So what the hell is it?

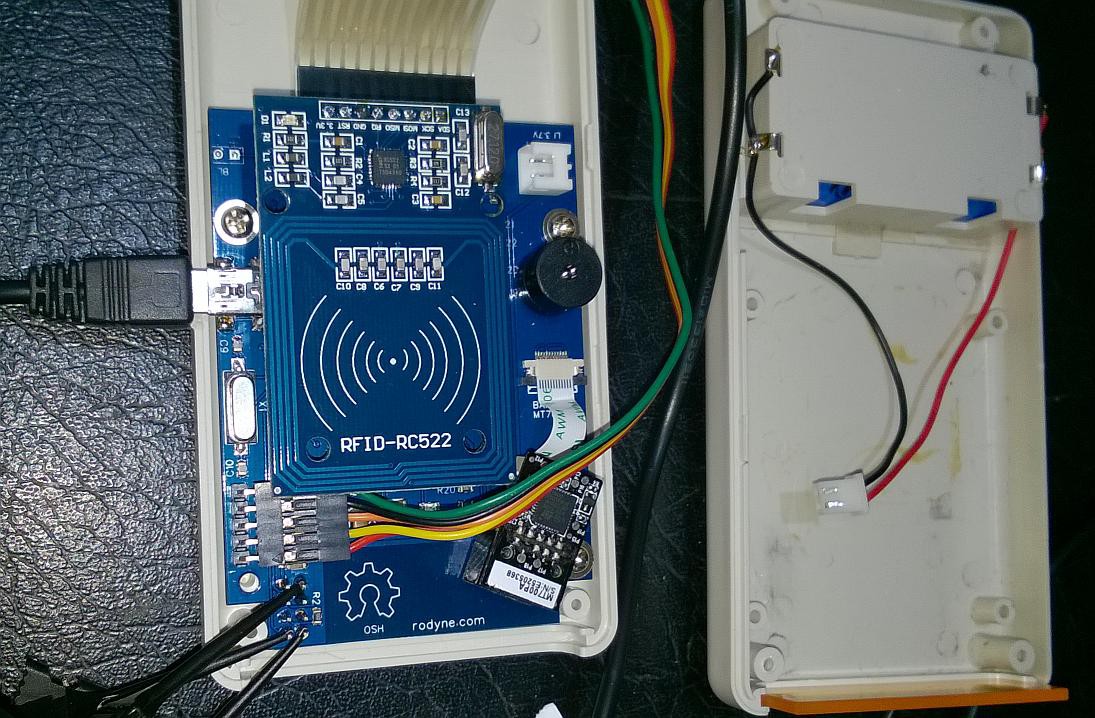

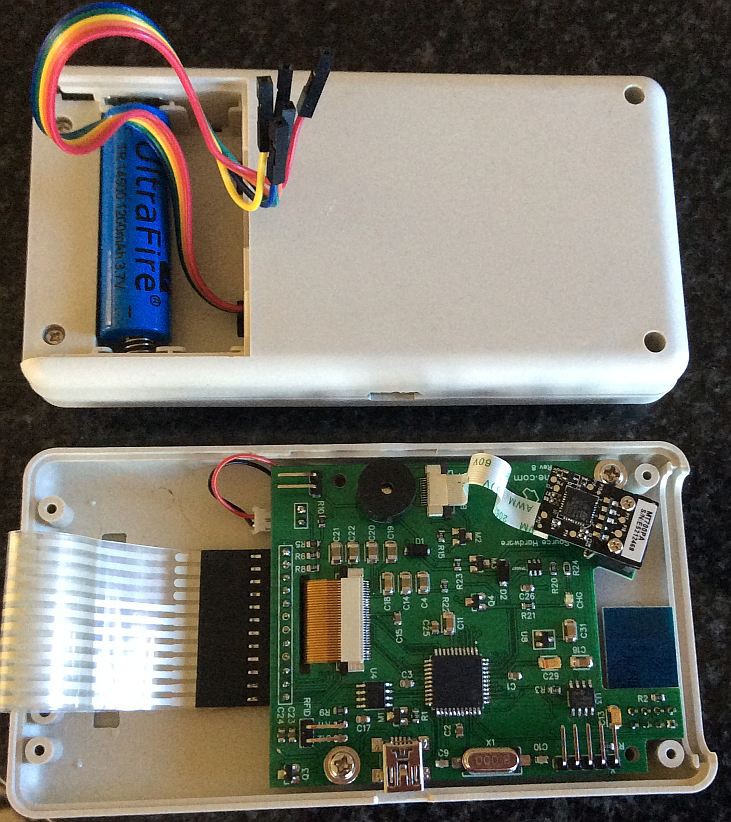

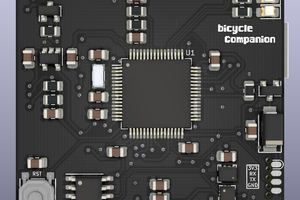

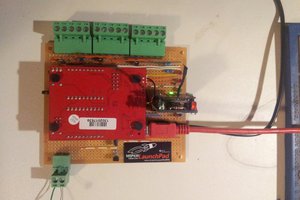

A handheld battery powered terminal with Display, Keyboard, WiFi, RFID and Barcode scanners.

What would I use it for?

Anything that requires data capture (RFID, barcode or numeric input) shops, warehouses and factories are good environments for this.

Specifically?

Well since you ask, almost every factory and Production Facility in the world from large to small would benefit from extending their office production system onto the factory floor where real time updates and status changes can save time on QC checking and prevent data duplication.

For example at my customers winery in New Zealand, job sheets are written and printed by the winemakers in their office and given out to the supervisors. Supervisors then assign the work to an operator and signs the job on and off for QC purposes. The job sheets are usually hand written on with tank levels and additions made etc and then returned to the winemakers to update stock and inventory systems and ultimately the financial systems. Bar codes and RFID tags are used extensively to identify paperwork and assets such as barrels and tanks, but they are not utilised as much as they could be to prevent errors.

In an ideal system every operator and every supervisor would be issued with a data collection terminal so in our winery example:

- The operator scans the job barcode to check the job is still the correct status, as this is real time the office staff can un-issue the job and prevent it going any further.

- If the job is OK the operator can then scan the tank or barrel RFID/Barcode and the system will confirm they have the correct tank, this will provide a padlock unlock code to them

- Connecting pipes between tanks are used for transfers and are barcoded, these can be scanned to ensure the correct path is in place before transferring wines

- Additives to be added to tanks are in barcoded bags, these can also be scanned before the padlock codes are issued

- The tank levels at the end of the job can be entered in real time.

Each terminal also knows who its user is as it is activated and assigned from the office, so each issued terminal can have a different set of permissions or programs, eg a normal operator can have a different program to a lab technician who will be able to enter temperatures or analysis results.

Similarly in the storeroom and warehouse the storeman could scan the product barcodes and real time enter new stock counts.

Note this wont be a finished project in the way others may be, simply for the reason that any final software and firmware will need to be highly customised to the system it will be used on, it will be a fully developed hardware system with a set of simple demonstrations on how it will connect to one of my clients systems, specifically to show everyone out there that none of this stuff is rocket-science and to give others the confidence to attempt it.

The thing that has stopped this is current barcode enabled data terminals have been really expensive and cheap ones poorly documented, Proper Industrial grade mobile terminals with bar-code scanners are upwards of US$1000, they generally run Windows CE or mobile or Android and have custom software written for whichever OS and application required. If you break these devices (and rugged devices still break quite easily) the repair is generally in the high hundreds as are all spare parts such as batteries. Clever people have tried with various degrees of success to use cheap android touch screens but these have a lot of drawbacks:

- They are generally not ruggedised

- Most do not have bar code scanners and RFID. Some people have tried to get cameras to read the barcode but it is rarely seamless or intuitive for operators.

- Tablets/Phones generally have a production lifespan of 6 months to a year before they are replaced as are the spares which are generally not easy to find and end-of-life'd regularly

- The Operating system is also subject to updates which may or may not break the device.

- There is a lot of temptation to steal...

Boz

Boz

DrYerzinia

DrYerzinia

Matias N.

Matias N.

Reimu NotMoe

Reimu NotMoe

PK

PK

Note this project is complete. I have however made a follow on project for another customer with a slightly simpler design and replaced the WiFi with 866/915Mhz LoRa and replaced the RFID with a 125Khz one, battery life is improved a lot. Preliminary information here => http://rodyne.com/?p=844