-

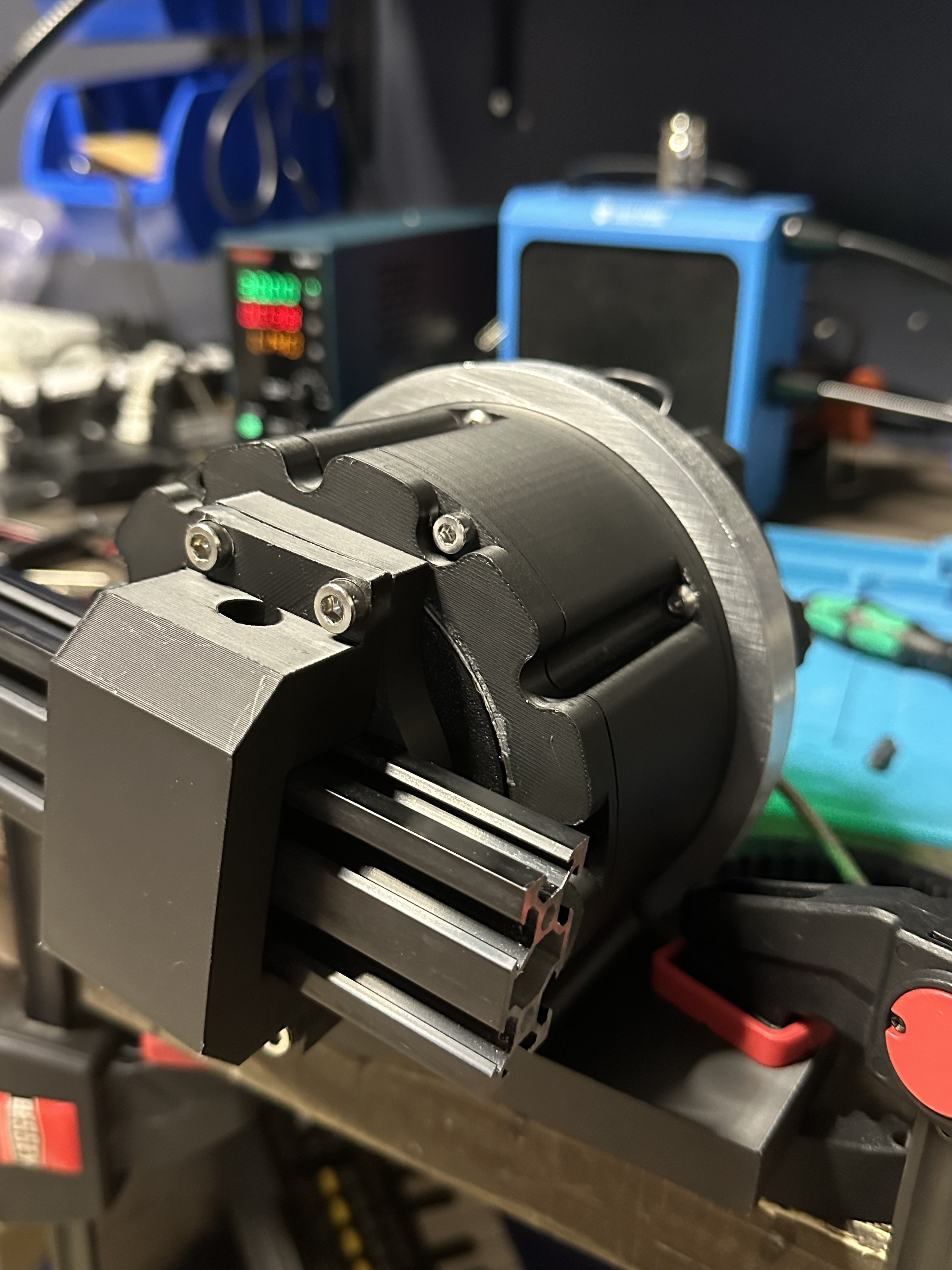

Encoder Mounted

08/14/2024 at 07:13 • 0 comments- Mounted the encoder

- Added more threaded inserts

I have mounted the encoder and confirmed that it works. Now i need to write some calibration code for the encoder to account for error (offset of encoder internally) to give a more accurate and clean reading. This calibration sequence should only need to be done after the joint is reassembled as the calibration values can be saved and reused on startup. Its important that these values can be saved because gathering these values for the calibrations would required the output to do at least one full rotation, which would suck if it needed to be done each startup. Once the encoders are calibrated, no homing sequence will need to be completed, the joint should always know its position even after reboot.

Side note, I believe there is a way to daisy chain these encoders. That would make life a lot easier because the motor drivers I plan to use are also able to be daisy chained. The less wires to get in the way, the better. My joint designs currently do not have a way to wire from itself to the next joint. I will be working on that soon.

Ideally all of the coding of the encoders will be done tomorrow and I will move onto the next thing.

-

General Update & Encoder Progress

08/13/2024 at 07:09 • 0 comments- Tested encoder with Raspberry Pi 5, will be connecting the Pi 5 to ROS soon

- Rebuild parts to include threaded inserts

- Added output encoder mount

I am planning on using the Moteus r4 for the motor drives as it is less expensive as the Odrive S1 especially if 6 are needed. These controllers are small and can be easily daisy chained with is very helpful for a robotic arm.

For the final design I plan to have all of the Joint calculations and simulation of the arm on a computer connected via ROS to the arm. Ideally the arm would subscribe to the angle publisher, drive the motors using that information and maybe if needed publisher the actual joint angles from the output encoders.I am also looking into carbon fiber for the body of the arm where I am connecting the joints.

-

Recent Tests

08/12/2024 at 02:58 • 0 comments- Smaller Ball bearings (3.175mm)

- Less internal friction

By lowering the internal friction I have been able to achieve 37.2 Nm from the Joint. This is a big advancement, I will be looking into designing the output encoder and moving forward with the arm.

-

Smaller Ball Bearings

08/11/2024 at 02:25 • 0 comments- Changed the ball bearings to 3.175mm instead of 10mm as it will allow for thickening of the FlexSpline and smoother operation of the Wave Generator.

- Under too much load the FlexSpline snaps where the top of the cup connects to the base of the teeth.

-

Metal has arrived, ROS progress

08/10/2024 at 07:41 • 0 commentsMetal Ring Arrived today, it seems to have stopped the skipping, but there is still too much internal friction. It is too difficult to turn the input of the joint, I am working on a fix.

ROS and inverse kinematics is coming along well, should implement well as a system. I am attempting to make it so all I need to do is enter the DH Parameters and the math will do the rest. turns out that's more difficult than I thought.

*The Metal part is the Aluminum Ring around the Circular Spline in the image above*

-

Metal and ROS

08/04/2024 at 04:51 • 0 comments- Ordered Metal part to prevent Circular Spline from flexing

- While waiting, I am working on the ROS backend for the final arm

-

Fixed Bearing Friction

07/26/2024 at 21:08 • 0 commentsI was able the achieve the proper ellipse shape of the FlexSpline with little friction. It seems that making the Inner diameter of the FlexSpline Teeth (Where the bearing contacts) and the Outer diameter of the wave generator as large as possible lowers the friction.

-

Wave Generator Shape

07/25/2024 at 01:37 • 2 comments- Made Wave Generator Separate from planetary gears so it can be optimized faster.

After playing around with the shape of the wave generator, I found that it controls everything. after a few attempt I was able to make the Joint Back drivable once fully assembled. I have modified the shape of the wave generator to optimize of tooth contact. I believe I have found the perfect shape, but currently when using this shape there is too much friction for the ball bearings to move. I will be working to fix.

-

New Wave Embedded Wave Generator

07/24/2024 at 01:46 • 0 commentsThis new design has much less friction, surprisingly it is back drivable!

-

Improvments

07/22/2024 at 19:38 • 0 comments- Easier access to internals

- Removed most plastic threads for long M4 bolts and lock nuts

- Wave Generator now has direct contact with the FlexSpline, no sub flexible piece

- Strengthened output for stronger testing

- Adding Treaded inserts soon

I will not be moving forward with add the joint encoder until it is as strong as I would like. I am getting close but still not there yet.

Jared Fenster

Jared Fenster