-

Main PCB Design

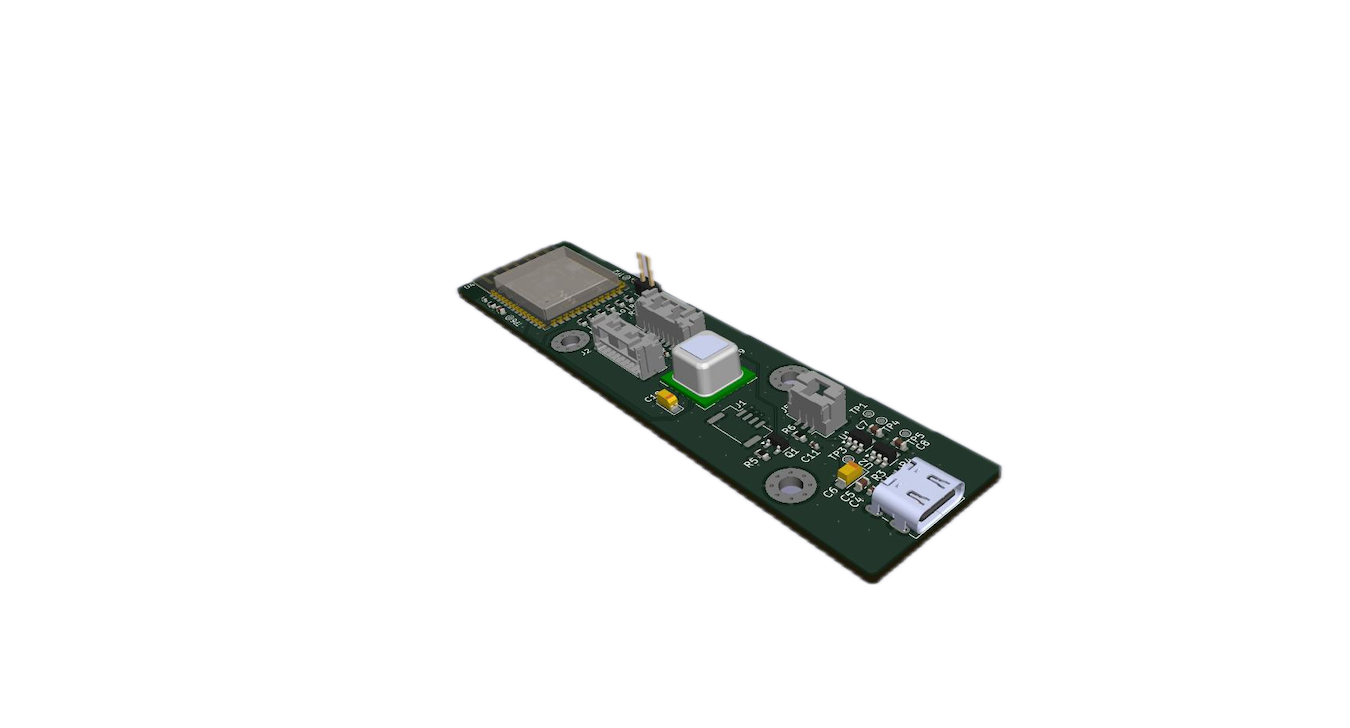

09/23/2024 at 04:55 • 0 commentsOnce I selected the appropriate processor and sensors, it was onto the PCB design

![]()

Designing the printed circuit board (PCB) for my smart hive project was an intricate and rewarding process, and it wasn’t something I tackled alone. Recognizing the complexity involved, I decided to collaborate with a talented university student who brought fresh insights and technical skills to the table. Together, we worked on laying out and designing the PCB, ensuring it would meet all the specific needs of my IoT beekeeping system.

The PCB serves as the central hub where all the electronic components connect, making it essential to get the design just right. We had to carefully consider the physical constraints of "bee space" and ensure that the board was compact yet efficient, fitting seamlessly into the hive without disrupting the bees. Additionally, the layout needed to optimize power efficiency and signal integrity while minimizing noise, crucial factors for maintaining accurate data transmission from the various sensors.

The collaborative effort allowed us to combine practical engineering with innovative design, resulting in a PCB that not only functions perfectly but is also easy to assemble and integrate into the hive. This experience underscored the value of merging academic knowledge with hands-on experience, leading to a design that will serve as the foundation for the ongoing development of my smart hive prototype.

You can view details of the board, components and wiring in 'Files.'

-

The Answer is Blowing in the Wind

09/23/2024 at 04:00 • 0 commentsBees actively manage the air quality within their hives

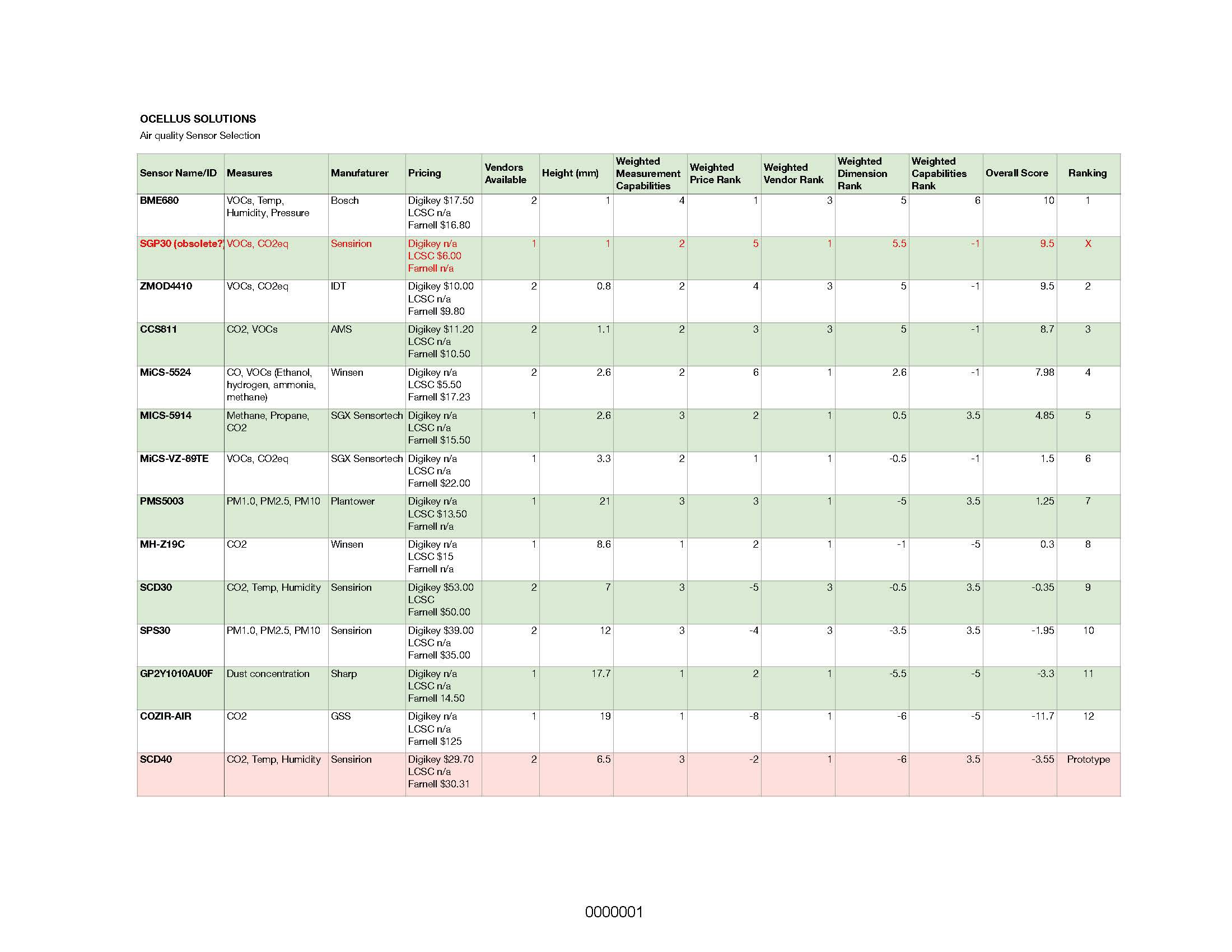

Monitoring CO2 levels inside the hive became a priority for me because elevated levels can signal issues like overcrowding or poor ventilation, which can stress the colony. I needed to select a CO2 sensor compact enough to fit within the hive's "bee space" while also maintaining low power consumption and high sensitivity. Getting accurate CO2 measurements is critical to allowing me to respond quickly to potential issues and ensuring my colony remains healthy and productive.

![]()

-

It's All About the BUZZzzzZZzzzZzzzZZZzzzz

09/23/2024 at 03:40 • 0 commentsWhat set's our IoT project apart from all others is the reliance on Machine Listening.

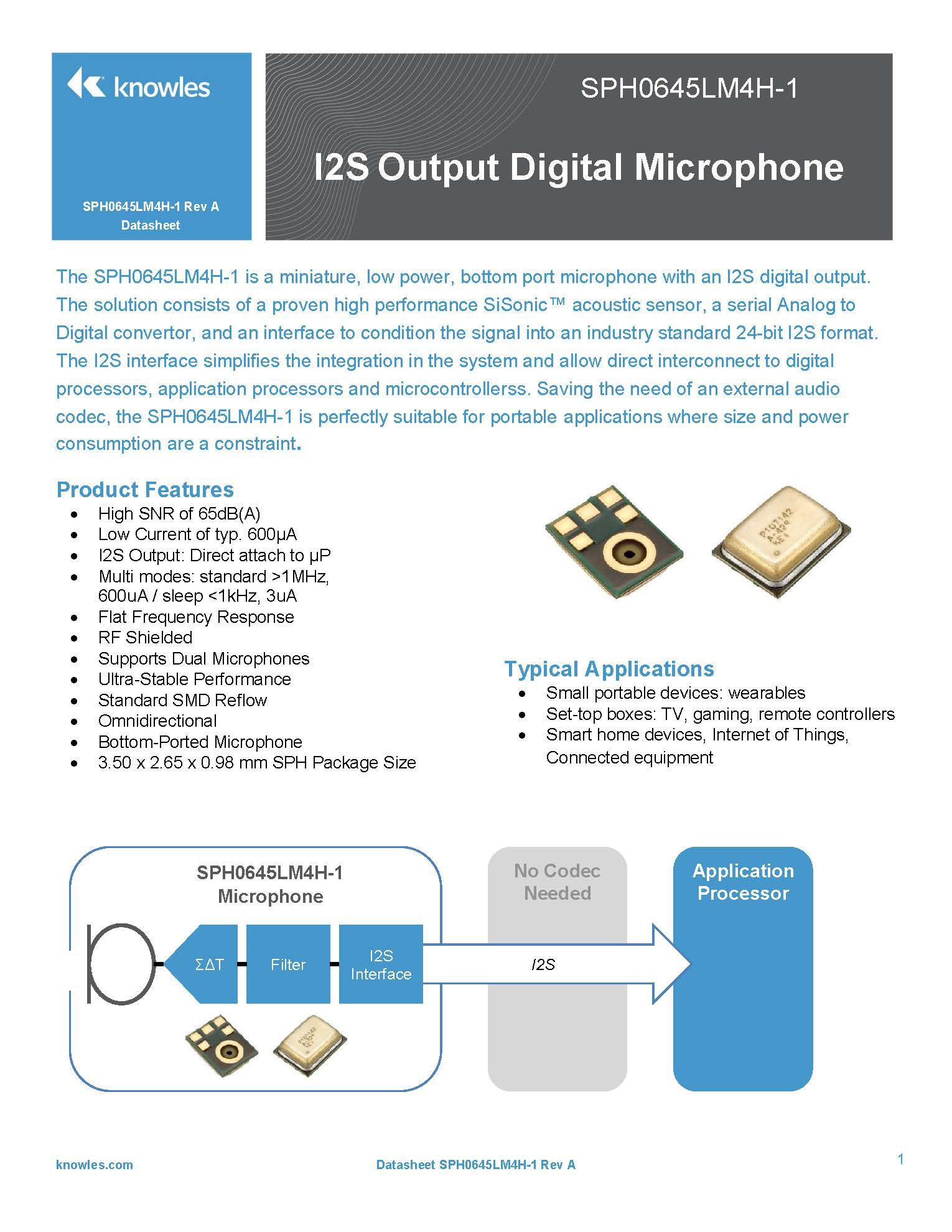

When it came to monitoring the sounds inside my hives, choosing the right microphone was a critical decision. The selection process began with a deep dive into the unique acoustic environment of a honey bee colony. Understanding the frequency ranges, sound patterns, and decibel (dB) levels of bee communication was essential. Spectrograms, which visually represent the frequencies of these sounds over time, provided valuable insights into the specific acoustic signatures I needed to capture.

After extensive research and consultation with experts—including entomologists specializing in bee behavior, physicists focusing on acoustics, and engineers from leading companies—I made an informed decision. I spoke with professionals at Knowles, TDK, GoerTek, and Brüel & Kjær to narrow down the options. Ultimately, I selected the Knowles MEMS I2S microphone for my prototype. This microphone was chosen for its precise sensitivity, low power consumption, and ability to capture the critical frequency ranges of bee sounds accurately. Its small form factor also fits perfectly within the "bee space," ensuring the microphone could be integrated seamlessly into the hive without disrupting the colony.

I'll post the datasheet from the Knowles mic we use in our prototype in documents and the cover page here.

![]()

-

40W of Heat Energy

09/22/2024 at 22:48 • 0 commentsCan you imagine - 40,000 bees can generate up to 40 watts of heat energy.

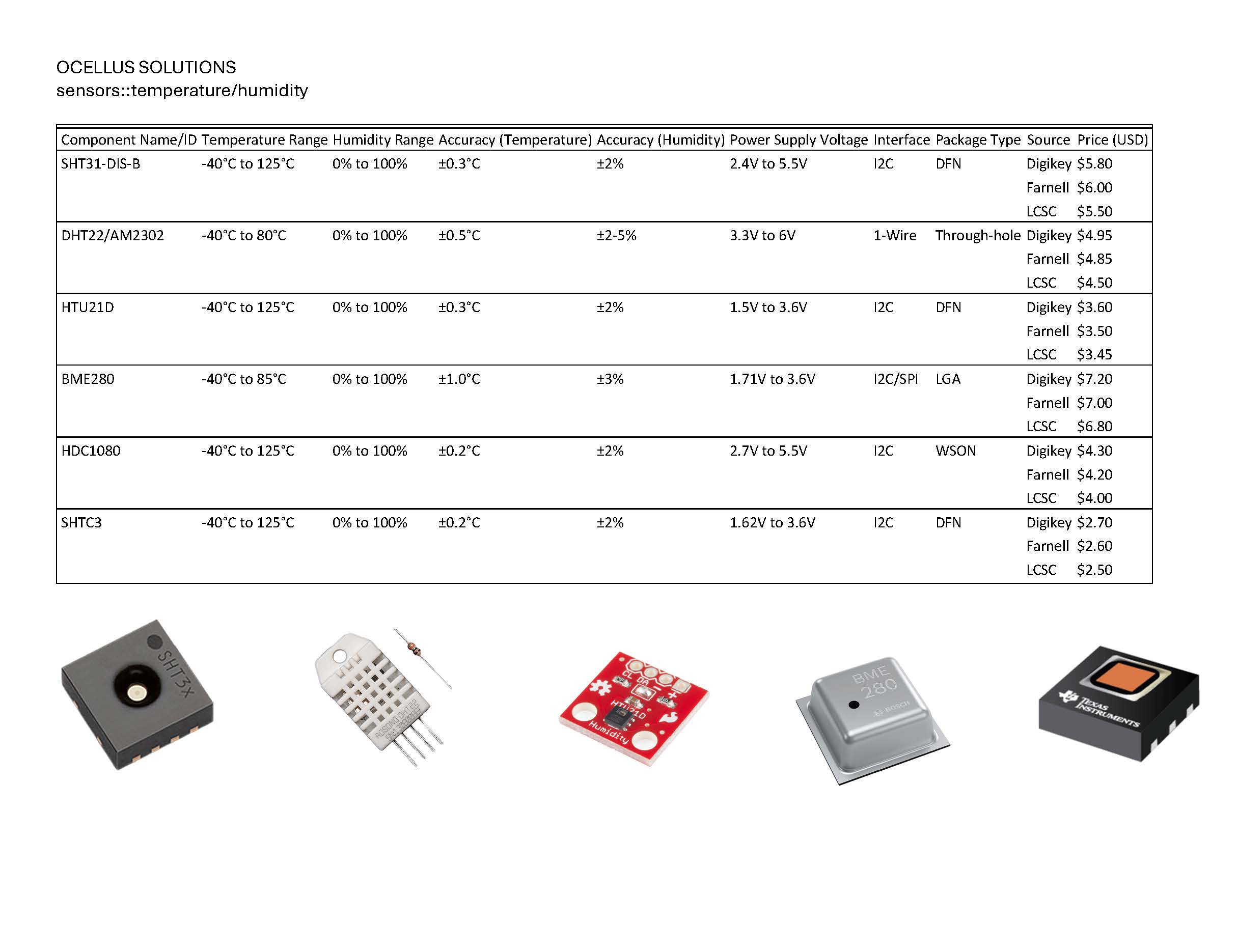

Honey bees need to keep the temperature and humidity within a hive within a certain specific range if the baby bees (eggs, larvae) are going to develop. It's kinda like a hen sitting on an egg. Without these conditions, the next generate of bees might be lost.

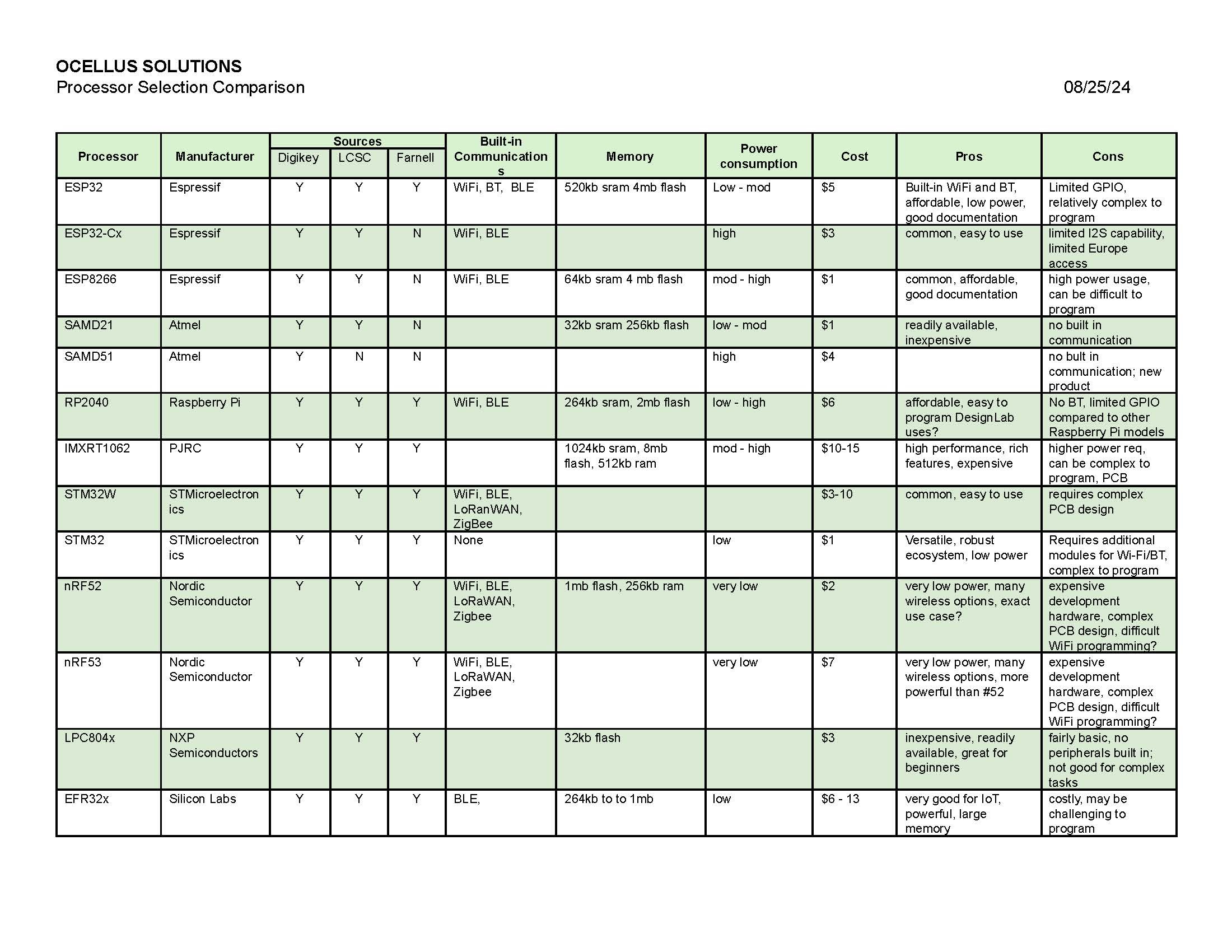

Temperature and humidity are key indicators of hive health, so I knew I needed to get this part of my design right. In my smart hive prototype, selecting the right sensor to measure these parameters is crucial for accurate, real-time data collection without sacrificing size or power efficiency. I also had to ensure that these sensors fit within the limited "bee space" inside the hive, all while providing reliable, long-term performance in such a unique environment.

![]()

![]()

-

What's an MCU?

09/22/2024 at 22:42 • 0 commentsYou'll recall I have NO background in electronics. I come from a career in healthcare. So when I first heard we needed to select an "MCU" for our board, I was left to conjure up some sort of medical abbreviation ... maybe Medical Care Unit?

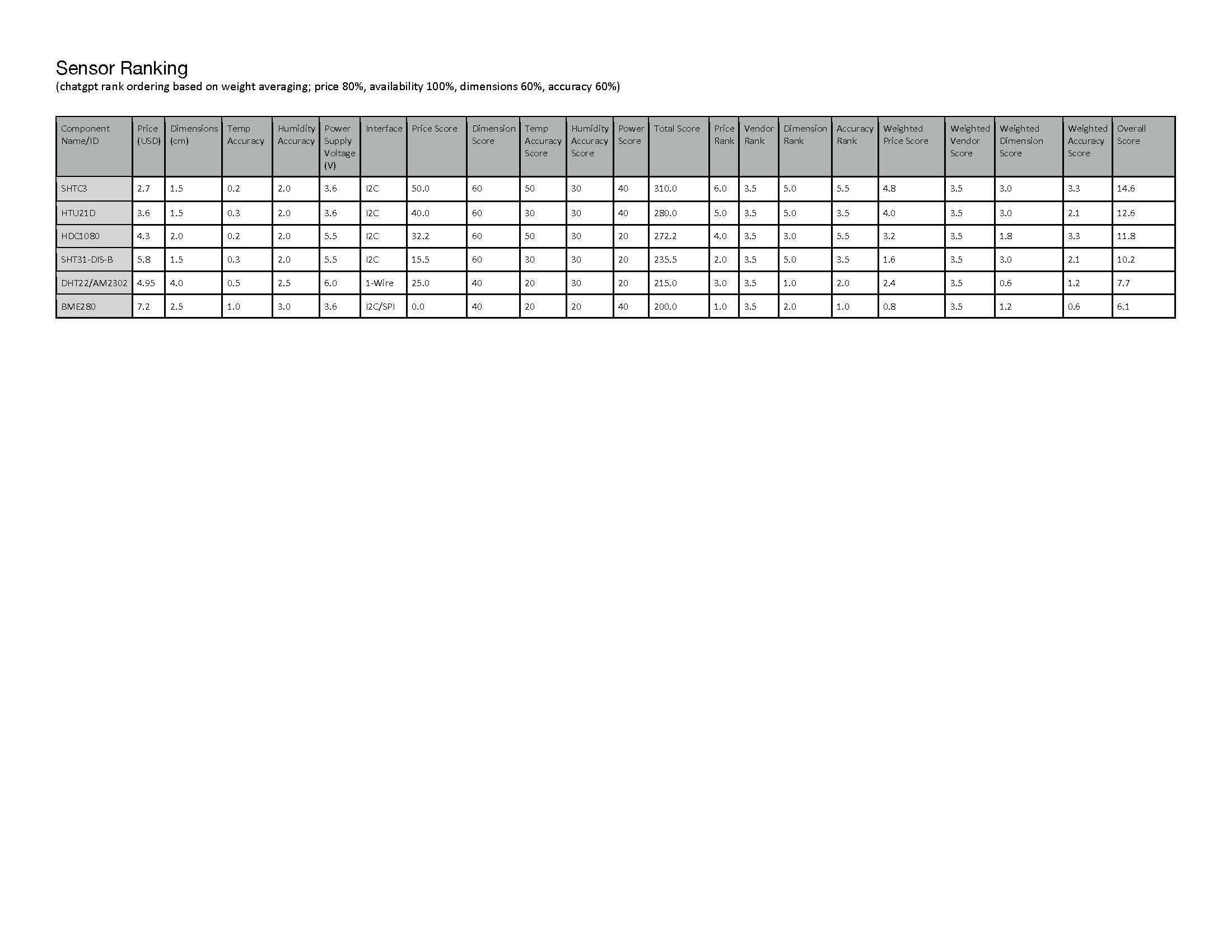

Having learned that the microcontroller unit (MCU) is the brain of my IoT-enabled beehive monitoring system, making it one of the most critical components in my design. I had to consider several factors when choosing an MCU, such as processing power, energy efficiency, and ease of programming, all of which directly affect the performance and longevity of my prototype. To help with the selection, I created a table comparing various MCU options, focusing on trade-offs between processing capability, power consumption, and physical size

![]()

-

Measure Twice (or 22 times), Fit Once

09/22/2024 at 22:38 • 0 commentsMy first digital caliper!

Little did I know I needed such an instrument.

I quickly realized how crucial it is to carefully select the right electronic components. From my perspective, these components need to be easy to assemble, solder, and wire while keeping power demands low to extend battery life. But I also had to consider the unique constraints of beekeeping, particularly the concept of "bee space"—a gap of roughly 4-8mm that bees naturally maintain within the hive. Ensuring my electronics fit within these dimensions was essential to avoid disturbing the hive environment.

-

Hive Tech - Using IoT to Save the Bees

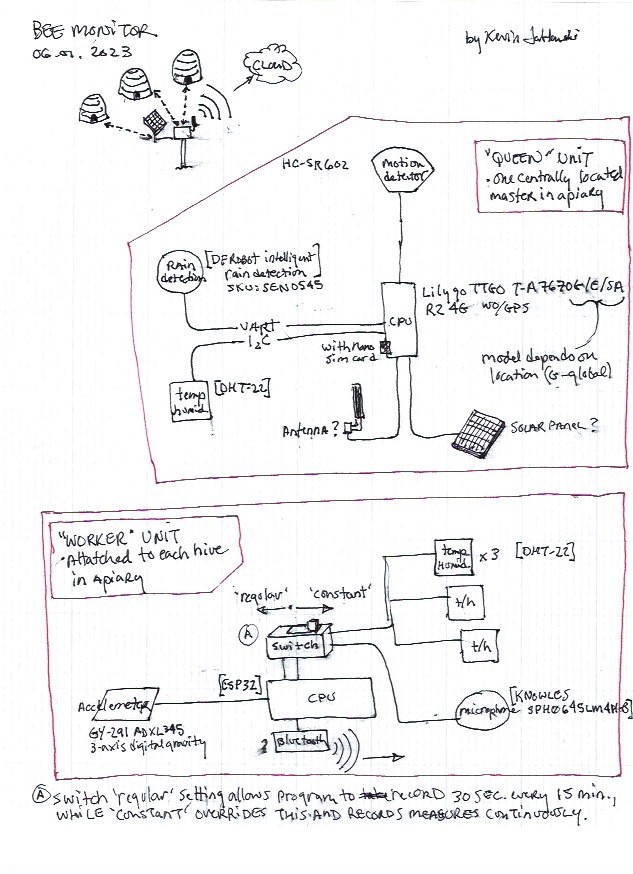

09/22/2024 at 21:41 • 0 commentsIn modern beekeeping, maintaining the health of multiple hives across an apiary is a challenging task, often requiring frequent, intrusive inspections that can stress the bees and disrupt colony activities. By leveraging IoT technology, beekeepers can monitor hive health remotely, reducing the need for these disruptive checks. The concept involves placing sensors in each hive to measure critical parameters like temperature, humidity, CO2 levels, and sound. These sensors transmit data to a central unit—aptly named the "queen unit"—which collects and processes the information for real-time insights into each hive's condition. This setup allows beekeepers to identify issues early, such as the onset of swarming or the presence of pests like Varroa mites, without opening the hives. The centralized data collection not only simplifies hive management but also supports scalable monitoring across large apiaries, enabling proactive and less invasive care of the colonies.

![]()

-

It's called 'Destructor' for a reason

09/22/2024 at 21:33 • 0 commentsControlling the parasitic mite Varroa destructor is critical to saving our honey bees and our livelihood.

![]()

Varroa destructor ("Varroa") is a parasitic mite that poses severe risks to honey bees. The mites initially attach themselves to the bee larvae and live off their hemolymph (bee 'blood'). They also attach themselves to adult bees. While their parasitation doesn't often kill the bee directly, these mites cause the bees to become weakened and more subject to disease. Diseases that can be transmitted by the mites themselves. The difficulty controlling Varroa is complicated by challenges in early detection. Our IoT device will help beekeepers by notifying them early in infestation so they can take action. This should help the colony maintain its health.

-

Buzzing into IoT : My First Prototype

08/11/2024 at 23:01 • 0 commentsNot knowing anything about IoT, I applied concepts from my public health background to organize the process.

![Earliest sketch of component selection process Earliest sketch of component selection process]()

Taking on the challenge of building my first IoT prototype for monitoring beehives was like someone afraid of bees encountering a large swarm – a bit frightening. Here’s how I went from zero to prototype, navigating the basics and creating my prototype.

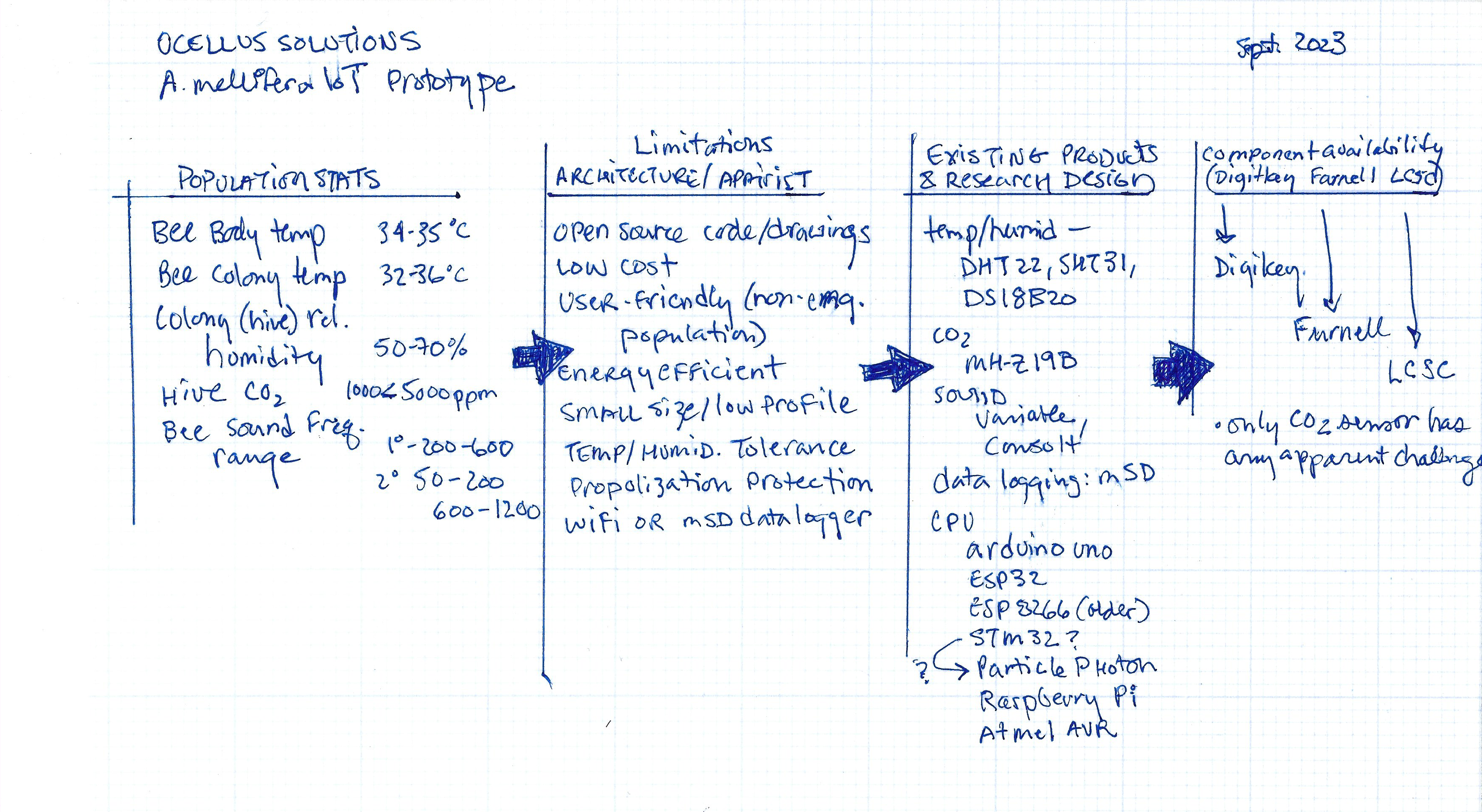

In Public Health, we often say ‘start with the population of interest.” OK, honey bees (yes, it is two words). I read a few books, pulled some scholarly articles, and took online and community college classes. I sketched out honey bee ‘demographics’ and characteristics of the beehive.

The next step was to consider the physical limitations of a beehive, the typical beekeeper, and my values. There is something known as “bee space” – it’s basically a gap of roughly only 5-8mm. Anything smaller is subject to being sealed with propolis, bees’ go-to glue for sealing things up. More than 8mm, and the colony will likely build an additional comb in its place. The bottom line is that there isn't much space to work! Most beekeepers are not electronic nerds, so everything has to be as easy to understand and use as possible. And because beekeeping can be an expensive endeavor, the final product has to be affordable.

I’d be silly (and was) to start to work on my prototype without researching what, if any, existing products are out there on the market. While several commercial bee colony monitoring electronic gizmos are on the market, they are often extremely expensive, difficult to install, calibrate or interpret, or don’t provide a meaningful UX. They are, at this moment, rarely used. We’ll change all this.

I summarized the various existing products and those used in scientific research. That proved to be extraordinarily useful. With each step in this process, I could narrow down the components and design elements to a more manageable level. The final step in this process was to help ensure that since this is an open-source, not-for-profit endeavor, folks throughout the Americas, in Asia and Europe, could purchase the necessary components.

Developing my prototype was all about learning as I went, keeping things simple, and building on what others had done. Now that the first version is buzzzzzzzzing along, I’m excited to keep refining it. Now, who’s ready to build their own IoT beekeeping project?

If you have tips and tricks or want to share your prototype stories, connect with me on Hackaday.io

-

It's All ελληνικά To Me

08/11/2024 at 16:47 • 0 commentsIt's All Greek To Me...

![mind cloud of confusion mind cloud of confusion]()

I don't know how many others are in a similar position as I am.

You've got an IoT idea you want to bring to fruition, but you know nothing about electronics, physics, mechanical design and 3D printing, or coding ... you don't know the difference between a resistor and a capacitor or between an Arduino Uno or a Particle Proton.

One year into my project, I'm still learning about all of these things. My background is in economics, psychology, medicine, public health and agriculture. Almost none of these are applicable to what I'm trying to accomplish. The one benefit—I'm curious!

Here's how I started my journey -

- Googled the heck out of ALL the subjects.

- Narrow my search by including words like 'basic' 'tutorial' "introduction," or "teach me."

- Specifically used scholar.google.com to find relevant publications

- Checked with my local community college and took a couple of relevant classes (ex. intro to electronics, C++ basics, Intro to digital design).

- Looked for easy-to-understand online videos on foundational matters (YouTube, Kahn Academy, All About Electronics, etc)

- After developing a basic understanding of my subject, reached out to interested article authors for advice.

- Searched blogs/websites like Hackaday.io, Adafruit.com, Github and Stackoverflow for similar projects.

- Then, try to connect directly with someone who's done something similar.

- I found local university professors who knew about some aspects of the subject and reached out to them. Be confident and you'll be surprised at how many folks will give you 15+ minutes of their valuable time!

- Used an AI chatbot (ChatGPT) - then verified the results.

- and, made a couple hundred drawings and idea board posts to bring this all together and formulate my first prototype.

I'd love to know your experience - how'd you approach your electronics project! Let me know.

- Googled the heck out of ALL the subjects.

Ocellus Solutions

Discovering IoT/AI solutions to help beekeepers maintain healthy bee colonies (and save the world in doing so!)

Kevin Jablonski

Kevin Jablonski