-

Laser marking test

03/16/2024 at 06:47 • 0 commentsKinematic system

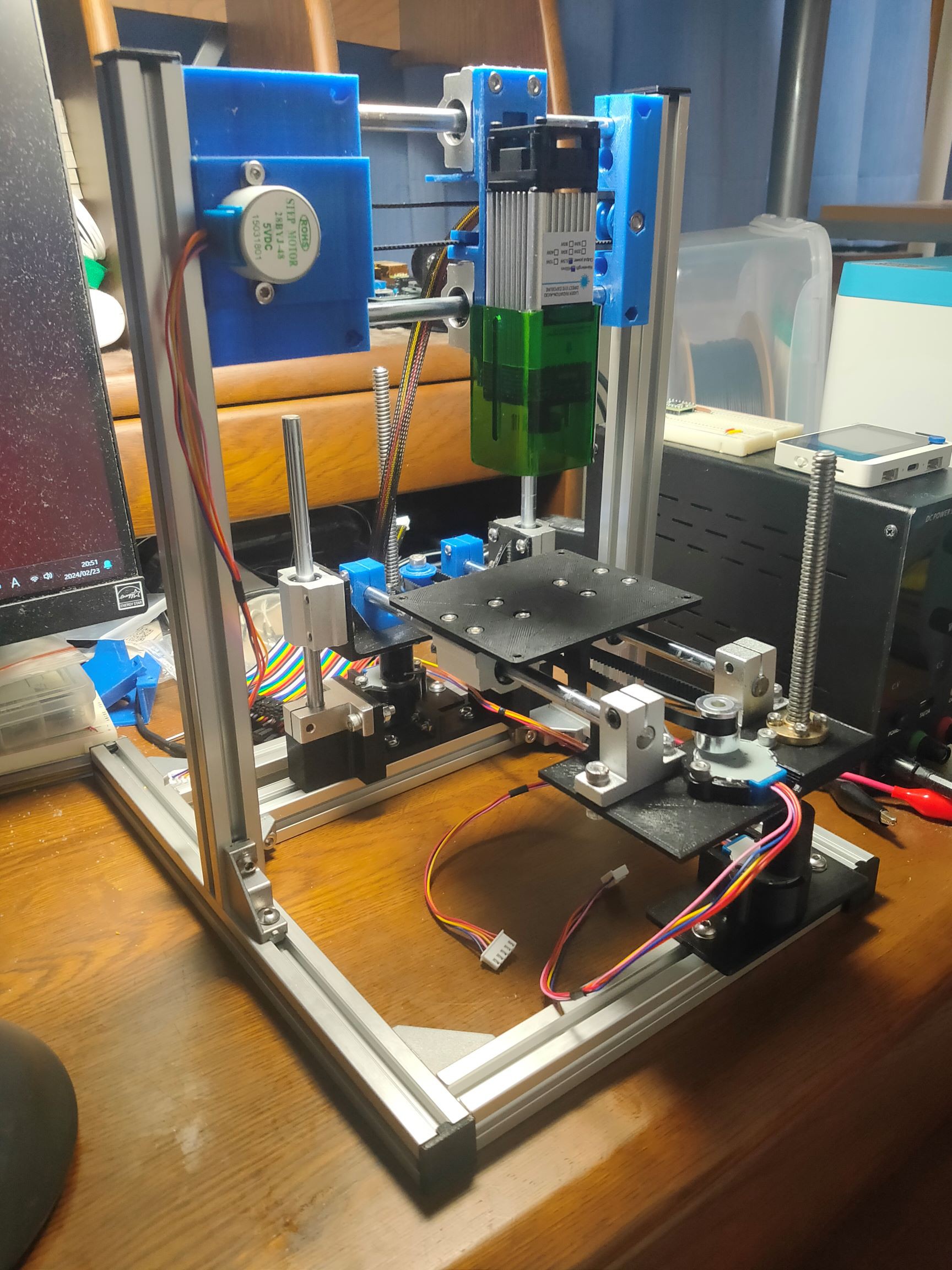

Recently (early March 2024), I built the kinematic system to move the laser head and the print bed.

![]()

The laser moves in X (left-right) axis, and the bed moves in Y (forward-backward) and Z (up-down) axis.

All the axes are driven by cheap 28BYJ-48 stepper motors.Operation as a laser marker

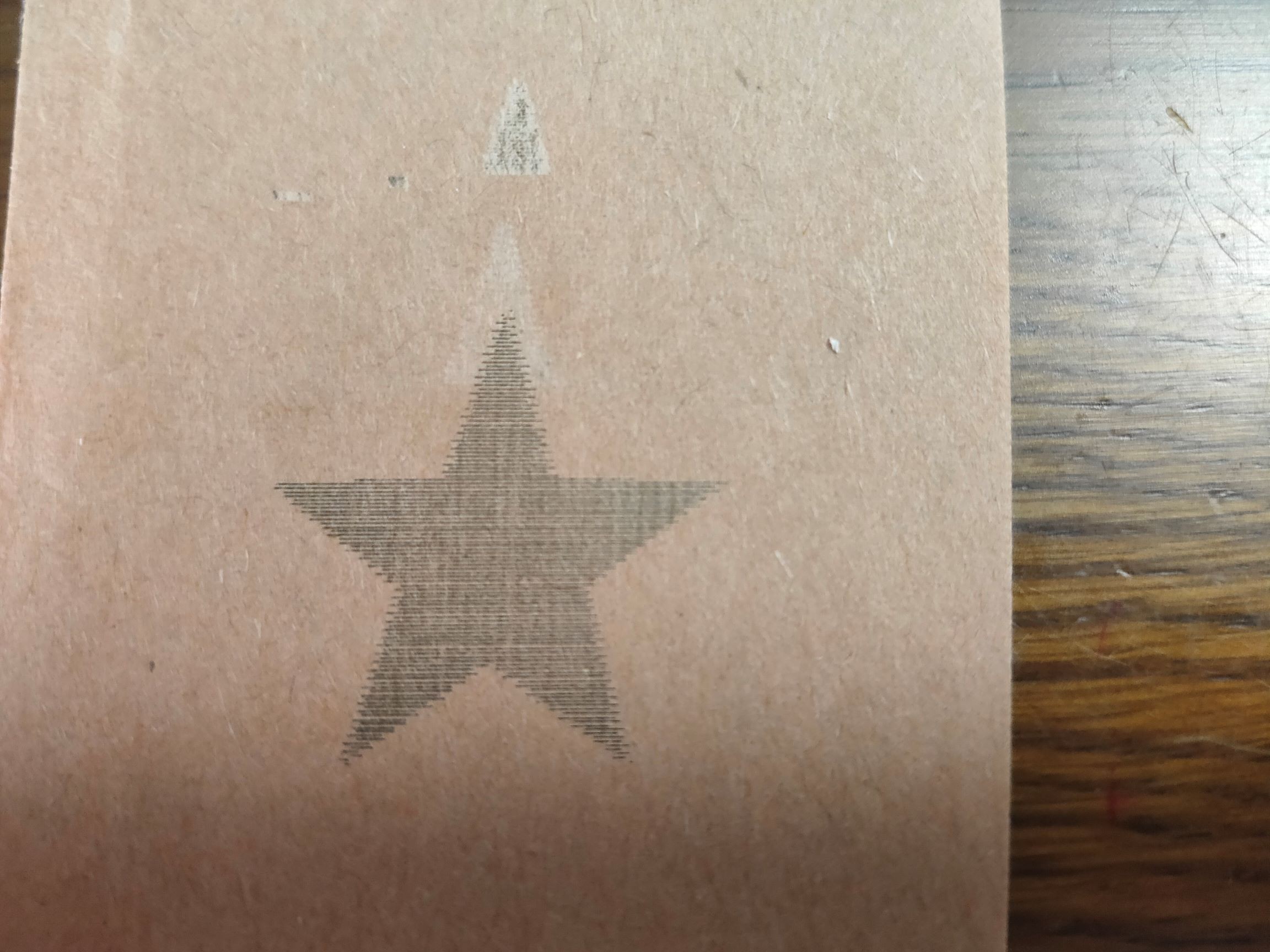

To test the kinematic system and laser control, I used the machine as a laser marker to draw burned image on a paper.

The image (★) was marked on a paper by raster-scanning laser.![]()

The burned image was clear, but there were "zig-zag" artifacts on edges.

As it indicates there are unexpected deviation of X position between left-to-right and right-to-left scan lines, there is room for improvement in mechanical accuracy and/or motion control program. -

Proof-of-concept experiment

03/16/2024 at 01:10 • 0 commentsIn the beginning of this year (Jan. 26), before building anything, I did a small experiment to confirm the most important idea of this project: hardening polymer clay with laser.

Methods

The materials are:

- Polymer clay: Fimo Soft (black)

- Laser: VoidMicro LD3070LA

- Diode laser module sold on AliExpress at approx. $32

- 5.5W, 450 nm (blue visible light)

![]()

The small amount of clay was kneaded and stretched into thin layer of about 1 mm.

Then the small area on clay was irradiated with laser, in a manner similar to filling an area with pen.

The laser power (PWM input) was set to 100%.Results

The irradiated area became hard rubber-like state, and it was not easily teared apart when pulled.

![]()

![]()

Therefore, it is proven that polymer clay can be baked with laser.

However, the process generated terrible odor. Safety of this process has to be investigated further.

Claymore - SLS 3D printer using polymer clay

SLS 3D printer using paste material (polymer clay) instead of powder for home use.

Satoshi Tanaka

Satoshi Tanaka