1 mm tight to be exact... That's the margin I have to work with before things start running into each other.

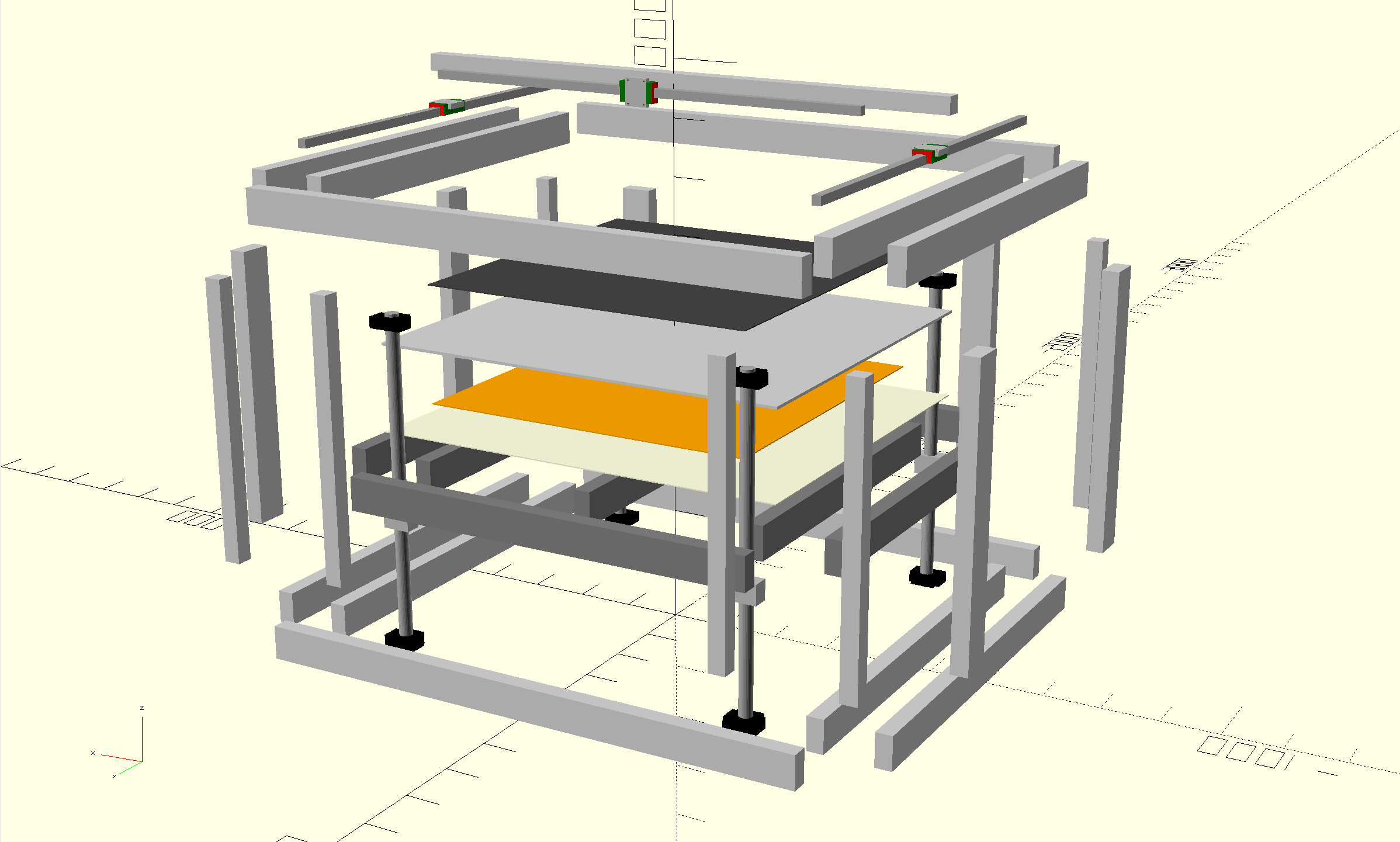

I was a bit quick on the draw and ordered the aluminium plate for the print bed yesterday. Measured it and all seemed well. Then I tested the homing function with a temporary bed (just a glass closet door from ikea with roughly the same size as the bed) and the bed hit the bearing blocks of the ball screws all the way at the top. Did not take those into account, did not fully realize the bed would be raised past these blocks.

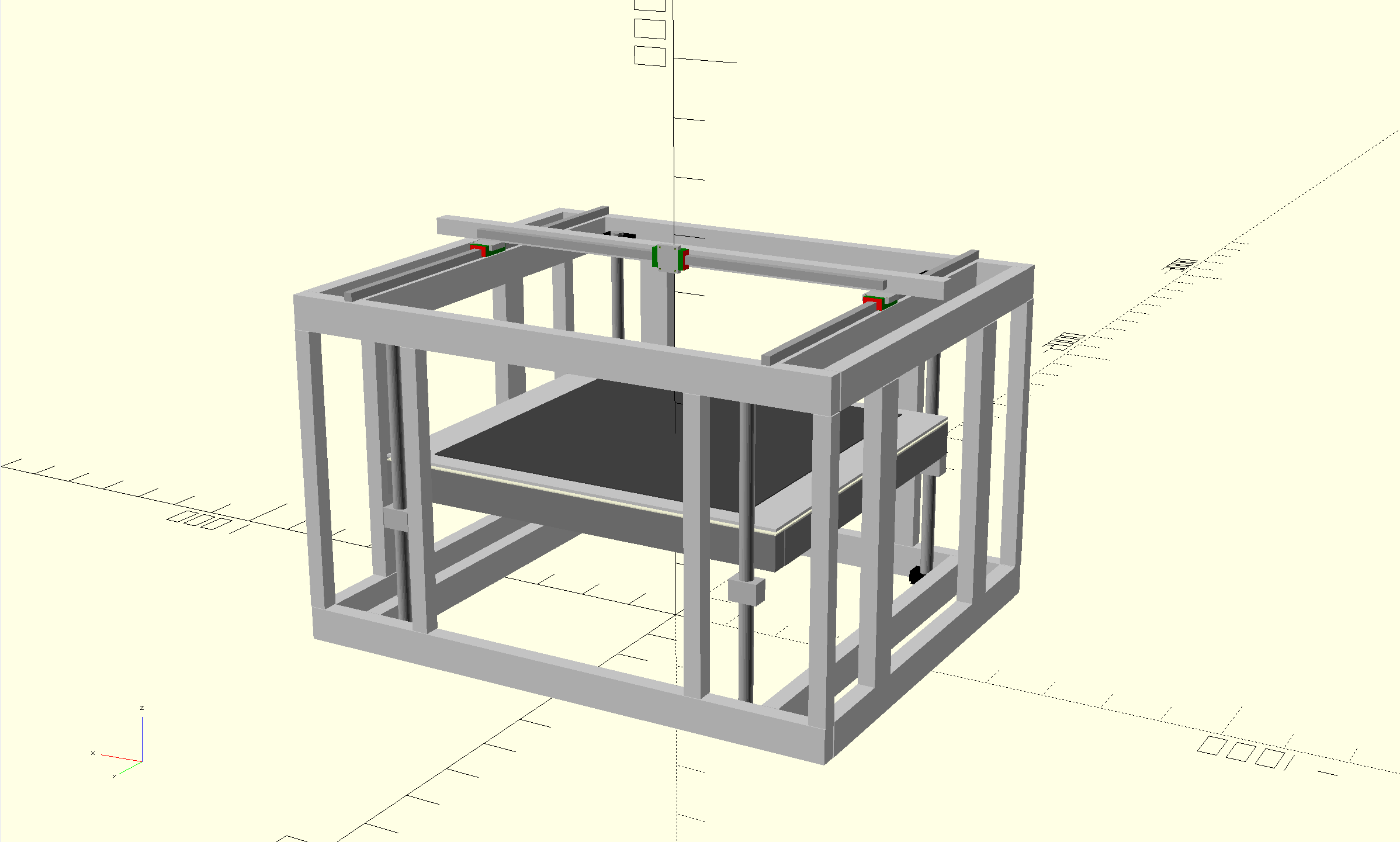

Now, the bed itself wasn't properly tightened and it seemed everything might just fit, but just to be sure (and because it was overdue) I drew the construction in openscad and realized the distance between the bed and the bearing blocks is going to be 1mm on either side. Not the kind of margins I'm happy with when basically "winging it".

But I just dropped 100 on the aluminium plate and another 100 on the extrusion profiles to support it, so I'm going to keep my fingers crossed and hope for the best.... otherwise I guess I'm buying a load of sanding paper and spend a few hours getting a few extra millimeters of margin somewhere....

E/S Pronk

E/S Pronk

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.