Here we will present two methods of making Mg-Bi composites; one mimicking cold spray, and another more analogous to brazing.

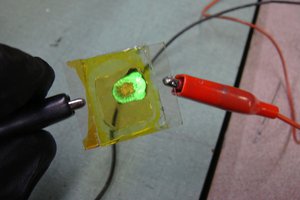

The samples resist delamination about as well as can be expected for laminates with layers of brittle bismuth. Much optimization remains to be done, and I look forward to seeing where people take this! I would be curious to see vacuum brazing of these composites for example, or hydraulic pressing and heating of larger surface areas, or futher optimization of the solvent bath used.

This project features:

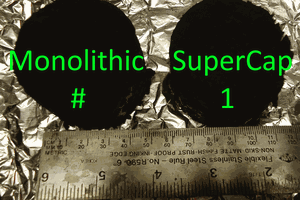

- Chemical process info for coating Bismuth onto magnesium with a reasonably durable bismuth coating (this might also be useful as a primer coating for people experimenting with magnesium electroplating)

- Preliminary test data of various solvents for the above process

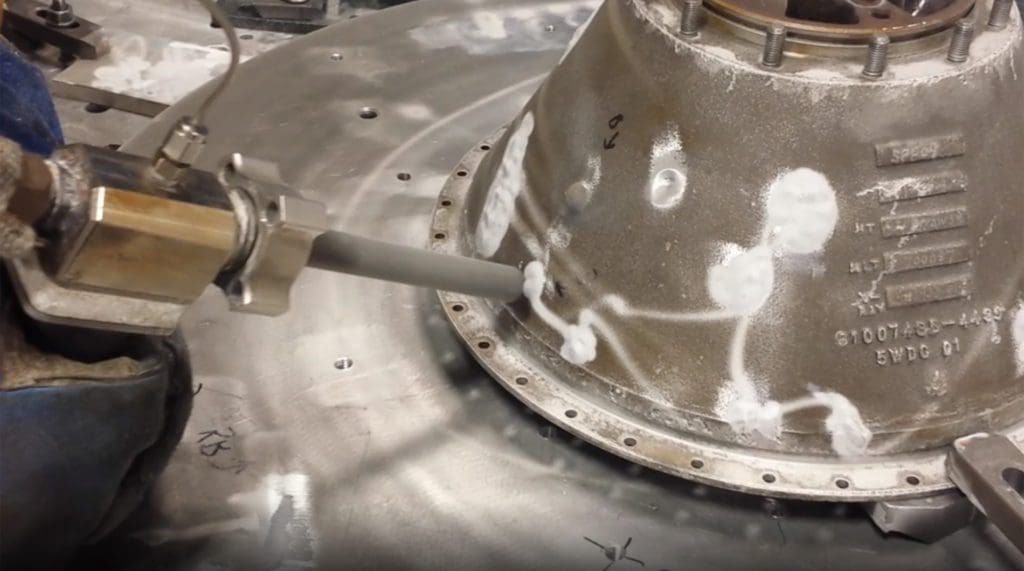

- Simulated explosion welding apparatus and instructions for solidifying the Mg-Bi composite at room temperature

- Initial documentation from tests of brazing in ambient environment under pressure

No need for a Github page for this project; the design details are quite simple and straightforward.

As mentioned above, this work is licensed under a Creative Commons Attribution 4.0 International License.

Michael Perrone

Michael Perrone

Cedric Honnet

Cedric Honnet

MECHANICUS

MECHANICUS

Ian Hanschen

Ian Hanschen

Matthew Borgatti

Matthew Borgatti

Also, since you mentioned Terahertz, the structure reminds me of a Bragg reflector, composed of alternating layers of different refractive index material. Bragg reflectors can even be used for X-Ray reflection. They are common in laser and fiber optic applications, and most high reflector (non-metal) mirrors work this way.