-

Impact Tester

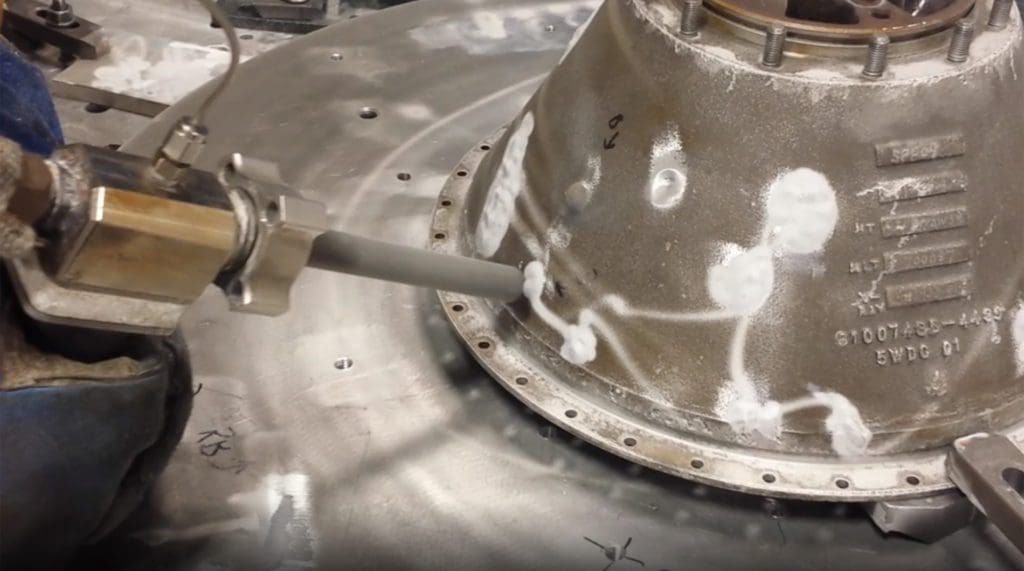

03/28/2024 at 22:44 • 0 commentsBismuth and magnesium, somewhat like gold and aluminum, are considered dissimilar metals, so heating or melting these materials and expecting a good metallurgical bond isn't the best way to do things. That's where cold spray technology comes in: if you shoot metal powder at a surface fast enough, it can mechanically and chemically bond to the substrate without ever becoming a liquid.

![]()

Image credit to VRC Metal systems

But cold spray systems cost hundreds of thousands if not millions of dollars to own and operate - so is there something we can do instead? It turns out there is! If you concentrate large amounts of force over a small surface area, you can simulate cold spray or explosion welding

(more images and details coming shortly)

-

What is the Mg-Bi composite?

03/22/2024 at 18:48 • 2 commentsBeing relatively well-versed in metallurgy and to some extent chemistry, quite a few conventional explanations come to mind when I think of the magnesium-Bismuth composite

![]()

- Firstly, the composite looks like it is produced electrochemically. Magnesium typically forms dendritic or feather-like structures as shown in the above image from Wikipedia during electrolysis of magnesium salts. If I were trying to reduce the formation of these dendrites in a battery for example, I might add some bismuth layers to redirect crystal growth and reduce dendrite formation, which could otherwise short out the battery. Supporting this argument, bismuth is often considered as an additive in magnesium batteries in many scientific articles to promote catalytic activity, provide reversible passivation, and improve magnesium battery efficiency and life cycle. [1], [2], [3], [4], [5]. It is certainly not beyond imagination (though it would require a water soluble bismuth salt that does not electrolyze easily, which is odd) that a magnesium-ion battery could have developed bismuth-magnesium layering during successive charge-discharge cycles, especially when considering article 3. And one could imagine such a prototype battery being used in 1947 by either the US or the USSR.

- Alternatively, the bismuth lamination may be a prototypical form of anticorrosion coating, of the type actively being developed by Modumetal for more standard industrial metals and alloys like steel. In these materials, the bismuth layer might act as a chemically passive layer to potentially impede corrosion, but considering the galvanic interaction between the bismuth and magnesium, I'm not certain how well that would work unless the bismuth coating is largely free of holes - which could be challenging given what I've seen with magnesium electroplating...

- If Bismuth improves the catalytic activity of the magnesium, one could imagine a magnesium extractive metallurgical process utilizing bismuth in some way, occasionally replenished, in the electrolytic bath, to reduce the energy required for electrochemical production of magnesium metal. The stripes could indicate this occasional introduction of bismuth salts into the plating bath. Alternatively, the bismuth could be used to make sure the magnesium easily flakes off of the plating electrode when plating is complete, or again to prevent the formation of magnesium dendrites so that the magnesium extraction bath can run for longer between batches.

But let's assume for a second that perhaps the composite was damaged by re-entry, weaponry or the crash-landing so it is not in its pristine state. It's certainly possible that the outermost Bismuth layer could have evaporated off in that scenario, and the magnesium could have been scarred in the way shown. What else might it be then?

- Such a laminate could possibly impede magnesium combustion, which could be a very useful property in aerospace applications. I certainly noticed some protection going on when blowtorching some of the samples - the bismuth would oxidize when the magnesium would normally burn, inhibiting ignition somehow, despite forming what I imagine would be a thermitic composite. With bismuth having such a low melting point, I'm not sure how well this would work in practice: I would expect delamination at high temperatures when the bismuth melts.

- Having personally played around with magnesium and bismuth electrochemistry in the past, I can attest that thin layers of bismuth on magnesium appear black, even if they are quite smooth (although perhaps the roughness was too small for my equipment to resolve) - so something interesting may be going on with optical absorption at the surface. Perhaps the composite indeed exhibits some interesting infrared and terahertz optical properties, as claimed online.

- If the material happens to be a terahertz or phononic waveguide, it is possible that the material is also an exotic fuel or power source, considering that Peter Hagelstein's work at MIT with Mossbauer Excitation transfer implies an inverse Mossbauer effect, perhaps it is also possible to use coherent terahertz to induce other types of nuclear decay, though admittedly if we assume alpha decay for bismuth, the momentum would probably be too high to couple to phonons well. There are other elements that could work much better in this arrangement however, if the intention is to induce nuclear decay. alternatively, as radionuclides accumulate in the Mg-Bi composite, it may be possible to use coherent THz phonons to induce decay and de-irradiate the material during space travel.

- Perhaps my best guess of all that I've listed so far is that the Mg-Bi composite is some sort of prototype radiation shielding. This rings especially true since the Mg-Bi composite was recovered near White Sands Missile Range. Optimal radiation shielding often mixes light elements with heavy elements, like the polymer-tungsten composites used as shielding at nuclear power plants. But most polymers would have their structural integrity compromised by radiation damage over time, and tungsten is usually considered too dense for aerospace applications except in niche applications, so perhaps magnesium and bismuth laminates offered some engineering advantages that they were testing out at the time. That said, given what I've seen in industry, I highly doubt such a composite would still be in use for this purpose: much better material combinations have been discovered since then.

If the material really is of alien or time-travelling AI origin, then it may be useless to speculate what the application may have been: in all likelihood they would be too far ahead technologically for us to be able to formulate relevant hypotheses. Nevertheless, whatever the Mg-Bi composite is, with this Hackaday article, everyone will now have the capability to explore its material properties for themselves, and hopefully we can crowdsource a reasonable answer.

Well those are my thoughts on the matter; what do you think the Mg:Bi composite is?

Bi-Mg Laminates

We demonstrate that Art's Parts, recieved at Coast to Coast Radio, are in fact easy to reproduce with human technology

Michael Perrone

Michael Perrone