Reflections:

General reflections from last time

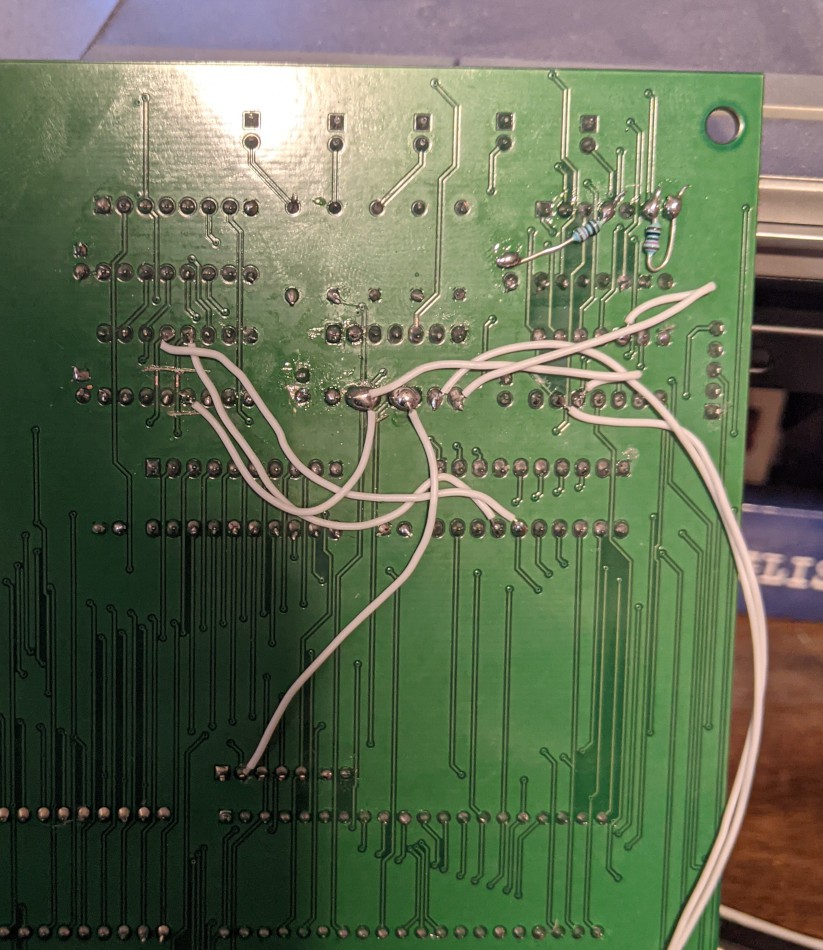

Well you read the title here, so its not hard to guess what the outcome from the first PCB run was. In short, the 1st PCB design has issues.

I tried working evenings for the last week to get it to come to life, however there are a ton of stability and possibly further routing mistakes that meant that all scaled into very bad ringing, noise and timing issues. To be clear, none of this is the manufacturers fault. All the issues and pitfalls in this design lie solely on my shoulders. I have plans to fix the issues, but its going to take some time and a step back to really understand the problem.

What is next?

I want to take a step back and look at the design in pieces. I still have a handful of boards left over from the HB6809, There's ample prototyping space on there for me to experiment with. This weekend I want to start by building a very simple but very stable Pierce oscillator, and see if I can get the CPU, RAM and ROM to come up on a 16Mhz base clock. Once this works I will work to add subsystems and to a much better job of documenting the build up as I go.

On the firmware side over the next two weeks I want to focus on getting the RAM to stage on the breadboard build without using the latches. I think I can use the CPU to stage it's own ROM space by feeding it one byte of machine code at a time running in peripheral mode (I discuss this in the architecture overview) . This will further get the chip count down, which is important because the end goal is to have a computer that is built on 10cm x 10cm boards (or less) and currently they are 170x170 so we need almost a 50% reduction, or to switch to a mini frame design with expansion headers that link the boards together. I also DO still want a 68C09 motherboard that just drops into a PC case, because that was the whole idea in the first place, but a lower cost version would also be nice in terms of making the design more accessible.

PCB review how they hold up to rework:

Speaking of the PCB's, I wanted to share my thoughts on the boards produced by PCBWay, what you get in terms of cost for a large format board like this as well as what it's like to rework a two layer rapid turn PCB like this with manual tools.

First, and I've touched on this before, PCBWay does a higher than average job on masking. If you wanted to make a short run of boards with ENG or even Lead Free HASL, for commercial sale these boards really do hold up. Nothing peels with normal handling, and it stands up to even the highest level of abuse. The edge finishing is top notch, nothing is left with a sharp edge (unless you specify that, of course!) and I never felt like if I handled the boards without gloves that I would be cut or that the edges would catch on the work surface. Other manufacturers in China do not take the time, as PCBWay does, to really get this right.

As an example, the 14 pin socket had to be completely removed to rework trace mistakes that were made in the design files using just manual tools (which always require a level of care), I was able to remove the socket and replace with only minimal mask removal, and all of this was around pins which tie into board planes. If I had a a reliable way to preheat the board none of this would have even been an issue given the finishing on the PCBs.

On average, PCBWay is more of an expense. But all of these touches are a value add, and I believe given the blazing fast turn around to North America, the quality really is worth the expense. I would have no problem recommending them over the other producers in China, they do a great job with what you pay for. Additionally they don't over charge for shipping and have several options depending on your required turn around (which all obviously scale with the price.) They also continue to offer a low price on 10x10 PCBs that matches all the other sellers in the region with larger format PCB's scaling up from that point with a minimum quantity of 5. All in the cost of the PCB's would have been around $10 a piece, with shipping being around $10 a piece for DHL shipping (for a 170x170 mm board, buying 5) not cheep by any stretch of the imagination. However when you factor that the shipping is almost exactly the same price as the boards you begin to see that the cost for the value is really priced to move -- especially when you look at what you pay for 5 boards produced here, paying around the same for shipping.

Conclusions:

Thanks for taking the time to read, and share this experience with me. I will be working towards a second hand wired prototype over the next few weeks, with hopefully some answers to why the first design did not work as well along the way. I think the take away here is that even a failed result is a good result if you learn something. Hopefully I can figure out what I did wrong by bringing up the computer in a different way and possibly understand a bit of my mistake in the process.

Dave Collins

Dave Collins

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.