Need Statement: A way for the MBEEC to store petri dishes and separate sediments in a quick, organized, and intuitive manner, so that students can spend more time learning and observing sediment under a microscope.

Specifications:

— Is capable of holding the necessary amount of petri dishes securely

— Is intuitive enough to be used by both staff and students, allowing for each petri dish to be uniquely identified

— Minimal size allows for product to be placed on the table as well as easily stored on the boat

— Reduces the time the process takes for MBEEC educators to sort the sediment samples

— Can maintain stability in a moving boat without being secured

| Description | Measurement | Units | Target Value |

| The petri dish holder should be able to tip over without dropping any petri dishes | angle | deg | 90 |

| The MBEEC needs a certain number of petri dishes | # of petri dishes | ea | 8 |

| The petri dishes are already owned so need to fit in designed product | size of petri dish | cm | under 9.5 cm

|

| The number of steps it takes for both students and staff to receive petri dishes | steps | # | less that previous |

| Can fit within the storage and table space allotted | storage/ table space on boat | cm/sq | fits on table |

| The time it takes for Tim to organize the sediment collected into the petri dishes | time it takes to organize sediment | seconds | 210 |

Design Description:

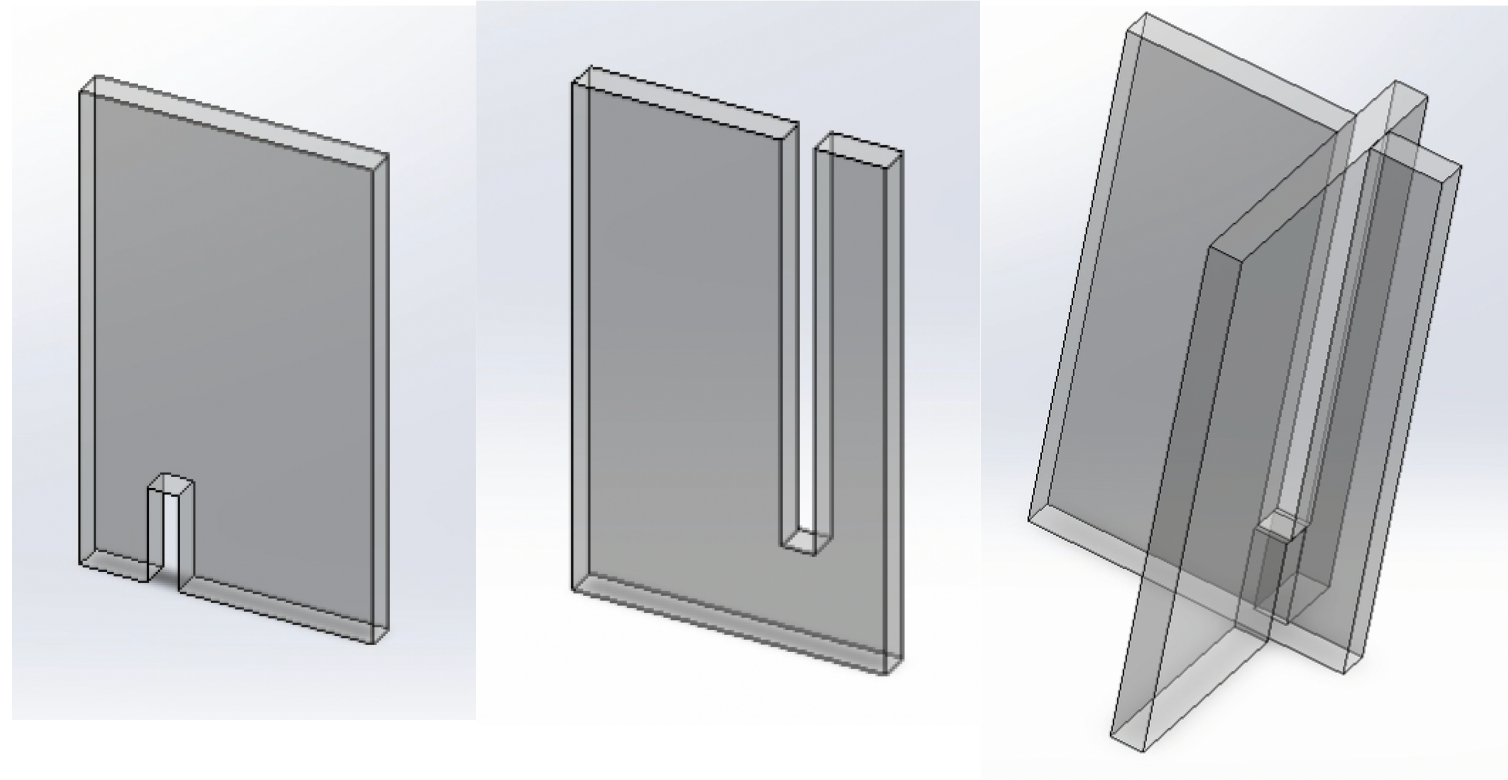

— We considered different materials and settled on acrylic as it is water-resistant, salt water safe, and durable. Additionally acrylic material is compatible with Laser cutting machines and is readily available.

— Color coding the shelves allows for easy identification of each petri dish, as they differ based on the size of the sieving plates used to sort the sediment samples.

— Additionally, 3D printed figures were printed in order to identify between the two sites where sediment is collected.

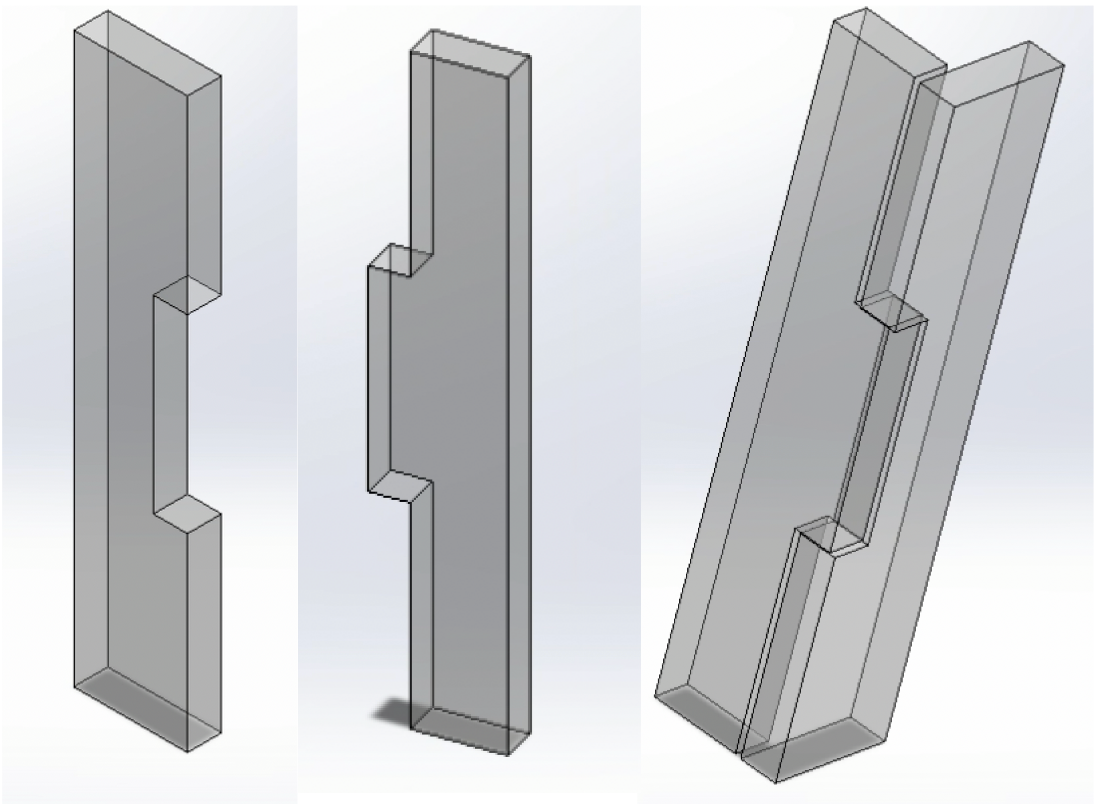

— In order to keep the Petri dishes safely inside the structure without using additional space when set on the table, a sliding door mechanism was implemented. This additionally made it possible to only expose one site at a time.

— The way chosen to secure the doors is by placing magnets upon each of the doors. Four on each corner of the door, and one on the side shelves. This allows us to secure the doors in different positions whether that be fully closed, or partially open and exposing only one of the sites when required.

— The client additionally asked to implement handles into the design during one of the feedback review sessions. Therefore after exploring different options, it was decided to include rope handles as it allows for the user to carry the storage system in one hand as you would a gift bag. It also has the ability to compress and lay flat which is beneficial for storage purposes.

— The individual petri dishes were labeled with color coordinated paint pens to correlate them to the colored shelves allowing for easy identification amongst children of all ages.

— In this current design, the largest petri size used was 8.2mm x 2.1mm. Dimensions may need to be adjusted depending on the size of petri dishes used in other scenarios.

Testing:

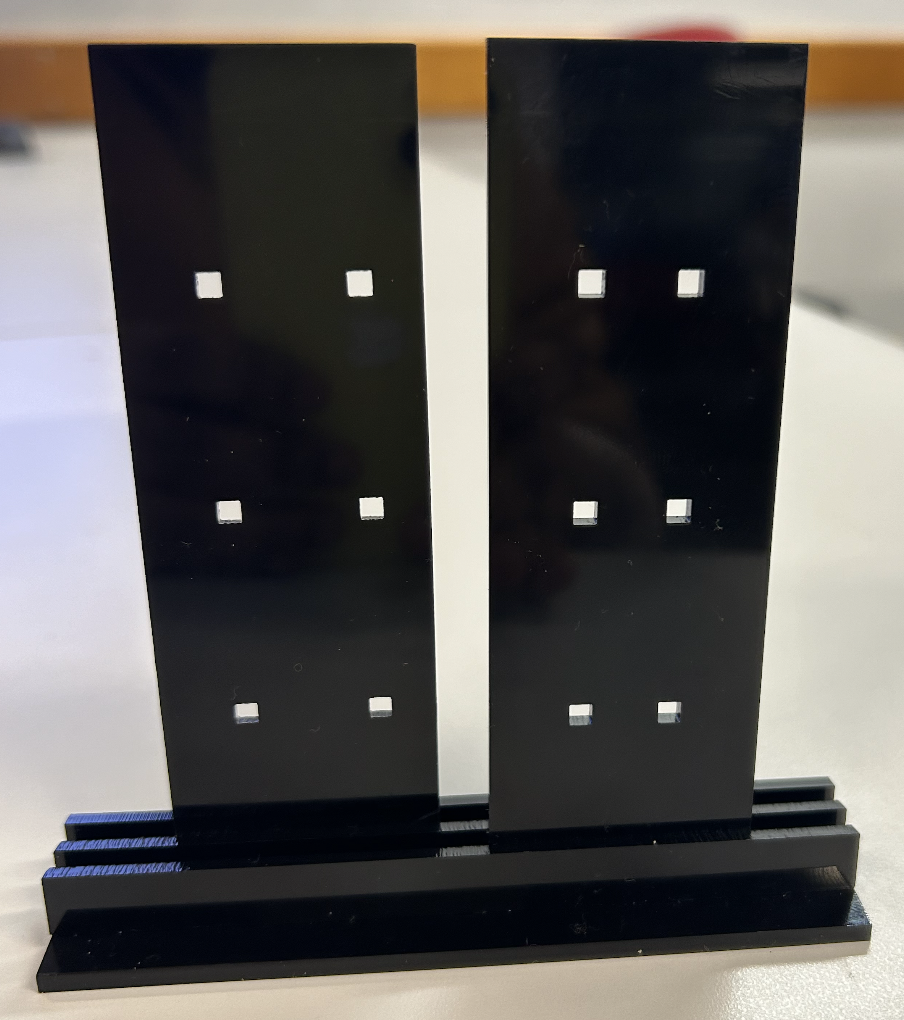

— Different connections such as edge lap joints, end joints and multiple end joints were tested to identify the most secure method for connecting the acrylic panels.

— Rough prototyped assemblies were produced to ensure the chosen connection methods can be assembled in a relatively simple manner.

— Different tolerances between the sliding doors were tested to ensure doors slide as seamlessly as possible.

Conclusion:

— In the future, some things we would reconsider in the design include amending or changing the style of the edge lap joints as a few snapped along different steps of the cutting, assembly and delivery of the product. None of this affected the structural integrity as of this time, but posed some questions for further analysis.

— Overall, the assembly process required some finessing in order...

Read more »

Nickcasio

Nickcasio

TAIBHSE DESIGNS

TAIBHSE DESIGNS

Stjerne

Stjerne