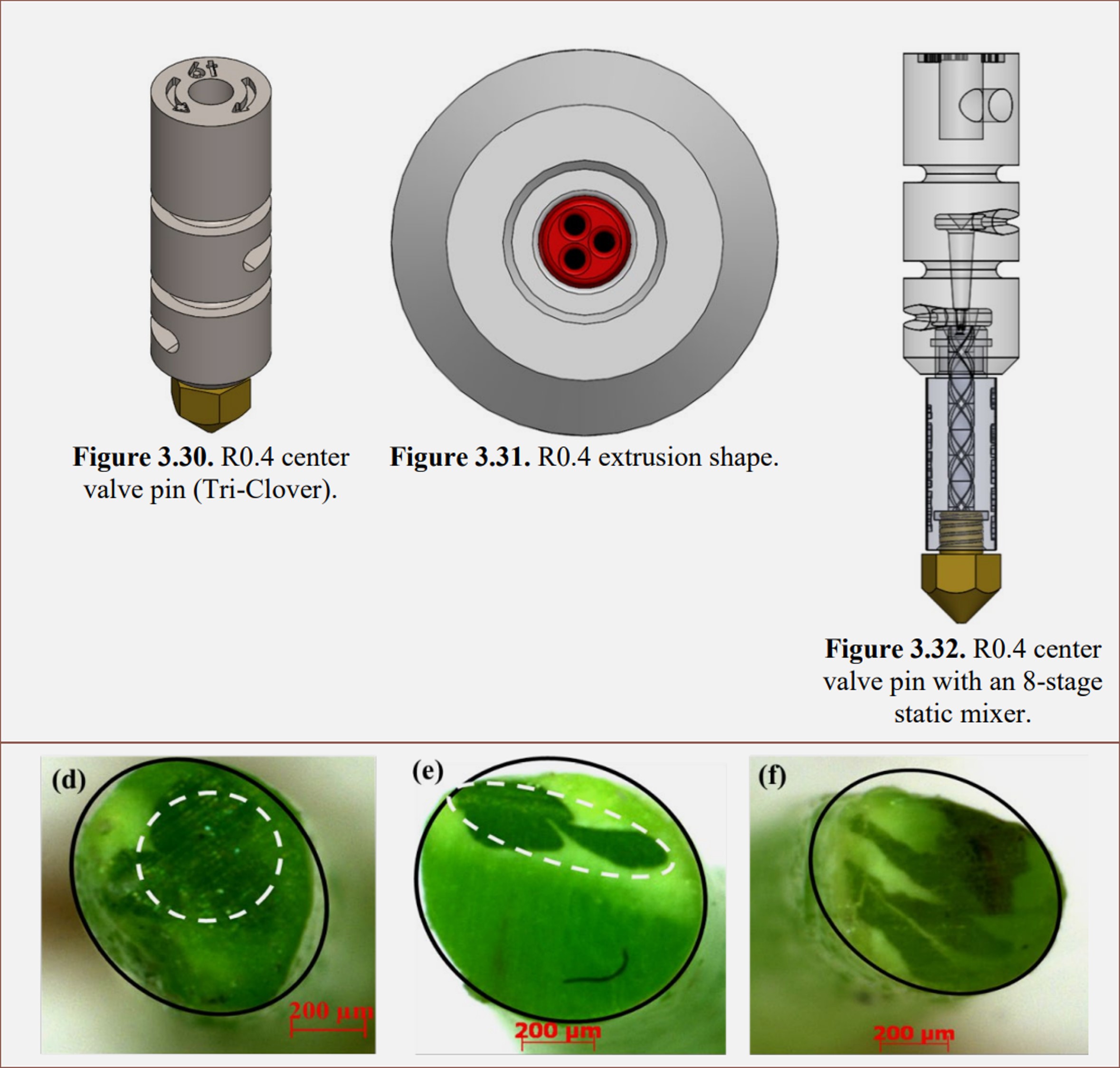

- One of the unique pin designs was one that had 3 smaller holes instead of one. At high shell amounts, the core got pushed to a side. The static mixer just made some layering effect in the extrusion.

![]()

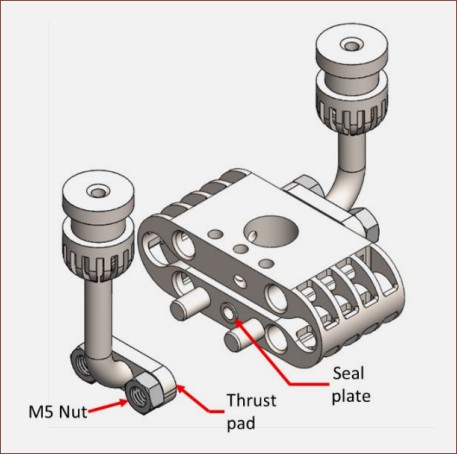

- Not sure how it's being sealed though. While on the subject, in an earlier design, he added a "seal plate" which looks like the geometry I added to Coaxial8or R3:

![]()

- He still uses Marlin's mix feature and had to use the bed heater to control the second cartridge. If you remember back for Coaxial8or R0, I used the chamber heater.

- I noticed the little gap around the sealing face of the nozzle, so he probably knew about the whole bottoming-thread thing.

- Oddly enough, only single material flow simulations were conducted.

- He put switches so that the cooling fan can be turned off to allow material to heat up in the cooler section to clear blockages.

- Further work was simulating 2 different polymer flows and mounting to a "hobbyist printer (e.g.,

CR-10, Ender 3, Prusa) to support streamlined integration", which I've respectively kinda-done and done. His intent for the simulation was to visualise the cross section; I believe the OpenFOAM simulations I've run are viscous Newtonian fluids and they seem to do a good enough job.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.