An underwater glider works on a similar principle as normal air glider where the medium is water. There is no propeller in either glider, but the main difference is that unlike air gliders, underwater gliders use a neat trick to climb back the water column after gliding down. They do this by changing their density. Gliders are carefully designed to have a density very close to that of water. Then by simply changing their volume (which can be achieved using a simple piston pump or an inflating oil bladder), they can change their density and use the buoyancy force to fly up and down the water column.

By moving a large weight internally (usually the battery pack) it can control its pitch and by rotating the weight, it can roll and therefore fly towards a certain heading.

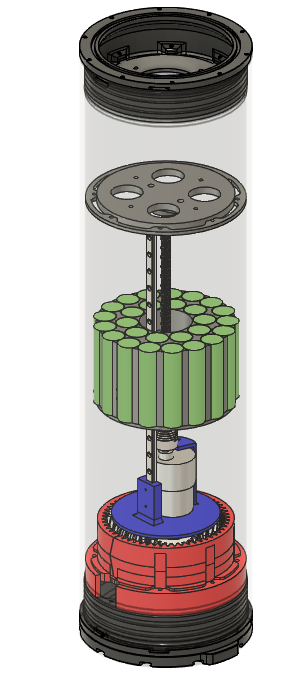

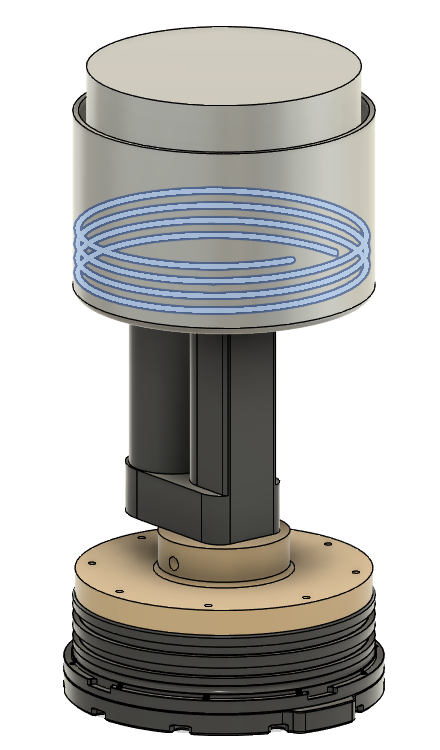

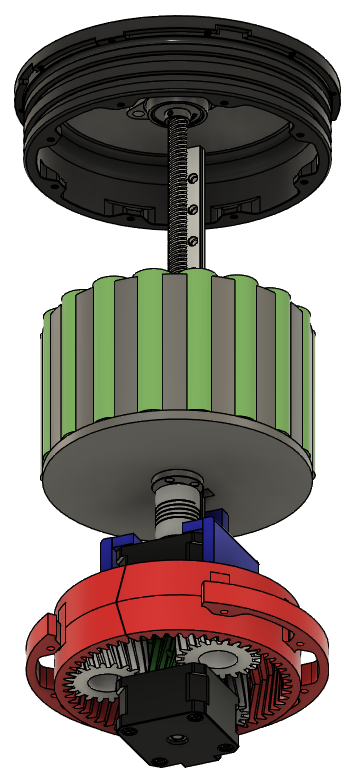

The glider will consist of three separate sections. These are buoyancy drive, mass shifter and electronics sections. Each section will be housed inside a 5" BlueRobotics pressure housing. This way, later we can upgrade the buoancy drive section to reach the full 1000m depth.

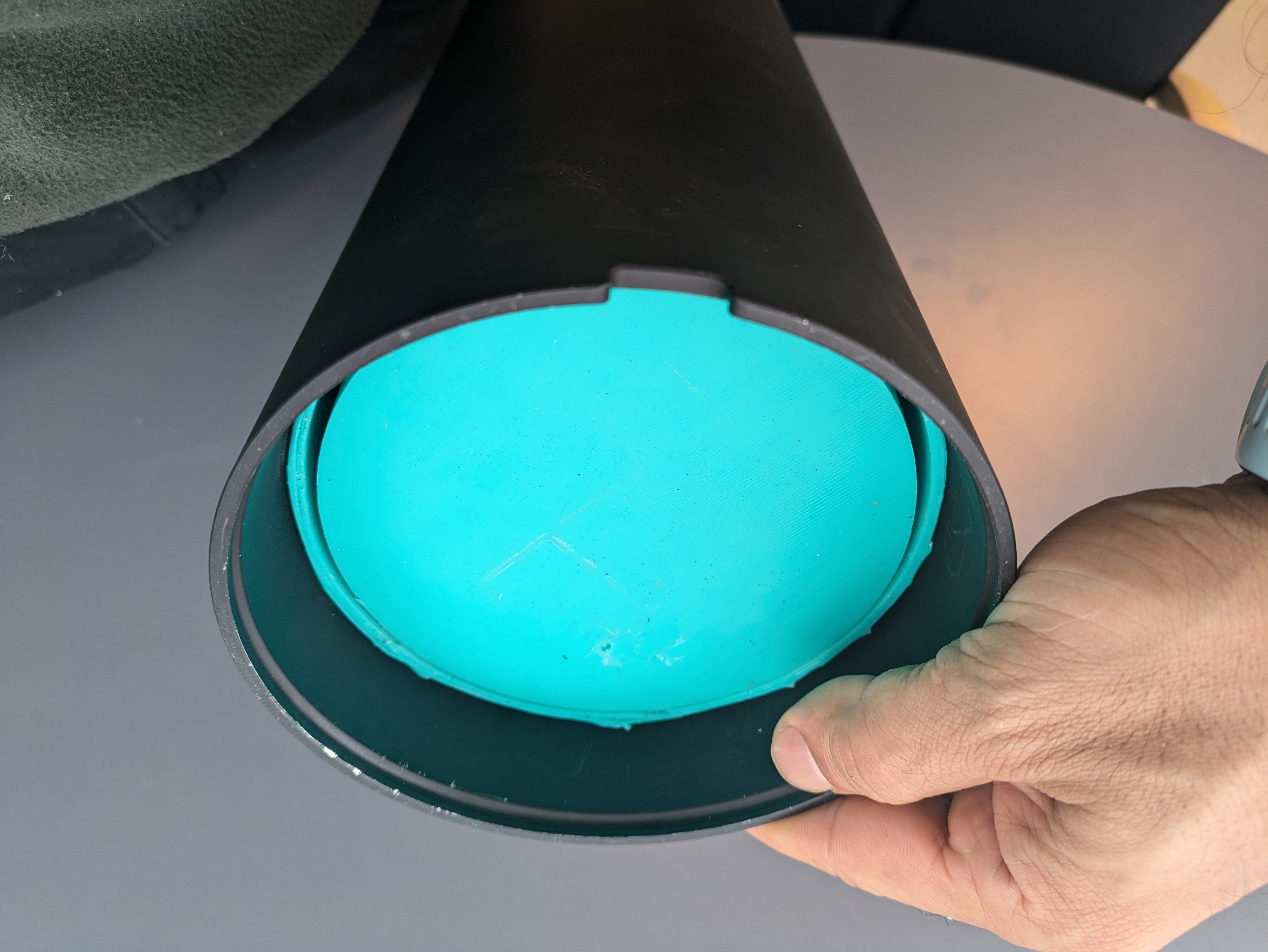

Initially I will focus on making a simple but robust buoyancy drive system. This will inistially consist of a custom-made rolling diaphragm and a linear actoator. Next step is to focus on the mass shifter system. As for comms, I am planning to use GSM and LoRa at the beginning and add Iridium at a later stage. The aim of this first build is to quickly and cheaply put together something functional and see what major changes needs to be done for the next version.

Ehsan Abdi

Ehsan Abdi