Want to get one?

If you want to get this board and its accessories, visit the product page at:

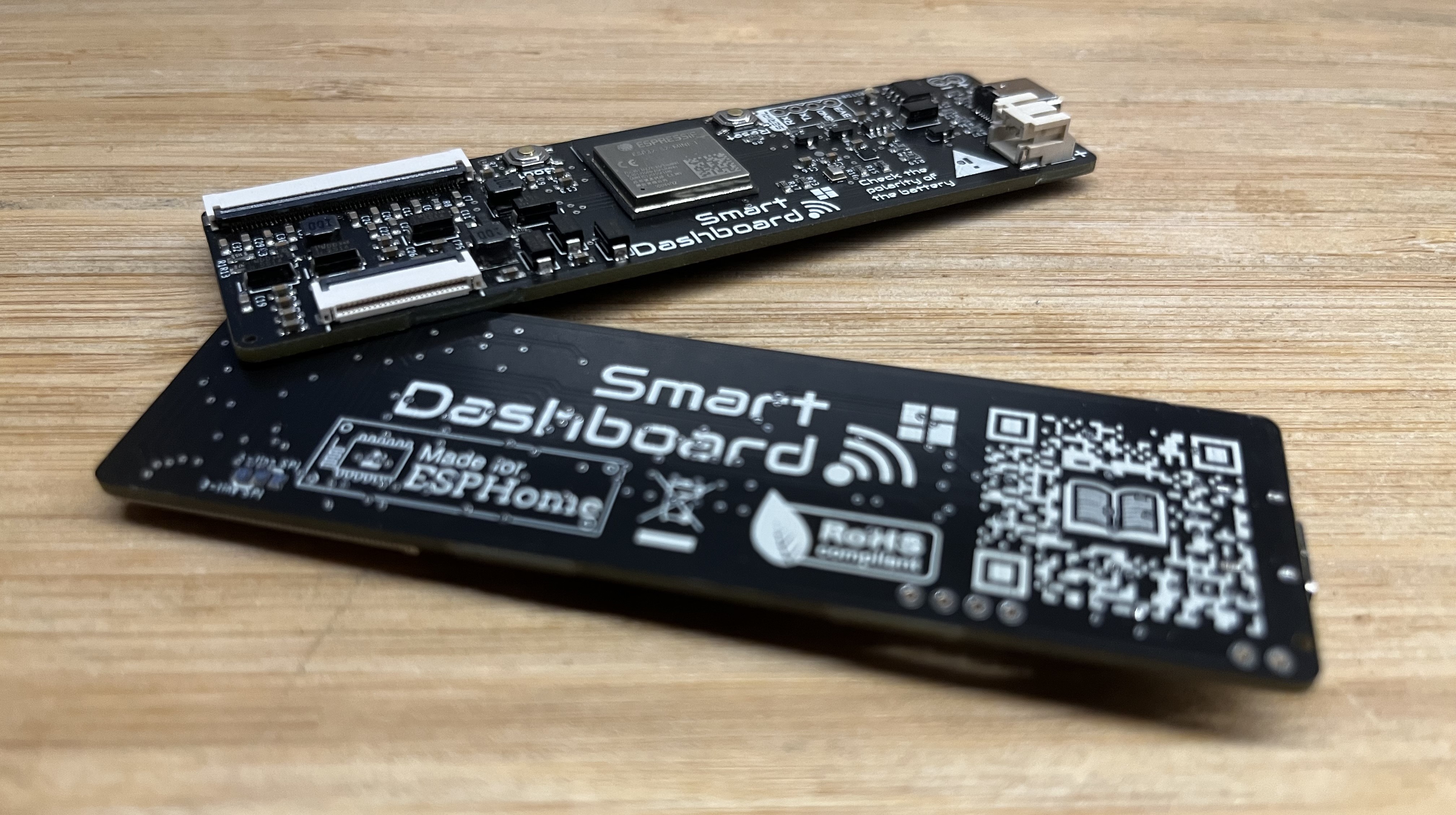

The electronics

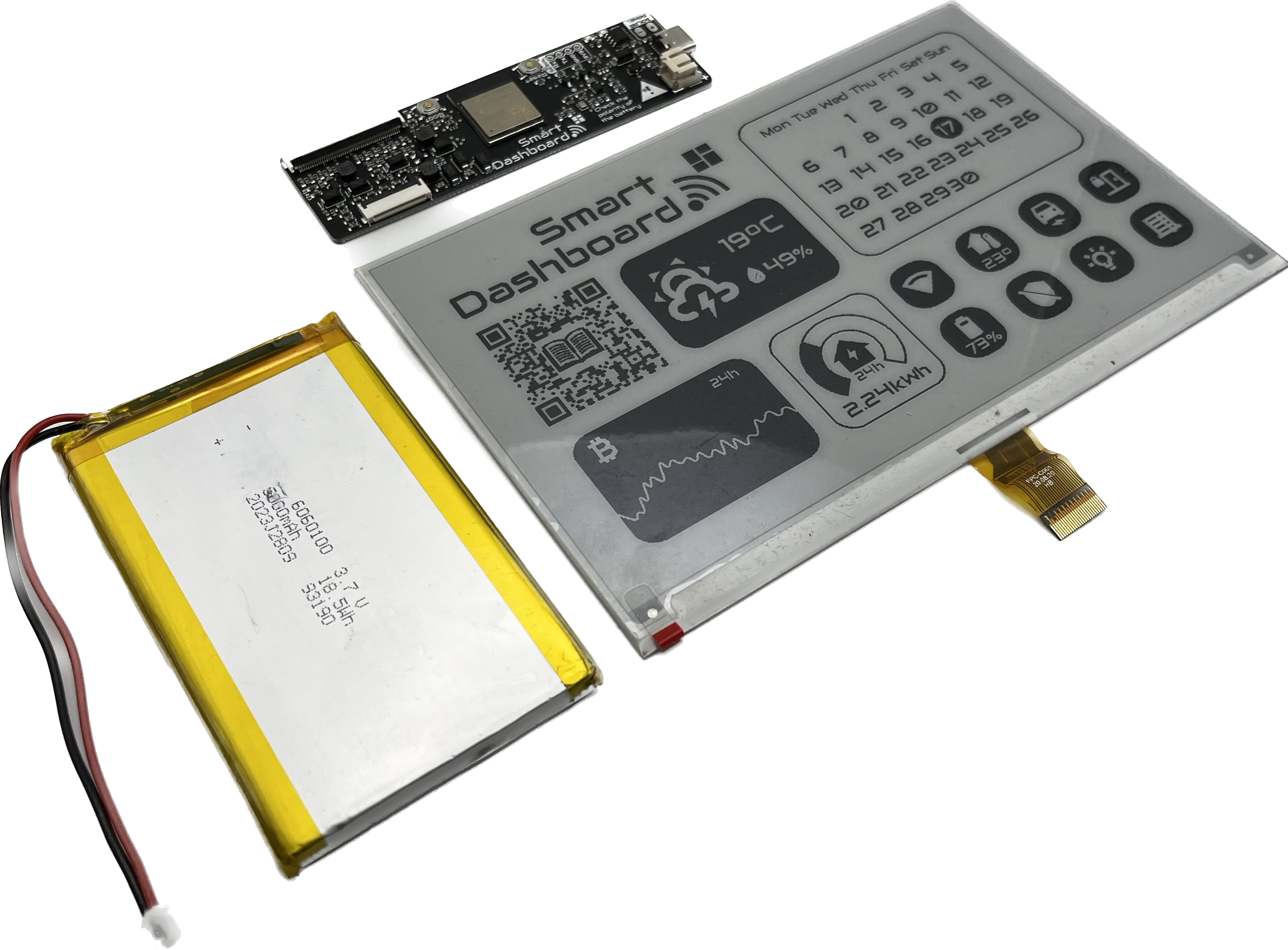

The Smart Dashboard features an ESP32-S2-MINI as the primary controller and includes the necessary circuitry for driving an e-paper display. To accommodate experimentation with different e-ink displays, it has been designed to support two options:

- The Waveshare 7.5" black & white e-ink display (successfully tested):

- The Waveshare 7.3" 7-Color e-ink display (currently untested): If you are interested in testing a Smart Dashboard with this display, please contact me directly.

Additionally, the Smart Dashboard integrates a BMP280 for environmental condition measurement and an LC70923 for monitoring the battery. To achieve a long-lasting 5000mAh battery life without recharging for months, the ESP32 enters deep sleep mode (and turns off the sensors) for 1 hour, waking up for less than 10 seconds.

For enhanced independence from external power sources, support for an external solar panel has been added, although this feature may be less useful when the device is located indoors.

The wooden stand

I initiated the project by creating a 3D model in Catia, designed to accommodate the electronics and display. I kept in mind that the design should be suitable for machining using a prismatic CNC. Following the design phase, I 3D printed a prototype to ensure that the dimensions were accurate and that all the components would fit seamlessly.

The first challenge I encountered was preparing my meticulously designed model for CNC machining. I employed the integrated CAM tool for this purpose. Since I intended to manufacture it at Vienna's HappyLab, I selected the BZT-PFK-1607-PX, a 3-axis CNC machine with dimensions of 1668 x 750 x 250 mm, which proved to be more than adequate for my project. Unfortunately, none of the settings in the CAM software allowed me to generate a readable G-code for the CNC. After spending a whole morning attempting various configurations, I decided to change my approach and use the CAD/CAM software recommended by the lab for their machine: VCarve.

After investing additional hours recreating the model in VCarve, configuring the machining parameters, and conducting tests on a spare piece of pine wood I had at home, I successfully produced the desired stand.

A significant element contributing to the elegance of this design is the bamboo stand. This minimalist design was milled from an IKEA chopping table, specifically the APTITLIG, a bamboo board measuring 480x280x16mm. To achieve the desired height and angle for the stand while accommodating the electronics, I had to cut and subsequently glue together two precut boards, resulting in a raw bamboo piece measuring 200x70x32mm, ready for machining.

Although I had to adjust feedrates and speeds during the process to prevent any damage to the wood or the tool (due to the slight difference in hardness compared to pine wood), I ultimately achieved a beautiful stand that only required some fine sanding.

Jon

Jon

非常期待你的作品!请问大概什么时候能开源?