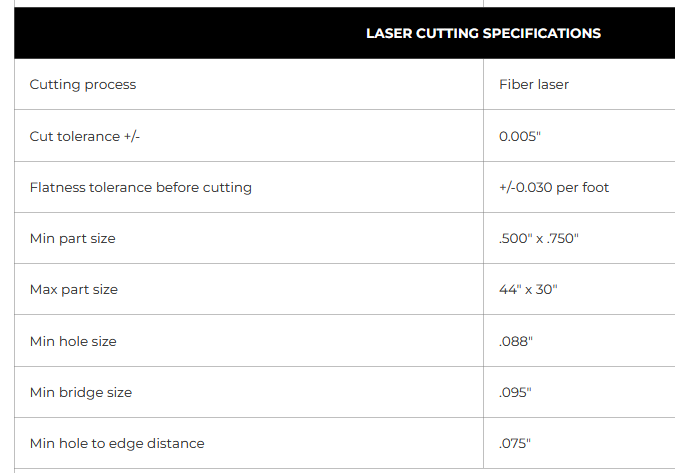

Read the specs! My plate got rejected because the holes were too close to the edge and violated some DFM rules from the fabricator:

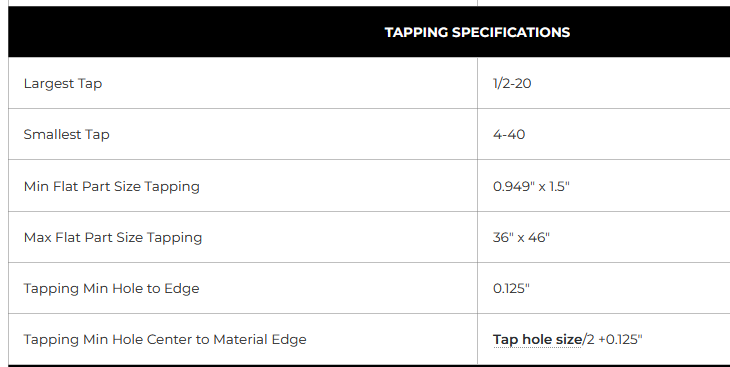

Then it got rejected again because the _tapped_ holes were too close still:

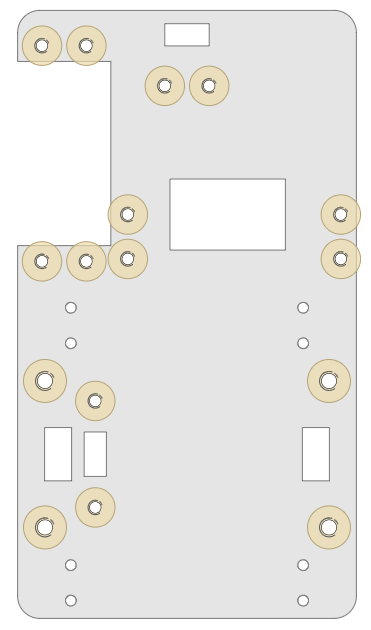

Then it got rejected again because the _tapped_ holes were too close still: For the second round, a helpful customer service rep sent a picture with minimum clearances around each hole, which highlighted the eight offending taps (and eight taps that were within spec, since the yellow circle stayed within the outline):

For the second round, a helpful customer service rep sent a picture with minimum clearances around each hole, which highlighted the eight offending taps (and eight taps that were within spec, since the yellow circle stayed within the outline): Dang, they were patient with me. With any luck the latest iteration goes through; I moved a few taps in a bit where I could, and changed the servo mounts to non-tapped slots. Hooray for helpful vendors. I'm so used to checking design rules for PCB vendors; maybe I didn't think about it much here because I'm used to bending the waterjet cutter to my will and probably making non-conforming parts in the process. Slow down, do engineering, etc.

Dang, they were patient with me. With any luck the latest iteration goes through; I moved a few taps in a bit where I could, and changed the servo mounts to non-tapped slots. Hooray for helpful vendors. I'm so used to checking design rules for PCB vendors; maybe I didn't think about it much here because I'm used to bending the waterjet cutter to my will and probably making non-conforming parts in the process. Slow down, do engineering, etc. zakqwy

zakqwy

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.