-

color representation

09/12/2023 at 03:45 • 0 commentsIn order to challenge color expression, we produced a lenticular lens panel capable of displaying RGB.

We designed the lens shape and also made the lens itself. -

8bit gray scale demo

09/04/2023 at 07:09 • 0 commentsWhen you tilt the grayscale panel, the ratio of white and black changes according to the angle. We achieved an 8-bit grayscale display representation by varying the angle in 256 steps.

How about this? The title is 'The Wave.' I think we've effectively captured the grayscale gradient, don't you?

-

panel for grayscale

08/21/2023 at 07:50 • 0 comments![]()

![]()

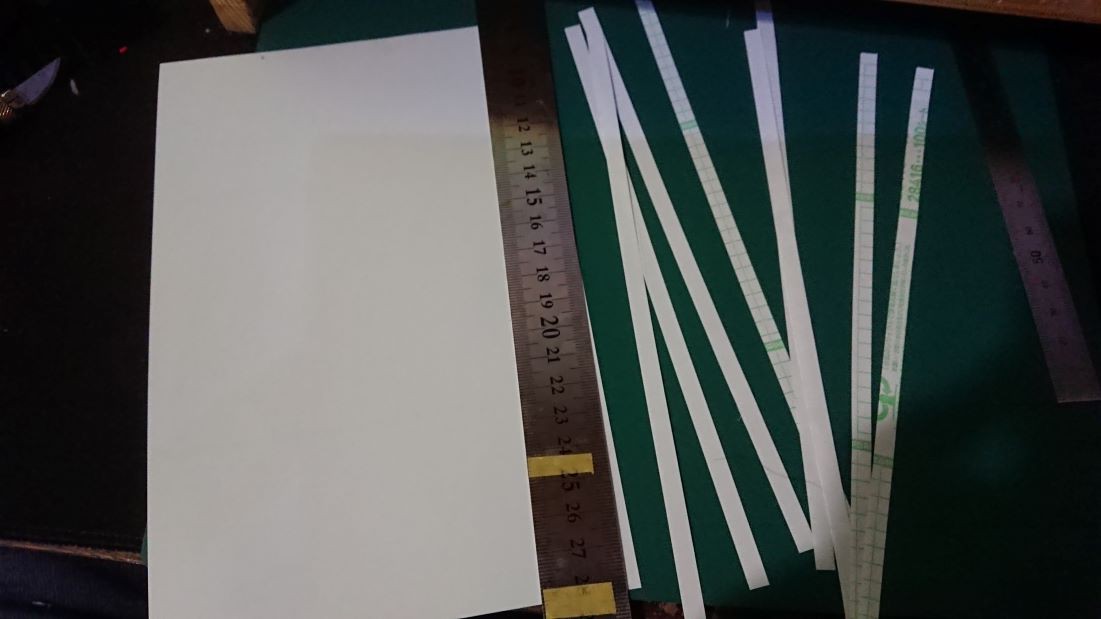

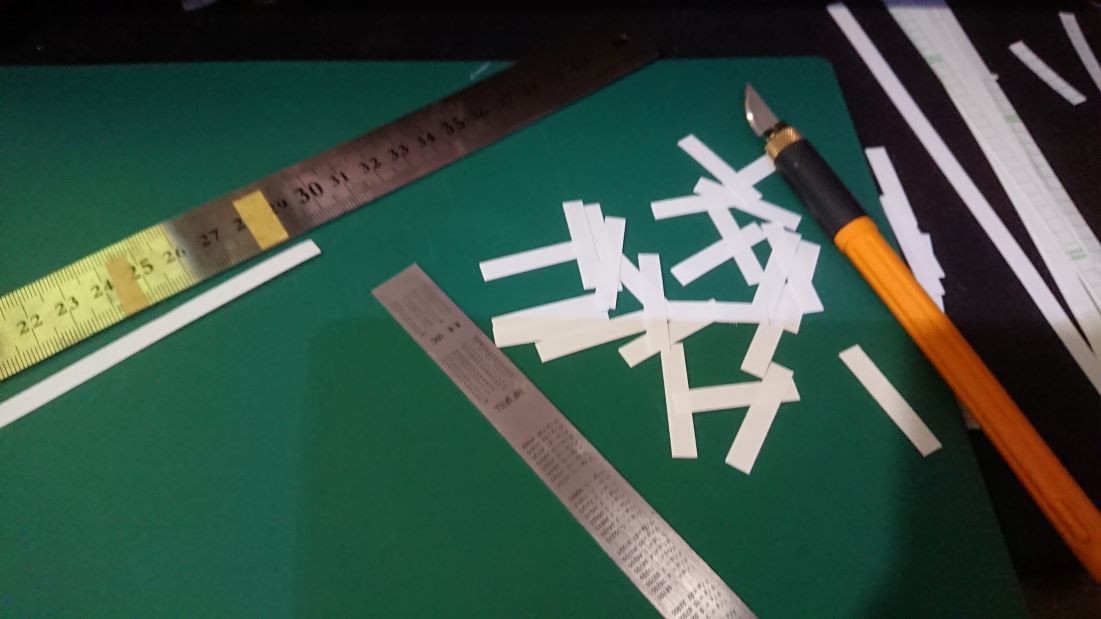

A panel for grayscale purposes has five ridged protrusions. One side of these ridges must be colored black, while the other side should be colored white. Initially, an attempt was made to color the necessary portions black by masking the white parts, but, as shown in the photo, this approach failed. This was due to the fact that the 3D-printed part has layered irregularities, causing the paint to flow beneath the mask.

![]()

![]()

![]()

Therefore, a decision was made to output the parts with black filament and apply white stickers. The stickers were created by cutting down larger ones typically used for labeling. Since five stickers need to be applied to each panel, a total of 1,280 stickers had to be created and affixed for 256 panels.

-

Conversion to Grayscale Display

08/08/2023 at 06:56 • 0 commentsAfter the mirror display proved to be effective, we shifted our focus to the development of a grayscale display. The grayscale display achieves its effect by painting the opposing slopes of a mountain-shaped panel in black and white, utilizing the changing ratio of visible colors based on the angle. Initially, we had planned to achieve this through painted partitions, but due to several challenges in the process, we resolved it by applying white stickers to the black parts.

The resulting panel exhibits color changes based on the angle.

Utilizing four by eight of these panels, it becomes possible to create displays like the one shown.

-

Testing the mirror array display

07/21/2023 at 06:57 • 0 commentsThe day has finally arrived when I can test the mirror panel version of the mechanical display. The rain that had been falling until yesterday has stopped, so I will go to a nearby rice field. This place also serves as an inspiration for me.

I confirm the directions, set up the display, and wait for dusk. Adjusting the angle of the mirror, I set the display in motion.

Using the colors of the approaching night sky in the east and the sunset coloring the western sky, I was able to display it as a monochromatic color display! This can truly be called a true color display, as it can reproduce an infinite number of colors. A display that captures the colors of the sky has come to life.

Please overlook the resolution and refresh rate for now. :-)

-

Moving 256 servos

07/20/2023 at 02:30 • 0 commentsNow that we have strengthened the power supply, we are finally going to test moving 256 panels.

From what I can see, they are moving smoothly.

The sight of 256 servos moving simultaneously is truly spectacular.

Due to the relatively slow processing of Micropython, even though we intend to move them simultaneously, we can observe a slight time lag on the wave. -

Reinforce power supply

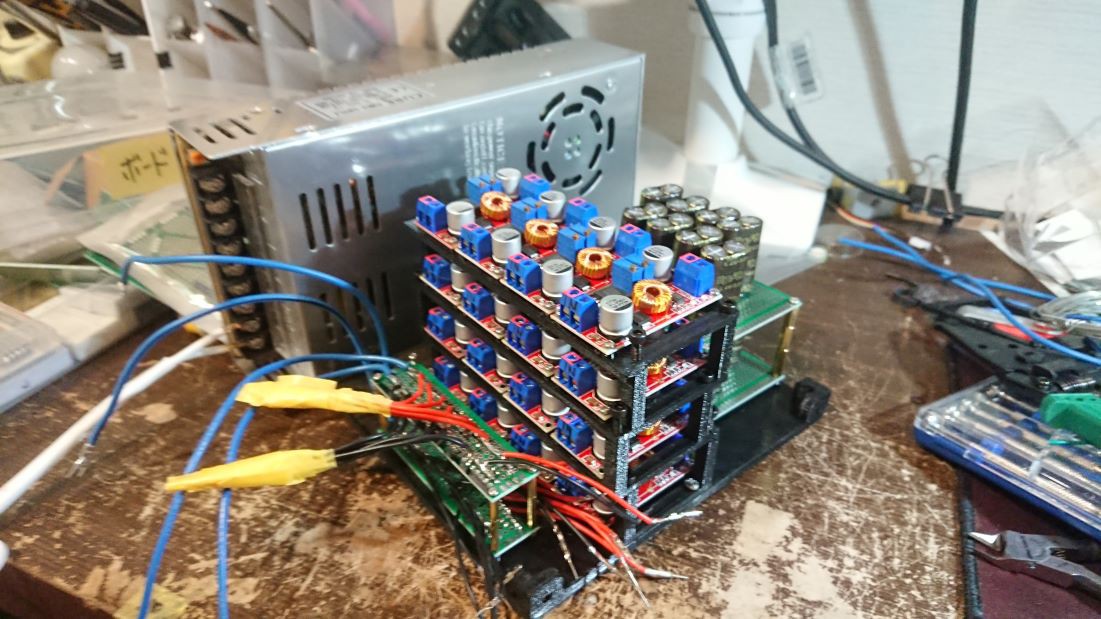

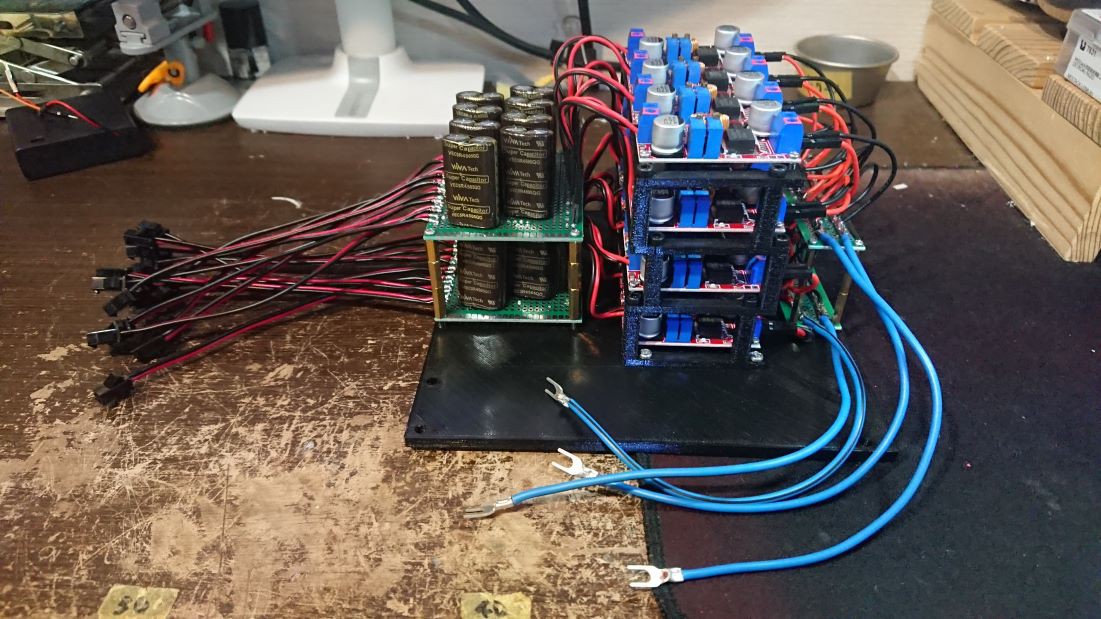

07/18/2023 at 04:44 • 0 commentsIn the previous stages of development, we used a stable power supply with a maximum capacity of 10A. It supplied DC12V, which was then stepped down to 5.5V using a DC-DC converter for each unit. However, when I connected 8 units together, we exceeded the 12V10A limit. As a result, we obtained a new stable power supply with a capacity of 12V30A and changed the DC-DC converters to units with current limiting functionality.

![]()

When the servos are operated vigorously, the momentary current consumption per unit increases to around 10A. To address this, I have added 5F EDLC (Electric Double-Layer Capacitor) to each unit.

![]()

With a power supply of 12V30A, it becomes a significant amount of energy, and therefore, attention must be paid to the thickness of the cables and connectors used. Since current also changes when voltage is converted, it is especially important to be cautious.

Considering that this display will be used outdoors, we also anticipate the use of 12V lead-acid batteries.

-

Assemble a 256-pixel display

07/11/2023 at 23:14 • 0 comments![]()

After persevering with three hours of diligent assembly work every night, i have successfully assembled a display consisting of 16 units and 256 pixels. The calibration process for all these servos has been quite challenging, but i will keep pushing forward, envisioning the final outcome.

The calibration involves determining the PWM control values for the left maximum, center, and right maximum positions. The intermediate values will be calculated and controlled using linear approximation.

On the upper-right panel, i have experimentally attached a mirror panel. I have secured it with a magnet sheet to facilitate the exchange of panels and achieve various visual effects.

The current major challenge is that the size of the work desk is completely insufficient. :-)

-

caribration

07/03/2023 at 07:17 • 0 commentsThe recently assembled servos have not been set to their home positions. Since the servos used in this case are the most affordable ones, their encoder accuracy is not high. Achieving precise angle control may be challenging. However, we can compensate for the lack of accuracy by defining the maximum, center, and minimum positions and mapping the positions in between relatively.

The video shows the servos adjusted to their maximum angle positions. The angles of each pixel appear to be almost consistent.

I have completed the calibration of the device, so I tried coding the wave motion.

-

Assembly of the Four Units

07/03/2023 at 07:06 • 0 comments![]()

I will proceed with assembling the four units since the parts are available. However, please note that without calibration, the panel orientations may vary.

![]()

Each unit has a structure consisting of a 4x4 array of pixel units mounted on a single base plate. Spacer and fastening components are used to secure the adjacent units while providing cable storage space. Additionally, a backplate is attached to create a double-wall structure, ensuring sufficient strength even with resin components produced by a 3D printer.

Mechanical Display

This is a mechanical display utilizing an array of pixel units driven by servos.

AIRPOCKET

AIRPOCKET