-

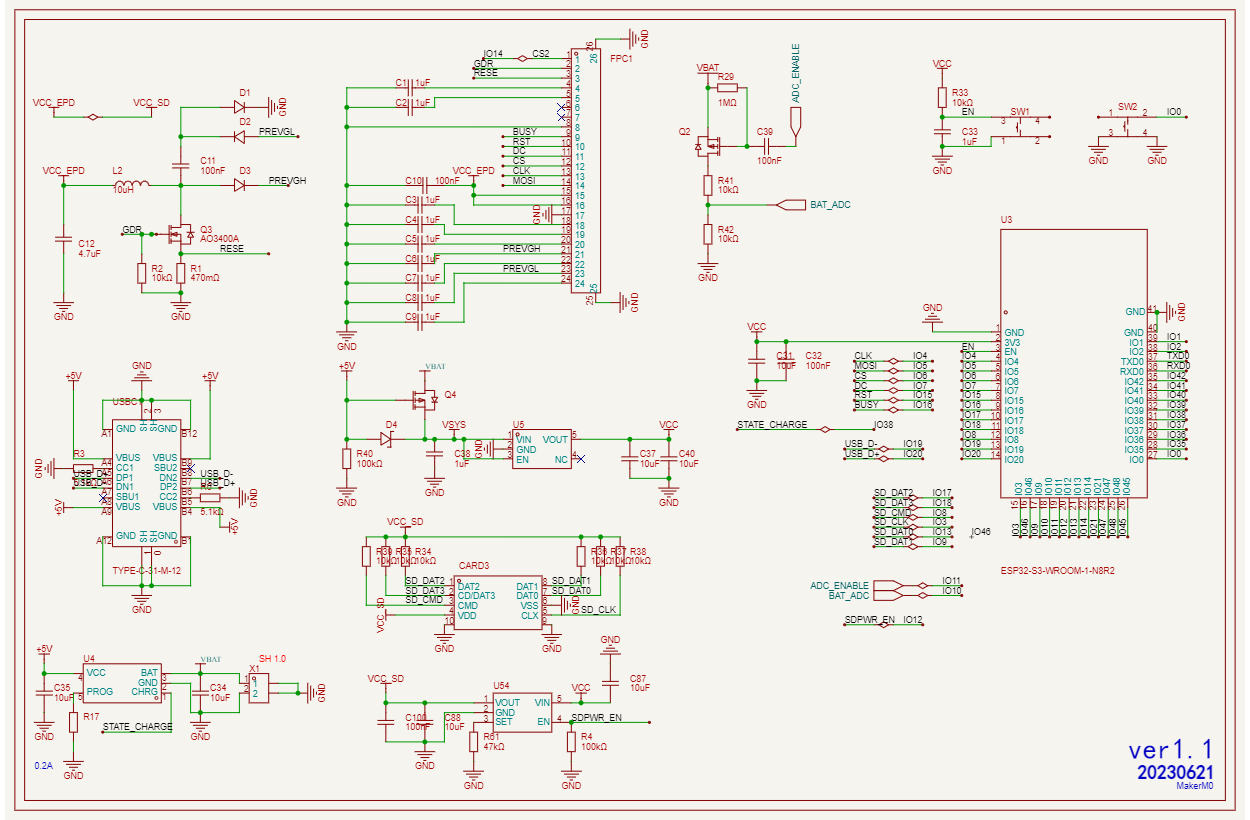

v1.1

06/21/2023 at 07:19 • 0 commentsVersion 1.0 still has some issues.

Version 1.1 fixes the existing issues.

The main thing is that the SD card does not work properly, and the pin of Data0 is modified.

Add CS2 signal to EPAPER.

![]()

-

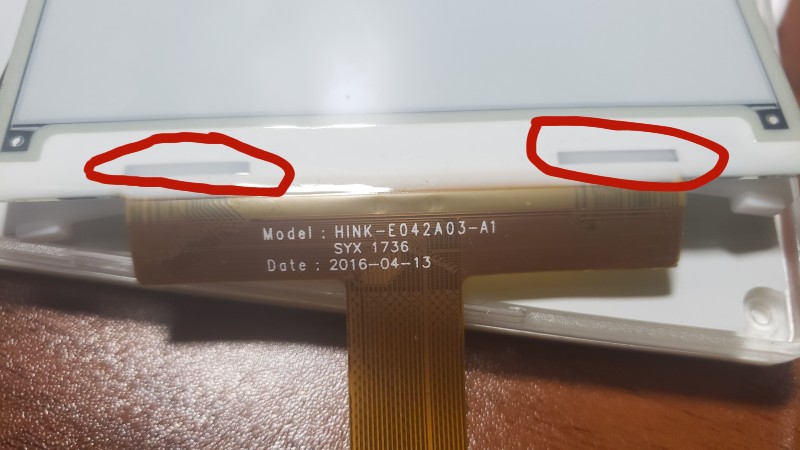

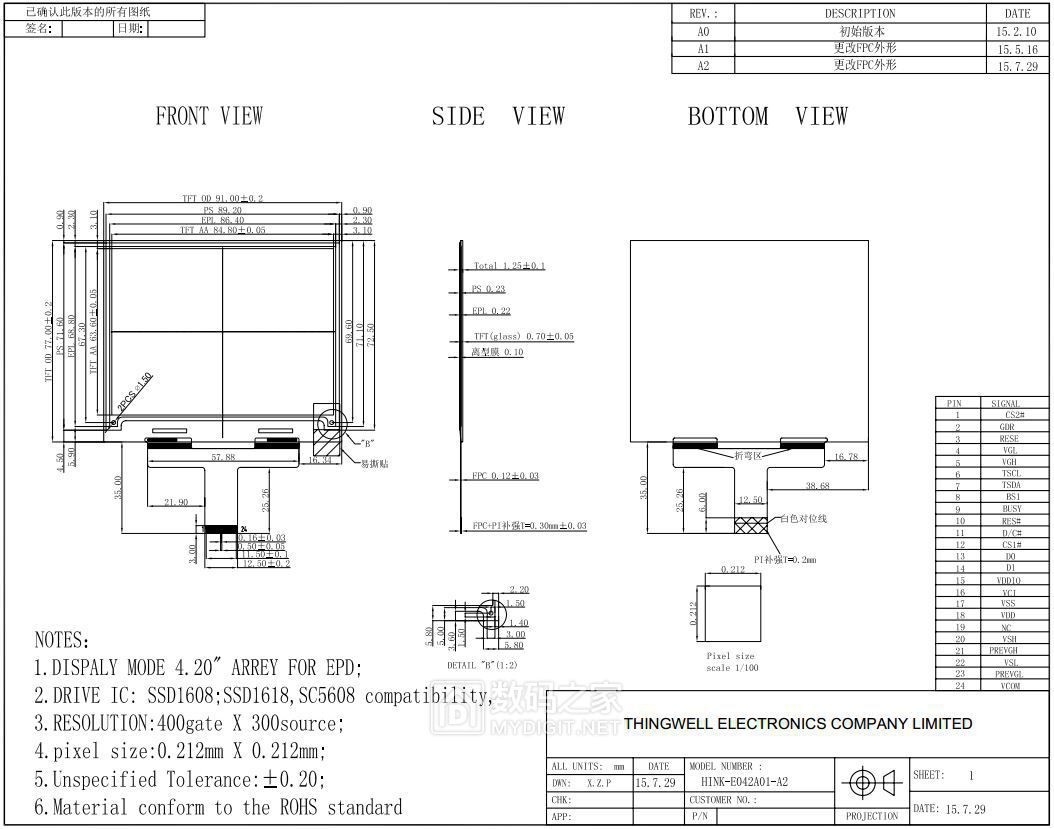

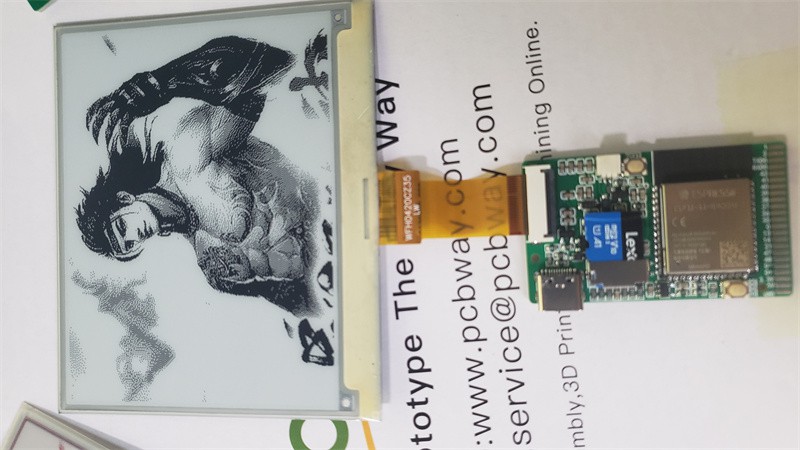

HINK-E042A03-A1

06/09/2023 at 12:56 • 0 comments4.2“,400x300

HINK-E042A03-A1

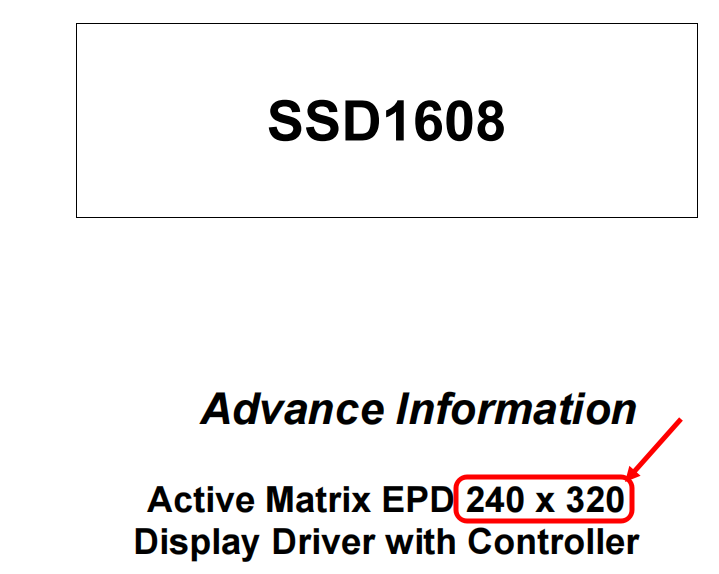

Drive IC:ssd1608

![]()

![img source img source]()

![]()

This screen has 2 CS pins, so the board needs to be modified.

The source code comes from the website.

I haven't tested this code yet, so I'll record it and try it when I have time.

const uint8_t EPD_lut[30]={ 0x66, 0xa6, 0x6a, 0x66, 0x55, 0x99, 0xaa, 0x66, 0x55, 0x95, 0xaa, 0xaa, 0x59, 0x55, 0xaa, 0x55, 0x88, 0x11, 0x11, 0x88, 0xf8, 0xff, 0xff, 0xff, 0xff, 0xff, 0xff, 0xff, 0x8f, 0x8f, }; void init() { EPD_RST_LOW; delayMS(10); EPD_RST_HIGH; delayMS(10); EPD_CS1_LOW; EPD_CS2_LOW; EPD_WriteCMD(0x12); while(EPD_isBusy()); EPD_WriteCMD3DAT(0x01, 0x2b, 0x01, 0x00); EPD_WriteCMD1DAT(0x3a, 0x16); EPD_WriteCMD1DAT(0x3b, 0x08); EPD_WriteCMD1DAT(0x21, 0x83); EPD_WriteCMD1DAT(0x3c, 0x33); EPD_WriteCMD1DAT(0x11, 0x01); EPD_WriteCMD2DAT(0x44, 0x00, 0x18); EPD_WriteCMD4DAT(0x45, 0x00, 0x00, 0x2b, 0x01); EPD_WriteCMD1DAT(0x2c, 0xb9); EPD_WriteCMD(0x32); EPD_WriteMultiDAT(EPD_lut, 30); EPD_CS1_HIGH; EPD_CS2_HIGH; } void write_left(uint8_t *dat) { EPD_CS1_LOW; EPD_WriteCMD1DAT(0x4e, 0x00); EPD_WriteCMD2DAT(0x4f, 0x00, 0x00); EPD_WriteCMD(0x24); EPD_WriteMultiDAT(dat, 7500); EPD_CS1_HIGH; } void write_right(uint8_t *dat) { EPD_CS2_LOW; EPD_WriteCMD1DAT(0x4e, 0x00); EPD_WriteCMD2DAT(0x4f, 0x00, 0x00); EPD_WriteCMD(0x24); EPD_WriteMultiDAT(dat, 7500); EPD_CS2_HIGH; } void refresh() { EPD_CS1_LOW; EPD_CS2_LOW; EPD_WriteCMD1DAT(0x22, 0xc7); EPD_WriteCMD(0x20); EPD_CS1_HIGH; EPD_CS2_HIGH; while(EPD_isBusy()); } void sleep() { EPD_CS1_LOW; EPD_CS2_LOW; EPD_WriteCMD1DAT(0x10, 0x01); EPD_CS1_HIGH; EPD_CS2_HIGH; } void main() { init(); write_left(...); write_right(...); refresh(); sleep(); while(1); } -

update 2.13

06/01/2023 at 08:27 • 0 comments![]()

-

PCBWay and fast prototyping

05/29/2023 at 08:31 • 0 commentsPCBWay offers several advantages, including reasonable pricing, reliable quality, fast delivery time, and a range of value-added services such as free DRC file checks, free X-RAY inspections, and excellent online customer service. They also offer high-quality PCB prototypes and competitive quotes for large volume PCB orders. For DIY enthusiasts and makers, PCBWay also offers complete PCB assembly services, which is very attractive.

Based on these advantages, we not only recommend PCBWay, but we also look forward to working with them in the future. With their assistance, our hardware manufacturing has become easier, simpler, and more cost-effective. If you need an excellent PCB manufacturer to help you realize your hardware dreams, don't hesitate to choose PCBWay!

![]()

![]()

![]()

I have successfully used this board to drive several e-ink screens that I have on hand.

![]()

![]()

![]()

![]()

![]()

If you also want to make one, you can place an order directly by clicking the image below.

![]()

-

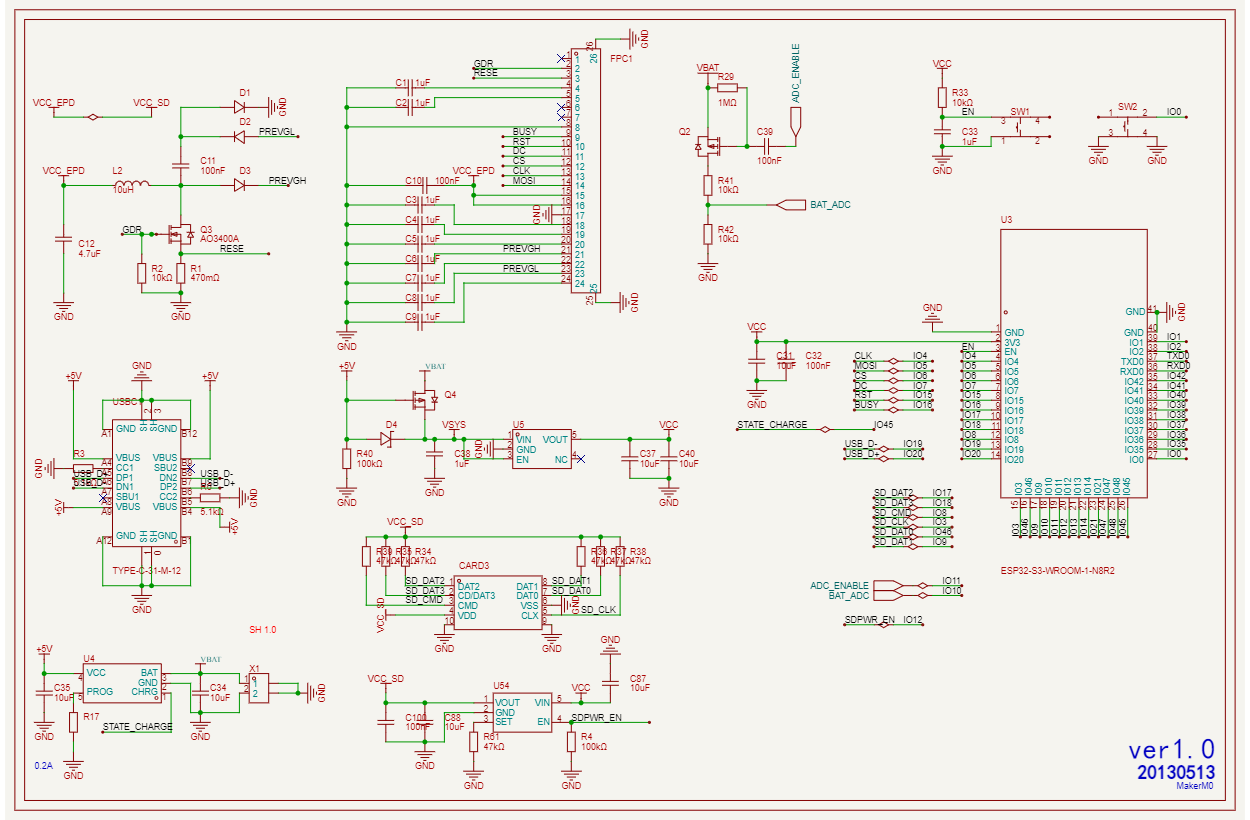

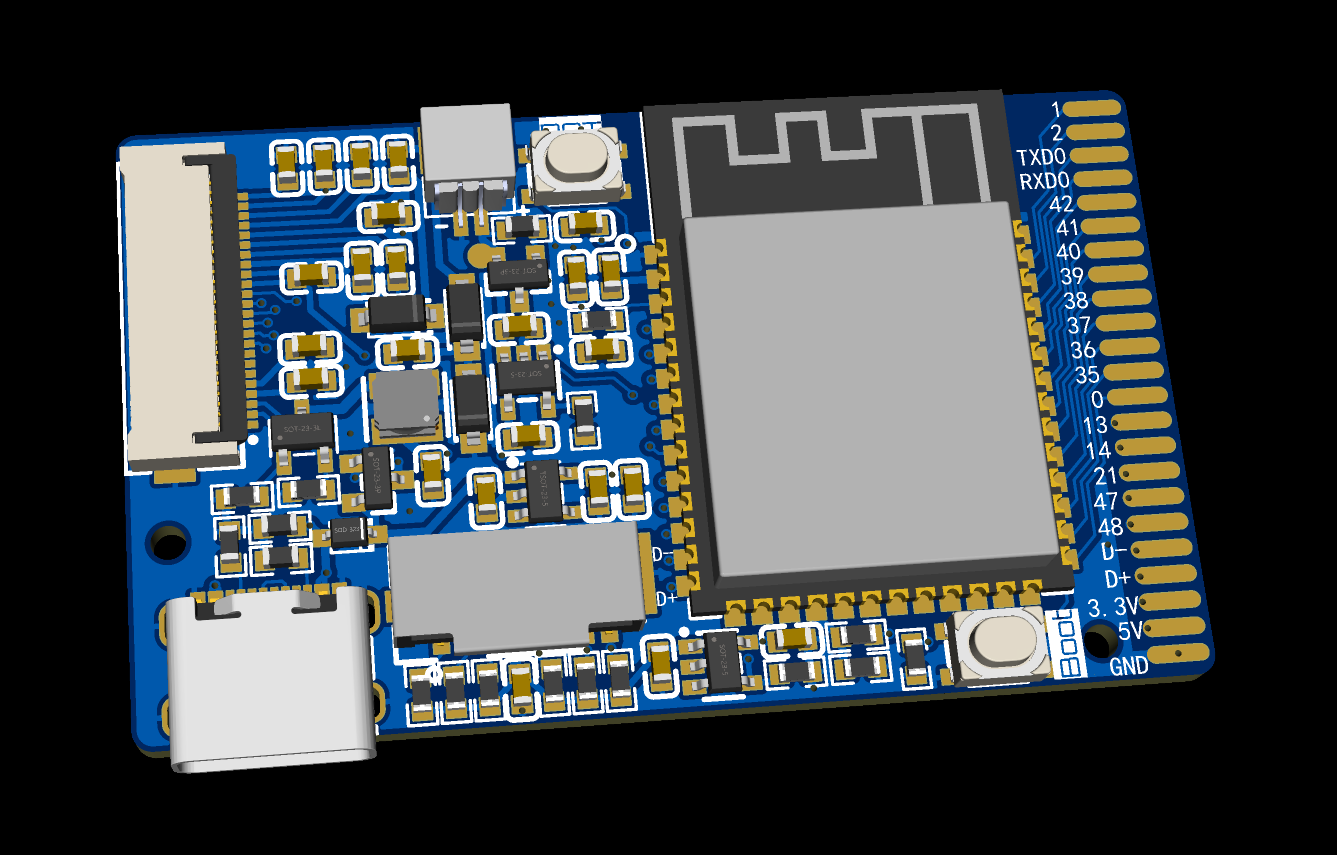

sch&pcb

05/13/2023 at 06:31 • 0 commentsIn the modern electronic field, more and more projects require a small yet powerful circuit board. Today, I would like to introduce a stunning PCB design, which is an only 50x30mm circuit board that supports microSD card, lithium battery charging, USB downloading, low power consumption, and includes related pin-outs for easy connectivity with other modules

![]()

![]()

![]()

-

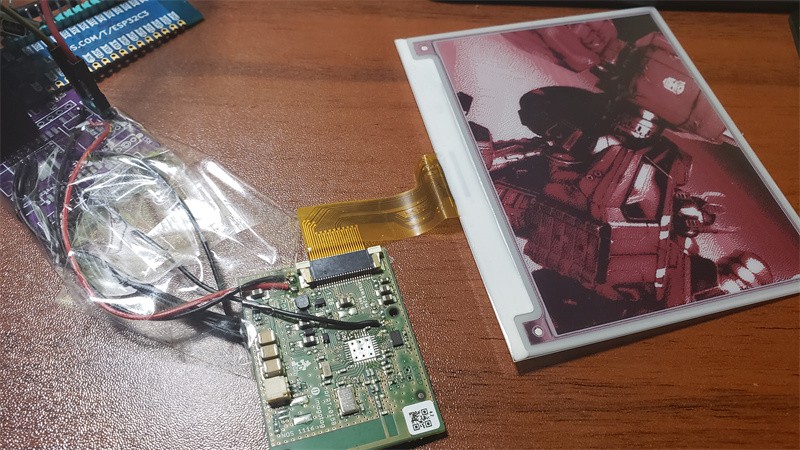

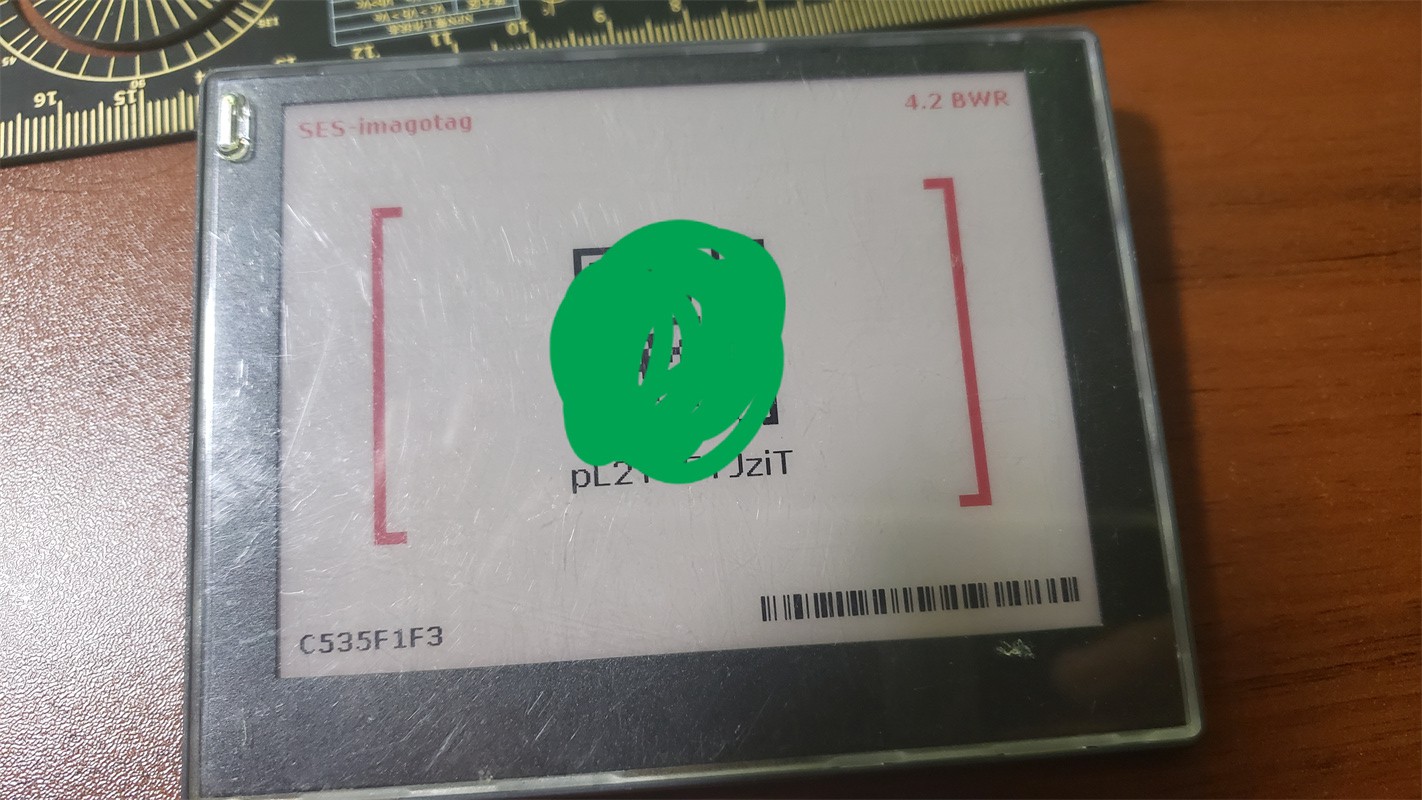

Begin

05/12/2023 at 16:39 • 0 commentsRecently, I received several 4.2-inch e-paper screens and found that they are controlled by CC2510. I tried to drive them using ESP32 and succeeded.

![]()

They are all SES brand and their model numbers are shown in the figure below.

![]()

![]()

![]()

![]()

![]()

![]()

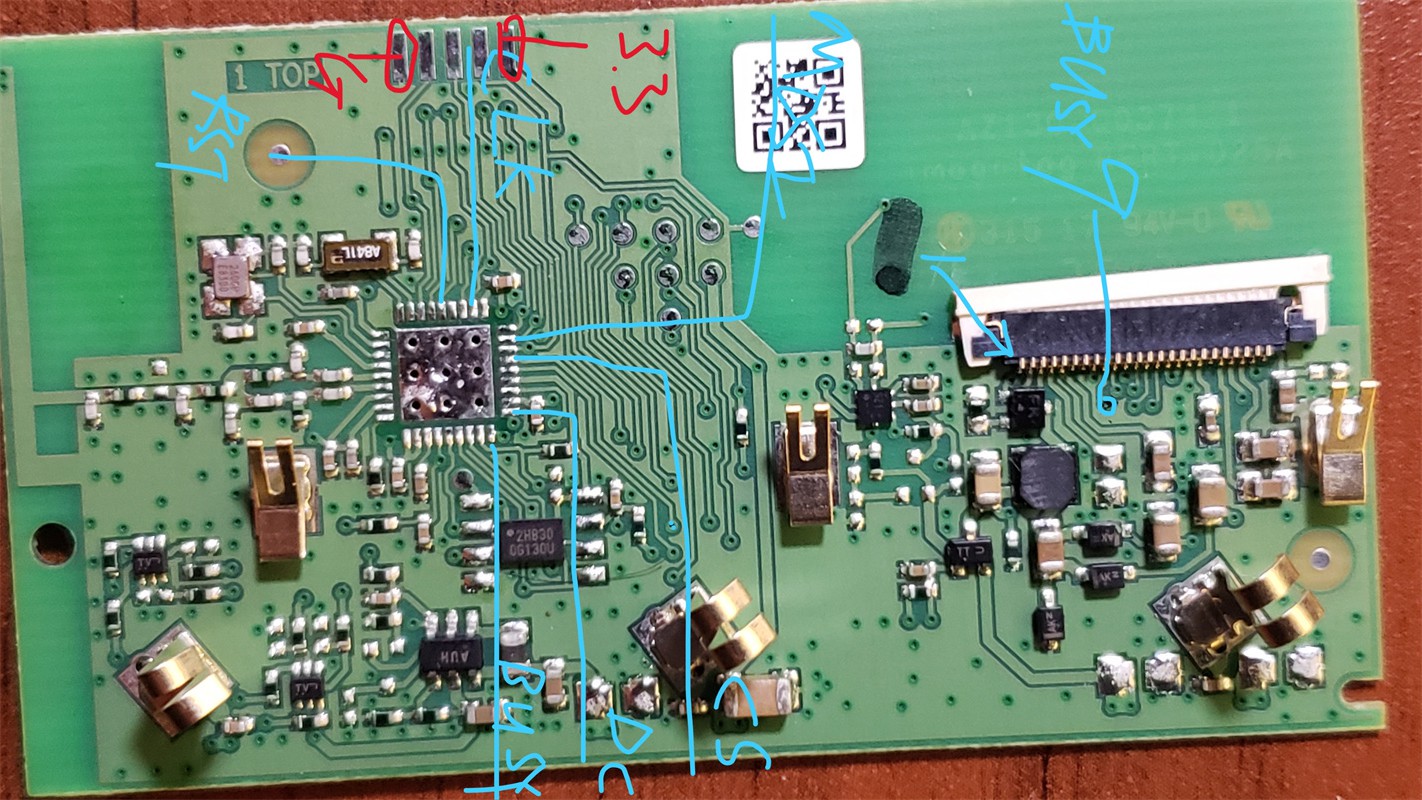

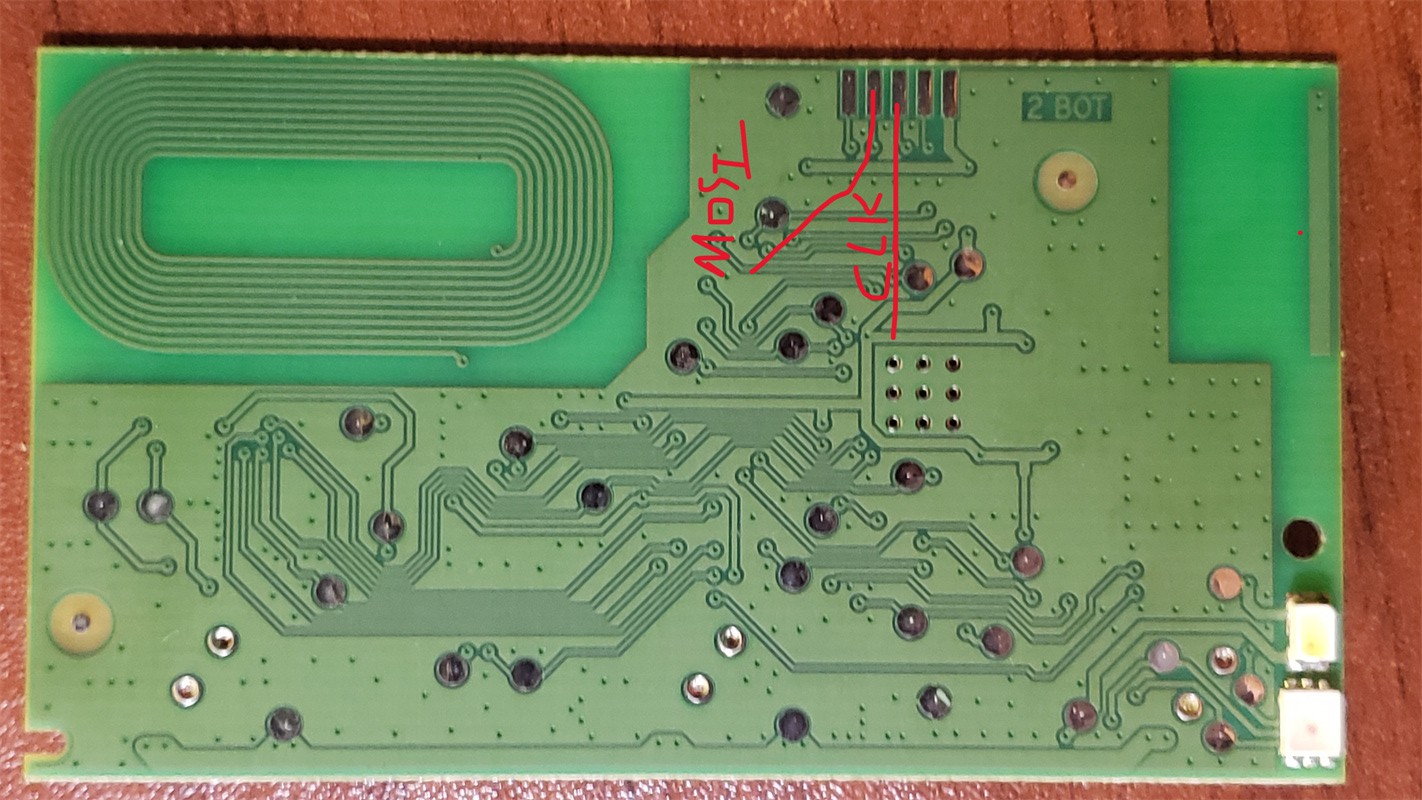

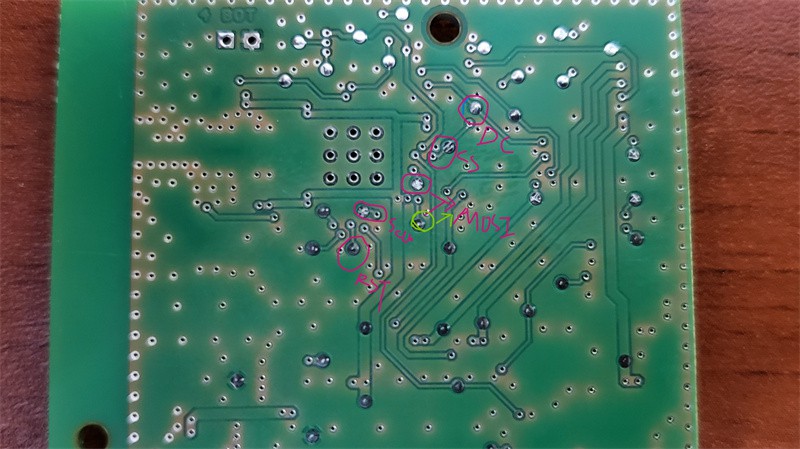

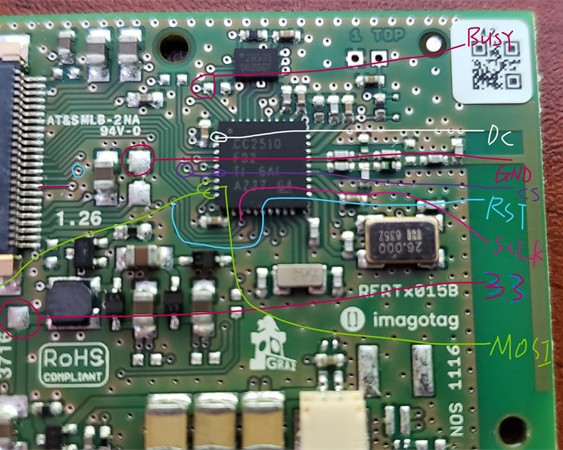

I tried opening them up to take a look and found that they all have CC2510 as the main controller. Since I didn’t have time to study them, I directly removed the chip.

After testing the circuit, I found easy-to-solder pads, marked in the figure.

![]()

![]()

![]()

![]()

The attached program is an example code from Waveshare, using ESP32 or ESP32-S3 to update images through the network and has been tested.

EPD.h is used to connect the development board based on the pinout.

SRVR.h can be modified to set up Wi-Fi, password, and IP address based on ipconfig.However, since the ribbon cables of these screens are arranged differently, I don't want to use jumper wires. Hence, I decided to design a PCB and use ESP32-S3 to drive the e-paper display. The design aims to support multiple e-ink screens on the market and achieve widespread popularization.

ESP32-S3 is a highly cost-effective high-performance chip that has a dual-core and a maximum clock speed of 240 MHz. It supports various communication methods such as Wi-Fi, Bluetooth, and Ethernet. When used in combination with e-paper displays, it can provide stable and reliable driving power. I will use this chip along with related development boards to design and produce a bottom board module, which facilitates quick debugging of secondary developers and speeds up the project implementation.

It is expected that the finished product of this module will have advantages such as low power consumption, high resolution, and portability, which can be widely used in the Internet of Things, smart homes, e-books, and other fields, meeting the multiple needs of users for e-paper displays such as performance and ease of use.

Whether you are a maker, developer, or DIY enthusiast, this PCB design is an open-source project that's worth looking forward to. It is expected to bring more DIY inspiration and drive the further development of e-paper technology.

MakerM0

MakerM0