-

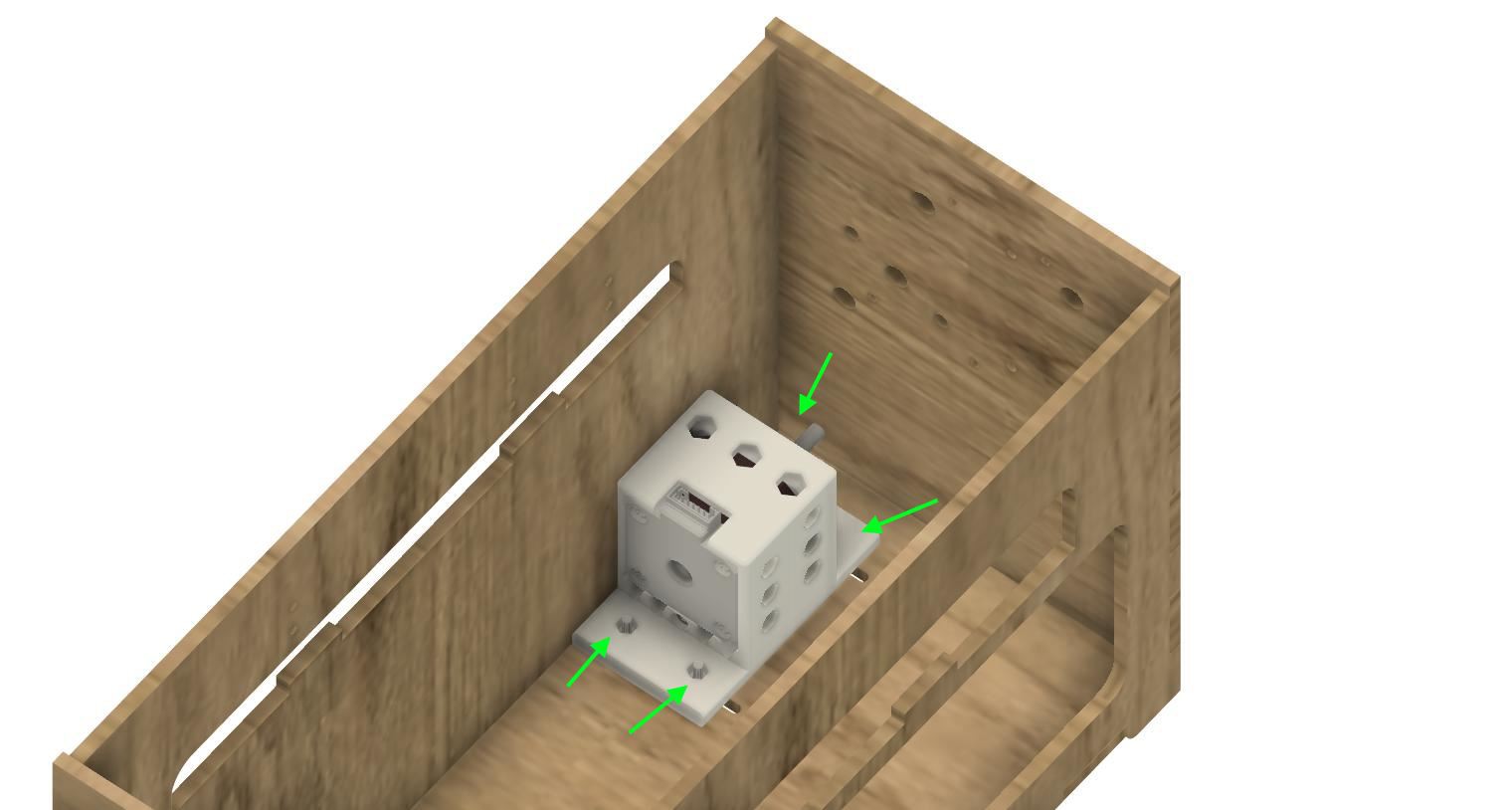

11Fix X and Y Motors

Fix the X Motors with 4 M3-14 screw, waschers and M3-NYL nuts

![]()

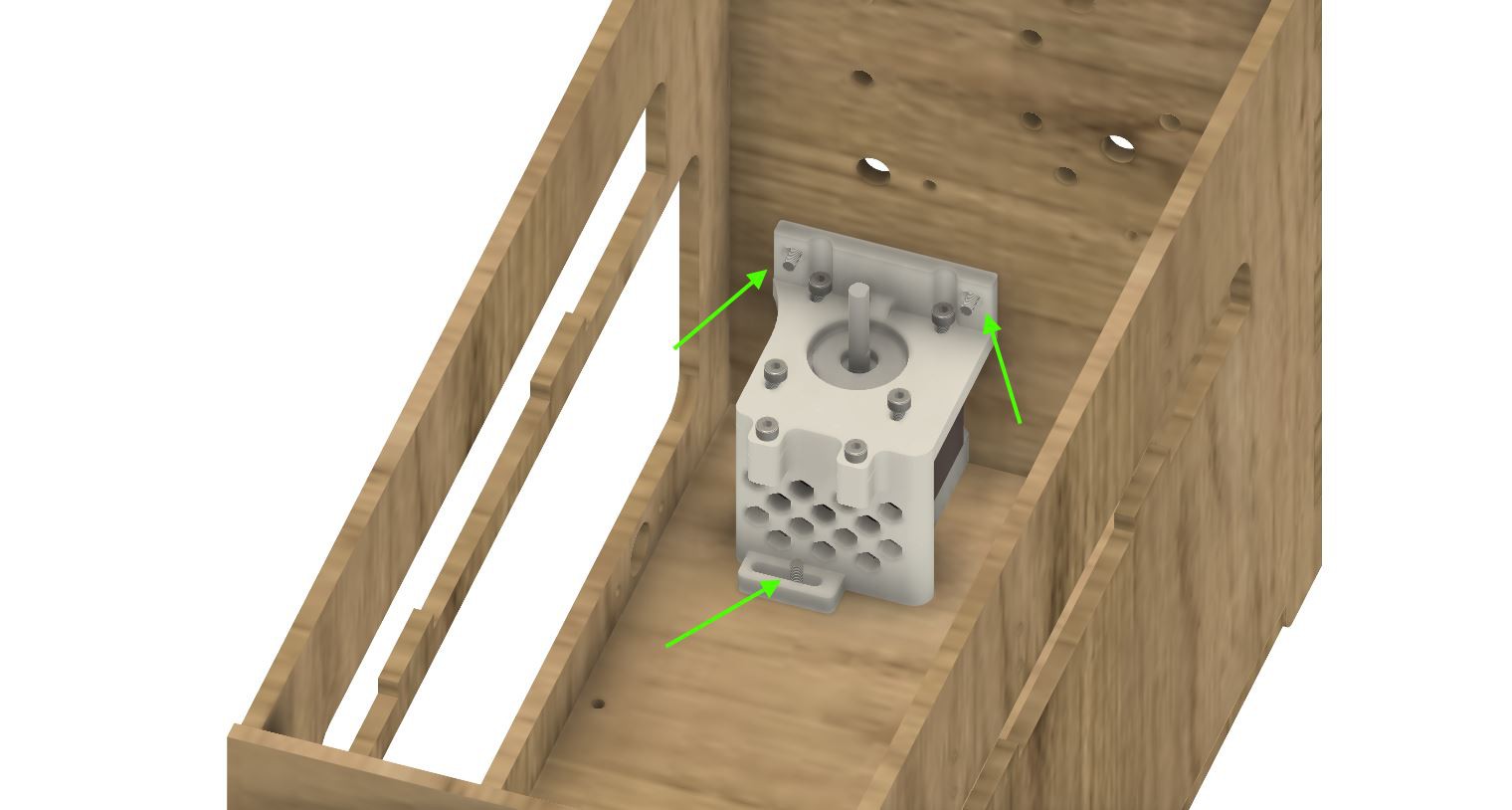

Fix the Y Motor 3 M3-14 screw, waschers and M3-NYL nuts

![]()

-

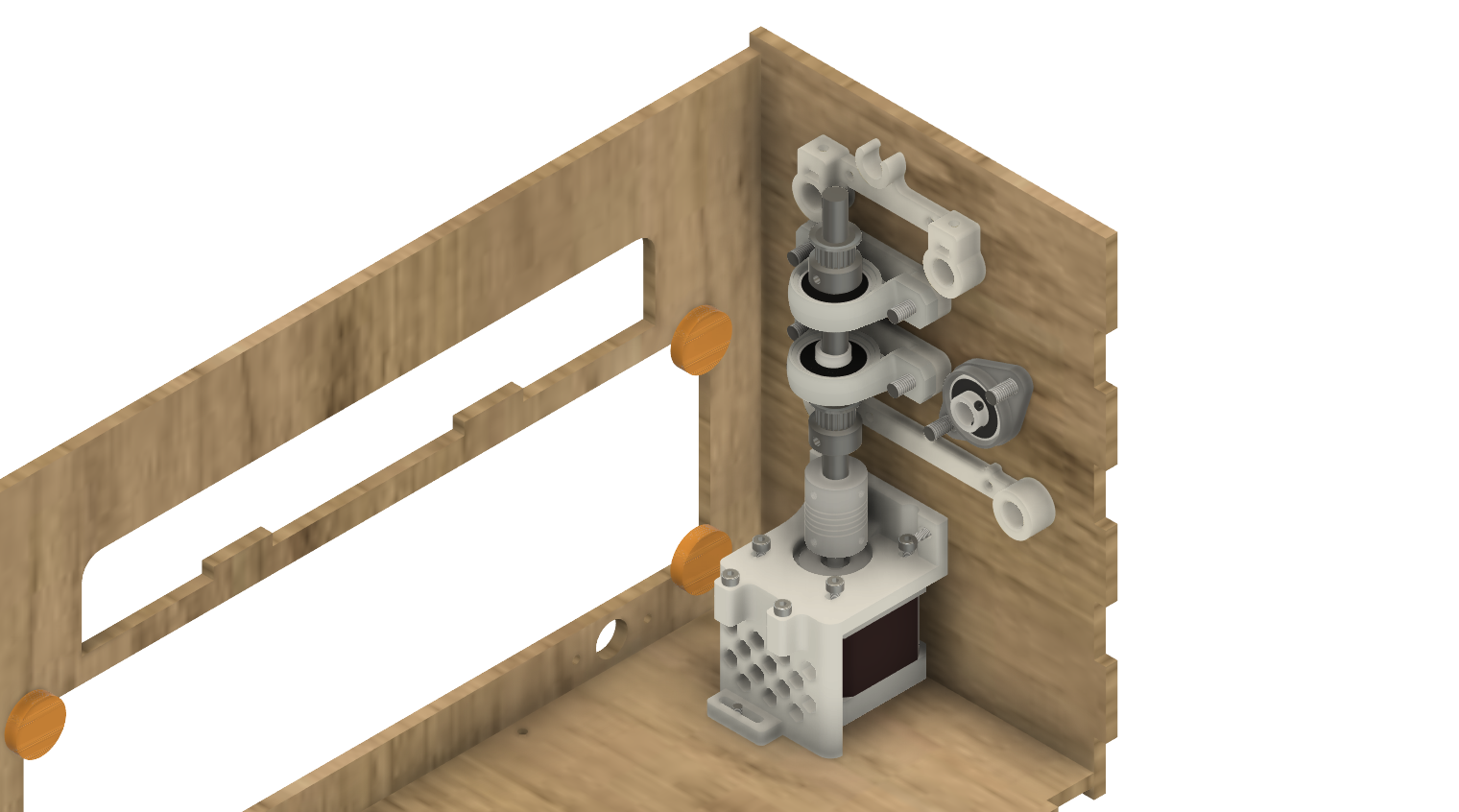

12Assembling left side

Fix 3d printed parts BOTTOM_AXIS_left and TOP_AXIS_left on the frame with M3 washers M3 Nyl nuts and M3-14

Add Belt tensionners DRIVEN_PULLEY_housing with 2 M3-20, M3 washers and M3-NYL

Add KFL-08 with M5-18, M5 wascher and M5-NYL

Fix the 20T bore 3mm pulley with M3-25 and M3 nyl

![]()

-

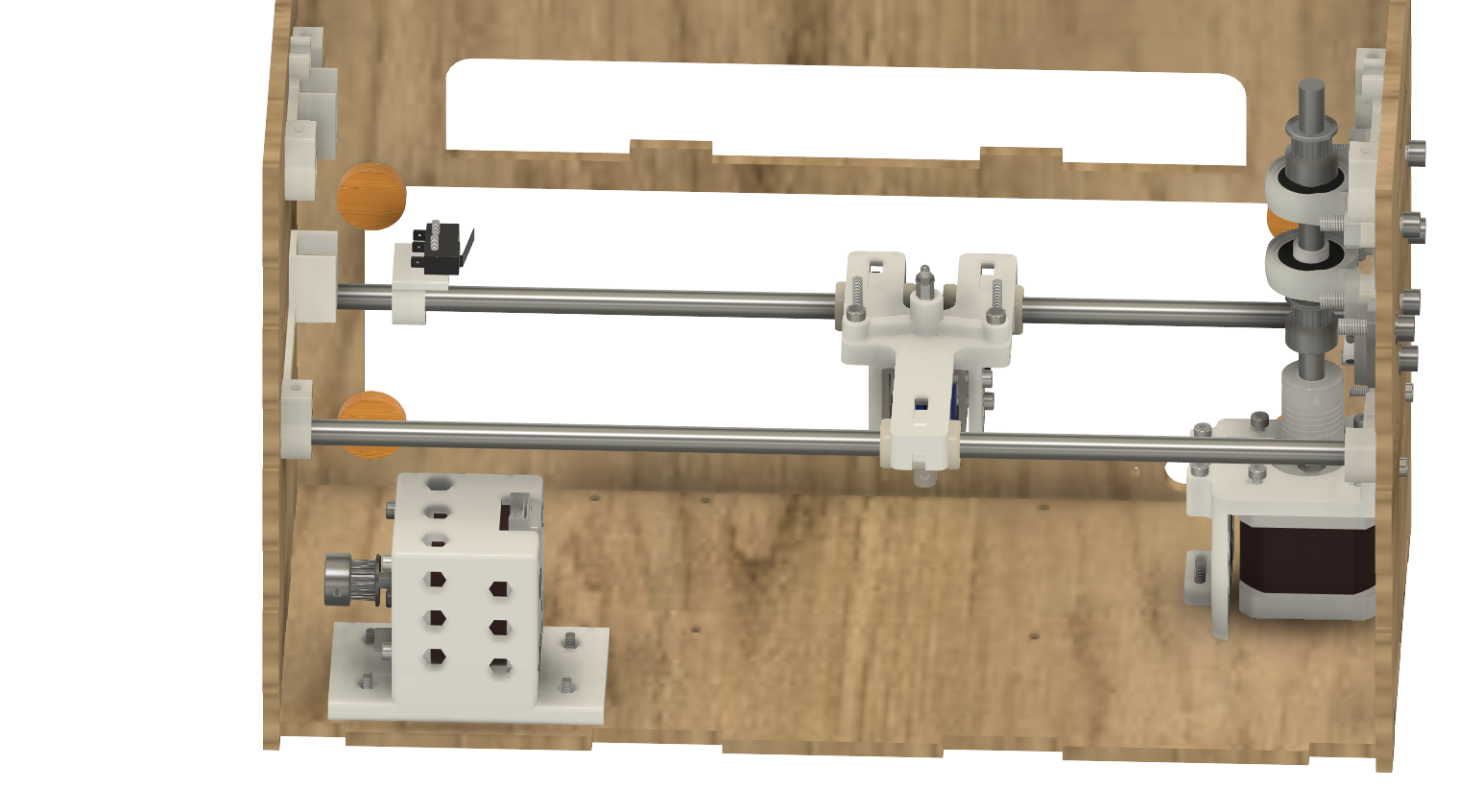

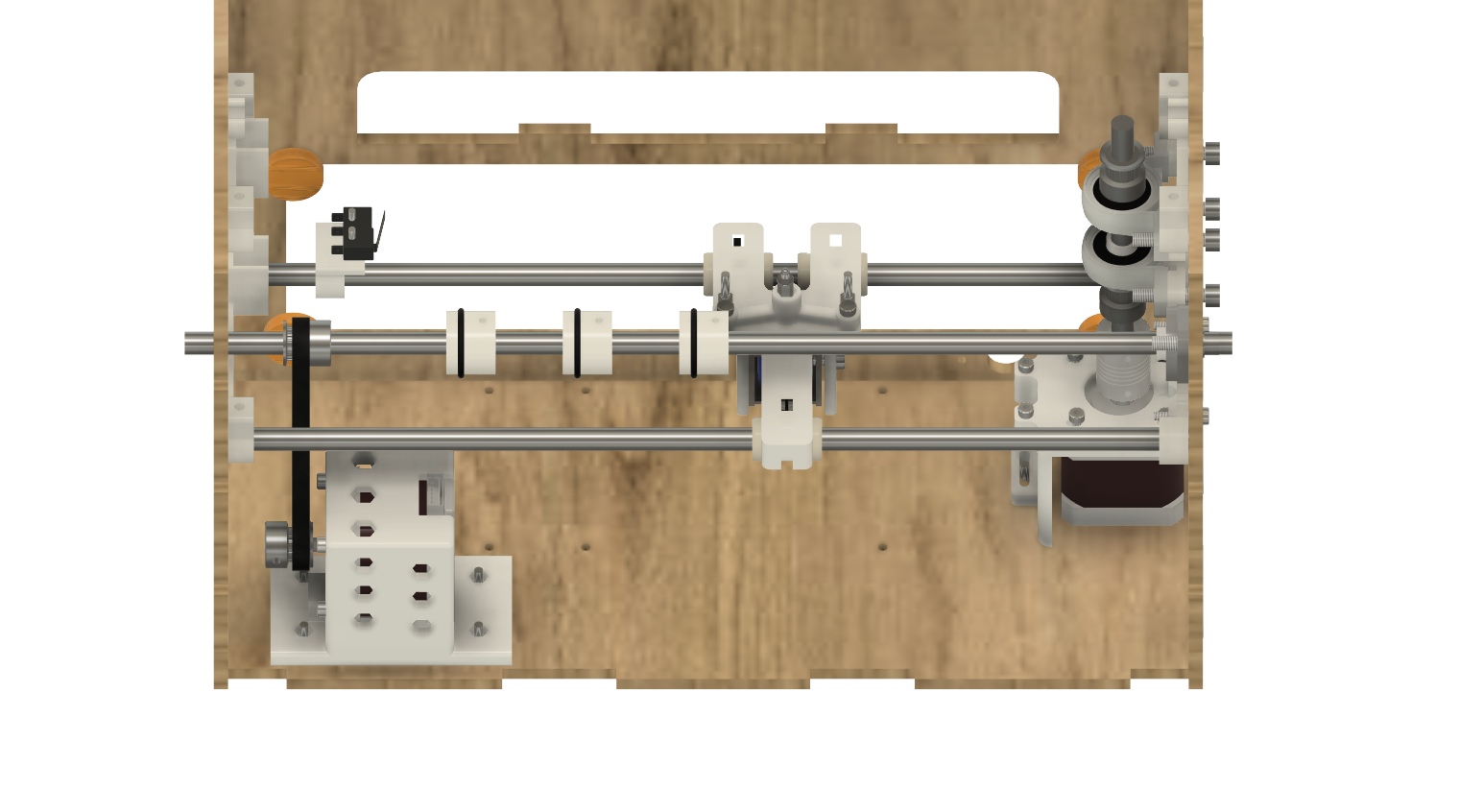

13Assembling right side

Fix 3d printed parts BOTTOM_AXIS_right and TOP_AXIS_right on the frame with M3 washers M3 Nyl nuts and M3-14

Fix 3D printed parts KP08_support and KP08 on the frame with M5 washers M5 Nyl nuts and M5-25 screw

Fix a KFL08 with M5 washers M5 Nyl nuts and M5-25 screw

build the axis with 110mm rod 2 GT2 20 teeth pulley and 8mm-5mm coupler

![]()

-

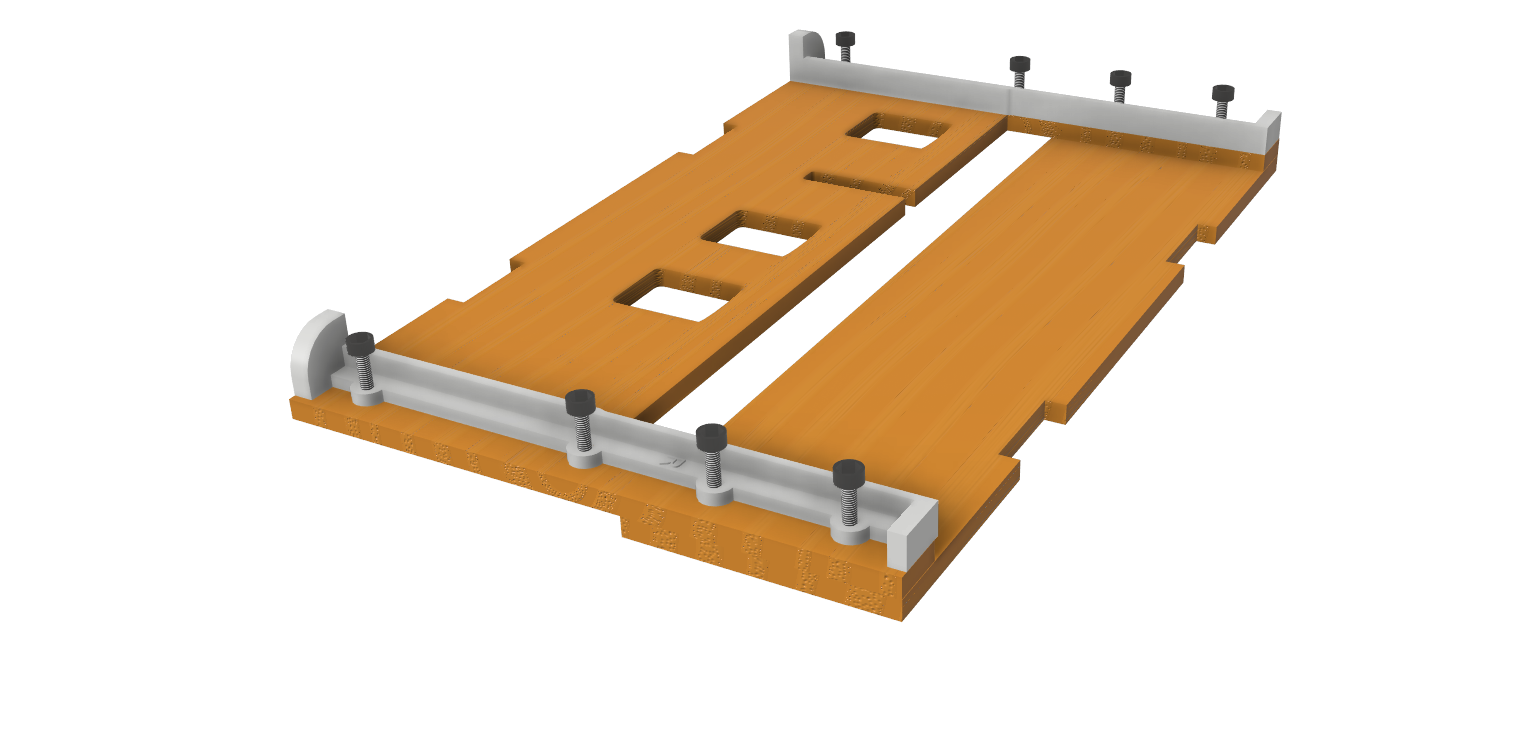

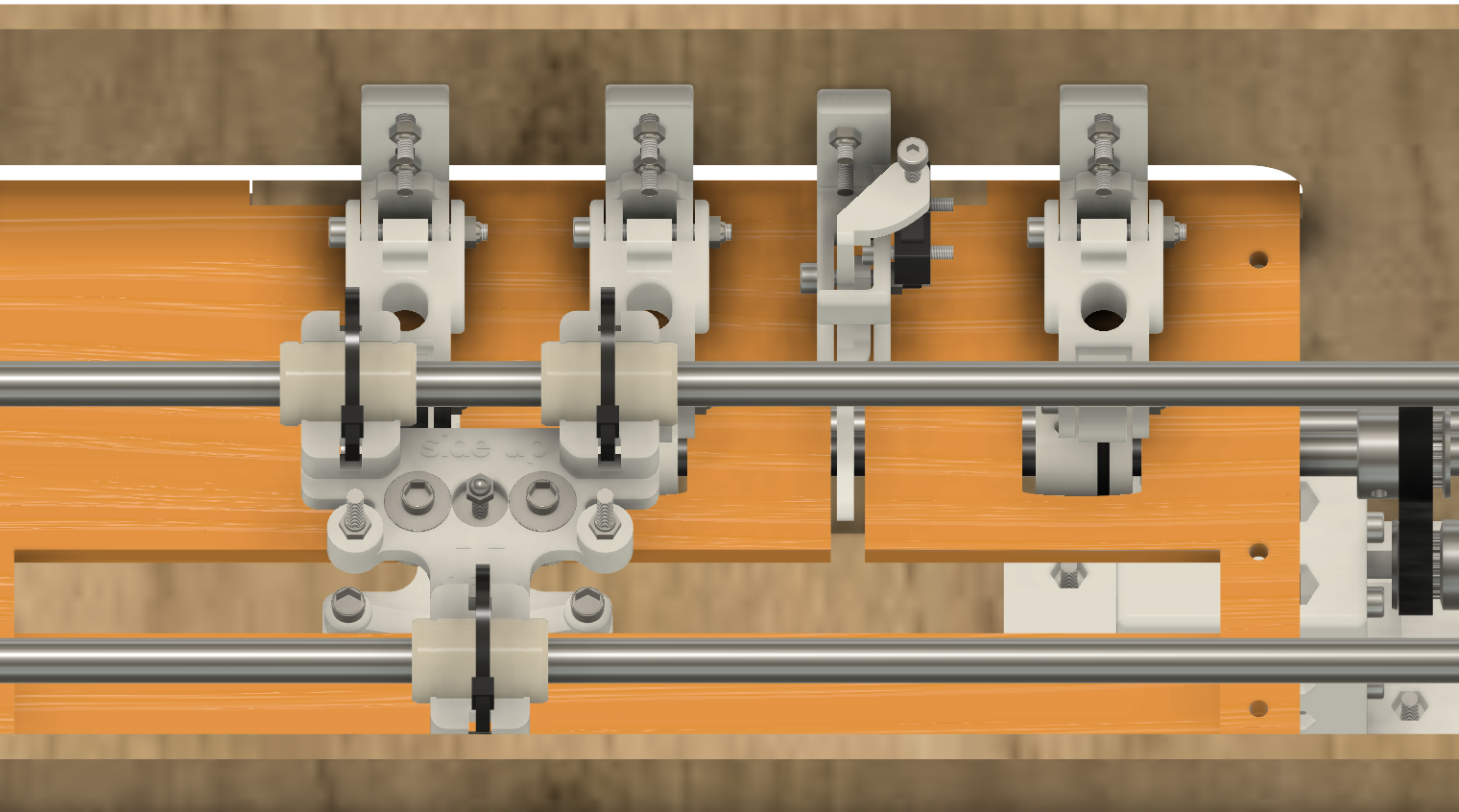

14Build bottom carriage

insert 2 330mm/8mm rod in the support, with the bottom carriage and the endstop support.

![]()

fix ~600 mm GT2 belt on the carriage, passing by the 2 pulleys on right and left.

-

15Build paper advance

insert the 360mm/8mm rod with a GT2 pulley 20 teeth, 3 paper roll with o-ring, and 200mm GT2 belt

![]()

-

16Paper support

fix PAPER_GUIDE_left and PAPER_GUIDE_right printed parts with M3-14 and M3-16 screws, M3 waschers and M3 Nylstop nuts

![]()

fix the paper support in the frame

![]()

you will need to adjust the paper roll for the paper support to take in place.

-

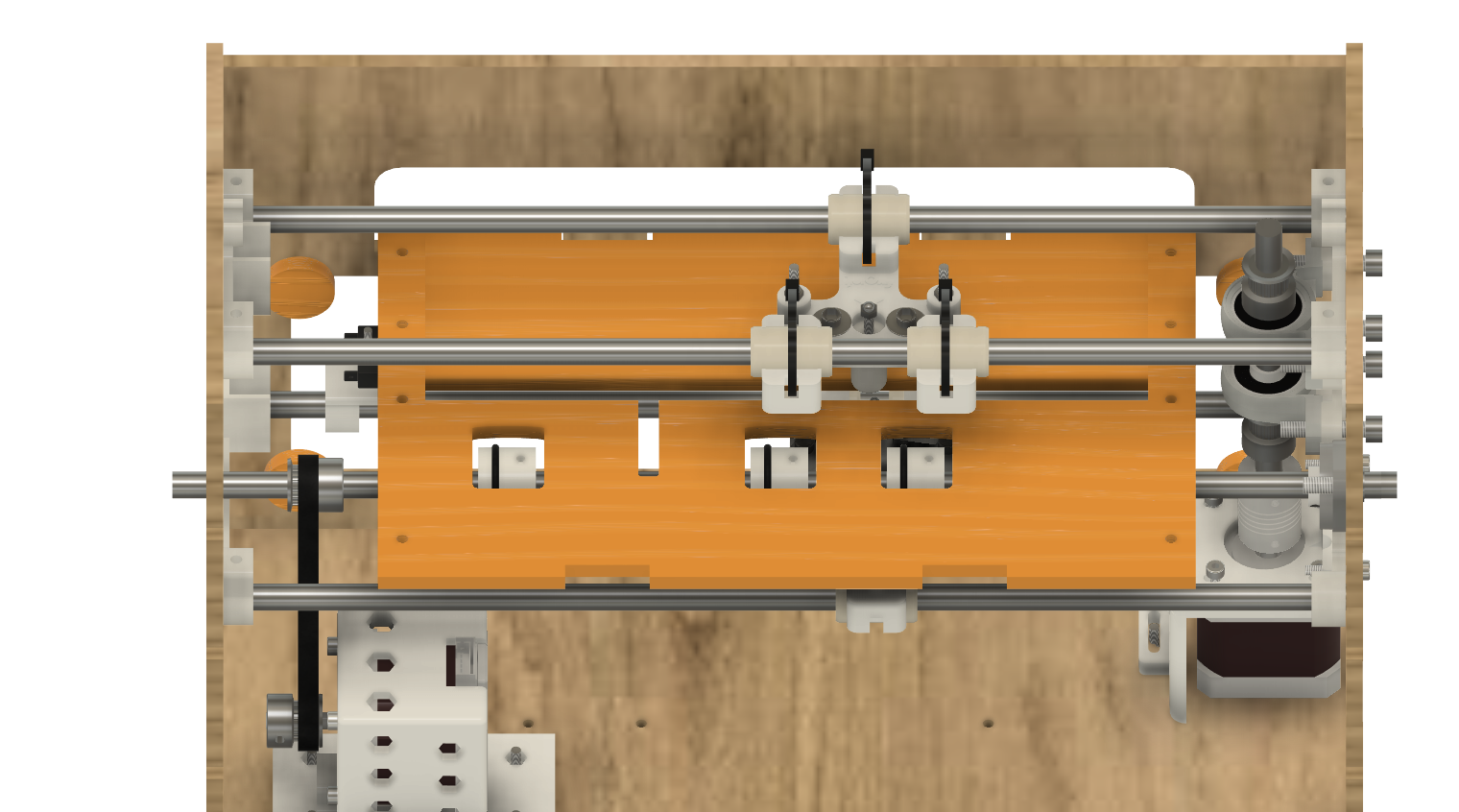

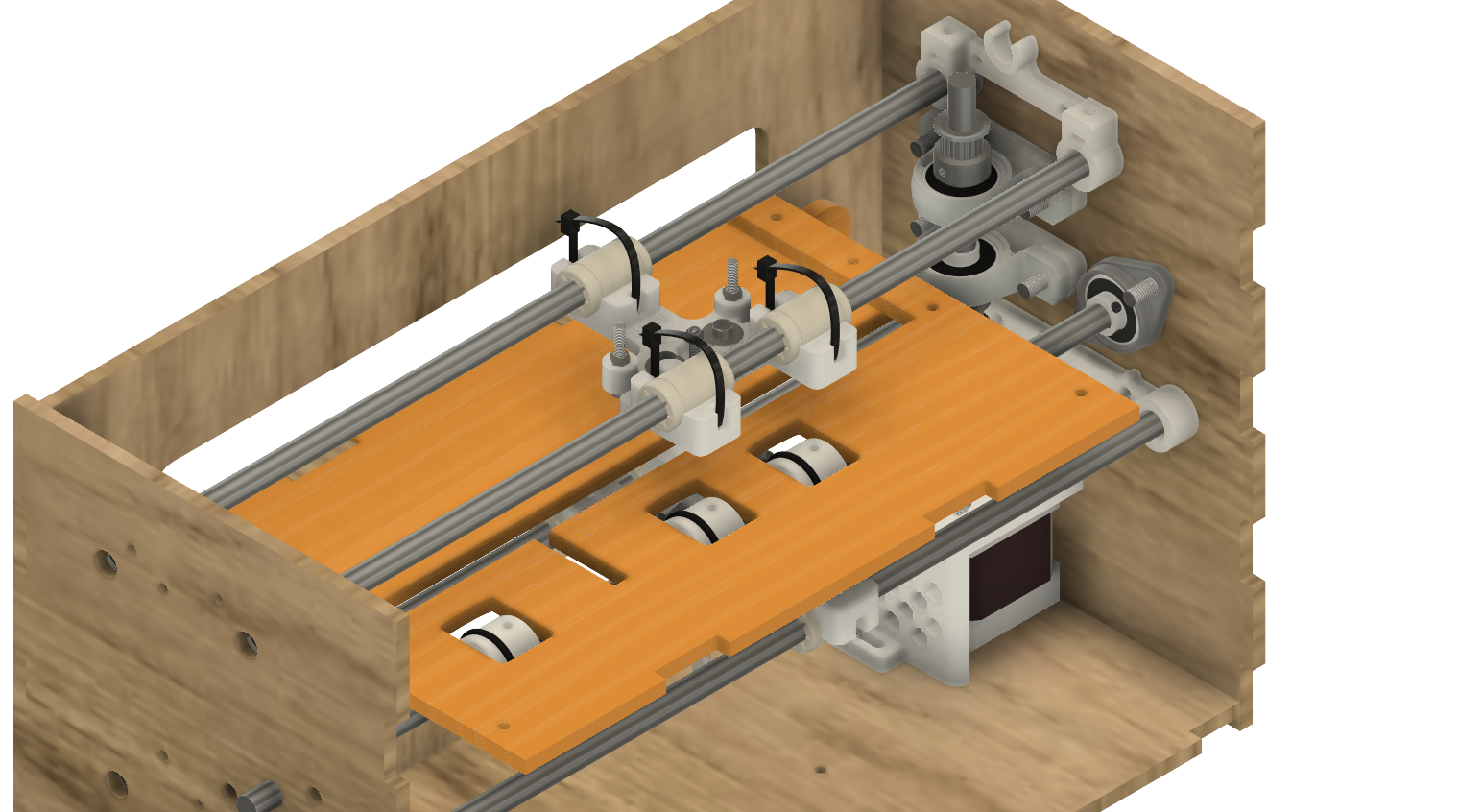

17Build top carriage

Insert two 330mm/833 rods in the frame with the top carriage

![]()

![]()

add ~600 mm of GT2 belt on the top carriage, passing by the 2 GT2 pulleys on the left and right.

-

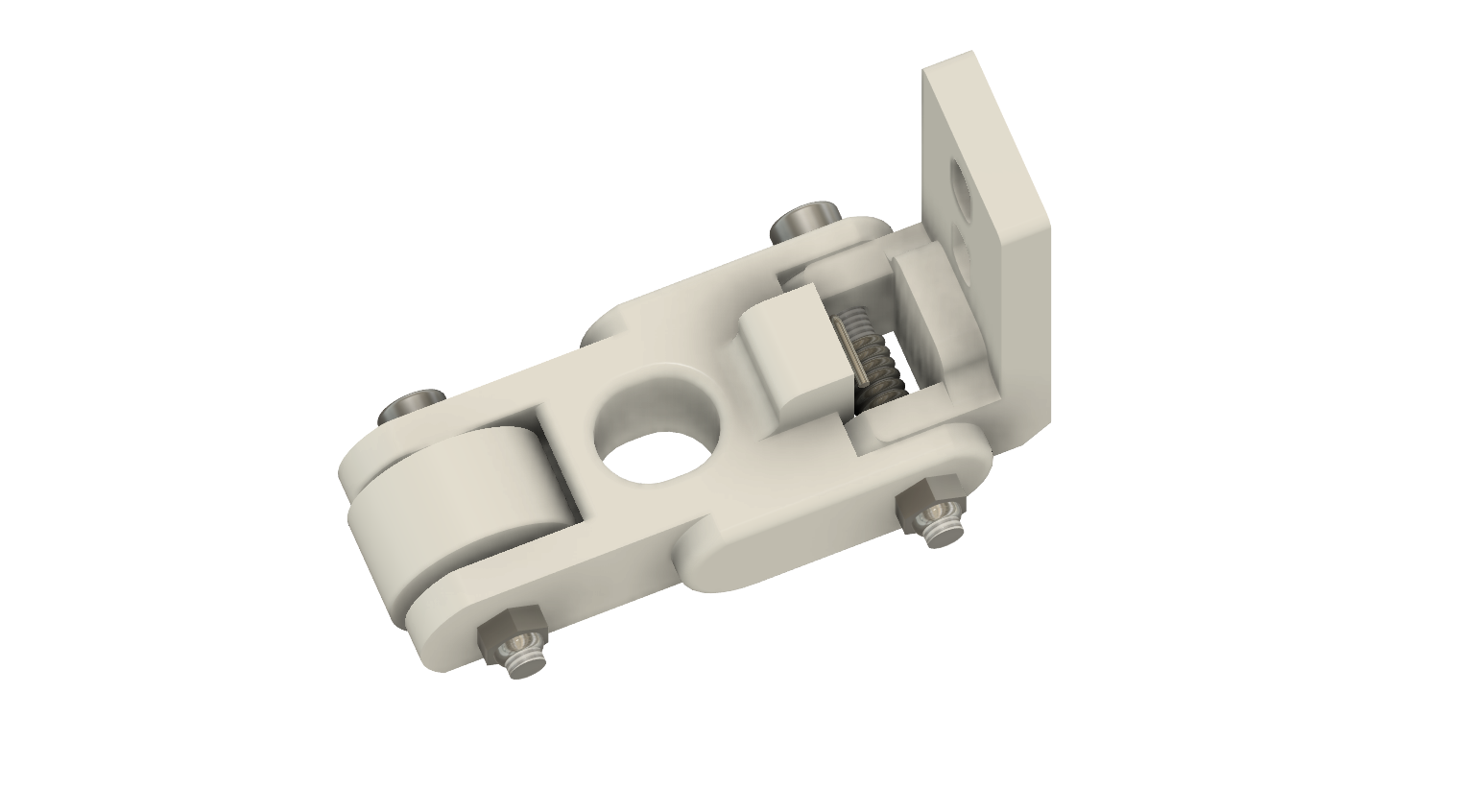

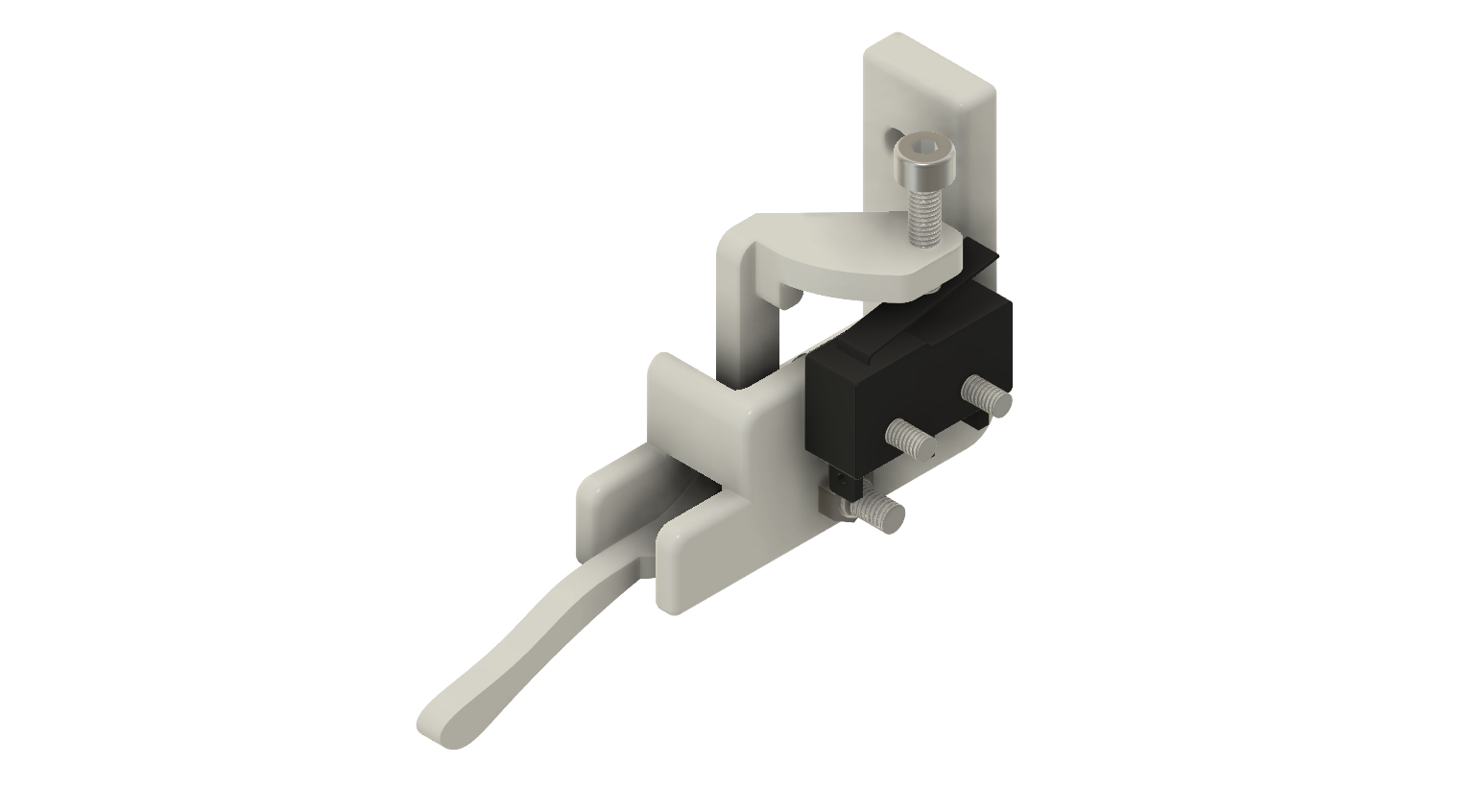

18Paper clibpoard and limit switch

Assemble 3 paper clipboards with 3d printed parts clipboard2_support, clipboard2, CLIPBOARD2_WHEEL using M3-25 and M3-20 screws, M3 nyl nuts and GT2 tensionner spring

![]()

Assemble paper (Y axis) limit switch with 3d printed parts ENDSTOP_Y_support, ENDSTOP_Y_lever with M3-20 screw and M3 nylstop. Fix the limit switch with two M2.5-14 screw and M2.5 nylstop nuts. Put an M3-12 screw on the lever.

![]()

Mount the 3 clipboards and the limit switch on the frame with M3-13 screw, M3 washers and M3 Nylstop nuts

![]()

-

19The final

- Adjust everything, tight the needed screws and belts

- Adjust the top and bottom carriage, the Braille stylus of the bottom carriageneed to slighty enter in the anvil of the top carriage.

- Mount the electronic board with drivers

- Wire the 12V alimentation

- Adjust the motor drivers if needed

- Wire the 2 limit switches on the board

- Connect the board to a PC with a USB cable

- Launch the arduino IDE, set it to MEGA2560 as CPU, and set the COM port of the board

- Open the sketch marlin.ino and upload it to the board

Close Arduino Ide and launch Pronterface to check everything

- Check the limit switches

- Check the Electromagnet with M3 S1 GCODE command

- Check X Homing

- Check Y Homing with a sheet of paper

if anything go wrong, address the issue and restart the tests

-

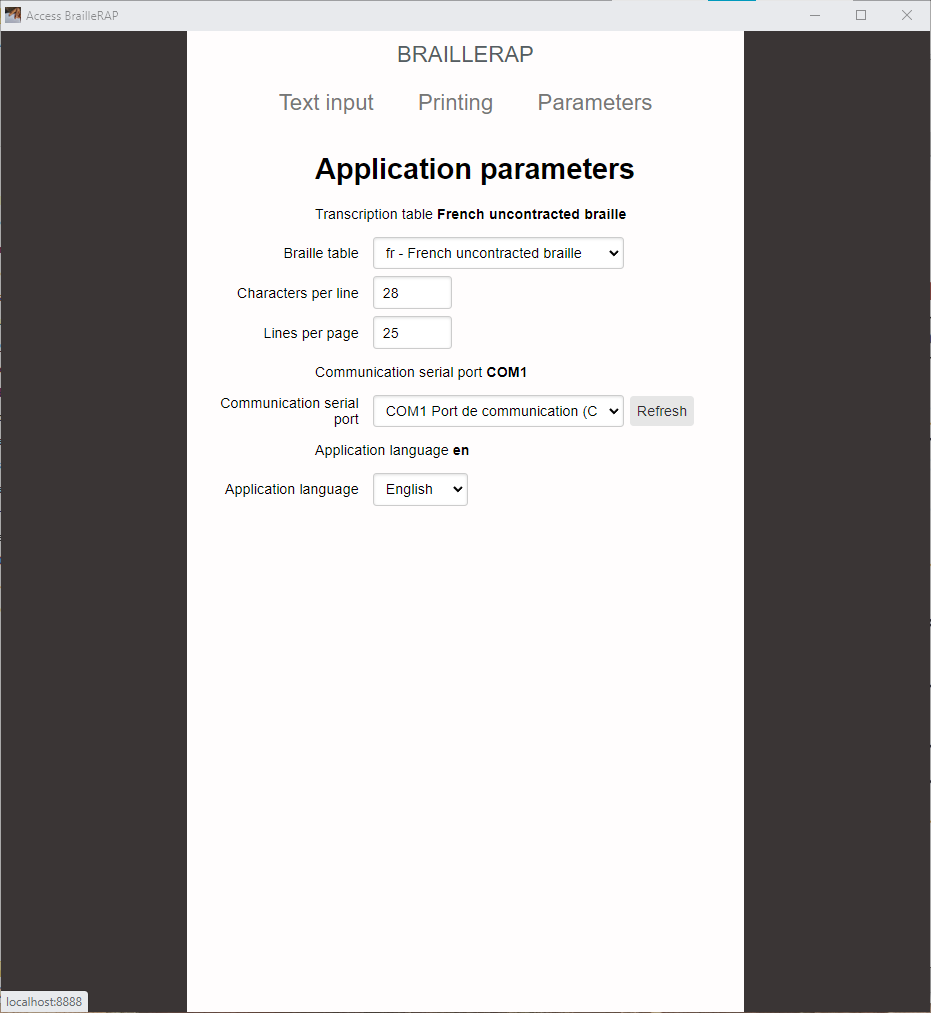

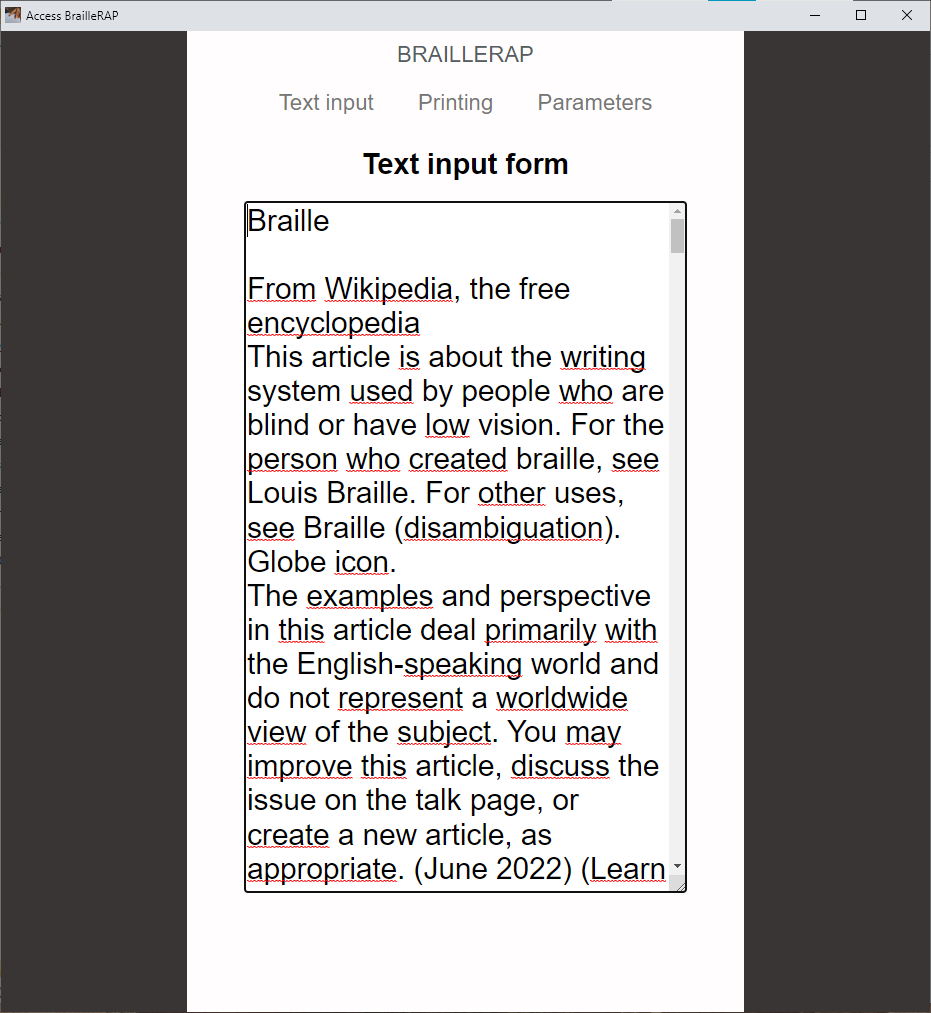

20Use

Install the latest version of AccessBrailleRAP (https://github.com/braillerap/AccessBrailleRAP/releases)

set the parameters :

- Braille Standard (you have the choice between 200 combinations of Braille Standard and language)

- Communication port

![]()

Enter some line of text, or copy paste something

![]()

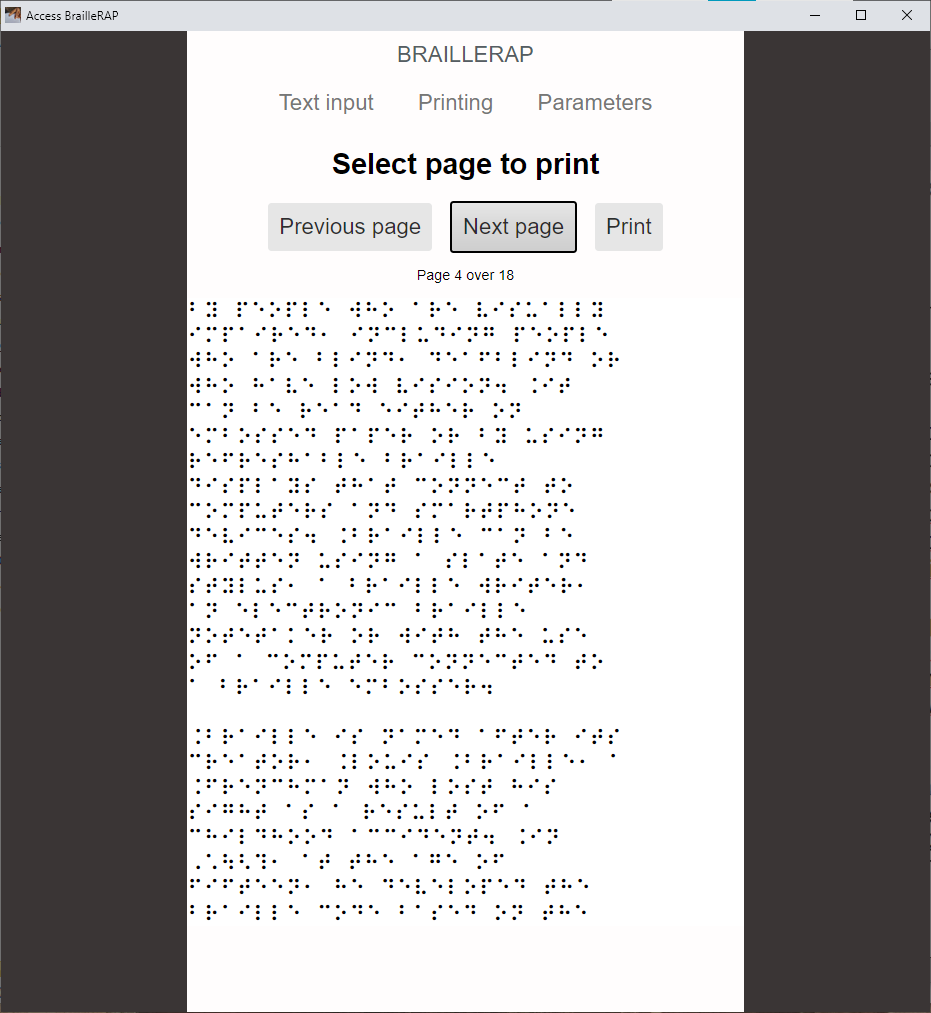

Translate in Braille, select the page of your choice

![]()

Use the print button

BrailleRAP DIY Braille embosser

An Open source Braille embosser in the spirit of RepRap

Stephane

Stephane

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.