If you have followed my previous project to reuse a fridge compressor as a vacuum pump you know that start/stop of this compressor can wear the contacts of the relays I used.

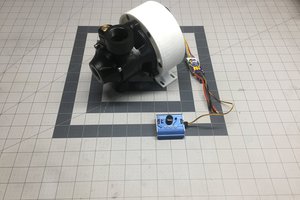

A friend of mine bought a DC motor diaphragm pump on Aliexpress.

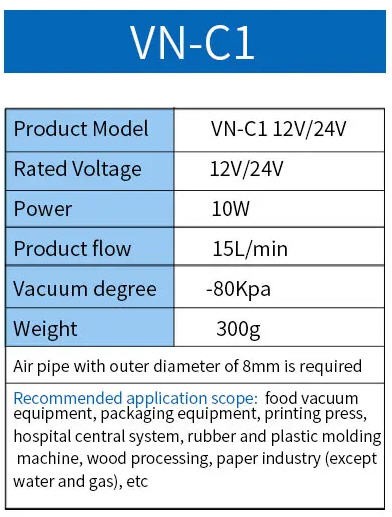

This pump has the following specifications :

you can find it easily on Aliexpress : DC Diaphragm 12v/24v Small Mini Air Vacuum Pump VN-C1 For Medical Cosmetology

The pump we have is the 12V model.

So I had to modify my electronics board to adapt it to this DC motor.

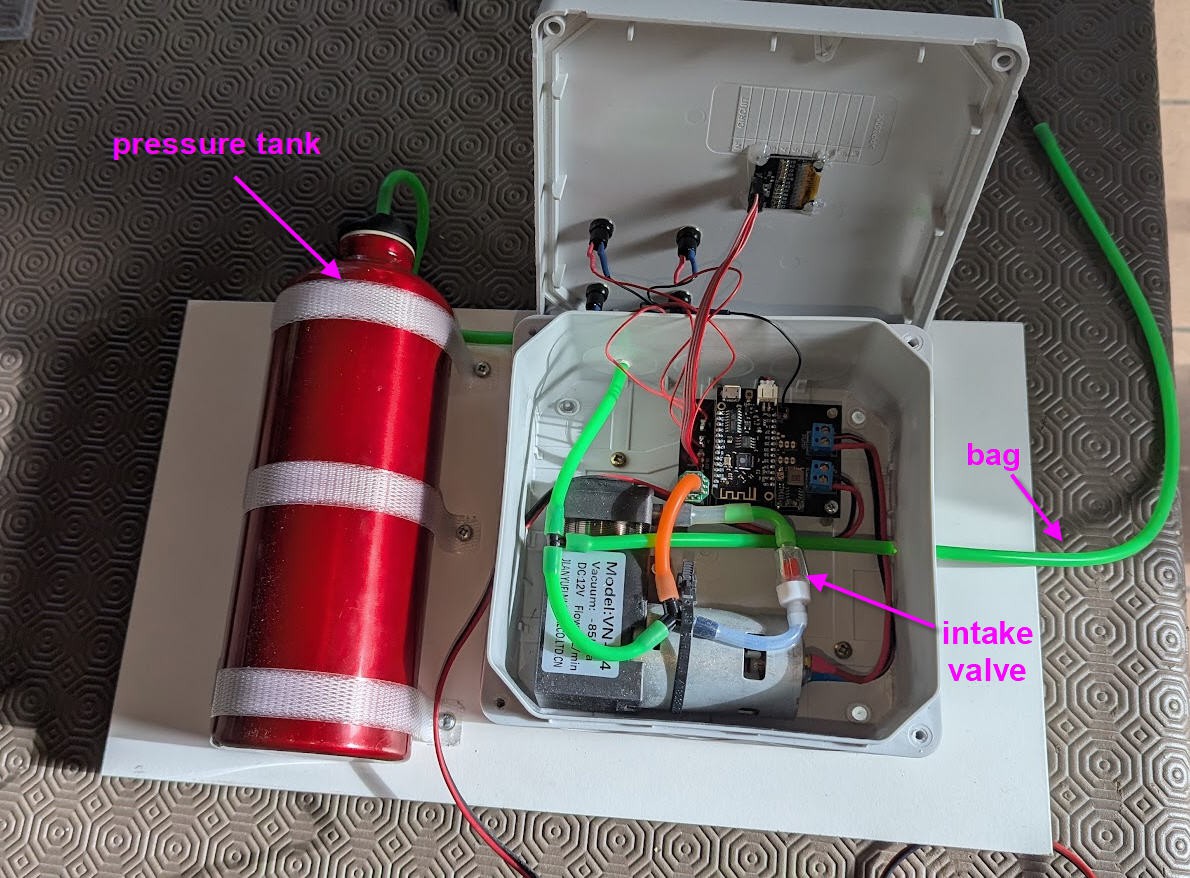

On this video you can see the system running on a VN-C4 pump. VN-C4 is a piston pump more powerful than the VN-C1 (but I stil prefer the VN-C1 !)

However the system runs with the same software !

Have a look to this log to see how the system is integrated with an intake valve.

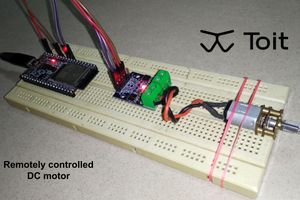

Electronic board to automate the vacuum pump

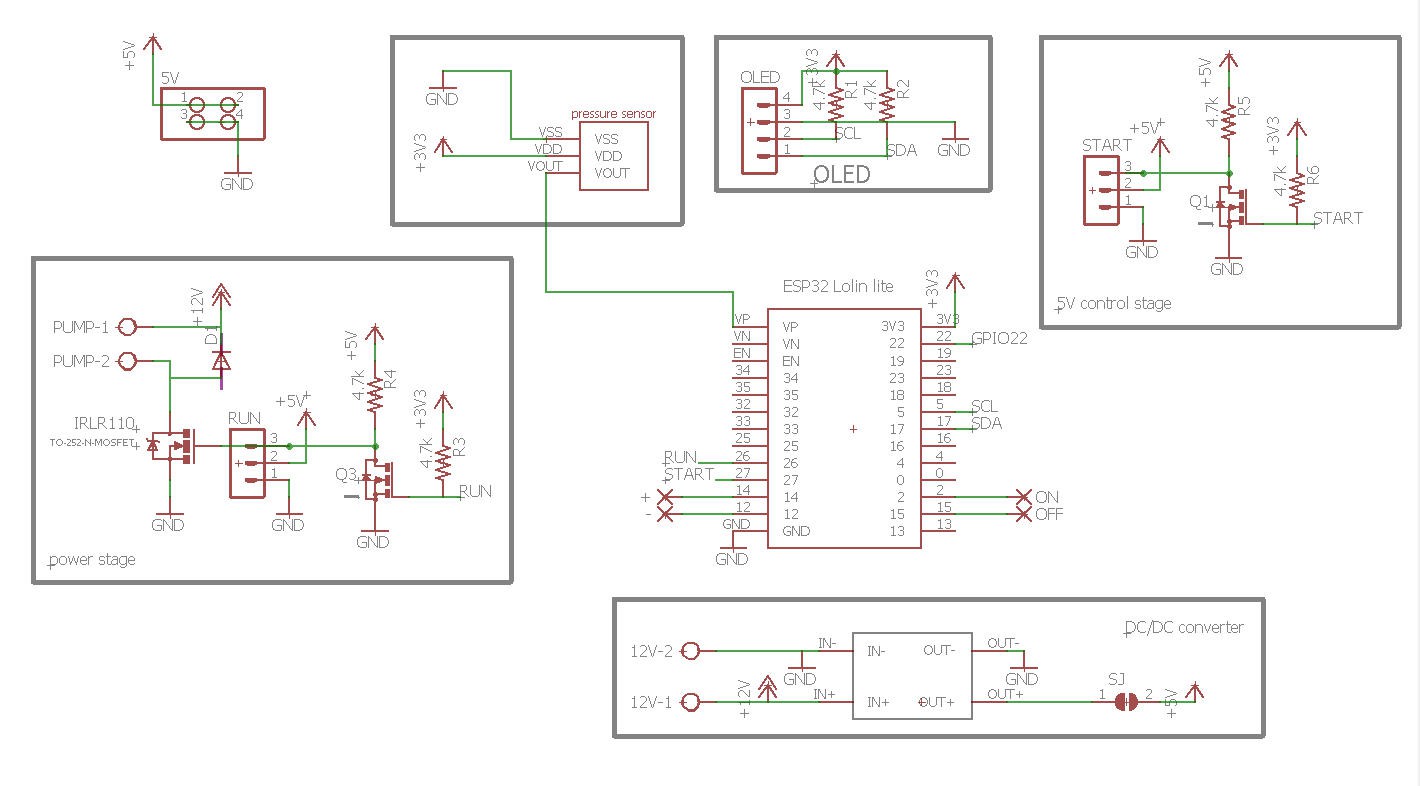

Schematics

Schematics of this board are a little more complex but remain very simple!.

- An ESP32 microcontroller will handle all the logic and communication with smartphone over Bluetooth Low Energy and WIFI over UDP

- two 5V relay boards can handle the fridge motor coils (compatibilty with fridge compressor)

- an OLED display could be used for debugging

- a pressure sensor will convert vacuum level into a voltage read by the ADC of the MCU

- a DC motor can be controlled via N channels Mosfets

- a brushless DC motor can be controlled with an ESC controller (optionnal 5V control stage)

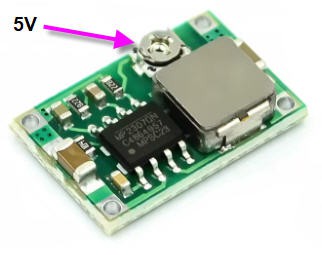

- The board is powered (optionnaly) with a cheap 12V to 5V DC/DC converter

So this board should be more versatile than the previous one as it can hadle a least 3 types of pumps:

- 230V AC fridge compressor

- 12V/24V DC diaphragm pump

- Brushless DC diaphragm pump

But we will focus on controlling the simple 12V DC motor pump.

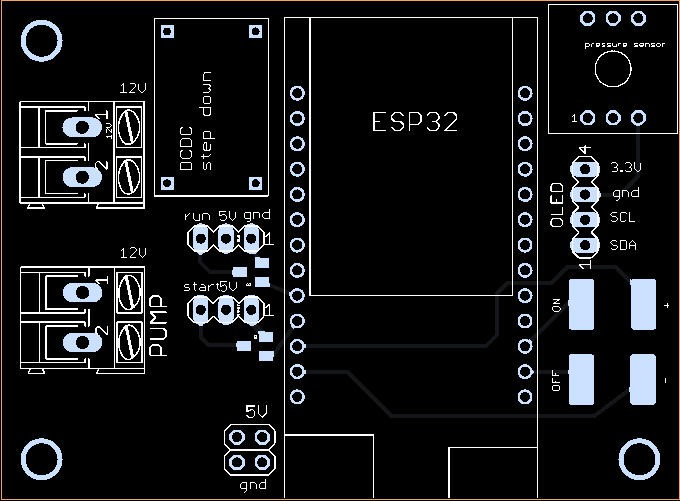

PCB

Routing this simple schematics was fairly easy.

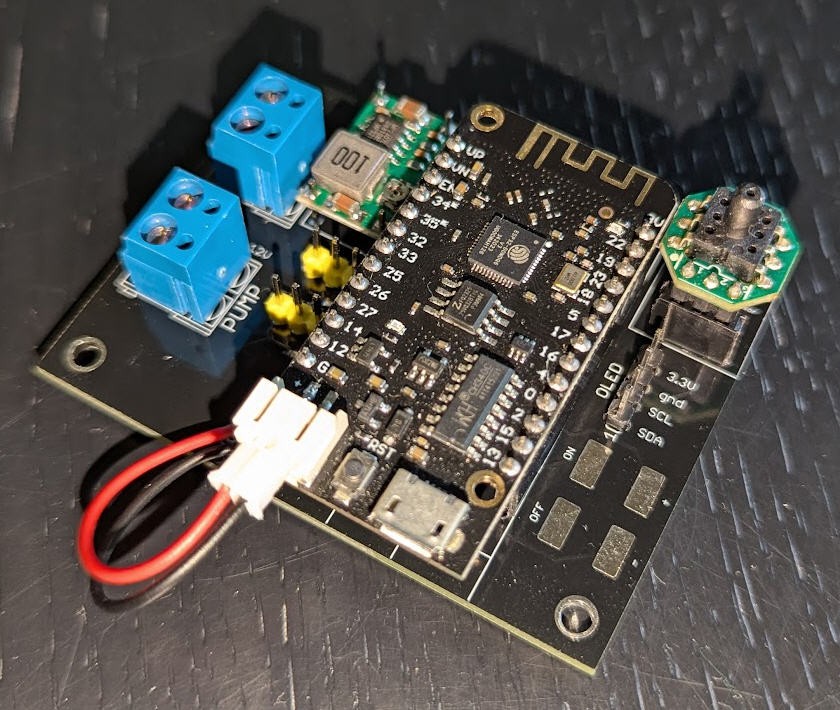

PCBWay kindly proposed to sponsor this project and has produced professionnal looking boards.

Quality is, as usual, excellent and the black silkscreen beautiful !

If you want to get one, simply follow this link : Vacuum Pump V2 @PCBWay

Soldering this board is fairly easy, even the small N channel Mosfets can be manually soldered.

The Bill of material is available here : BoM for DC motor vacuum pump. Total price is around 45€

Warning : before soldering the ESP32 tune the DC/DC converter so that its output gives 5V

These sensors are extremely cheap and can be found on AliExpress

Pressure sensor

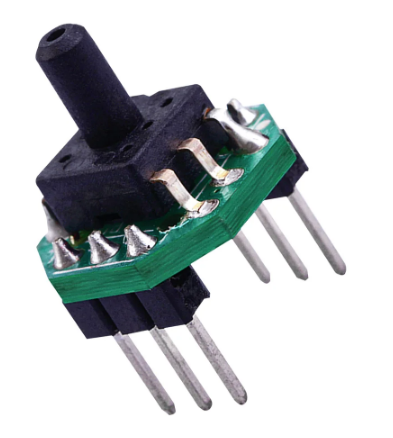

I choose this kind of sensor easily available on aliexpress:

Many references does exist, you have to select the right one: DC0.2-2.7V Barometric Gas Pressure Sensor Transmitter PCB Module Vacuum Negative Pressure -100 to 0kPa

- power is DC 3.3V

- pressure range should be for vacuum between -100kPA to 0 kPA

With a 3.3V device the output signal will be between 0.2V to 2.7V which is perfect for the ESP32 ADC levels

Datasheet was hard to find, but here it is : XGZP6847A Pressure Sensor Module

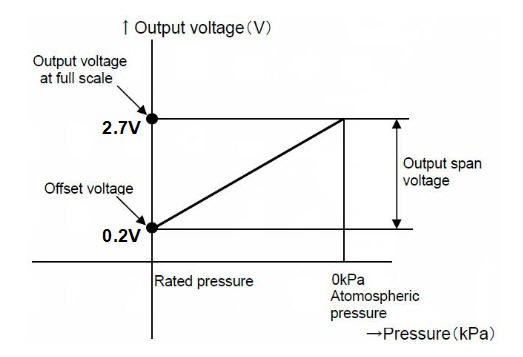

And here is its response when applying vacuum:

It is the same sensor as already used for the fridge vacuum pump. The DC motor pump is a little weaker than the fridge and can "only" produce 80kPa vacuum. And this is really more than enough!

It is the same sensor as already used for the fridge vacuum pump. The DC motor pump is a little weaker than the fridge and can "only" produce 80kPa vacuum. And this is really more than enough!software

software is more or less the same as for the fridge compressor.

I have however upgraded the ESP32 arduino code which is available here : DC motor vacuum pump firmware

For the sake of readability I reproduce here the existing documentation for the code (including the upgrades)

Firmware of the ESP32 could have been extremely simple as we basically just want the following features:

- start the pump

- [new] PWM power of DC motor pumps

- read pressure

- stop the pump if highVacuum is reached

- resume pump if low vacuum is reached

But I wanted something a little more user friendly:

- smartphone application with BLE communication with the ESP32 (optionnal)

- [new] smartphone application with UDP communication with...

JP Gleyzes

JP Gleyzes

Mark Atherton

Mark Atherton

Andrew Mayhall

Andrew Mayhall