I hate smartphones. They're designed to be disposable, fragile, obtrusive, addictive, and penetrative. The modern ones are so obviously a surveillance device and a money grab I just hate having one on me. However, access to data for navigation and more common things like text and voice is somewhat necessary for the traveling I do. To both solve this social problem I'm experiencing and to improve my hardware and software skills I've decided I'm going to build a "fantasy console," aka a cyberdeck. However, I want mine to have cellular phone functionality if possible. The wishlist for the device:

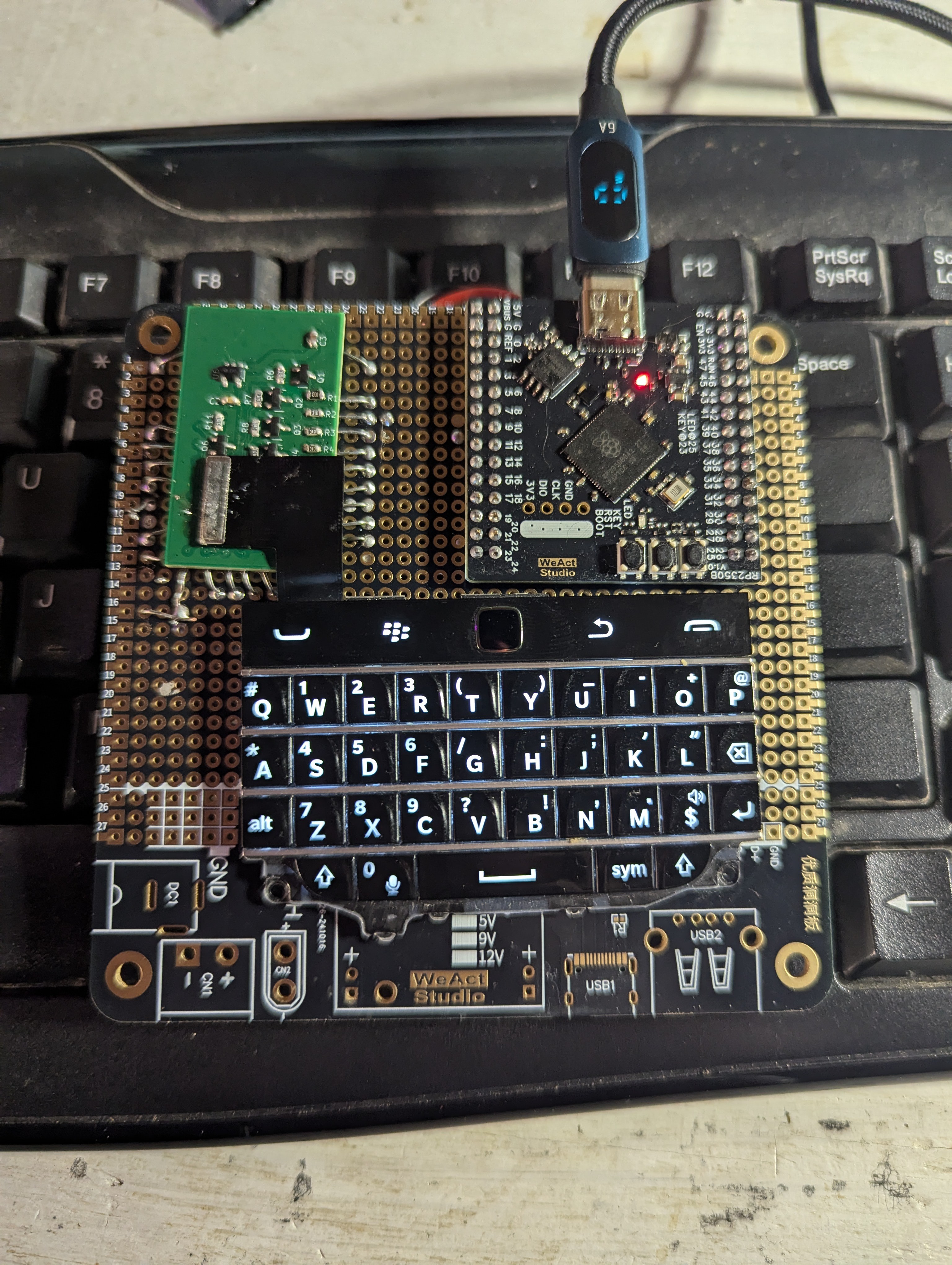

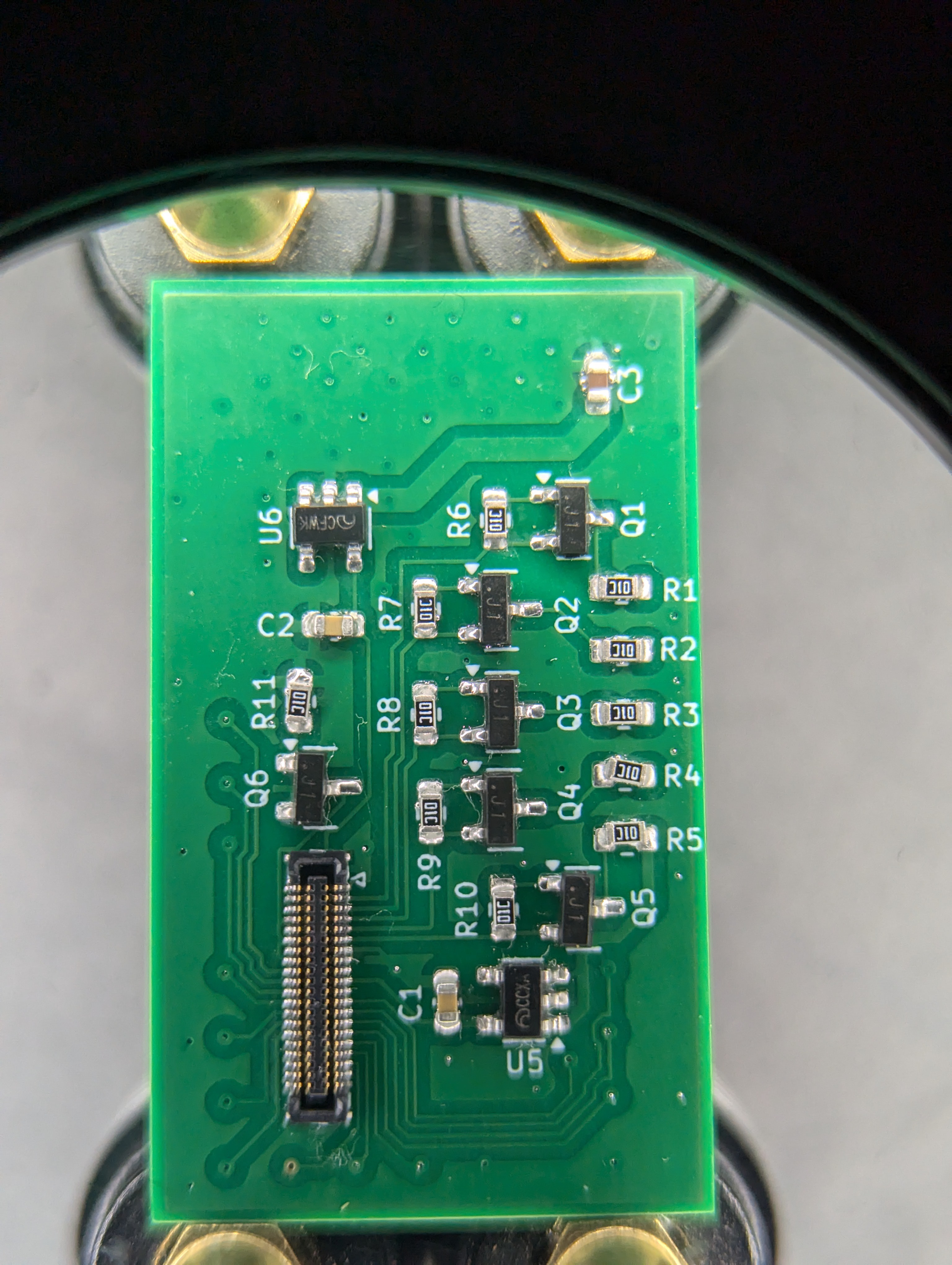

1) all components need to be easy to obtain, work with, repair, and replace. Nothing proprietary.

2) No touch screens, as their interface is power hungry and unnecessary most of the time.

3) Device should be complex enough to handle a Linux distro

4) Device will include some GPIO ports a la the Flipper Zero for add-ons

5) Physical switches capable of hard-cutting power on comm modules (LTE, WiFi, GPS, LoRA)

6) Optional: include LoRa capability on board

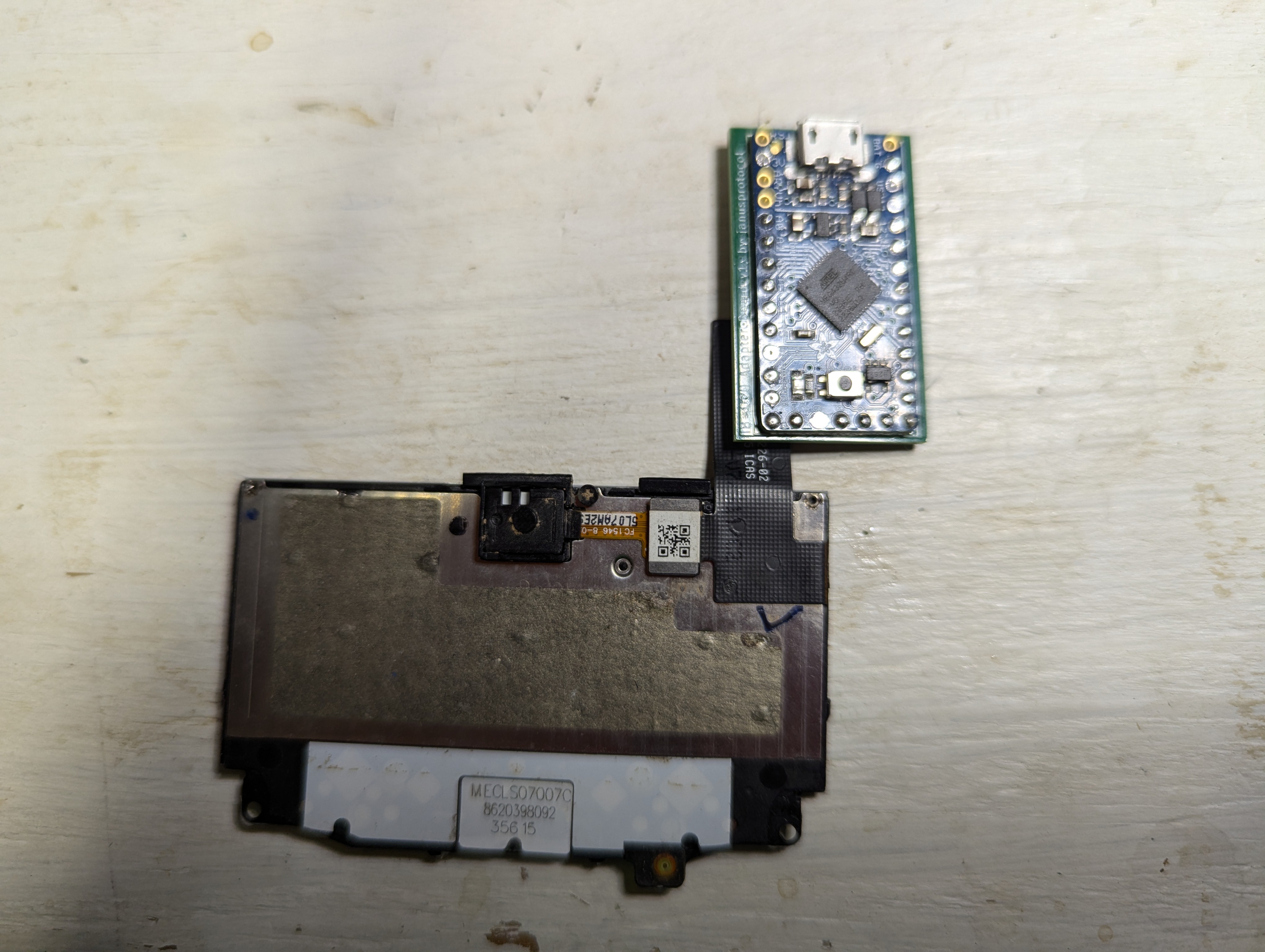

janusprotocol

janusprotocol

deʃhipu

deʃhipu

Mx. Jack Nelson

Mx. Jack Nelson

RasmusB

RasmusB

Pamungkas Sumasta

Pamungkas Sumasta

The hardest part of this project is going to be the software. I've been writing a graphics stack that includes widget library for devices like this for a decade and I'm still at a beta phase at best.

I also have userspace drivers for SPI displays I find them easier to work with than DSI and for small displays SPI is fast enough. SPI display with ST7789 and 320x480 resolution can be clocked fast enough to play video and the driver looks like this https://github.com/gfxprim/gfxprim/blob/master/libs/backends/linux/gp_display_st77xx.c