I've changed my "chamber" a bit so now main fan doesn't blow room temperature air on the IC/Tray.

Was able to bring temperature to 220°c

Now at 195°c solution started to bubble and Nitric acid (at least I think it's Nitric acid) was vaporized after 2-3 minutes. I applied another drop of Nitric acid.

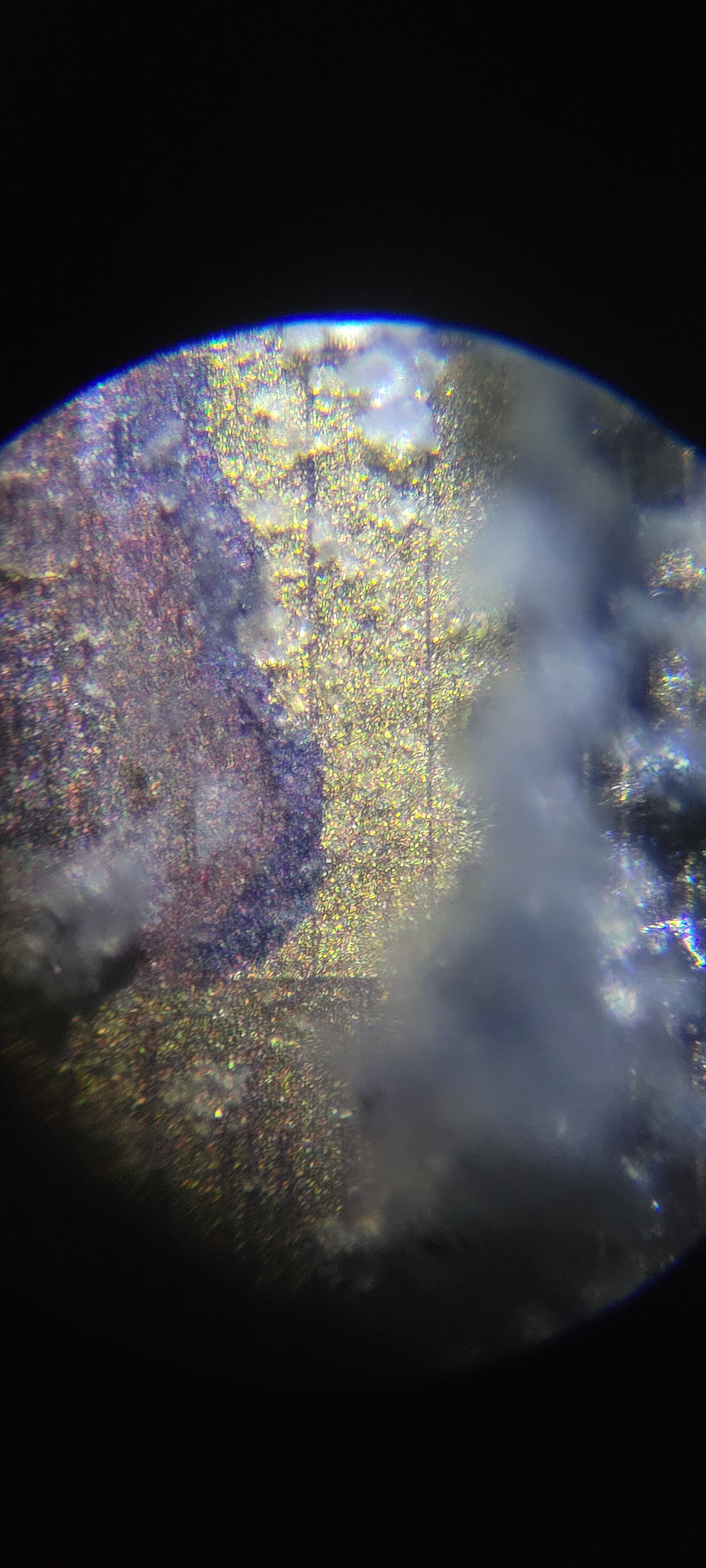

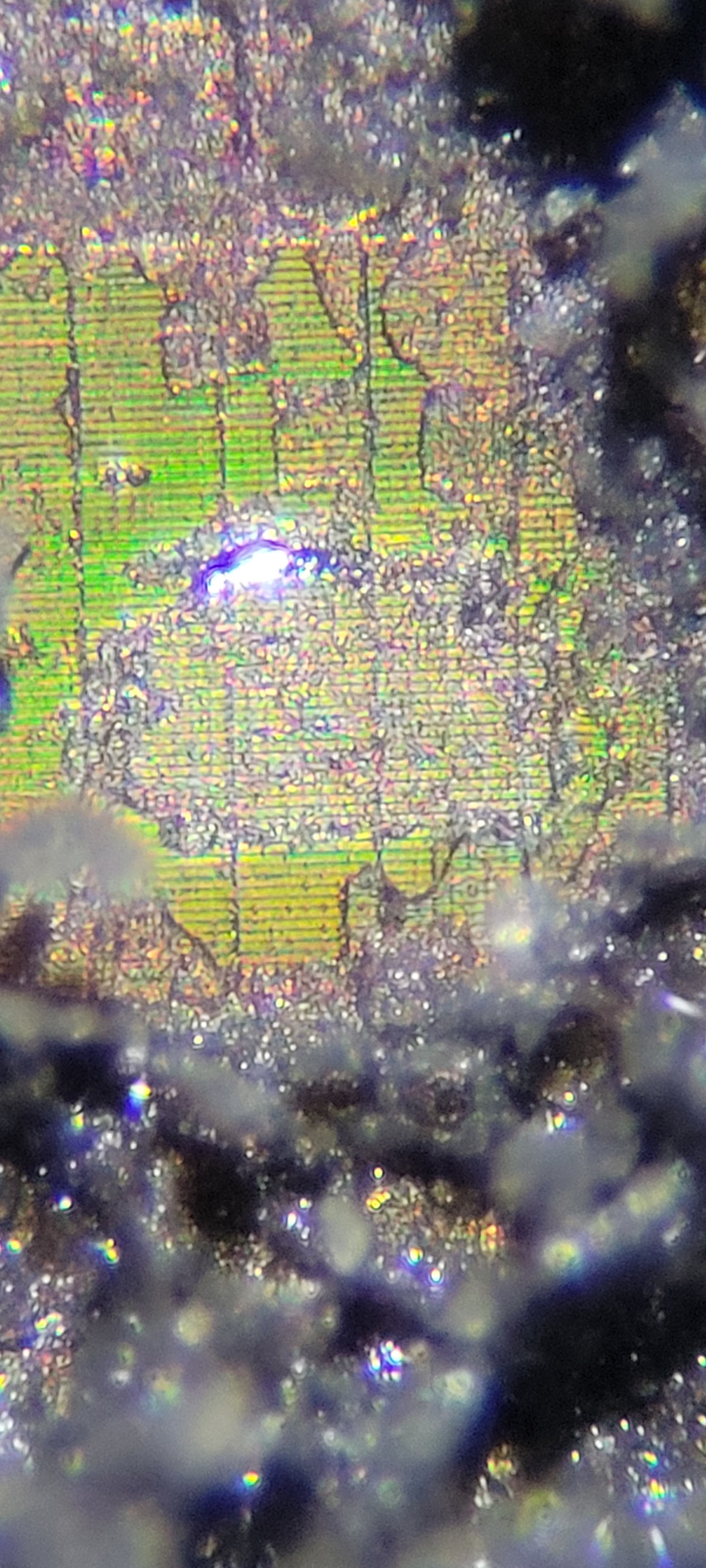

After all was done, sample was taken to be seen underneath microscope. The hole became much bigger which was a great news but something else caught my eye.

What it looks like copper being dissolved by Nitric acid. Maybe because I have accidentally broken the passivation layer.

This is another interesting point, can we remove upper copper layer just be cracking the passivation layer and applying Nitric avid?

It's very interesting question which we will deal later.

I believe the 'ice' looking sheets is the shattered passivation layer.

The gray in the middle is where drill's bit hit the silicone.

Next step will be taking new sample where passivation was not damaged.

I've tried to use new samples and I can see how epoxy being dissolved. But, it way too slow... We need more power/steam!!!

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.