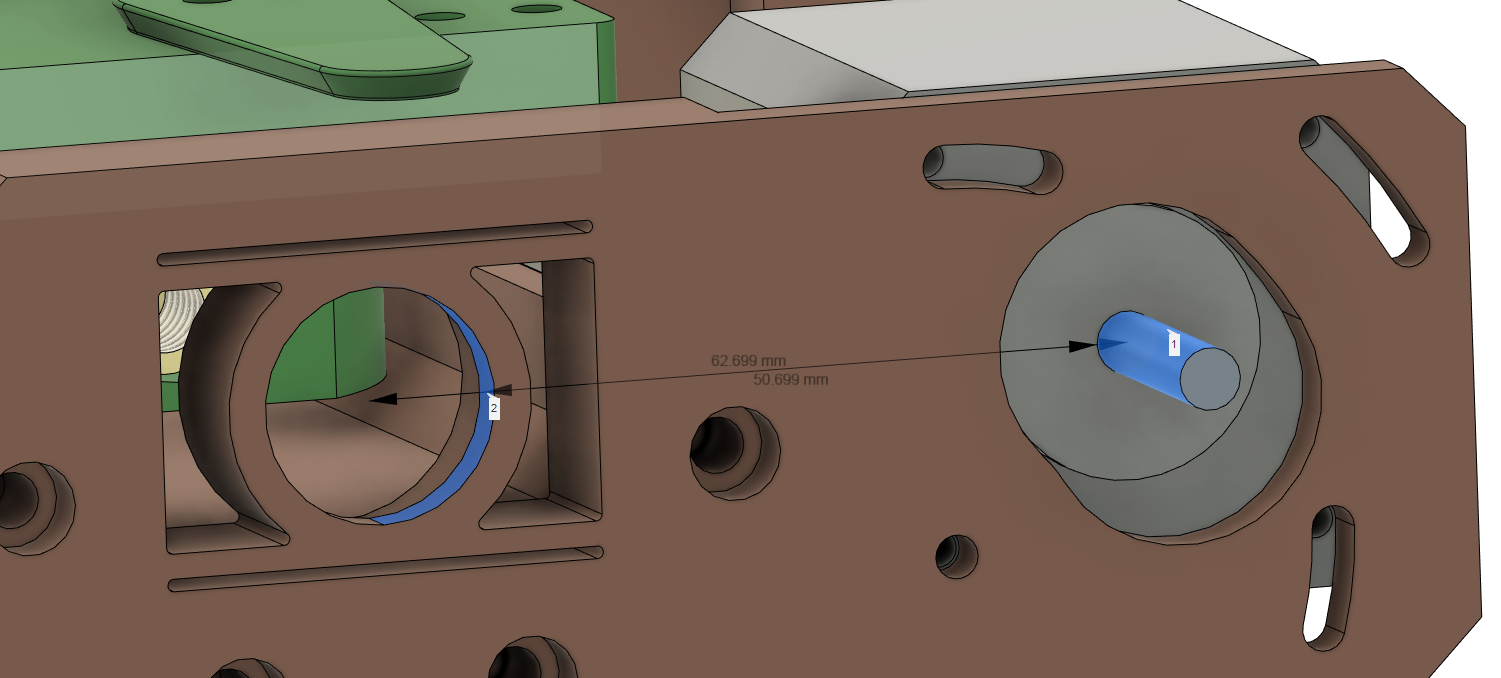

I measured center-to-center distances in CAD for nominal motor mount positions (i.e. not rotated in the generous tensioning mechanisms)

Perhaps not the cheapest option, but I'll find use for extras, and I really want motors spinning lead screws (and spindles) next weekend! Much yet to explore once the machine is powered, and only a few weeks left to do it. At some point before then, I'll bring the lead screws in to work and cut them down before starting my day; hacksawing a few long M3 screws is one thing, but I really can't be Dremeling hardened steel lead screws in my tiny Cambridge apartment. And the general backup plan in case the belts are the wrong size: print different size pulleys, I suppose.

Perhaps not the cheapest option, but I'll find use for extras, and I really want motors spinning lead screws (and spindles) next weekend! Much yet to explore once the machine is powered, and only a few weeks left to do it. At some point before then, I'll bring the lead screws in to work and cut them down before starting my day; hacksawing a few long M3 screws is one thing, but I really can't be Dremeling hardened steel lead screws in my tiny Cambridge apartment. And the general backup plan in case the belts are the wrong size: print different size pulleys, I suppose. Oh! And! The pulleys should have integrated handwheels, so it's a bit easier to move the machine manually. The R-axis has a limit switch but I got impatient this past weekend and didn't build in mounts for X- and Y-axis limit switches, and probably wouldn't find time to install, wire, and program their operation anyway. So being able to quickly manually move axes around before powering up the steppers will be nice. Although I haven found that the 4-flight lead screws backdrive pretty well, so maybe it's a non-issue.

Oof, should I have geared the steppers down at all, and bought bigger belts? I think I did this calculation earlier; I think the lead screws travel 8 mm per rotation, so at 190 steps that means ~40 microns of travel per step. Microstepping gets me a bit further, but even without it that should be good enough for a demo, right?

zakqwy

zakqwy

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.