Design Process

The three primary sections of the Voltmaster model are the following:

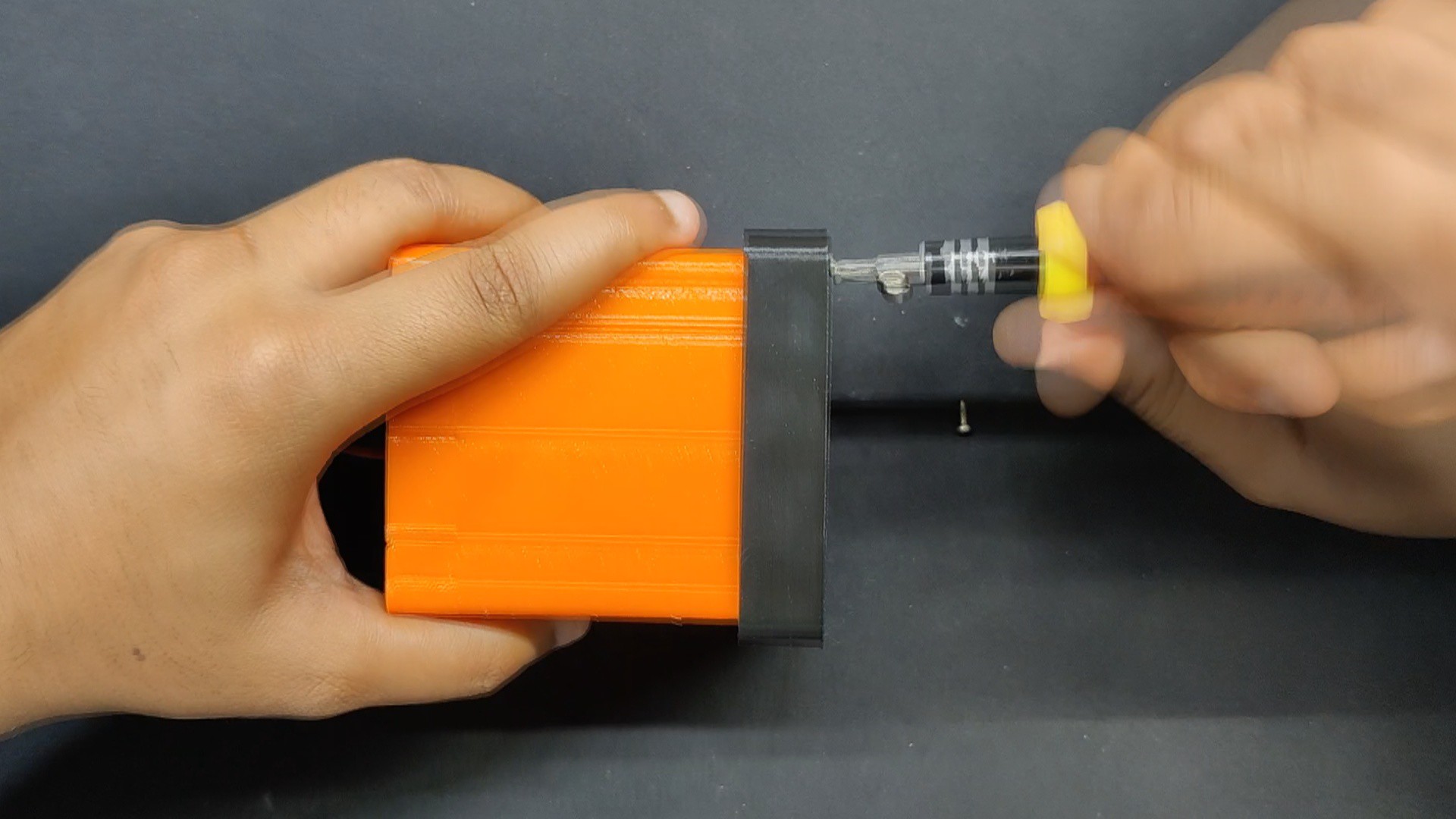

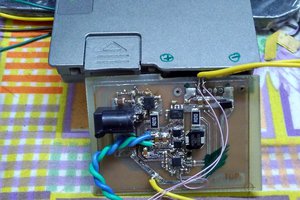

The circuit is held in place by the top section, which also has the power ON/OFF switch, indication LEDs, and 5V output banana pin socket.

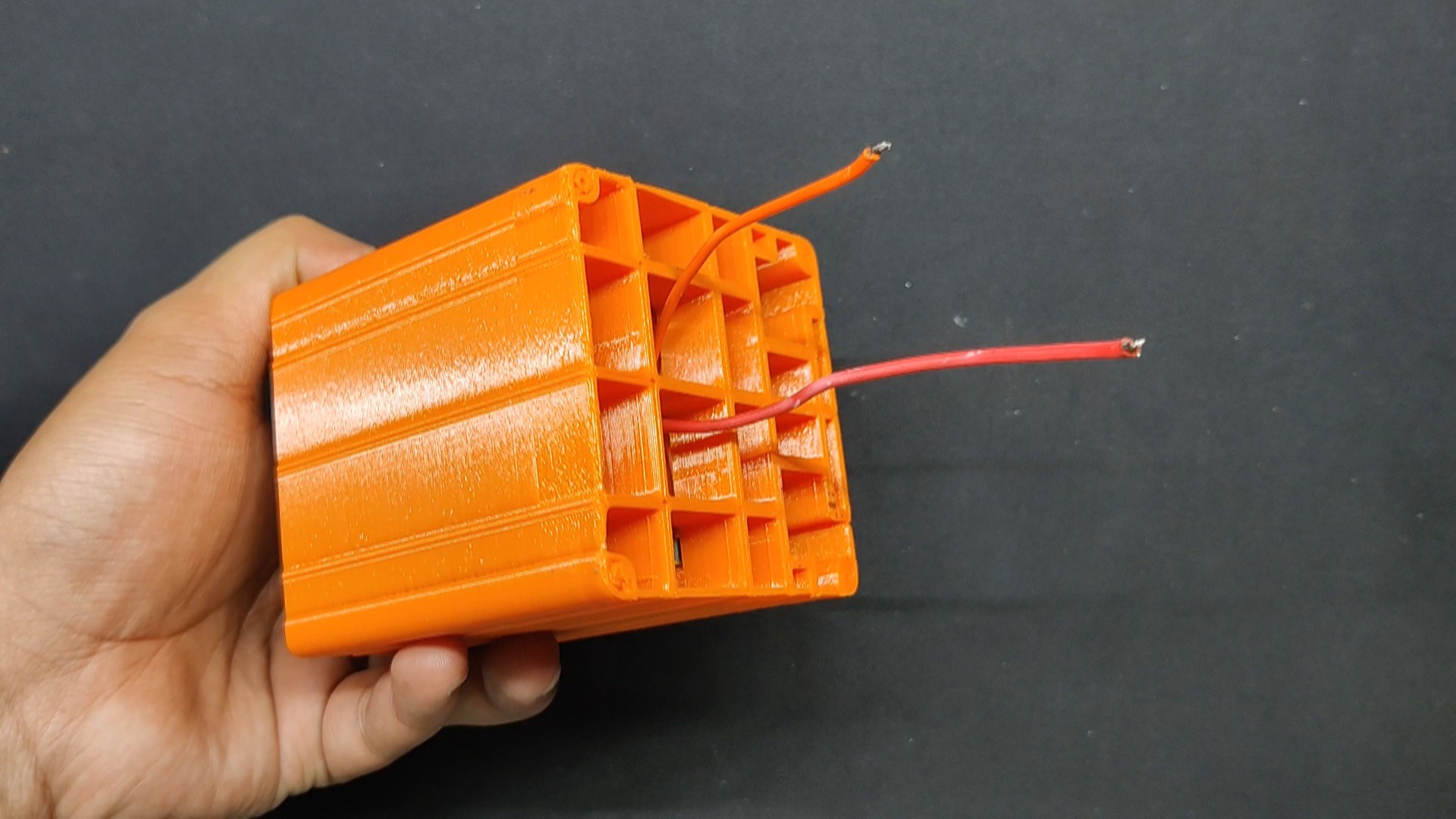

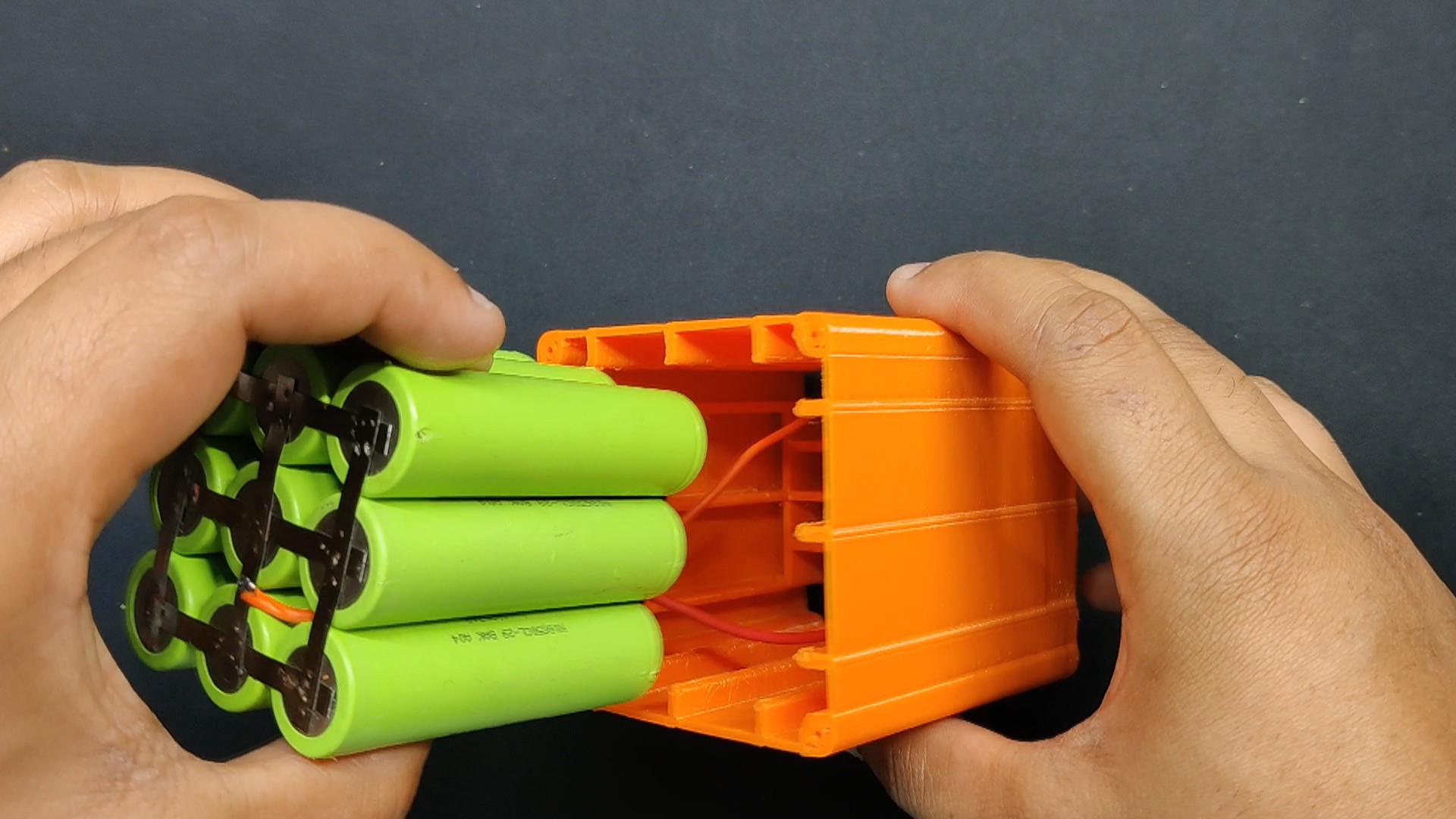

The lithium cell is held in place by the bottom and middle sections.

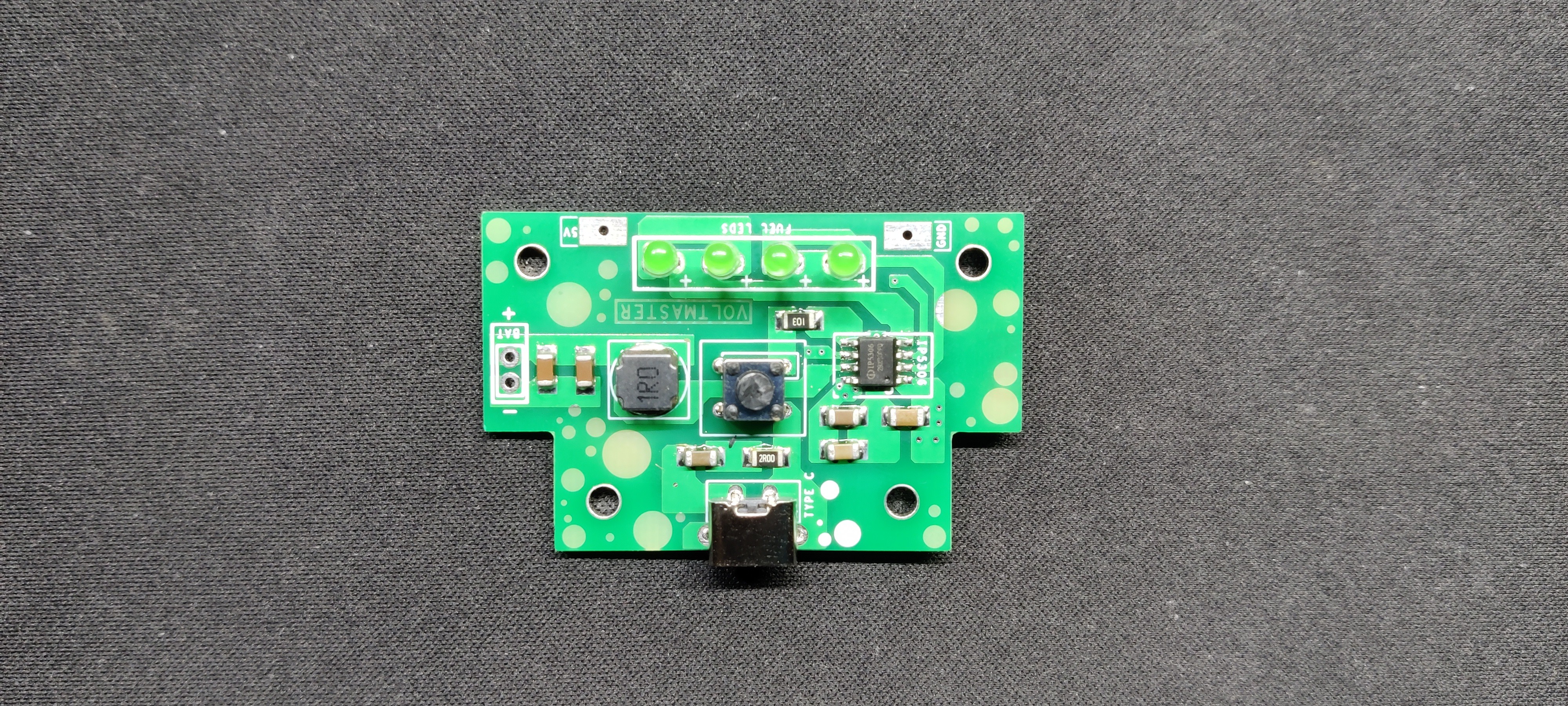

The first thing to be modeled was the circuit, which has four LEDs positioned close to the edge, a USB type C port on one side, and a switch in the middle.

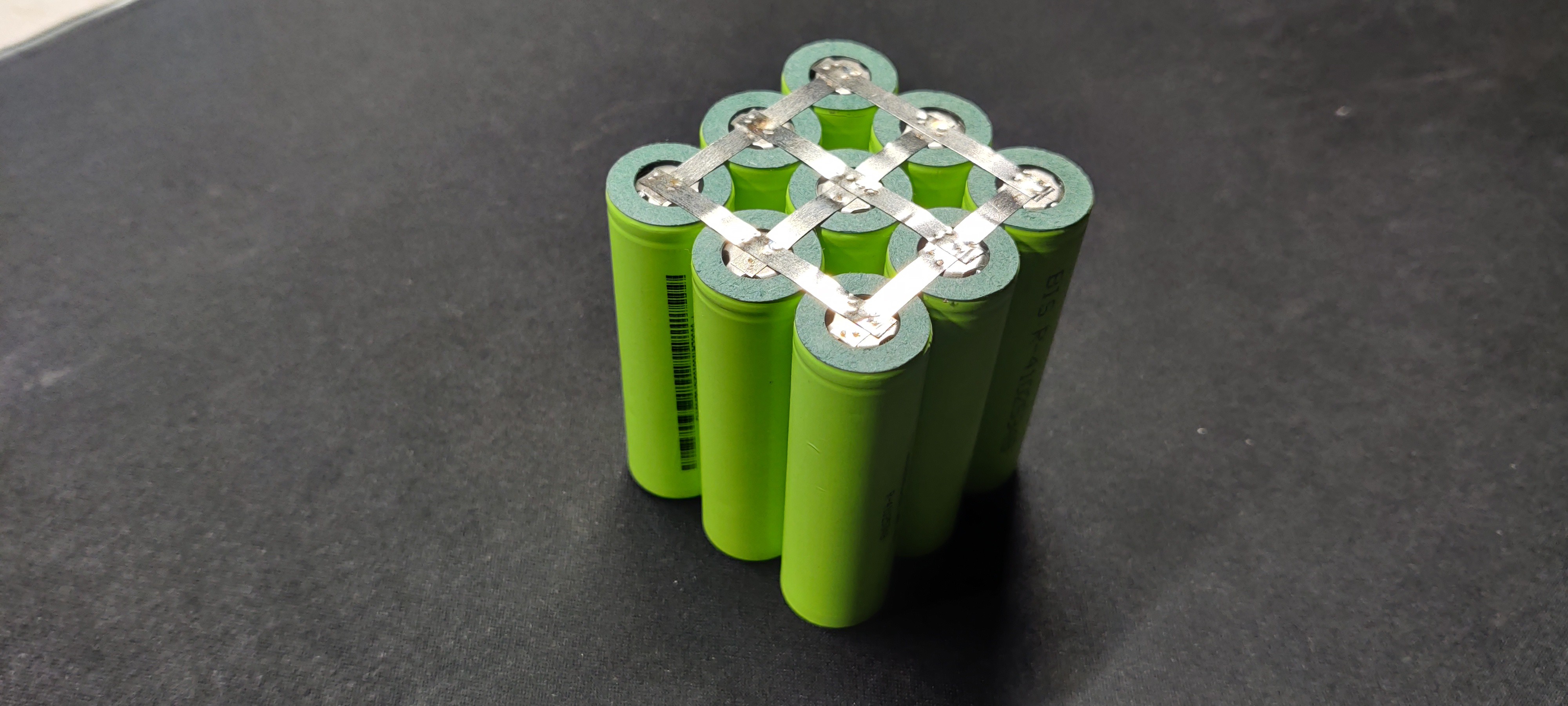

The lithium cell battery pack, which was made up of nine cells set up in a grid, was then prepared.

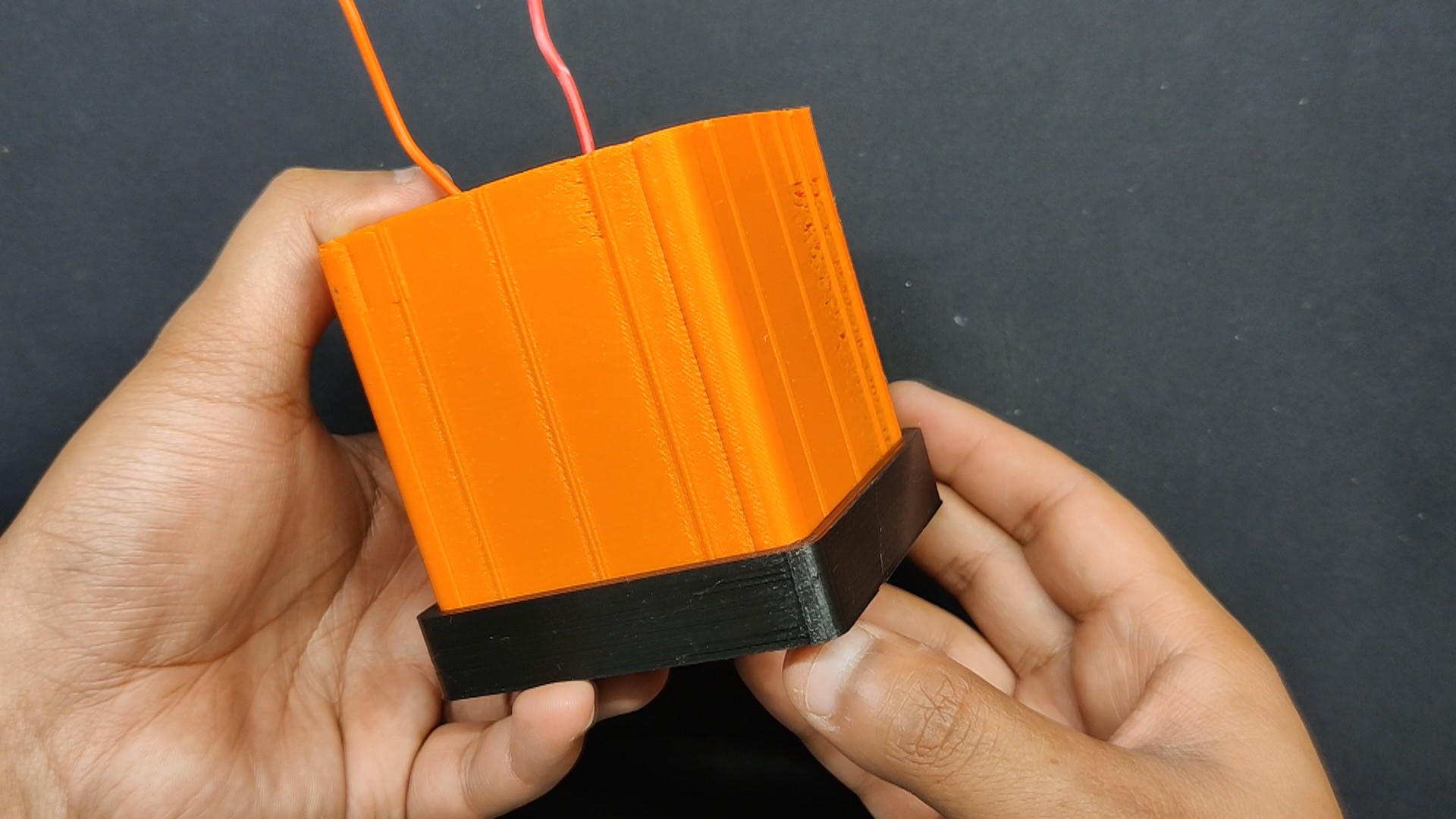

The battery pack served as the centerpiece of the model, and the circuit was modeled in the top section that houses the circuit and connects to the midsection. The battery is added to the midsection from the bottom, and the bottom lid closes the battery's entry point, thus locking it in place.

Additionally, we added three flat parts that attach to the front, left, and right faces of the midbody to enhance the setup's aesthetics and give it a subtle cyberpunk vibe. We have added a few patterns and designs to these flat sections to fit the cyberpunk style. Superglue will be used to attach these flat sections to the midsection.

We used the STL files that we had exported once the model was finished to 3D print the top and bottom sections in black PLA, the midsection and SWTCH in orange PLA, and the flat pieces in dual-color, black and white PLA.

There was also an accent part for the top section, which was 3D printed in orange PLA.

Every part had the same set of settings; we utilized a 0.4mm nozzle, 20% infill, and a 0.2mm layer height.

CIRCUIT

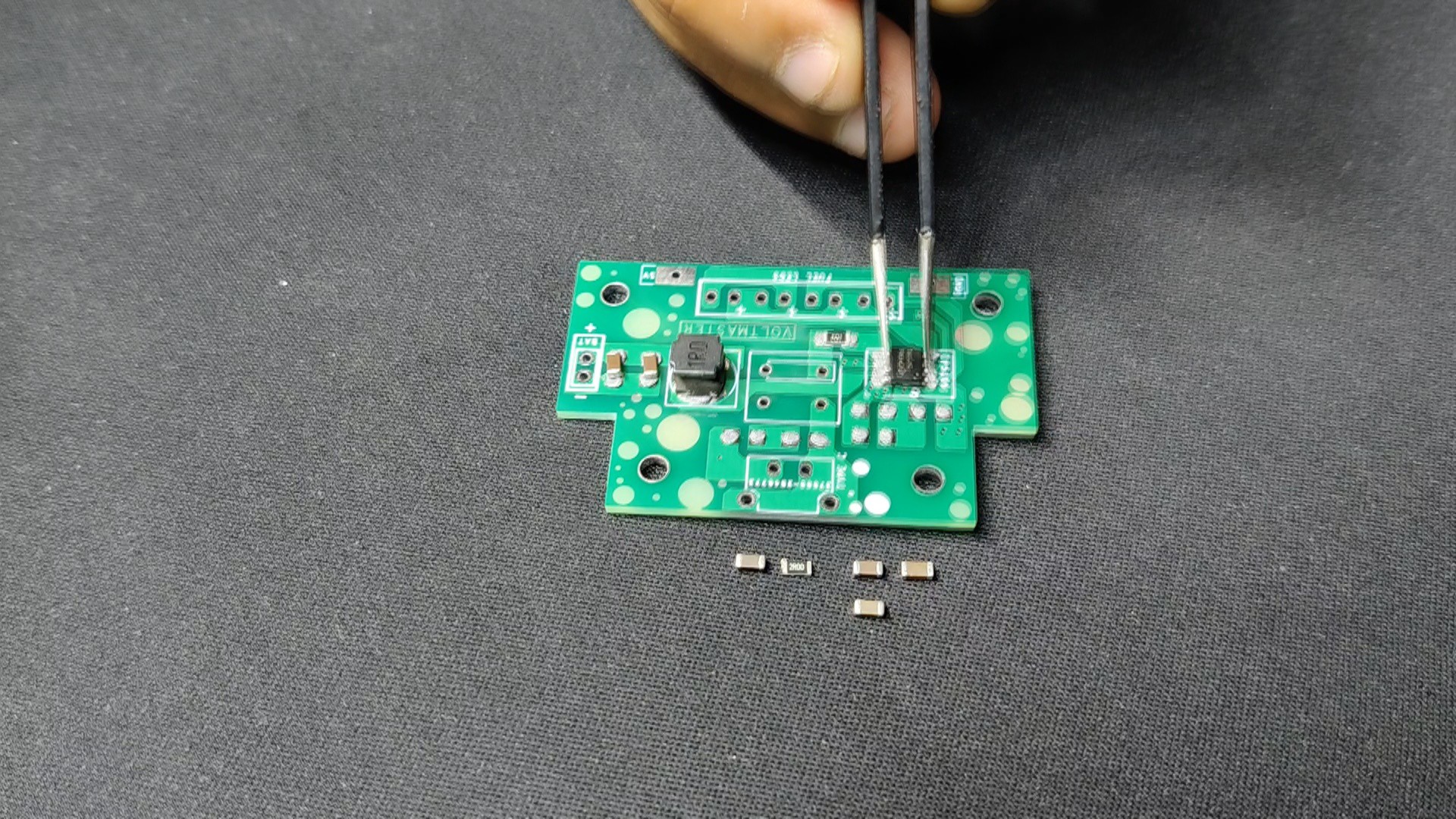

We prepared the schematic in which we used the IP5306 IC Setup, a power management IC that can provide stable 5V 2.4A with a 3.7V Li-ion Cell, to power the XIAO and the LEDs. Furthermore, this IC offers charging functions, such as a battery fuel indicator and charging cutoffs (low- and high-cut).

The push button included in the IP5306 setup can be used to turn the device ON or OFF in this instance. To indicate battery fuel, 3mm through-hole LEDs were installed. We have also utilized a through-hole Type C port, which has just the VCC and GND pins.

We wired the IP5306's output to a CON1 Pad, which will subsequently be linked to a banana pin socket in order to output 5V.

Following the preparation of the schematic, we created the board design, by referring to the previously created PCB model. Using the model dimensions, we created the board's shape and positioned the LEDs, push button, and Type C port in accordance with the PCB model.

HQ NextPCB Service

After completing the PCB design, we export the Gerber data and send it to HQ NextPCB for samples.

An order was placed for Green Solder Mask Board with White Silkscreen.

After placing the order, the PCBs were received within a week, and the PCB quality was pretty great.

In addition, I have to bring in HQDFM to you, which helped me a lot through many projects. Huaqiu’s in-house engineers developed the free Design for Manufacturing software, HQDFM, revolutionizing how PCB designers visualize and verify their designs.

HQDFM: Free Online Gerber Viewer and DFM Analysis Tool

Also, NextPCB has its own Gerber Viewer and DFM analysis software.

Your designs are improved by their HQDFM software (DFM) services. Since I find it annoying to have to wait around for DFM reports from manufacturers, HQDFM is the most efficient method for performing a pre-event self-check.

Here is what online Gerber Viewer shows me. Would not be more clear. However, for full function, like DFM analysis for PCBA, you, need to download the software. The online version only provides a simple PCB DFM report.

With comprehensive Design for Manufacture (DFM) analysis features, HQDFM is a free, sophisticated online PCB Gerber file viewer.

It provides insights into advanced manufacturing by utilizing over 15 years of industry expertise. You guys can check out HQ NextPCB if you want...

Read more » Arnov Sharma

Arnov Sharma

ElectroBoy

ElectroBoy

Kumar, Abhishek

Kumar, Abhishek

DIY GUY Chris

DIY GUY Chris