The needed items :

- Arduino Uno R3

- Motor Driver Shield

- Wheels [x4]

- IR Sensor

- Battery

- Battery Holder

- Female Jumper Wire

- Wood board

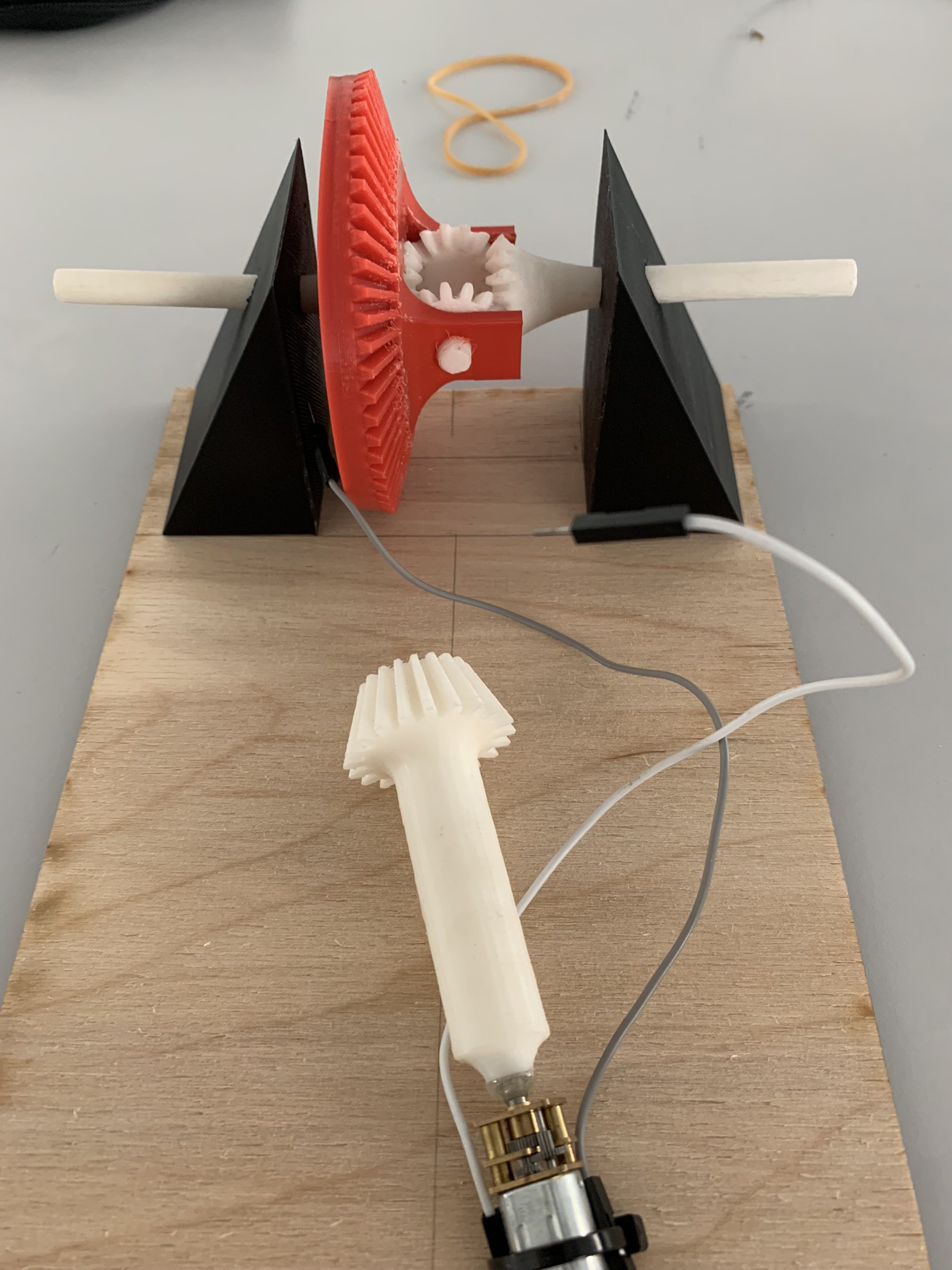

- Differential Gear Components

- Motor

- Card Boards

- Rubber bands [x4]

- Black tape

Arduino Car :

- Moving follow the line

- Distinguish the color of the floor

- Telecommande

- Cool decoration and design

- Stop when the route ends

Following this we changed the motor to a higher torque motor:

Following this we changed the motor to a higher torque motor:  After a bit of woodwork, we came up with a stable holder that stabilizes the motor. This construction made it into the final product.

After a bit of woodwork, we came up with a stable holder that stabilizes the motor. This construction made it into the final product. Through this, we are finally able to fully use the differential gear and use it in the way it was meant to be used. So our next goal was to add the wheels. Due to the gigantic size of the crown wheel, the wheels also have to have a large diameter. So we decided to go with Cardboard wheels, they are not very heavy and with the correct reinforcements its also quite stable.

Through this, we are finally able to fully use the differential gear and use it in the way it was meant to be used. So our next goal was to add the wheels. Due to the gigantic size of the crown wheel, the wheels also have to have a large diameter. So we decided to go with Cardboard wheels, they are not very heavy and with the correct reinforcements its also quite stable. So after adding the wheels we finally could try if they turned correctly and they did. After having time issues and discussing what our car could be used for we decided to make the car a shovel car. Having this new idea in mind we added a shovel in front.

So after adding the wheels we finally could try if they turned correctly and they did. After having time issues and discussing what our car could be used for we decided to make the car a shovel car. Having this new idea in mind we added a shovel in front. Which makes this our product, on top of that we tried to add line sensors with arduino.

Which makes this our product, on top of that we tried to add line sensors with arduino.

PixJuan

PixJuan

Dillon Nichols

Dillon Nichols

Kyle Rector

Kyle Rector

Alex Dunnett

Alex Dunnett