Goal:

Create a 3D printer for teaching users about the basics of laser SLA printing while encouraging users to experiment with new resins, and slicing algorithm. This printer would be an affordable way for makers to print wax resin and utilize investment casting for their projects.

Concept:

Build a laser 3D SLA printer that prints via standard gcode. Have full access to laser setting so I can experiment with different resins. Standard gcode allows user to examine toolpath. This also allows for high resin compatibility which is important for wax resin as those are some of the most difficult and expensive resin to print.

Laser: 405nm 150mw UV laser with a spot size of 70 micron

Build Volume: 13 x 13 x 18cm

Printer Size (Built): 25 x 25 x 63cm

Processor: ST 32bit ARM processor

Print file format: Accepts Gcode

Software: Tested Cura 2.3.1 + Autodesk Print Studio

Video:

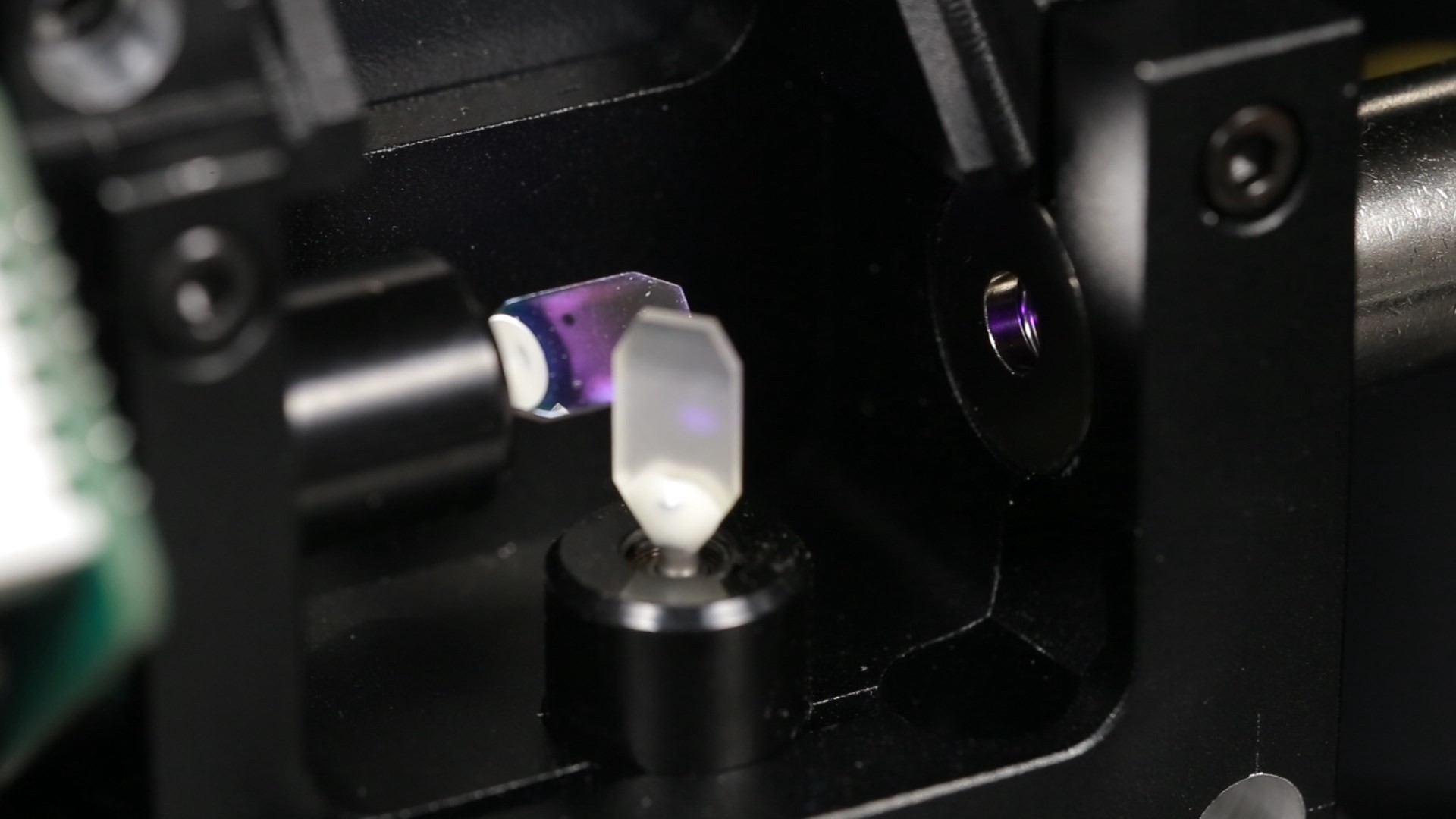

Laser Galvo setup

More details to be added soon

Field Test:

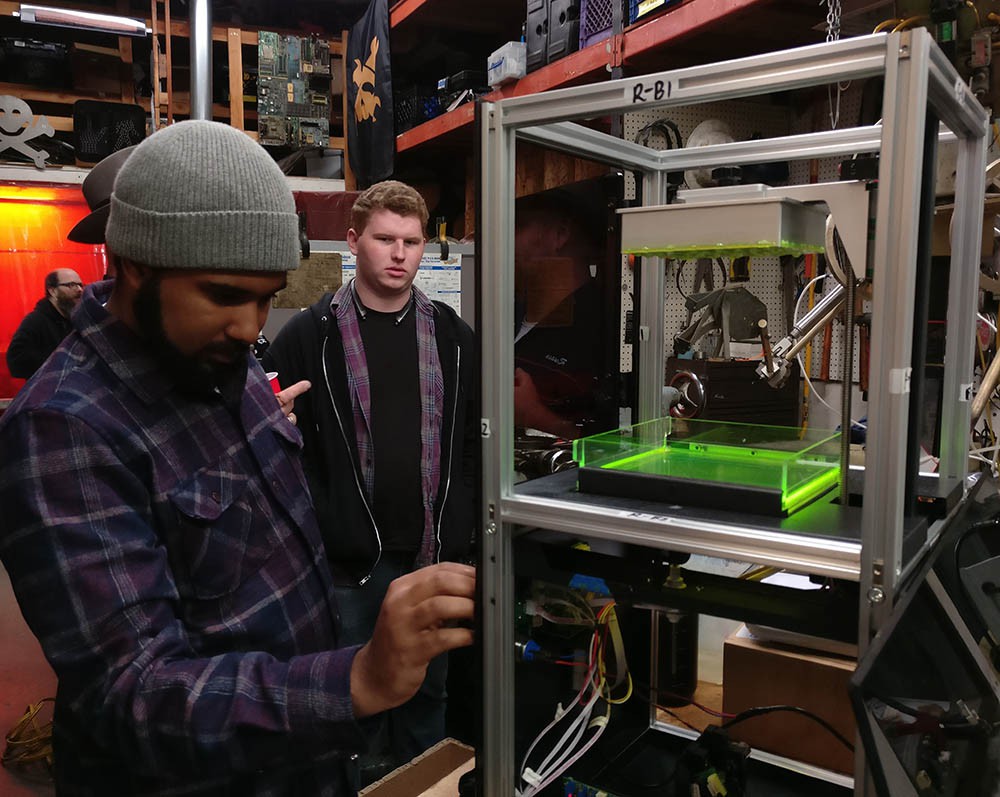

Build test at Maker Place in San Diego:

23b Space in Fullerton, CA

More detail yet to come.

Mark Peng

Mark Peng

Oliveira

Oliveira

Patrick Ryan

Patrick Ryan

Iqra Rehman

Iqra Rehman

Amos Dudley

Amos Dudley

I am guessing they probably had the same problem controlling precision and consistency as me. There is little or no real documents on Galvo drivers, if there is - you have to buy the ones for thousands of dollars, and probably spend maybe a year studying the circuitry to get it down.

The common economy Galvo boards do the trick for a fun little light show, but are time consuming and involved when it comes to dialing in the motors and boards, aligning everything to a laser precision.