Tenodesis Splint

Assistive device for spinal cord injuries (SCI)

Assistive device for spinal cord injuries (SCI)

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

What if we opt for one of these choices?

Our concept for the new mechanism is to enable pinch grip through a mechanical system while adding an electronics to allow for precise control of the pinch.

The two actuators on which we are focusing are:

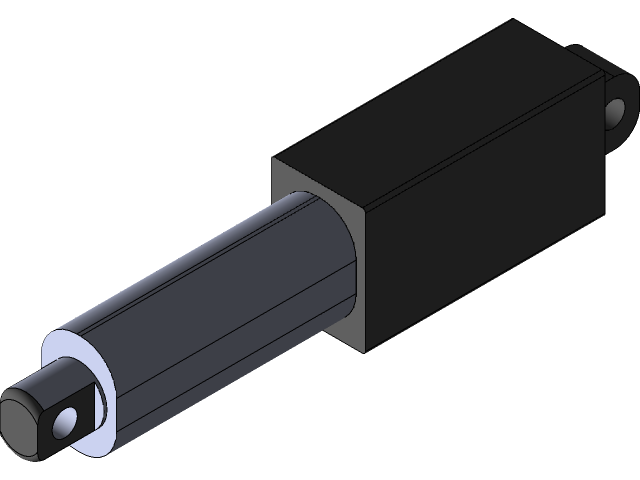

| ELECTRIC LINEAR ACTUATOR | SERVO MOTOR |

| A linear actuator is an actuator that creates motion along a straight line. It can be mechanical, electric, pneumatic, or hydraulic.  An electric servomotor typically needs to have low inertia, high voltage-to-speed and current-to-torque linearity, smooth rotation or translation, and minimal torque or force oscillation. It should also have no preferred positions and be capable of withstanding sudden power surges. | Here is an image of an RC Servo Motor that we could use to implement the pinch force regulation. A servomotor is a specialized motor, typically of small power, designed to handle wide and sudden variations in operating conditions. Unlike conventional motors, it must quickly and accurately adapt to changes in speed, driving torque, angular acceleration, operating cycle duration, and angular velocity. Servo motors are valued for their ability to provide high precision and control, which makes them essential in systems requiring accurate and responsive motion control. An RC (Radio Control) servo motor is a small, lightweight motor used in radio-controlled models. It controls angular positions within a 0 to 180-degree range. |

Here are some open questions we were able to ask WERO:

Thanks, WERO, for your support!

By now, everyone’s probably craving a simplified drawing of the Print Body Concept.

All the supports will be made from Nylon, except for the side splint.

Nylon (a.k.a. Polyamide) is a popular material in the plastics industry, known for its toughness and flexibility. Let's give it a chance to impress us with its properties!

When it comes to choosing the right material in the world of plastics, we often find ourselves weighing different properties and characteristics. In this post, we'll present you three key graphical descriptions: Young's Modulus, Yeld Strength, and Bulk Modulus. Each of these factors plays a fundamental role in determining the suitability of a plastic for various applications. So, which one would be your top pick when navigating the diverse world of plastics? Let's explore these options and see which might be the best fit for our needs.

The pros and cons of each option are noted on the small post-it. Rather than aiming for the perfect combination, the goal is to find an optimal compromise.

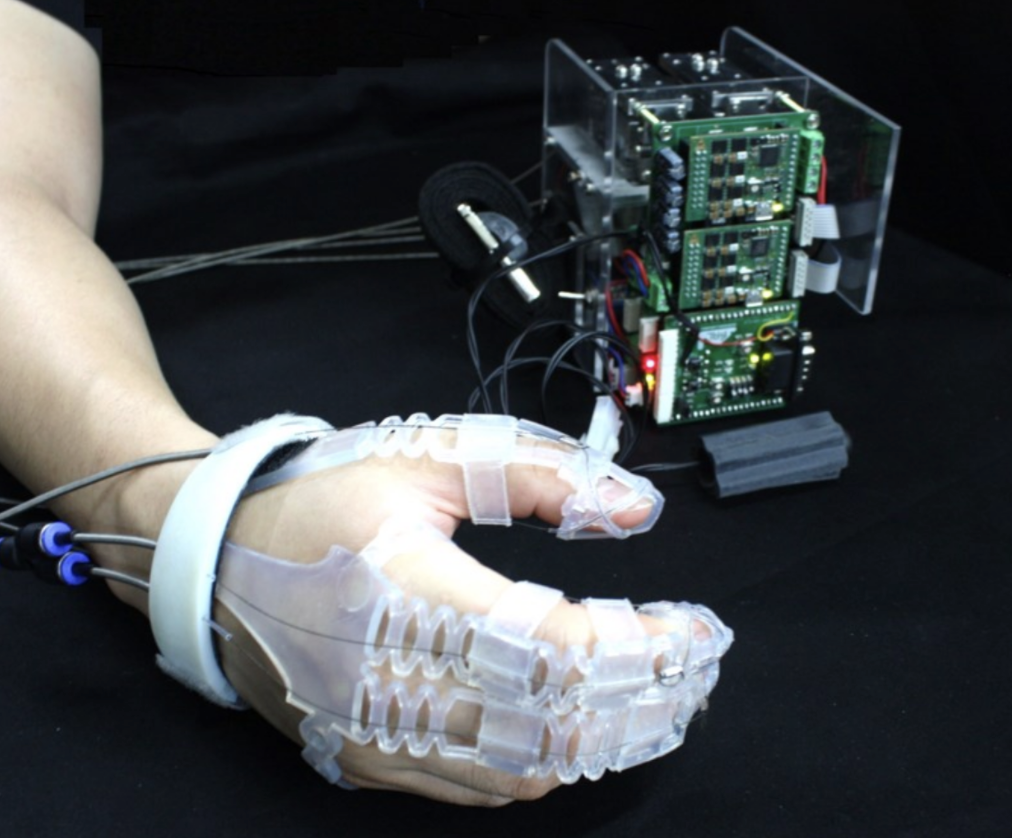

When we embarked on this journey about a year ago, it all began with an intense five-day program where we proposed a concept for a Soft Actuator Orthosis. The inspiration came from the innovative "Banana Fingers" project by MIT scientists.

Armed with a sphygmomanometer, we repurposed its micro air pump to inflate custom-made silicone chambers. We introduced a novel dual-IMU activation system, with sensors placed on the forearm and the back of the hand.

Since then, we've had the privilege of showcasing our system at the 2023 Supercon in Pasadena. We advanced our idea by integrating an hydraulic system syringe driven by an electronic linear actuator with the dual-IMU sensing system.

We're committed to a User-Centric Approach. The research we've conducted in recent weeks is crucial to this mission, driving us to propose new, user-focused innovations.

In this journey of innovation, it’s always exciting to see who’s stepping up to the challenge. If you have any insights or ideas that could help us uncover new opportunities, we’d love to hear from you!

Collaboration is key to pushing the boundaries and discovering fresh perspectives that can take our work to the next level.

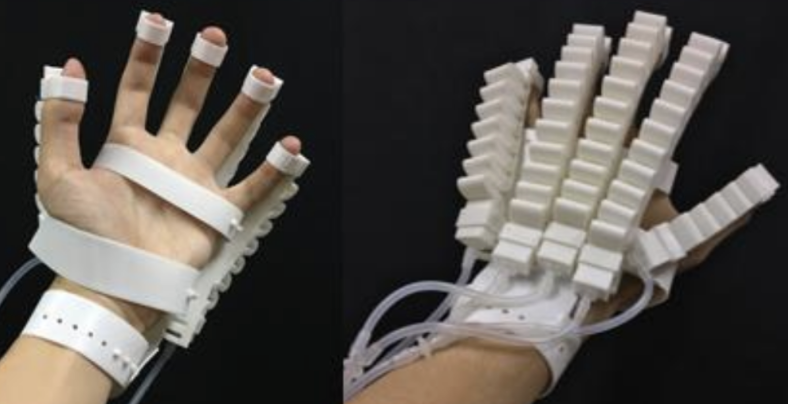

| Name of device | Overview | Video | Manufacturer | Classification |

| Exo Glove Poly |  | SNU Biorobotics Lab | Commercial device | |

| PIY Glove |  | University of Singapore | Commercial device | |

| SEM GLOVE |  | Bioservo | Commercial device | |

| Power Driven Flexor Hinge |  | Jaeco Orthopedic | Commercial device | |

| NeoMano |  | Neofact | Prototype | |

| RELab tenoexo |  | Hoffman et al. | Prototype |

In this blog post, we explore two journey maps that detail the user experiences of different orthosis types: the Soft Actuator Orthosis and the Flexor Hinge Splint.

Journey maps are powerful tools that break down the entire process a user goes through when interacting with a product, from initial engagement to final outcomes. They help us understand not just the physical steps but also the emotions, pain points, and opportunities for improvement at each stage.

The journey map covers the user's experience from putting on the device to using it for various tasks. It begins with wearing the orthosis through easy band sraps and adjusting the thumb and the fingers inside the support. The map highlights the challenges users face during setup, such as the presence of a thick thermoplastic material and the complexity of positioning the fingers correctly. As the user progresses to activating the device, switching on the actuator system can be cumbersome, often requiring precise movements and adjustments. The map notes how well the device performs in tasks like grasping and releasing objects, underlying both the strengths — such as ease of learning — and the limitations, such as delayed finger actuation and the need for improved grip control.

The wearing phase, requires the user to secure the device to the forearm and ensure that the thumb is properly supported. The map identifies pain points such as discomfort due to metal-skin contact and the difficulty of inserting fingers into the correct position. As the user moves to using the splint, the map illustrates the challenges of grasping objects, particularly when the wrist is extended. It notes that while the splint allows for natural hand movements without the need for external power, it struggles to accommodate all the various hand positions required for different types of grips, making some tasks difficult.

These journey maps are not just step-by-step guides; they provide a holistic view of the user’s interaction with the orthosis, capturing both practical and emotional responses. By breaking down each stage—wearing, activation, usage, and removal—we can identify where users experience satisfaction and where they encounter frustration. This insight is invaluable for designers and engineers, as it points to specific areas where improvements can be made to enhance the overall user experience.

What types of orthosis are currently available on the market? Understanding the various orthosis already developed is crucial for appreciating the choices made by other designers and engineers. Among the wide range of options, we’ve identified several key categories for assistive hand orthoses:

Mechanical

Electronic

Innovating within these categories involves a thorough examination of the advantages and limitations of each technology. To facilitate this, we have developed a journey map to guide our exploration.

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates