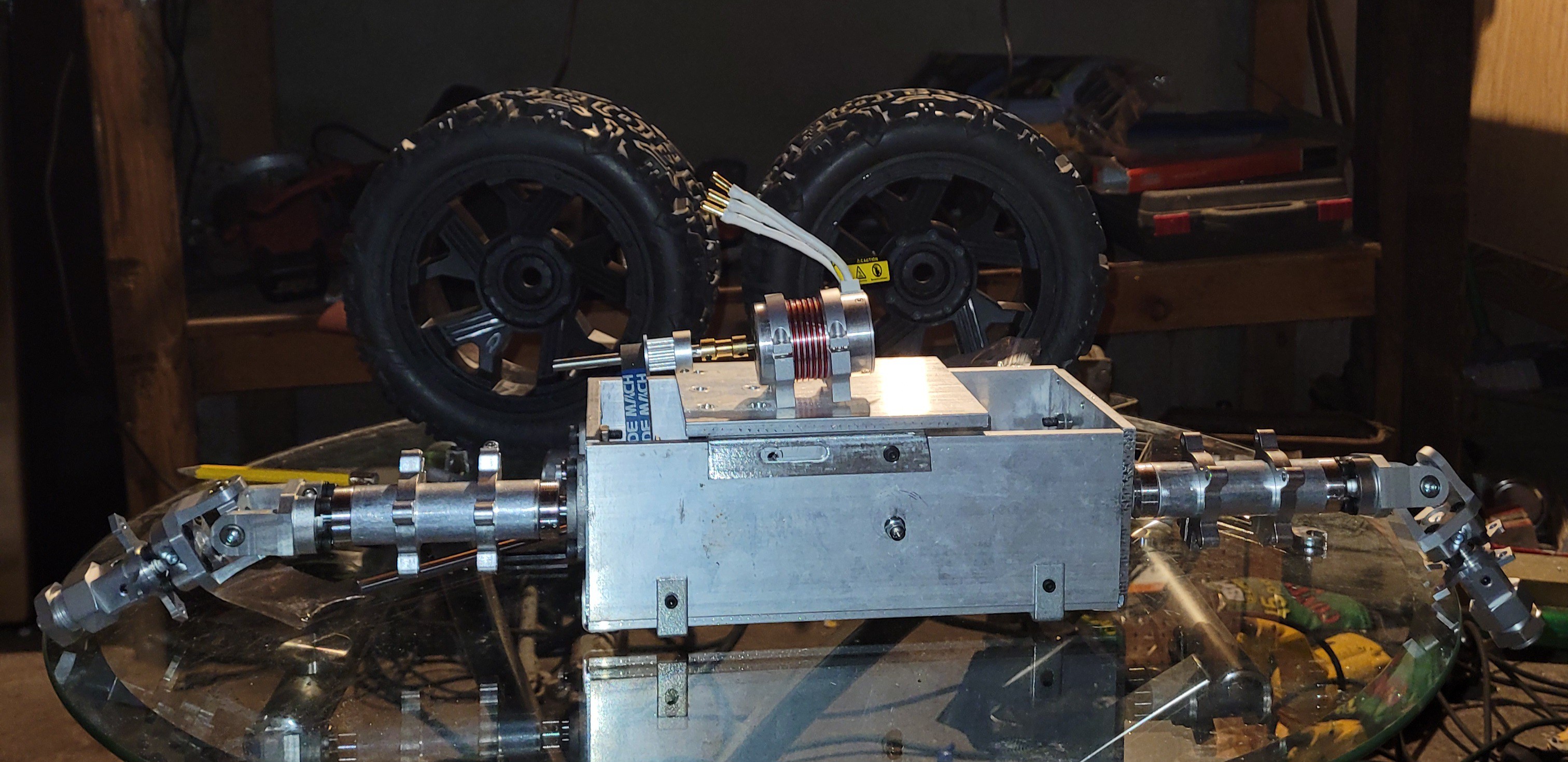

This project is moving but not as fast as I would like. Trial and error have been, and I guess will always play a role. Parts, tools, and finances are the time consuming elements, however, the finished project develops much faster in my head. I have many images of the parts and accessories I have purchased this far but uploading seems to be a tedious effort.

Once, I have this project on the road, I will begin the process of adding logic, camera, and robotic tendencies

addison.antoine74

addison.antoine74

shlonkin

shlonkin

Reed Foster

Reed Foster

honxen

honxen

Sergio Gugliandolo

Sergio Gugliandolo