Background

Powder-based 3D printers, called Selective Laser Sintering (SLS) or Powder Bed Fusion (PBF), have several advantages compared to other types.

For example, SLS-printed objects have little layer lines and exhibits isotropic strength, compared to filament-based (Fused Deposition Modeling, FDM) printers.

Also, they do not use harmful chemicals such as allergenic resins or intoxicating solvents, unlike resin-based printers.

And the most importantly, SLS printers can print overhangs without supports, because the prints are supported by powder that does not flow.

However, current SLS printers are limited to industrial use and not available for home or office use.

This is probably because of the troublesome natures of powder materials.

Firstly, combustible powders (such as plastics) are explosive.

Secondly, because powders scattered in the air can be easily inhaled by people, it poses health risks, such as lung damage.

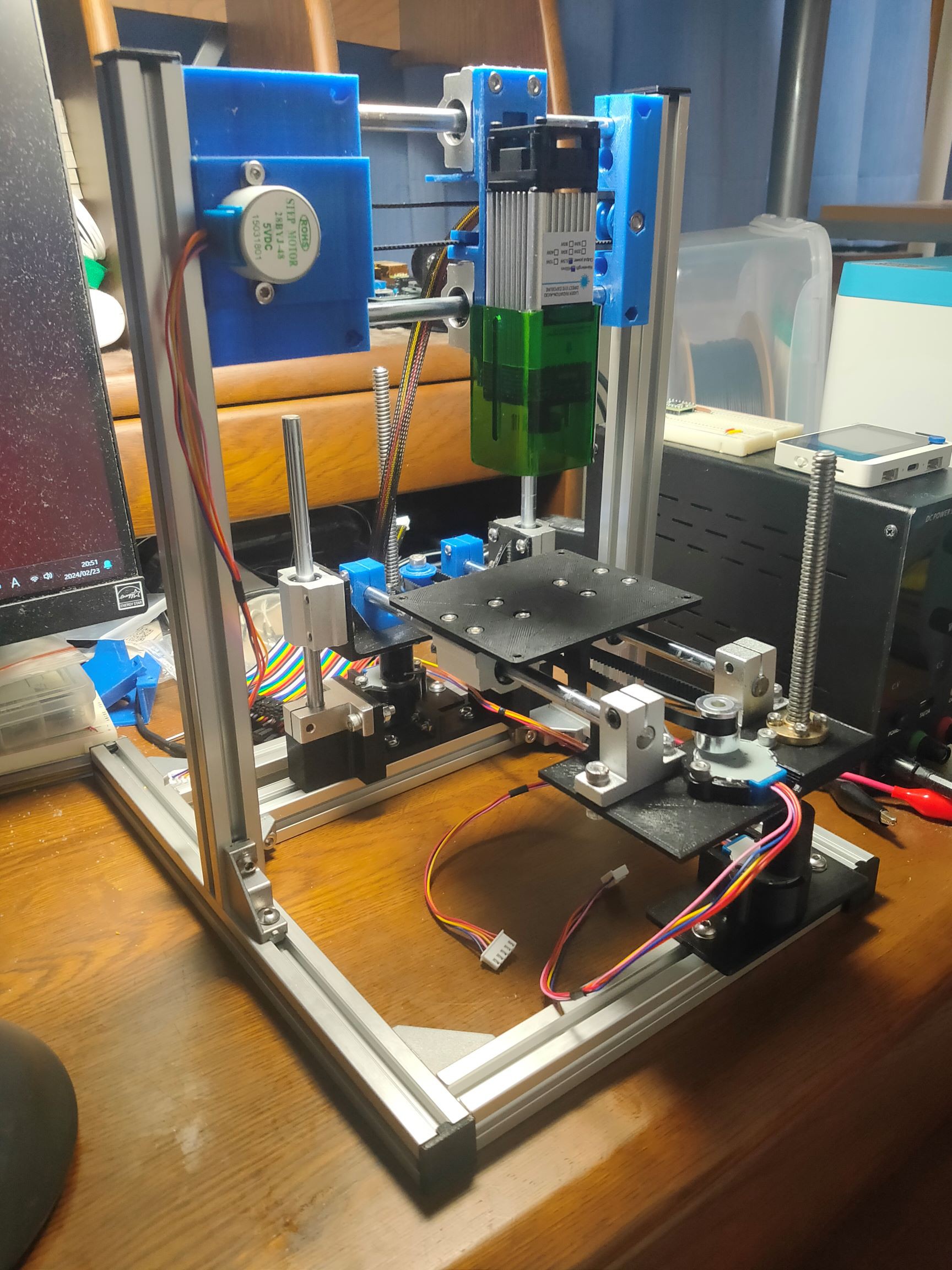

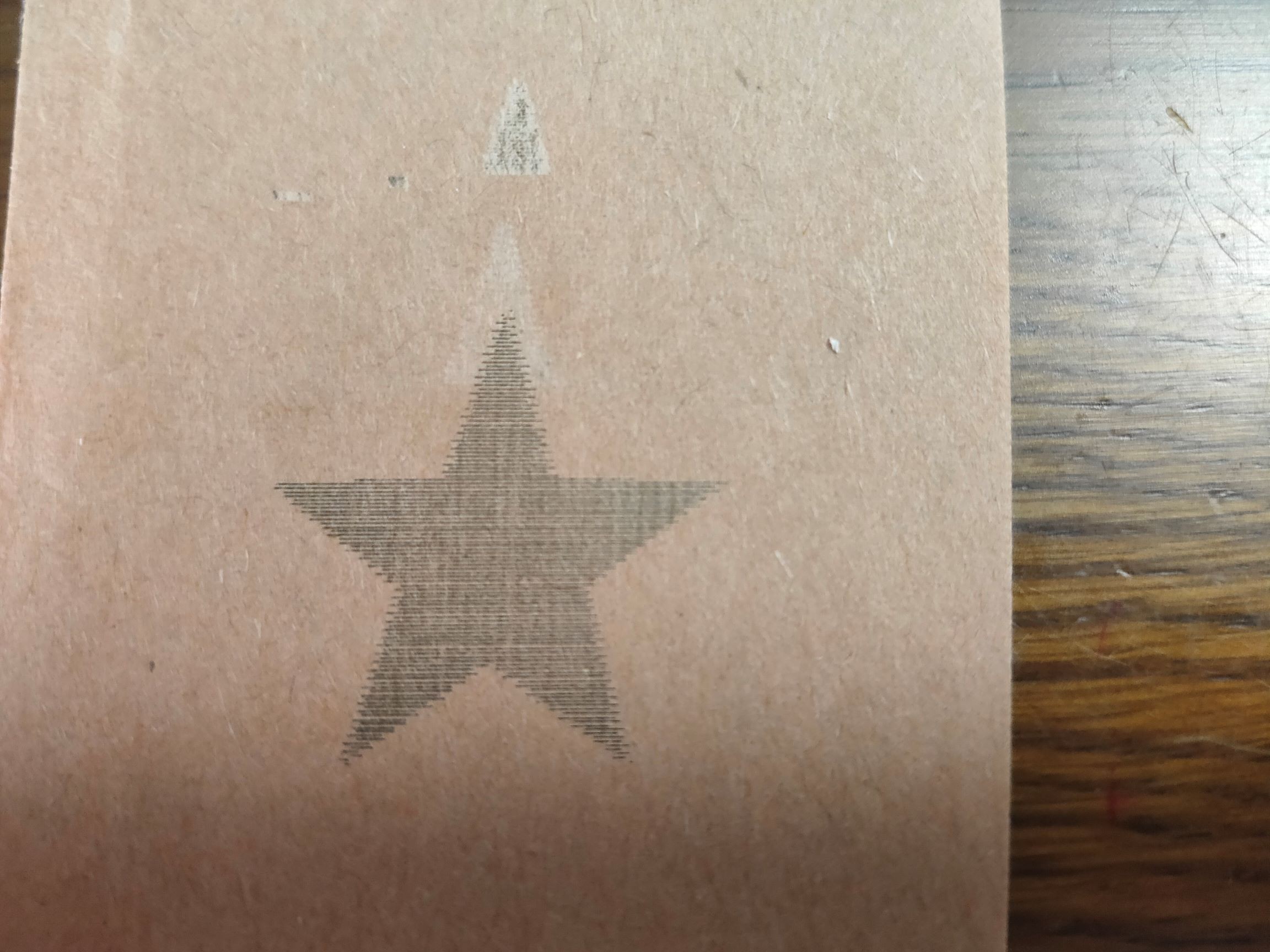

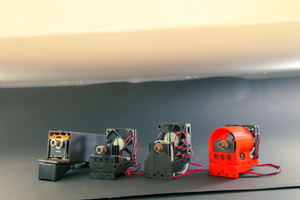

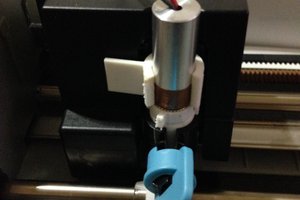

Idea: Paste Bed Fusion (PaBF)

Is it possible to avoid the aforementioned problems of powders, and make SLS usable in non-industrial environment?

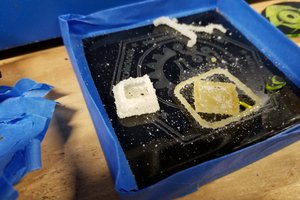

My solution is to use polymer clay instead of powders.

Polymer clay, such as Fimo and Sculpey, is a clay-like craft material that can be baked in cooking oven.

Because it is composed of thermoplastic (polyvinyl chloride, PVC) powder dissolved in liquid plasticizer, it might be used as an alternative to Nylon powders in SLS 3D printing.

While it has similarity to powder materials, it is significantly safer because polymer clay does not fly in the air and therefore free from explosion or inhalation risks.

Also, plasticizers used in current polymer clay products are not the harmful phthalates, according to manufactures (sources: Fimo webpage, Sculpey FAQ).

Acknowledgments

This project received the second prize (with prize money) in the 1st Marutsu DigiKey Student Idea Contest (See announcement from Marutsu in Japanese).

Satoshi Tanaka

Satoshi Tanaka

Retroplayer

Retroplayer