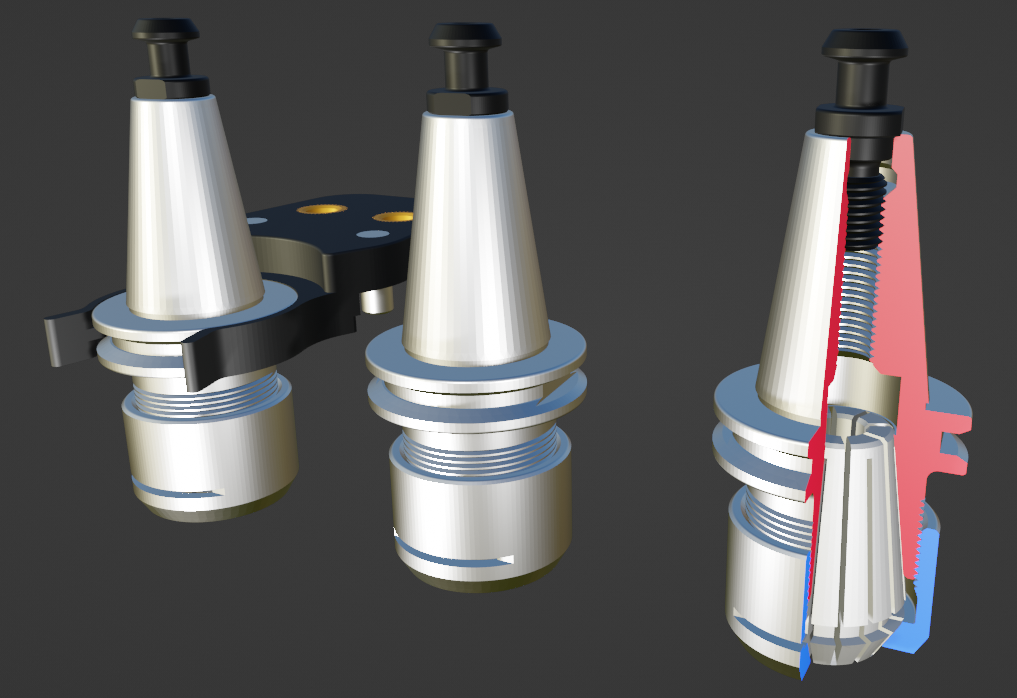

This design centers around an Iso20 tool holder, which can be purchased for very a reasonable dollar amount and comes in ER16 and ER20 collet sizes. Using an inexpensive tool holder will help me keep the cost of the system down as I will want many tool holders, but will only need one ATC.

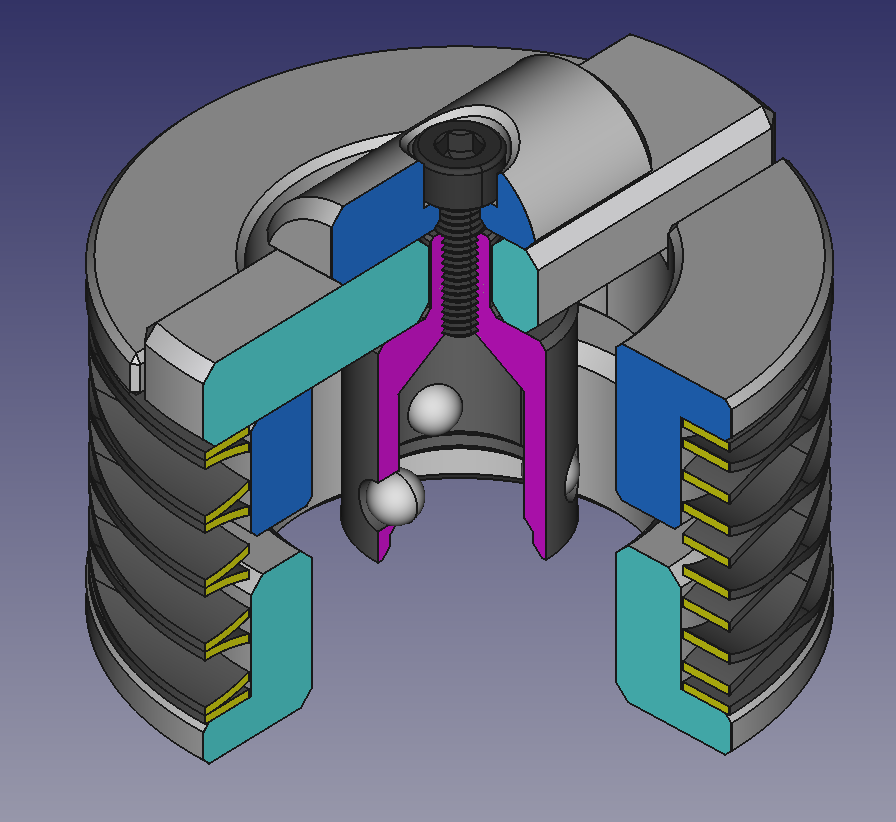

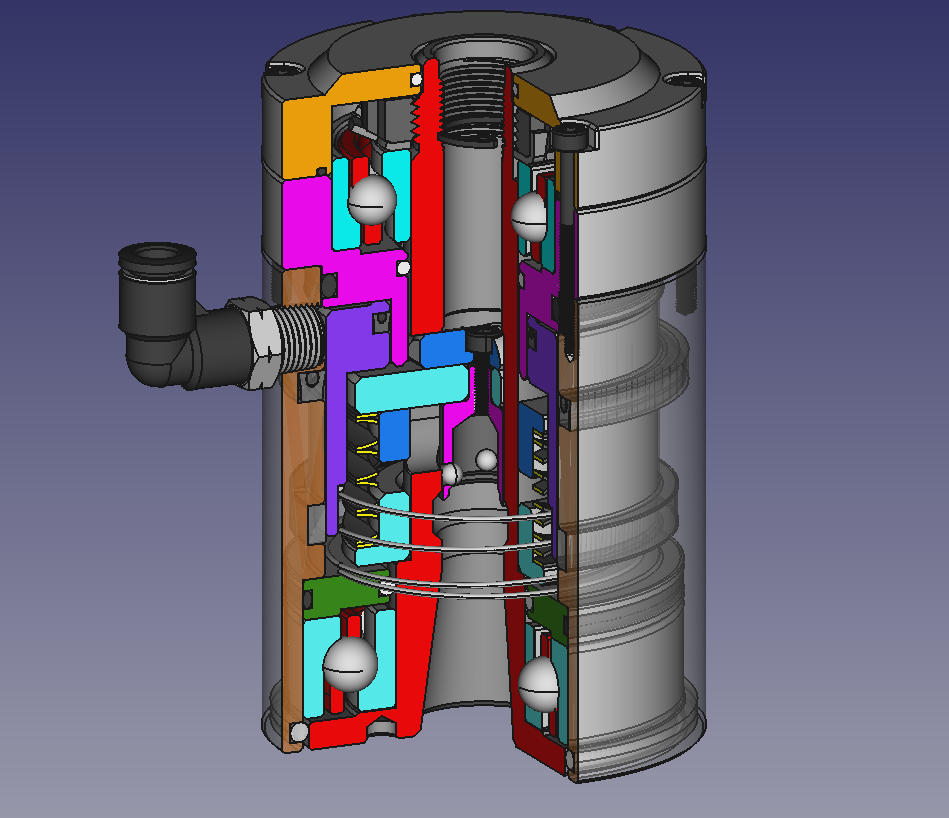

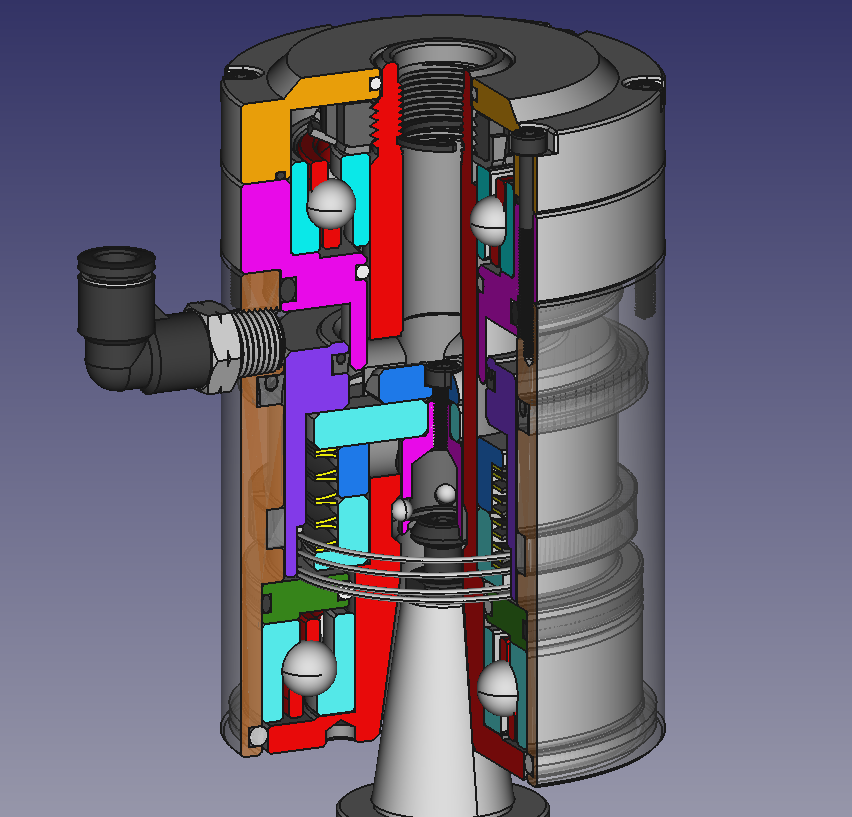

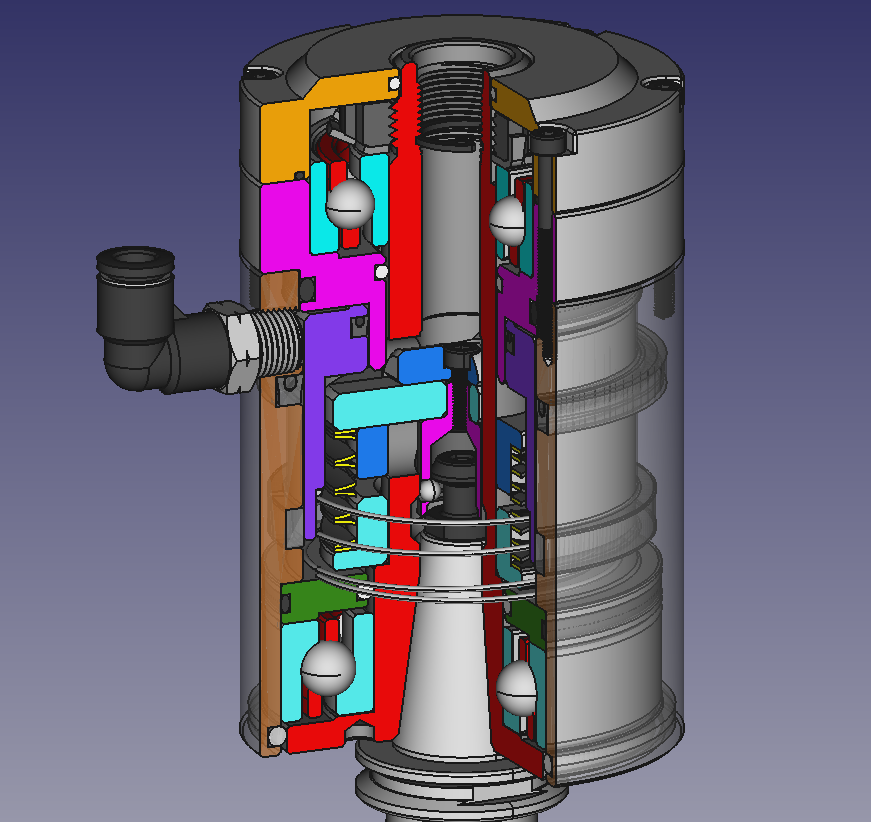

The spindle is supported by angular contact ball bearings that provide resistance to axial thrust. The design provides for PTFE seals between the non-rotating parts and the shaft that allows the bearing selection to include open cage bearings that can lubricated with either oil or grease.

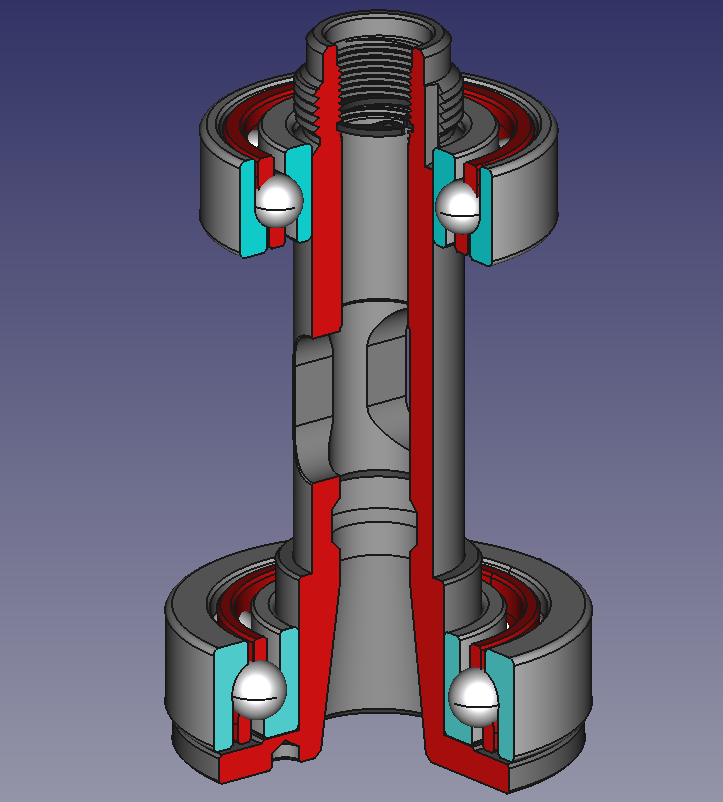

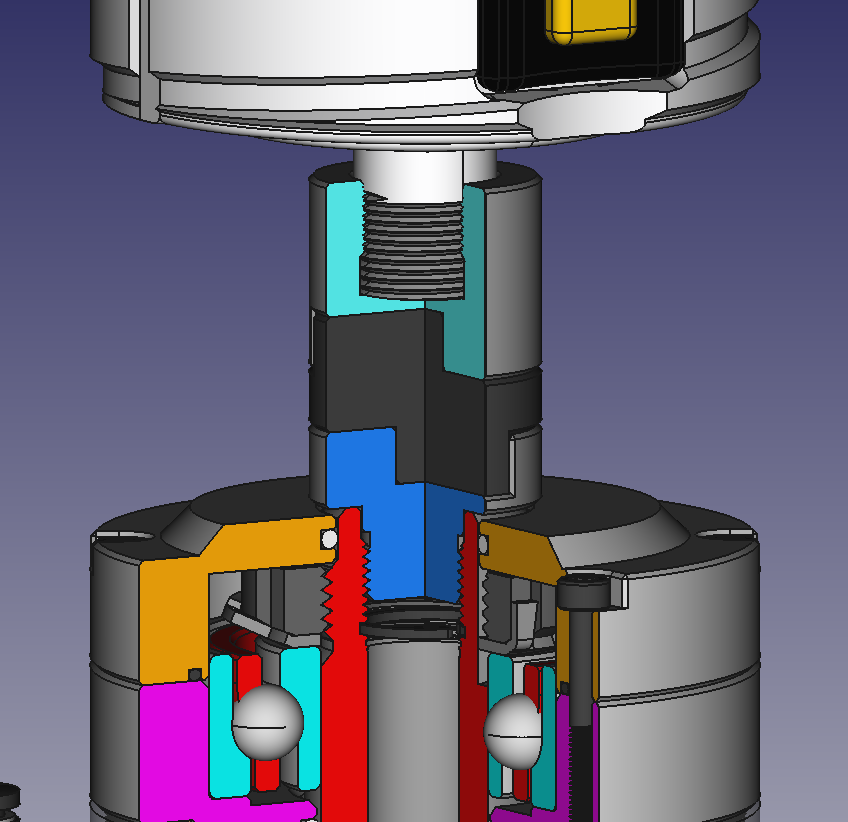

In order to keep the over all length of the ATC down, I designed the "grabber" around 3.5mm ball bearings that work the same way as pneumatic quick connect couplers. For the spring I found a very compact stacked wave disc spring.

To limit the travel of the spring and draw bar the spring guides make contact with each other at the bottom of the stroke and the half round washer on top of the draw bar makes contact with the top of the slot cut in the shaft. Being stopped by the slot in the shaft prevents the spring from pushing the piston against the top bearing housing when the ATC is unloaded.

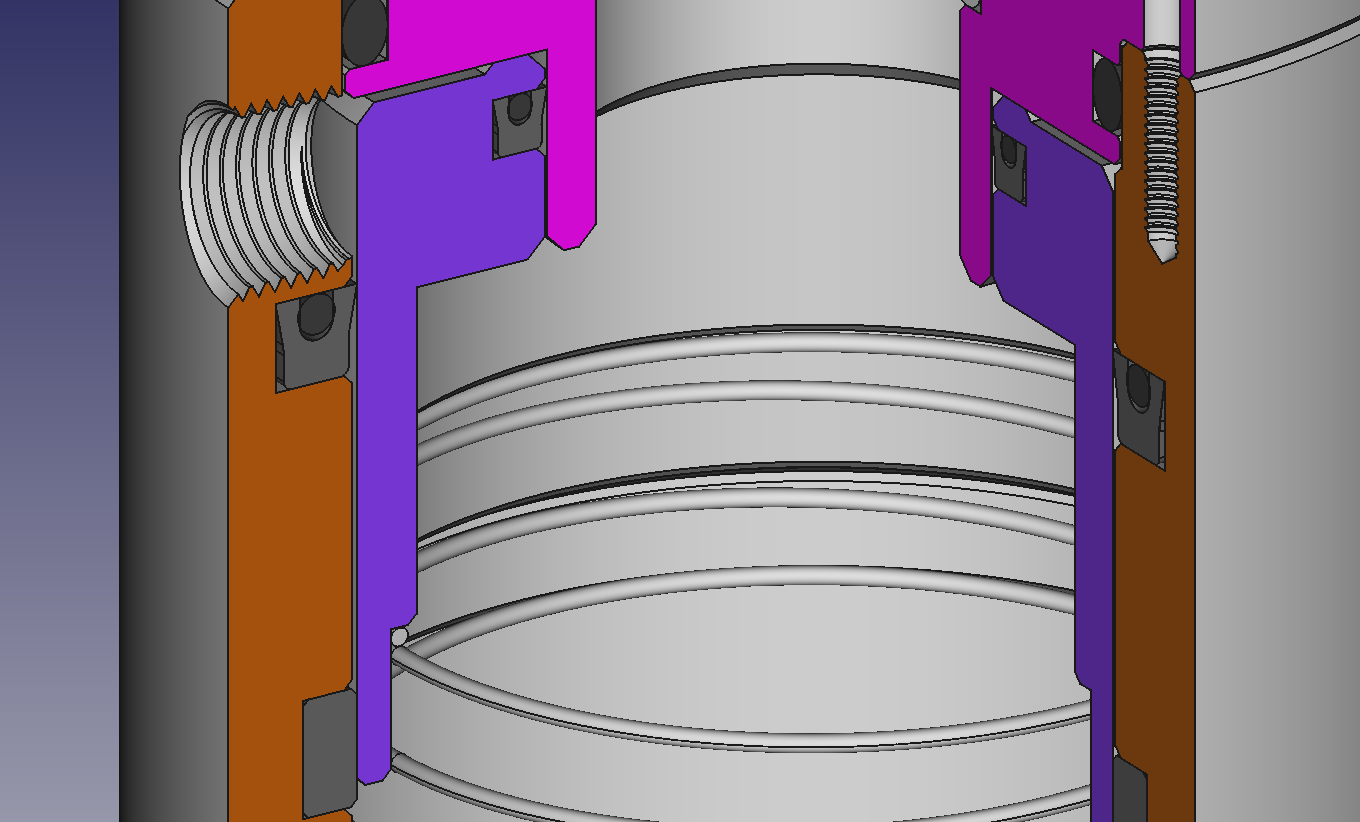

In order to make the manufacturing of the cylinder and piston easier I elected to orient the piston seals so that the surface the seal moves over is an O.D. That way the it will be much easier to polish, and I will not have to hone any I.D.s.

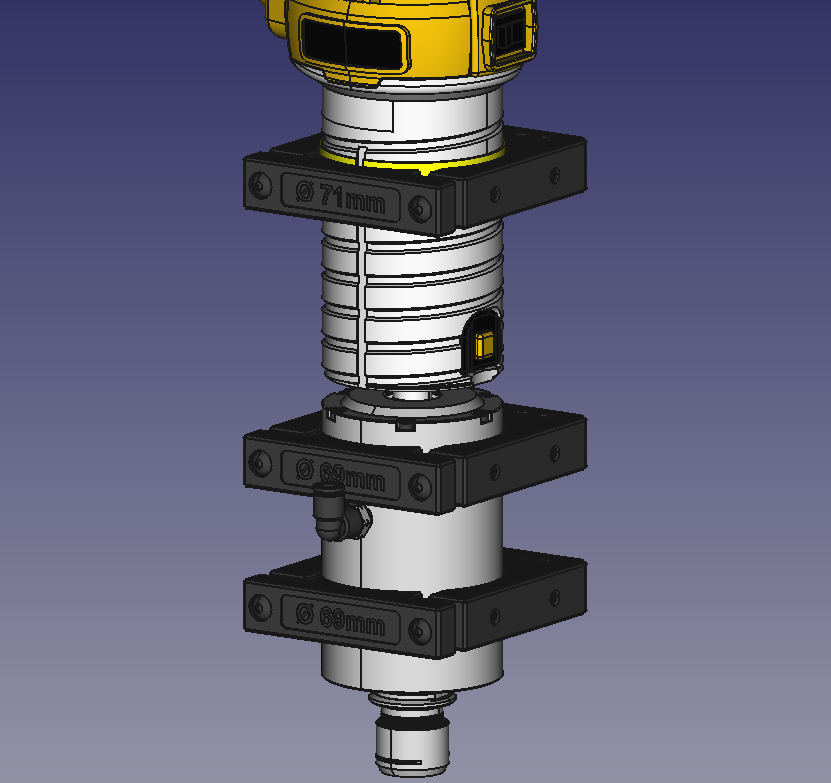

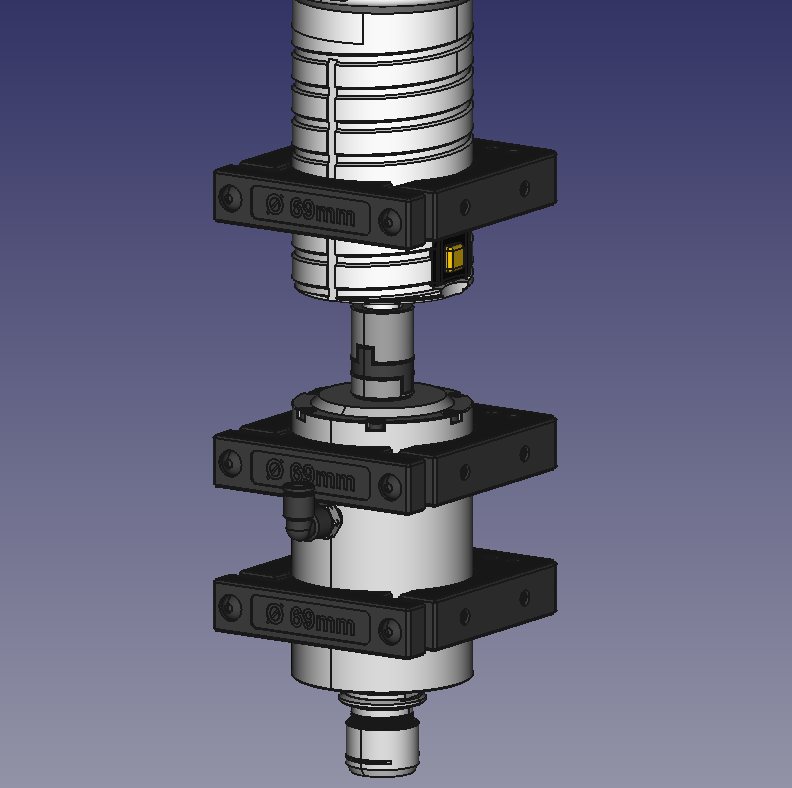

The shaft is designed to thread directly on to the M15-1 thread on the spindle of the Dewalt DWP611. But because I really don't like turning threads. especially metric ones, I'm very glad that I found a M15-1 tap and die set on Amazon for $20 and a M25-1.5 die for $16. That is going to make turning the shaft much easier.

As I'm not sure if the ATC and router will line up well enough, even with using a foam rubber liner in the clamp for the router (that is the yellow bit in the 71mm clamp), I have also designed a way of using a flex coupling to drive the ATC with the router. Because I want to make a custom flex coupling that has a low profile I elected to use an easy to make slider style coupling. The slider for the coupling will be made out of Delrin/Acetal, one of my favorite materials to machine.

The air pressure required should be less than 45psi to shift the piston its 5mm of travel.

Currently the most expensive part of this project would be the raw aluminum, so I am thinking about building a propane powered foundry to melt scrap aluminum and cast it in to rough shapes for machining. Well at least that is my excuse to build the foundry that I've always wanted. In other words, it's going to take me a while to build mine, so if you decide to build your own let me know how it goes.

Great concept, shame the link to the step files is broken...