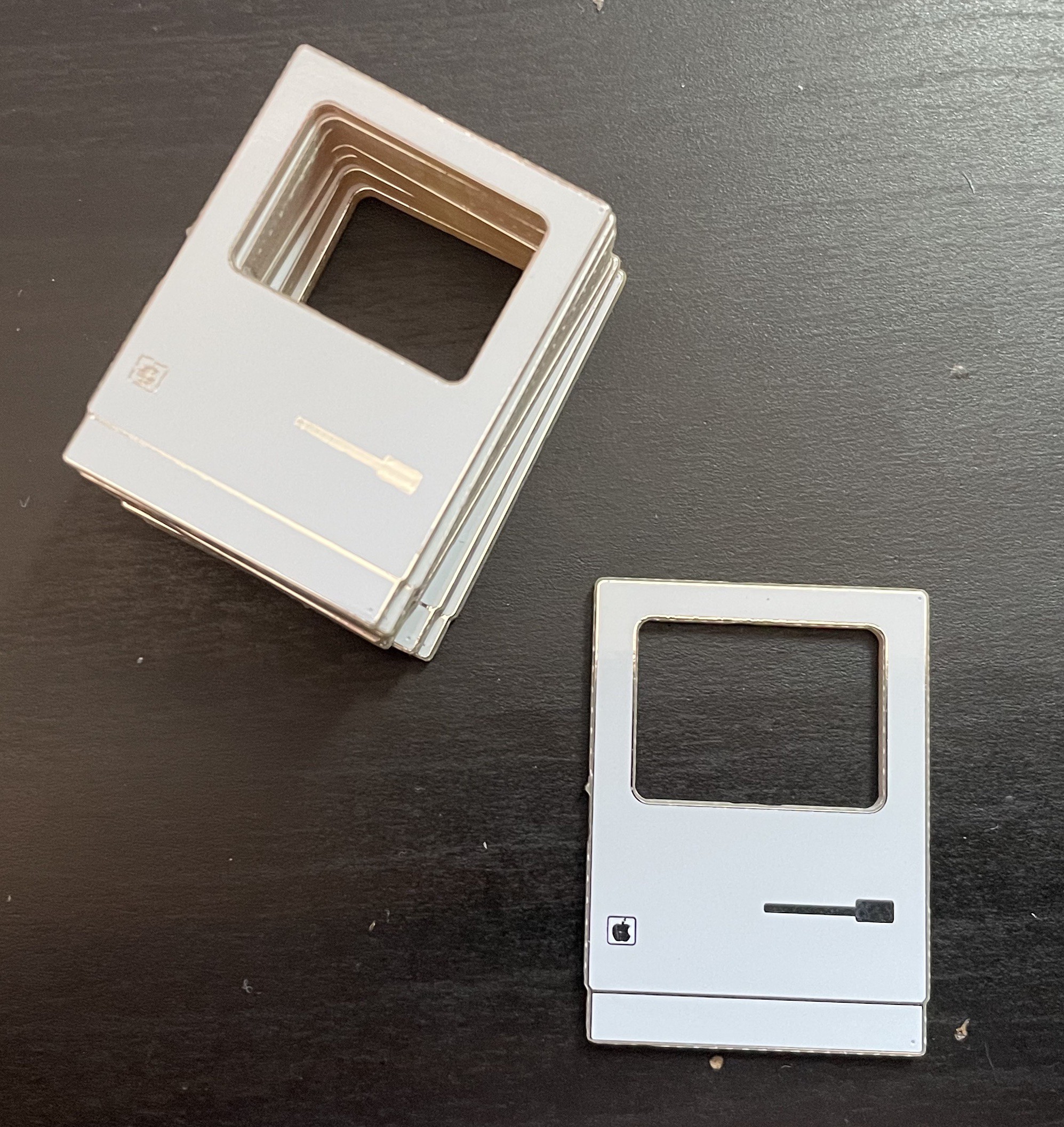

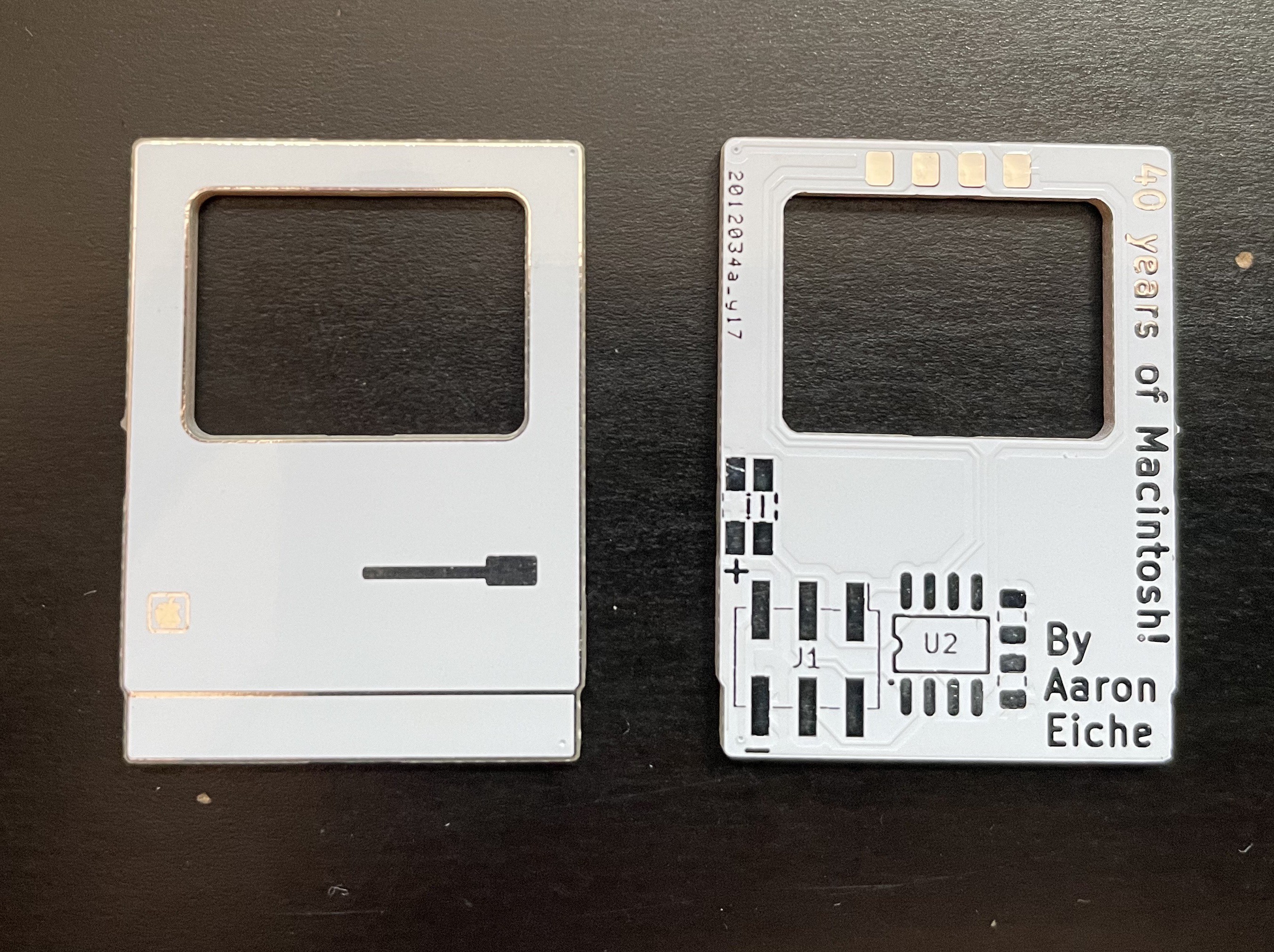

My first PCBs arrived yesterday and I'm really pleased with how they turned out! I was feeling a bit concerned about the detail of the apple logo, and and the outline around the shape that was provided by masking, but I don't think I could be happier with how it looks. It's really great.

I soldered one together and immediately ran into a problem. I couldn't get the programmer to talk to the chip. I checked the connections, checked the pinouts, checked continuity. I tried unplugging it and got the same response. The programmer didn't think there was a chip present - but the programmer reported that it was "already connected" and also reported the wrong chip.

I did a visual inspect of the header, and it looked like it really wasn't very well soldered onto the board. While I plan on reflow-soldering most of these, this first one I thought could just be hand-soldered. I added some more solder to the SWD pin (the 1-wire programming pin) and like magic, it worked!

For lack of a better-solution, I soldered some stranded wire to the display headers. I mentioned previously that I made these surface-mount because I wanted to keep the aesthetic of the front of the board - there wasn't room for single-row SMD header pins. My current plan is to use 20 gauge bare copper wire (like jewelers use) to go from the board to the display. I thought about just buying some solid-core wire, but it would require an awful lot of wire stripping on some very short wires.

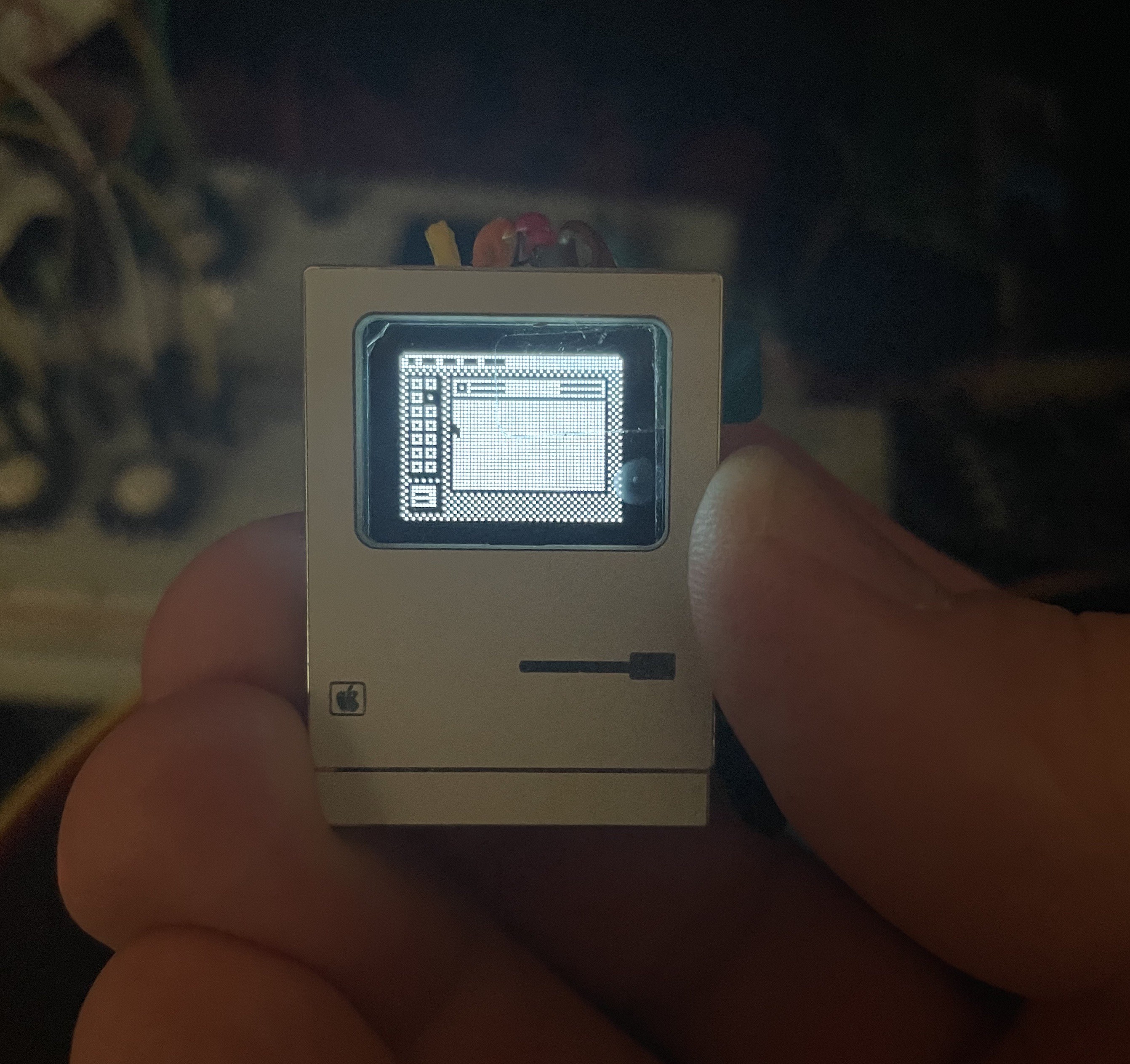

In the meantime, here is the assembled v0.5:

Next steps:

- Try the bare-wire screen connect

- Order the OLED displays

- Order new PCBs with the fixed header

- Finish the software (I have a lot of display stuff done, but the interactivity would be nice)

If I time this right, I think I could get them all built pretty quick. It'd be nice to not have this come down to the wire.

Aaron

Aaron

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Wouldn't be historically accurate or anything, but you've got a nice opportunity there to light the Apple logo -- expose the substrate in proper shape and put a LED on the opposite side to illuminate it. Just like I did with the little squares on the cyberdeck.

I soldered 1206 LEDs on upside-down manually for that, but I've since realized a 1204 (side-firing) will literally fit the same footprint and throw light in the proper direction without having to do any silly tricks...

Are you sure? yes | no

That's a cool idea, I'll have to mull it over a little bit. I have to remind myself not to get too wrapped up in historical accuracy - after all my display is 1/8th the resolution, and my board looks more like the Macintosh icon than the original Mac itself. I kind of like the shiny apple logo, but it's hard to make out unless its reflecting a darker color...

Are you sure? yes | no