-

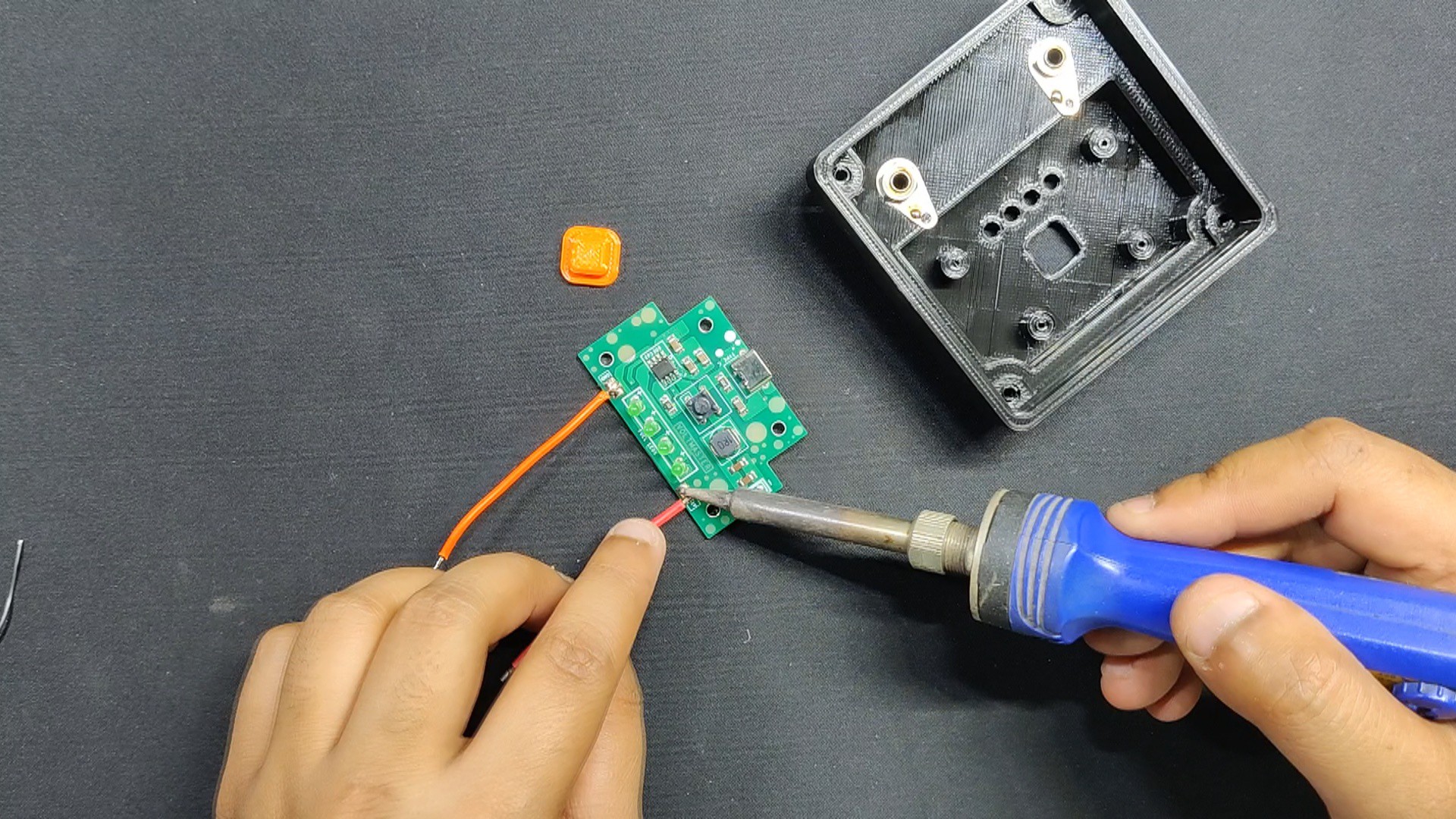

1Circuit Assembly process

![]()

![]()

![]()

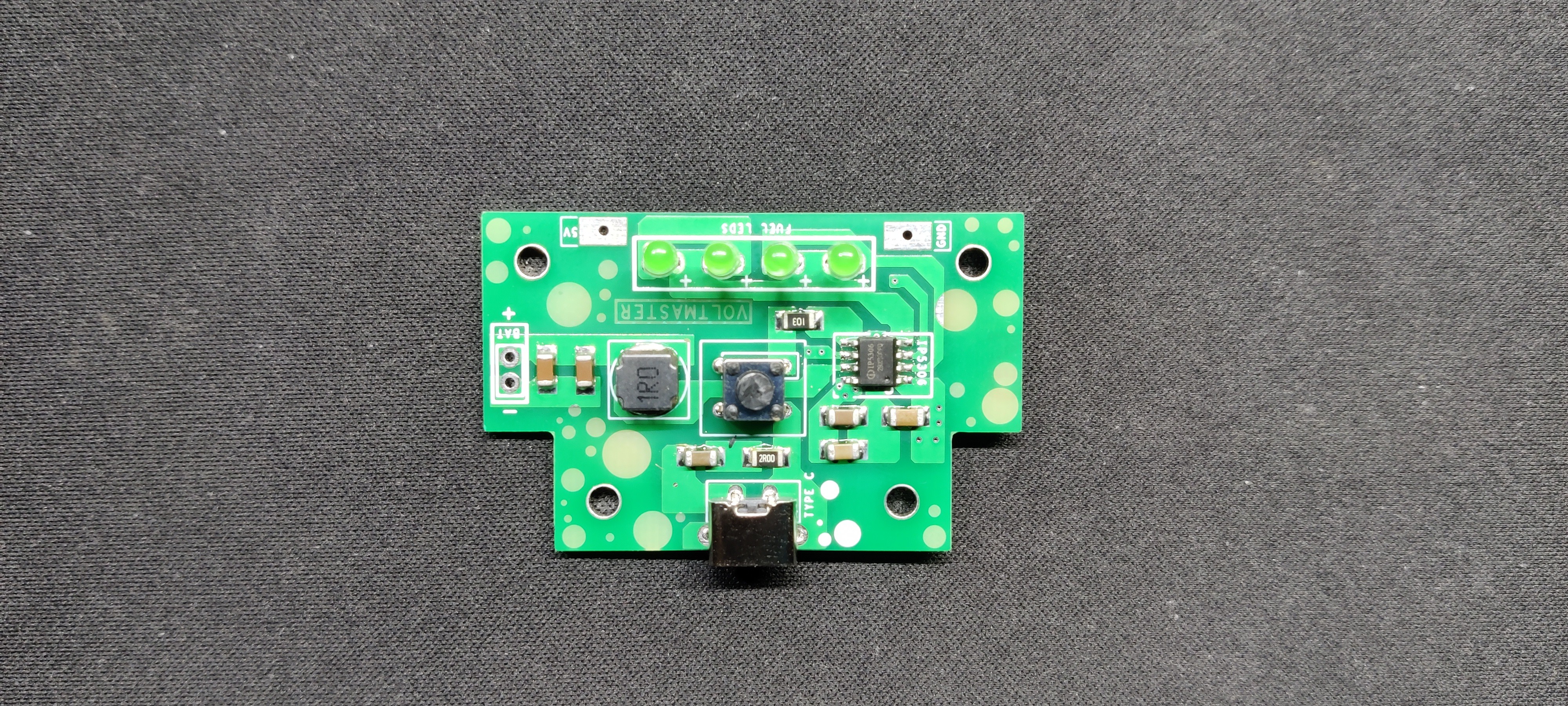

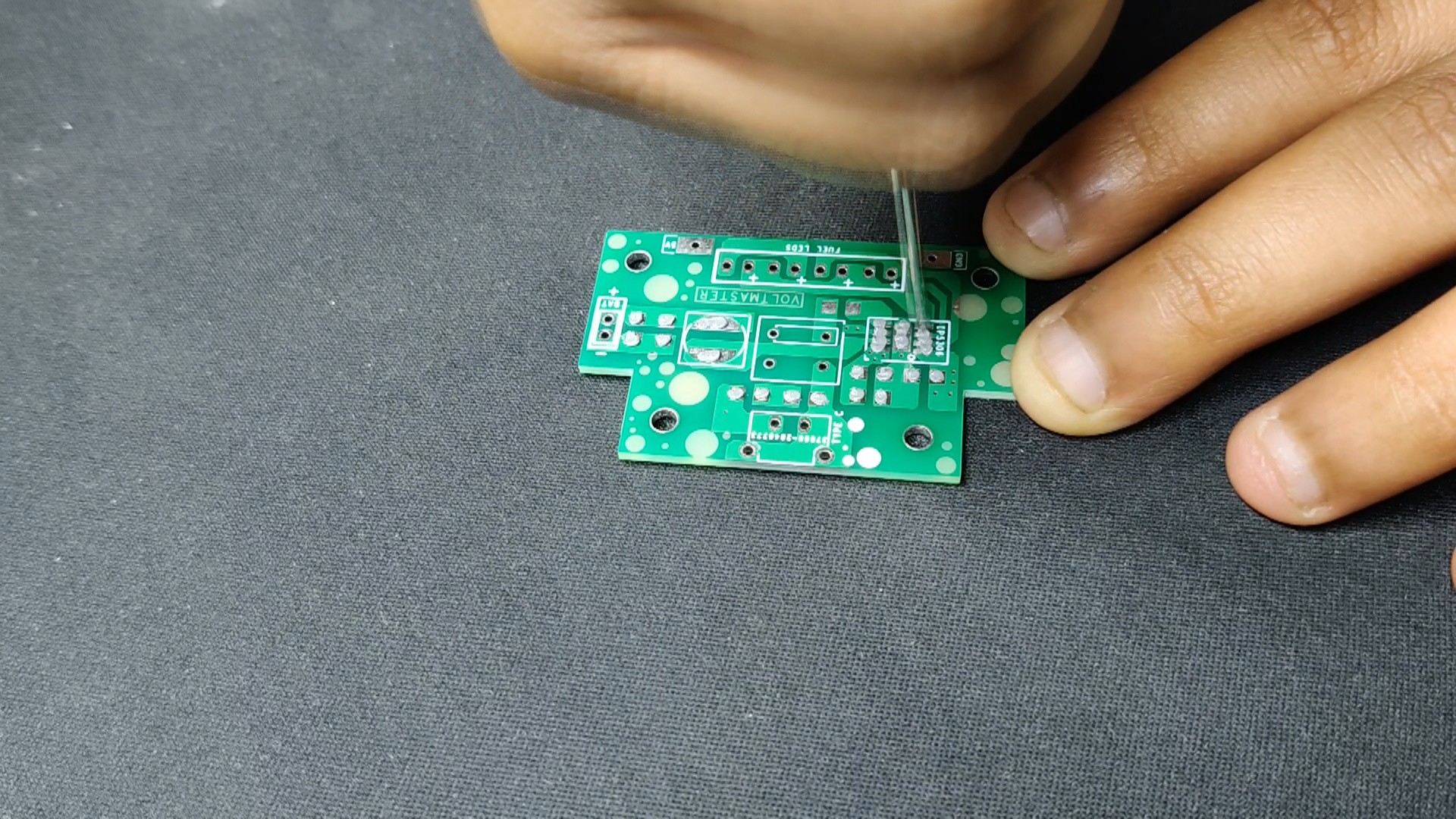

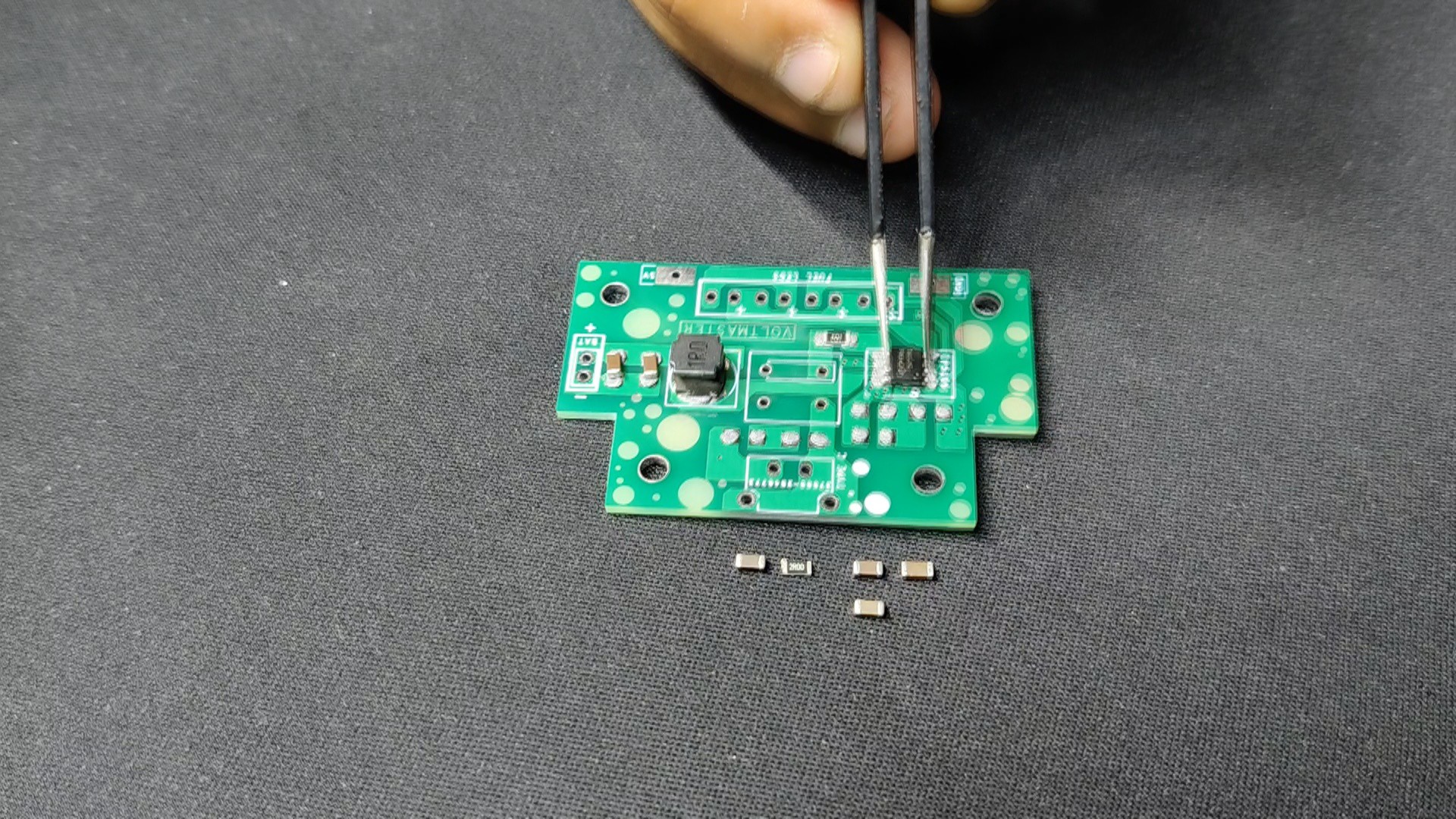

- We started the circuit assembly process by first adding solder paste to each component pad one by one using a solder paste dispensing needle.

- Next, we pick and place all the SMD components in their location using an ESD Tweezer.

- Soldering the SMD components requires the use of a reflow hotplate. The solder paste melts and all components connect to their pads when the board achieves the temperature reached by the reflow process, which essentially heats the circuit from below. Here, we are utilizing the brand-new MINIWARE MHP50 reflow hotplate.

- The push button, Type C port, and 3 mm green LEDs were subsequently put into the board's through-hole components, which were all located on the upper side of the board. Next, we use a soldering iron to solder their pads from the bottom side

-

2POWER SOURCE

![]()

![]()

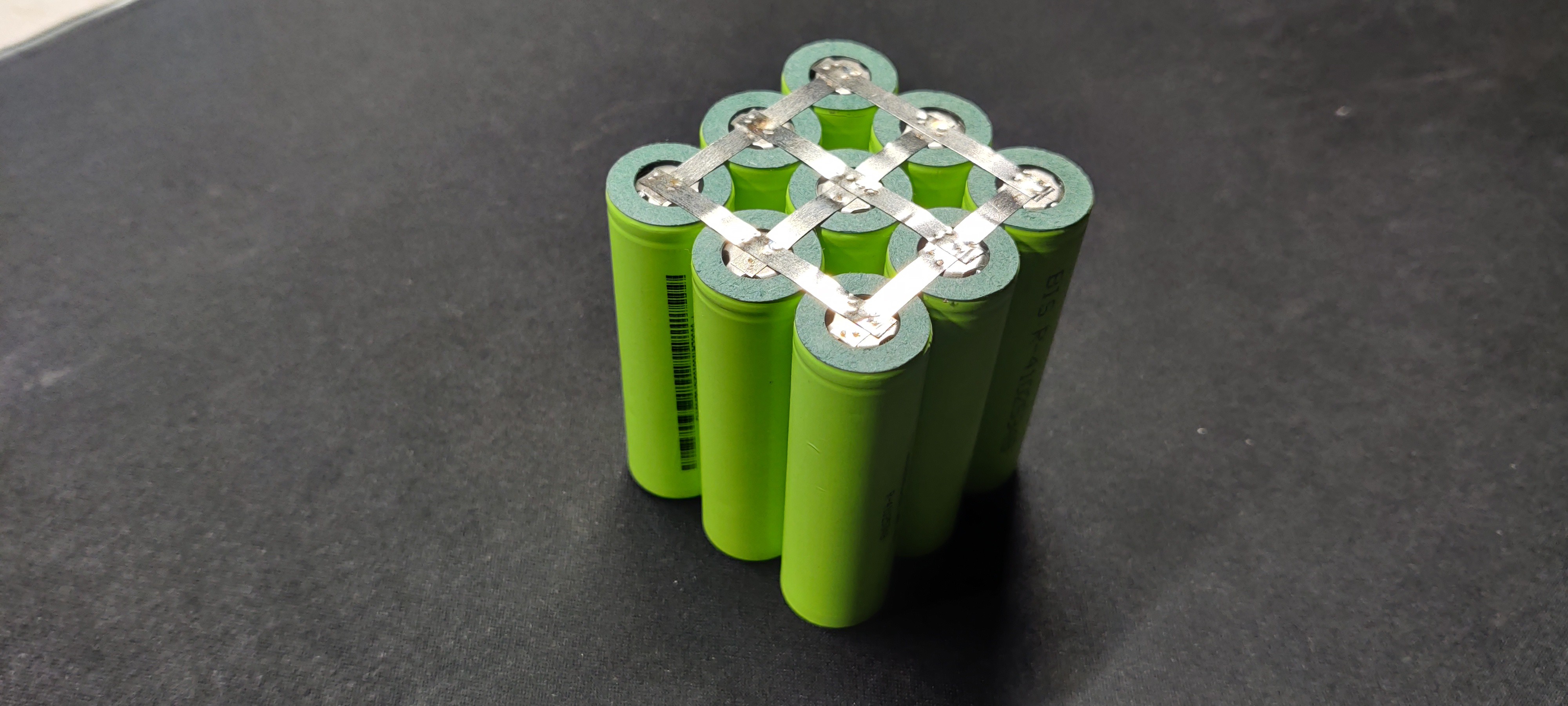

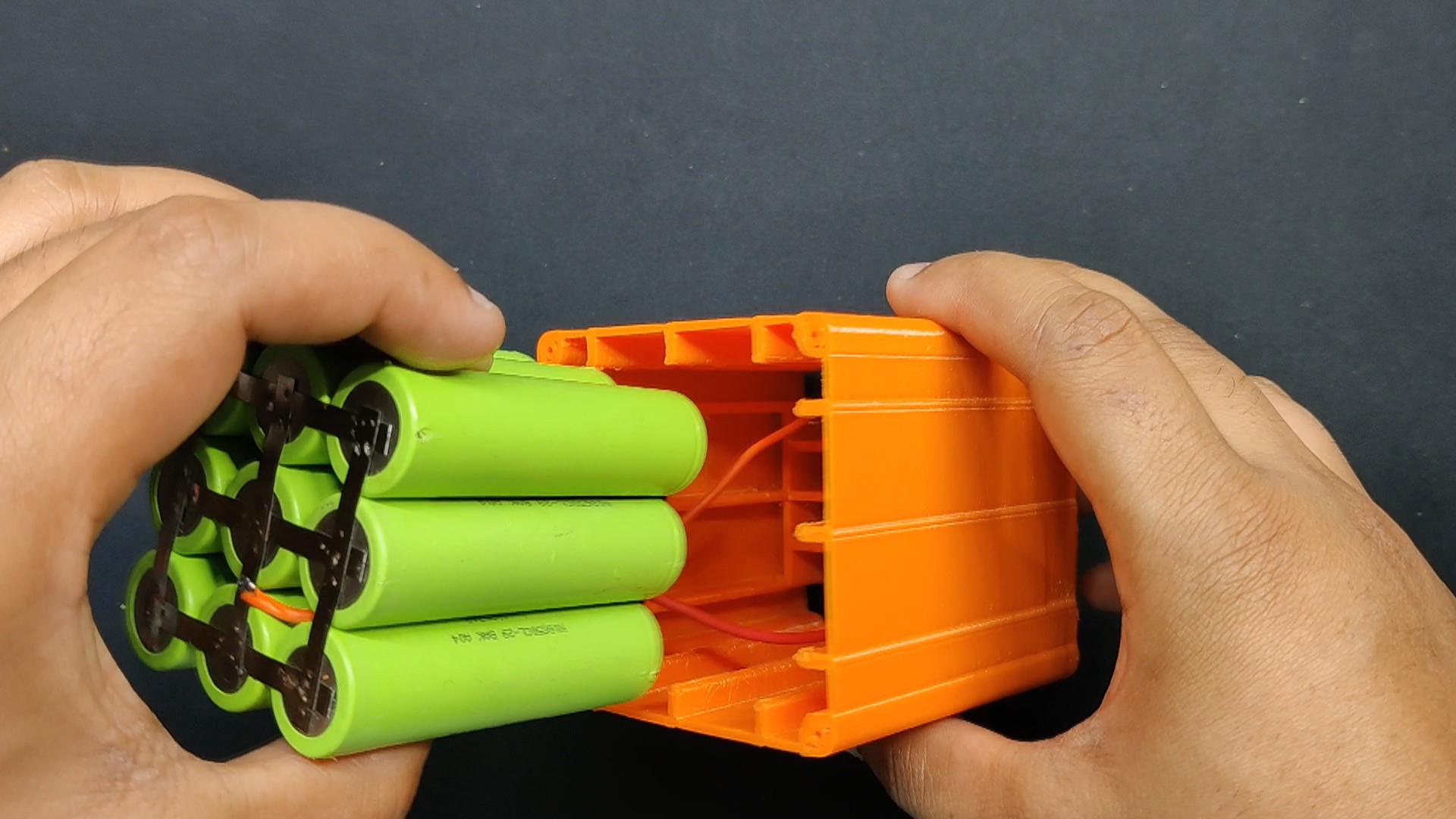

This project's power supply is a battery pack made up of nine 3.7V 2900mAh Li-ion cells linked in parallel. The total capacity of the pack is 3.7V 26100mAh (2900x9), which greatly increases the setup's overall backup.

In order to build this battery pack, we attach the positive and negative of every cell together to form a parallel connection. We do this by using nickel-plated steel strips. In order to complete this operation, we appointed a tig welder for lithium-ion cells, which is done in a professional battery pack manufacturing facility. We received assistance from a nearby battery pack factory, who performed the tig welding.

Why not solder the battery pack directly instead of using the Tig welding process?

For one simple reason—the heat from the soldering iron can harm the battery, causing it to burst, leak, catch fire, or explode—soldering directly to lithium-ion cells can be risky. In order to prevent them, we should always utilize nickel strips and tig weld them instead of soldering any wire or metal strip directly to the lithium cell's components.

-

3Mid Section-Battery Pack-Lower Section Assembly process

![]()

![]()

![]()

![]()

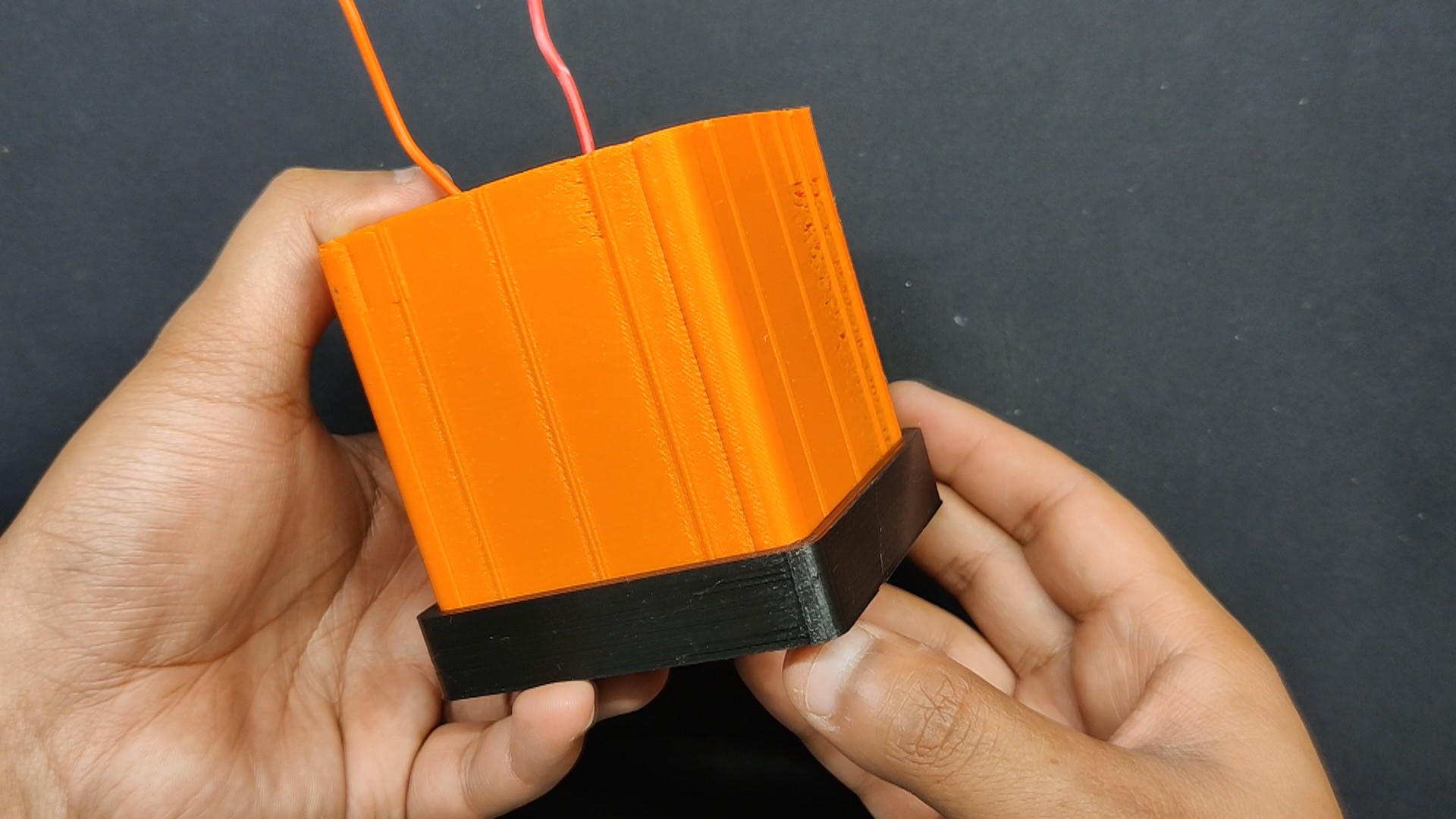

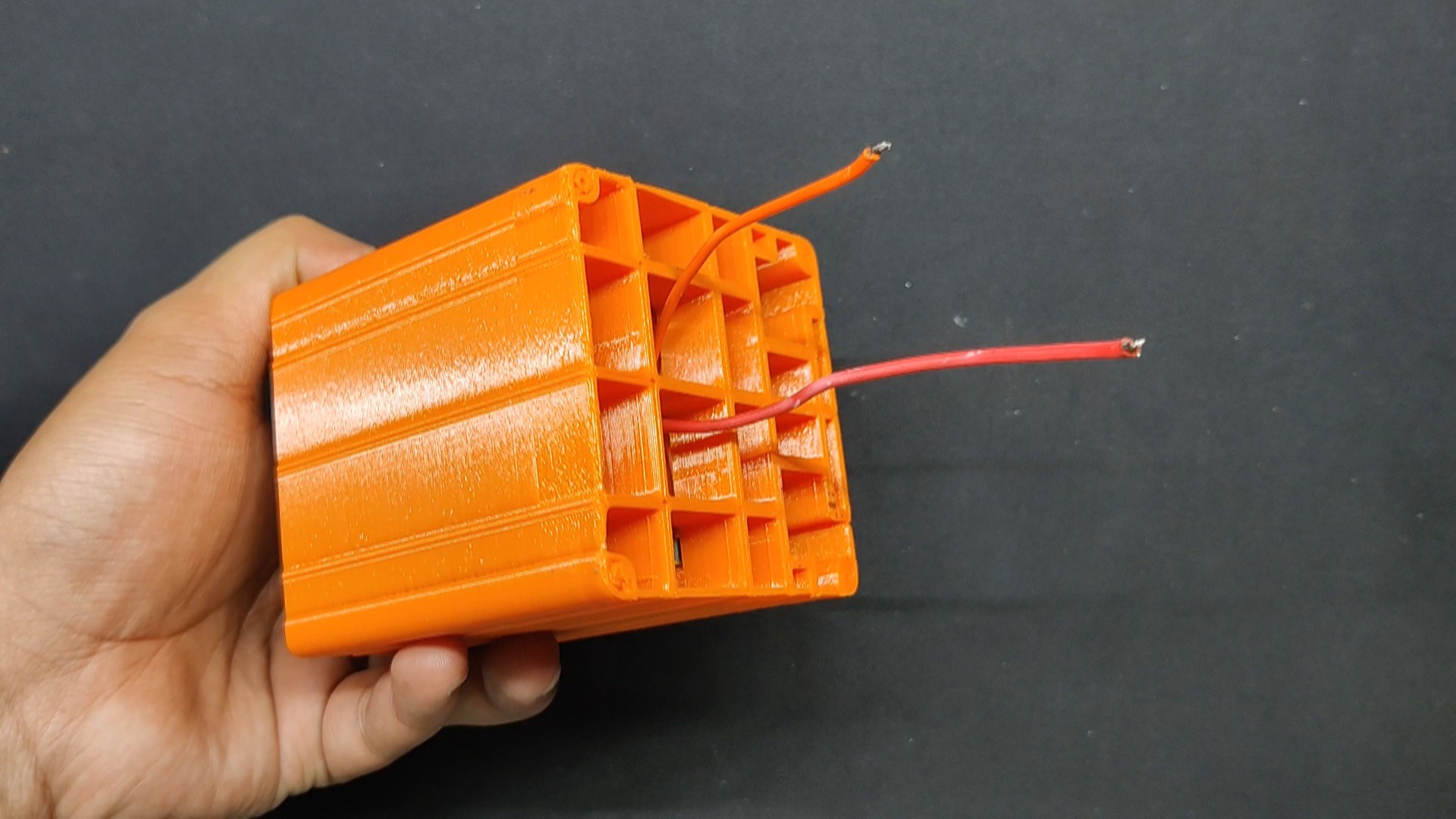

- We began assembling the bottom section assembly with the battery pack and midsection by first putting the battery pack inside the body of the midsection. We make sure to add the wire through the mid section grids so later we can easily solder them with the circuit.

- The battery pack is then secured in place by connecting the bottom piece to the midsection. Four M2 screws are then added to permanently fasten the two sections together.

-

4TOP Assembly

![]()

![]()

- Using super glue, we first attached the top accent piece to the top section to begin the assembly process.

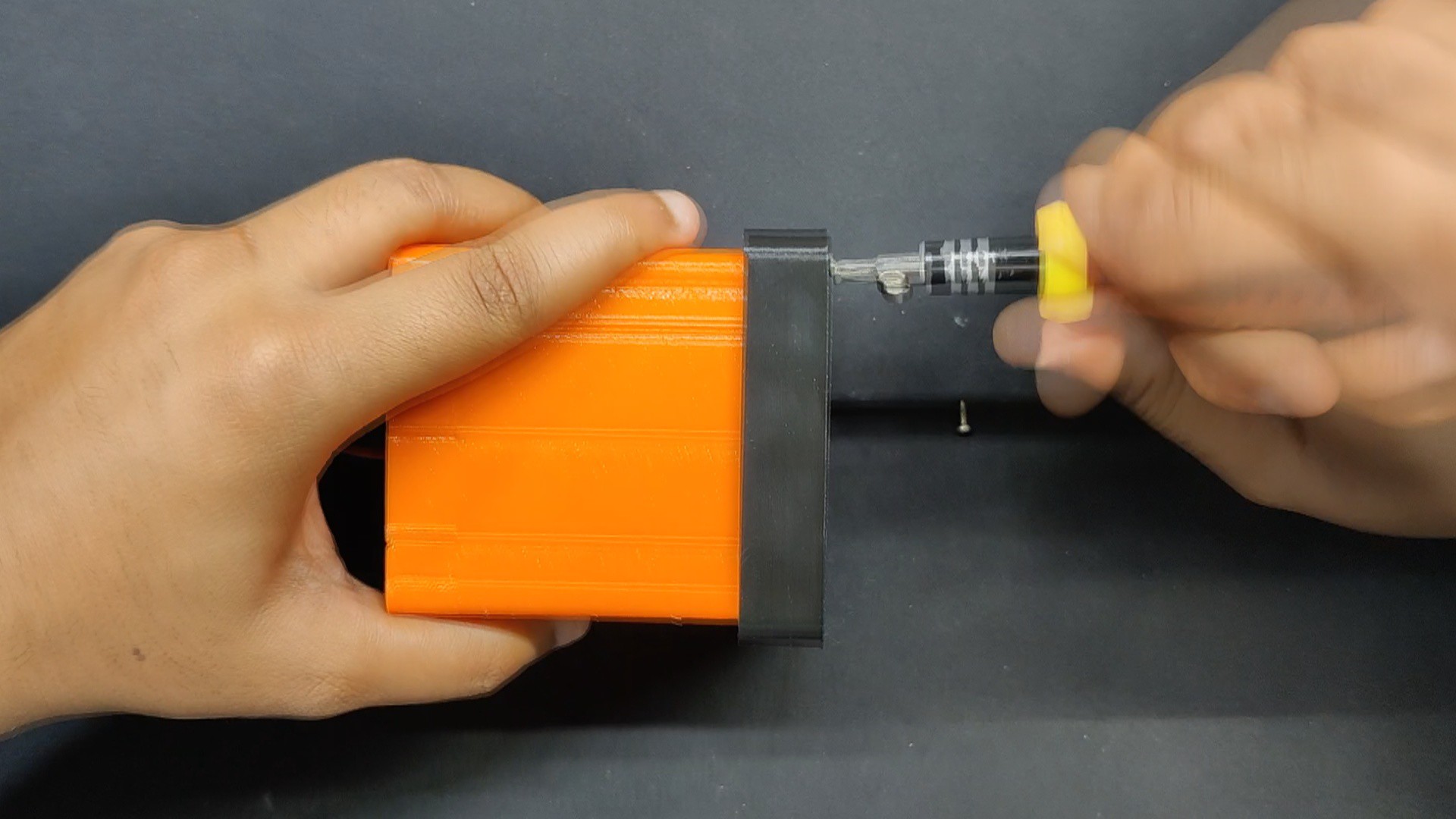

- Next, we unscrew the nut on each banana pin and tighten them on the top section body to position the positive and negative banana pin sockets in their proper locations.

-

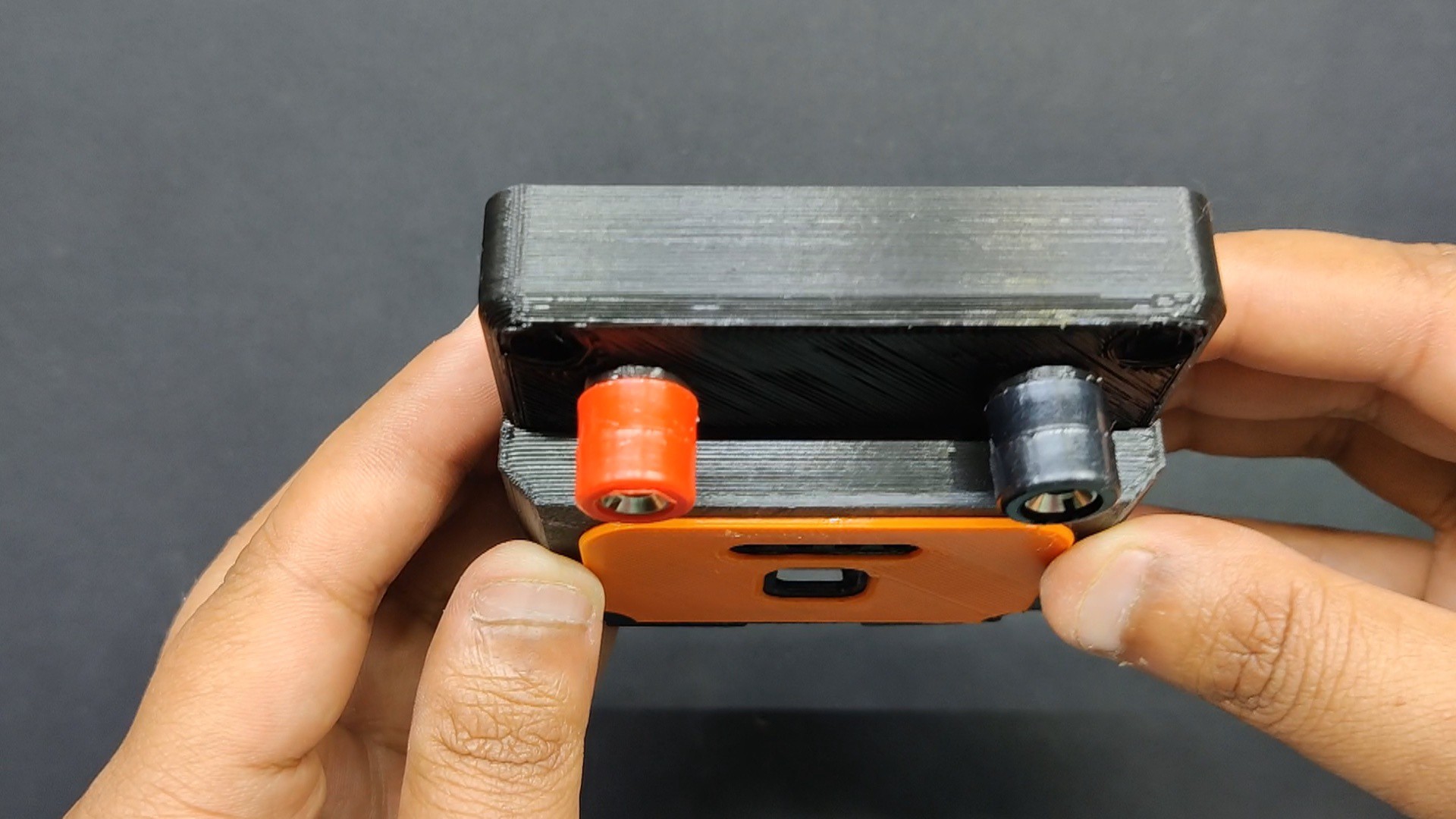

5TOP-CIRCUIT Assembly

![]()

![]()

- Wires are added to the circuit is 5V and GND terminals to begin the TOP Section and Circuit assembly procedure.

- The positive and negative banana pin sockets are then connected to these 5V and GND wires.

- After positioning the 3D printed switch knob, we inserted the wiring and fastened it with four M2 screws to the top section.

-

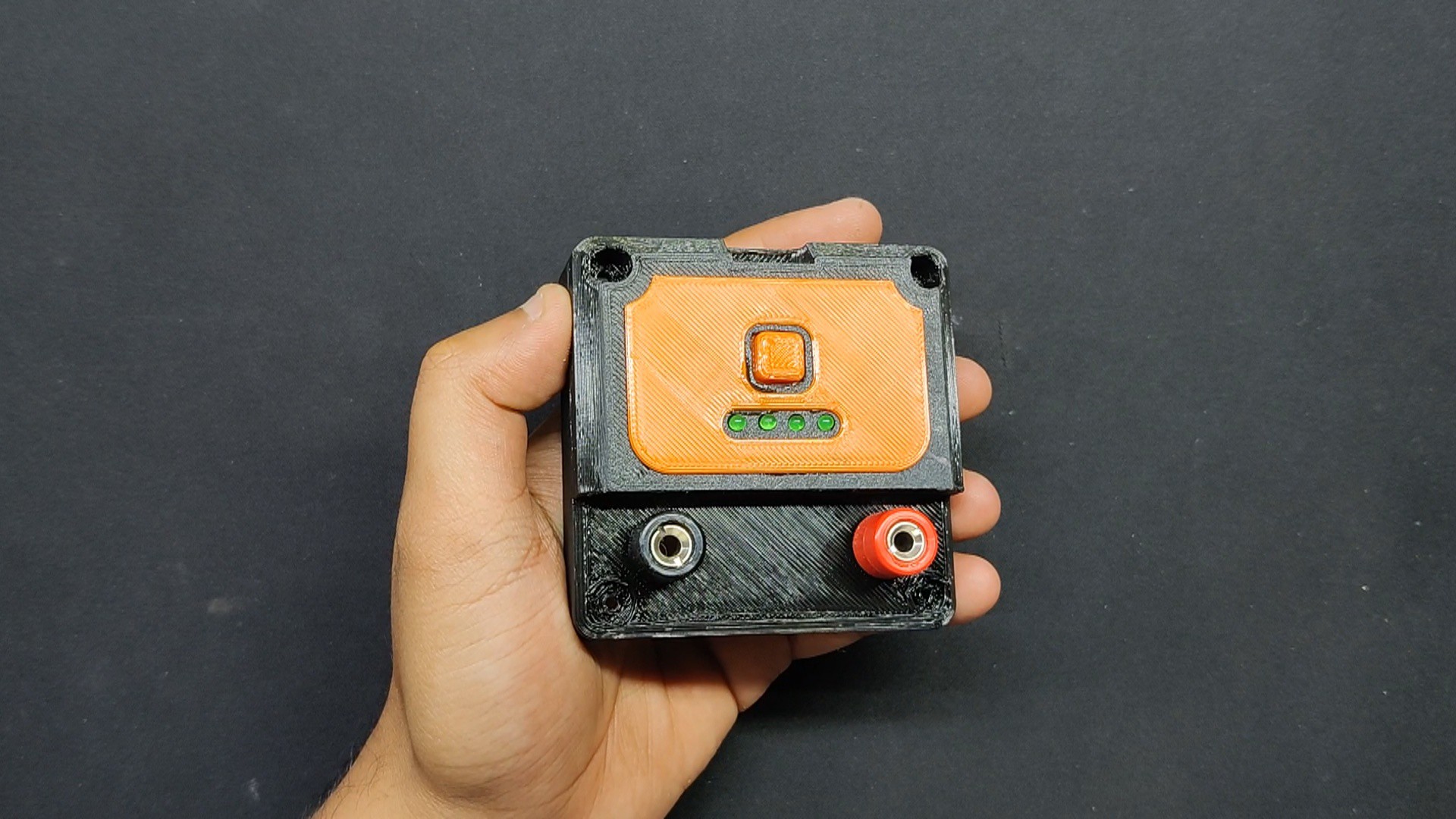

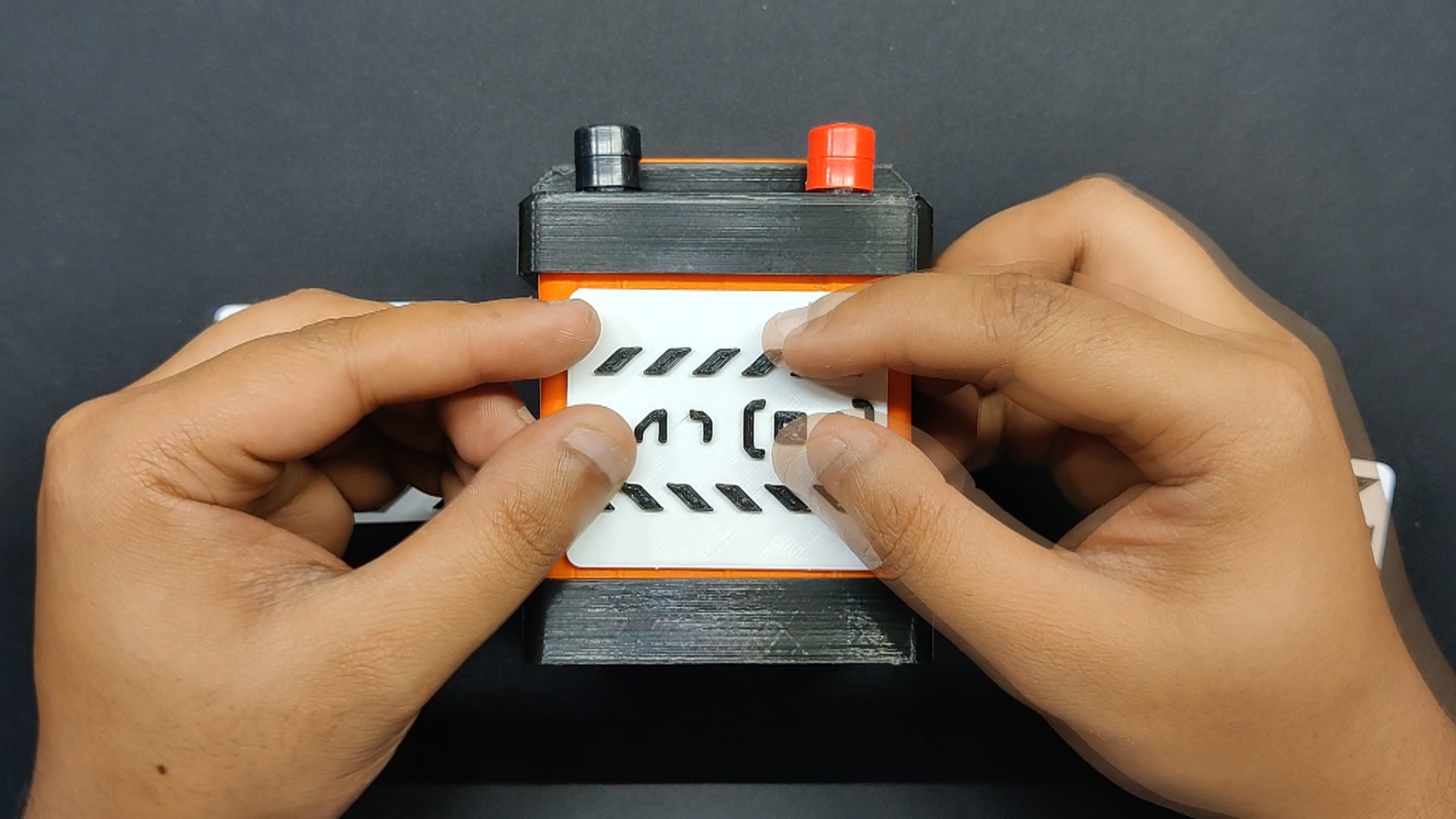

6Final Assembly

![]()

![]()

![]()

![]()

![]()

![]()

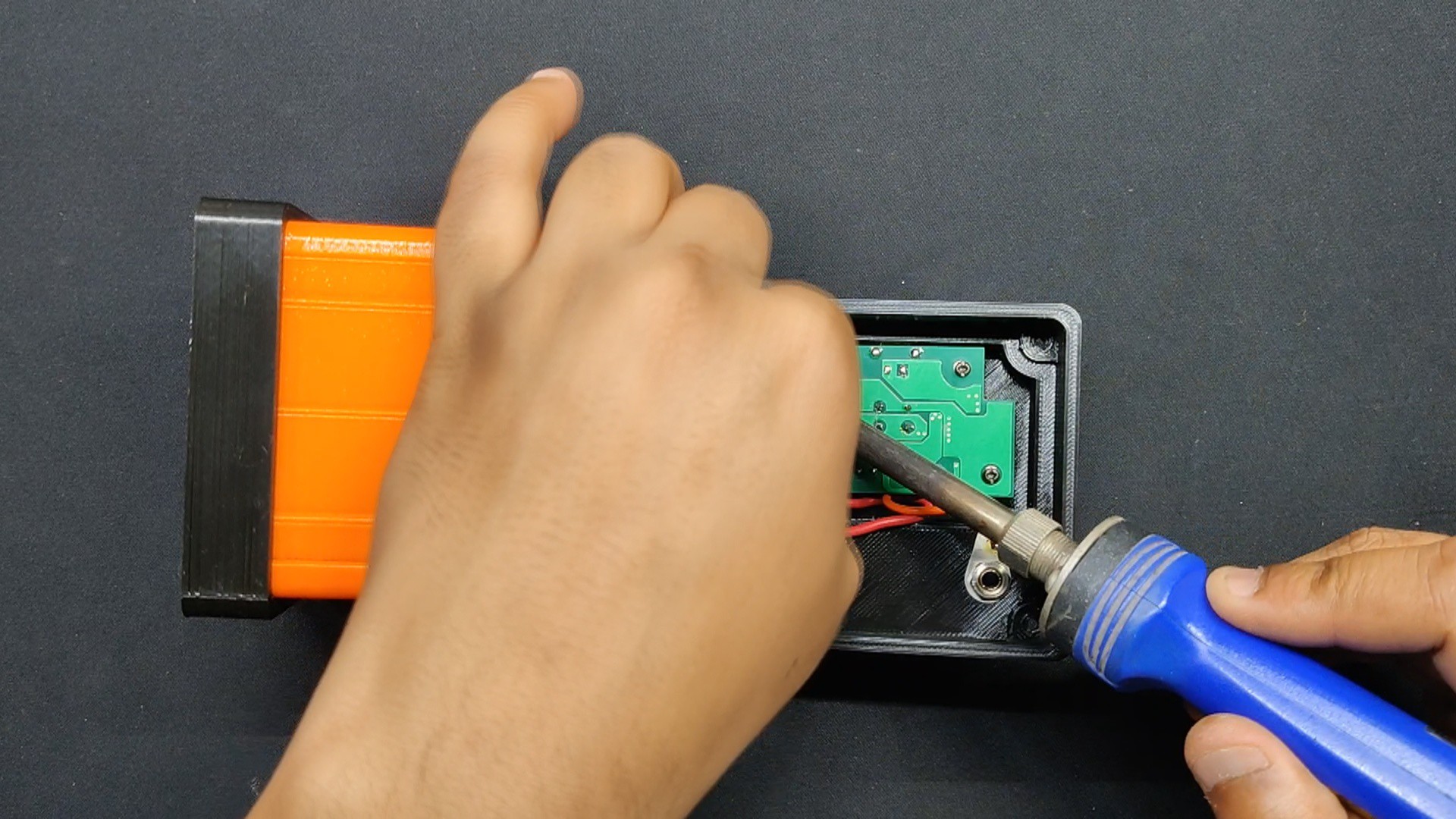

- We begin the Finale Assembly procedure by using a soldering iron to connect the battery pack's positive and negative terminals to the circuit's battery connectors.

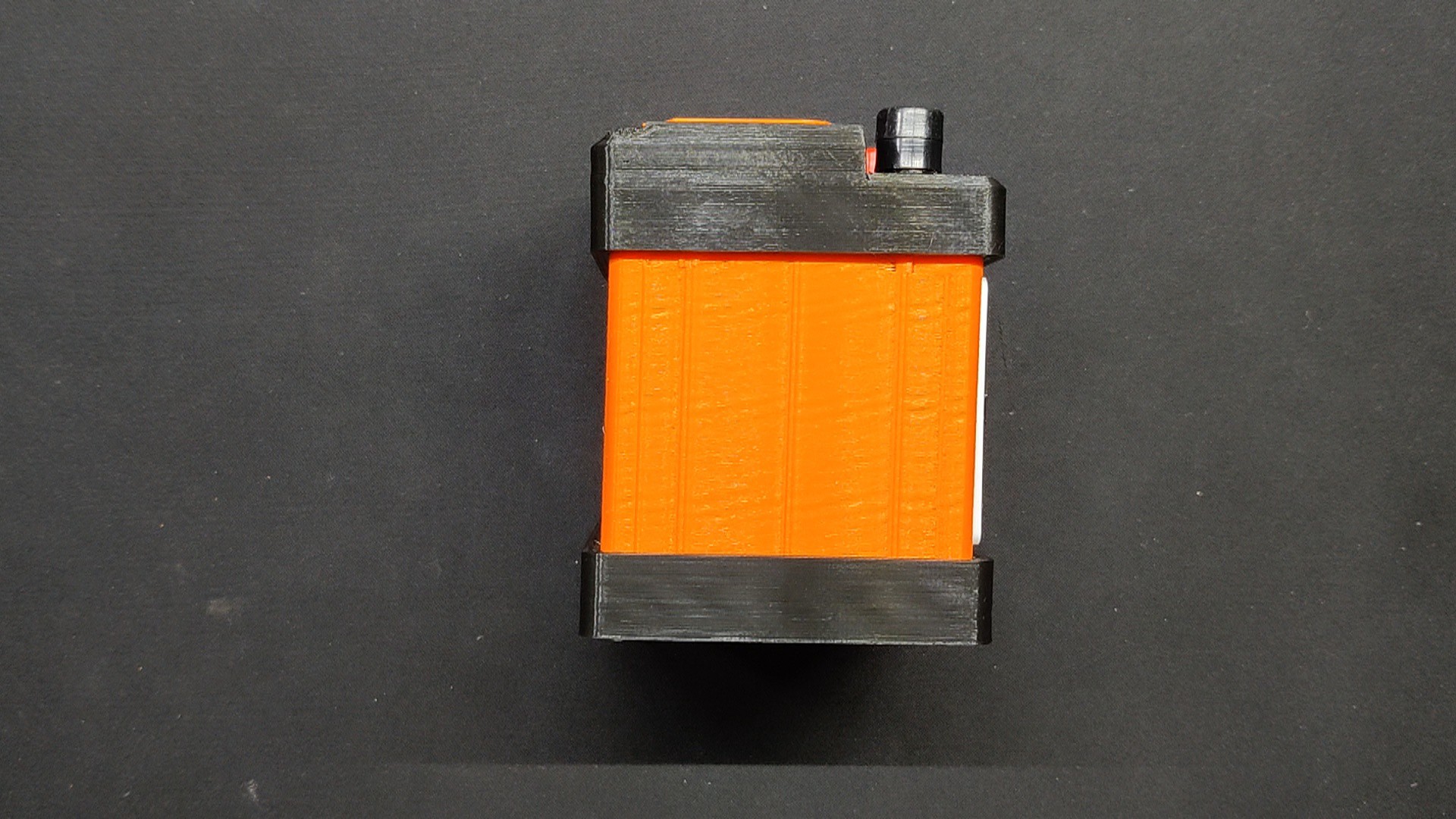

- The Top assembly section was then placed on top of the midsection, and four M2 screws were used to fasten them both.

- We used super glue to add the flat components to the front, left, and right of the midsection after fastening the three sections together.

- The Assembly is now finished.

-

7Result

![]()

![]()

![]()

![]()

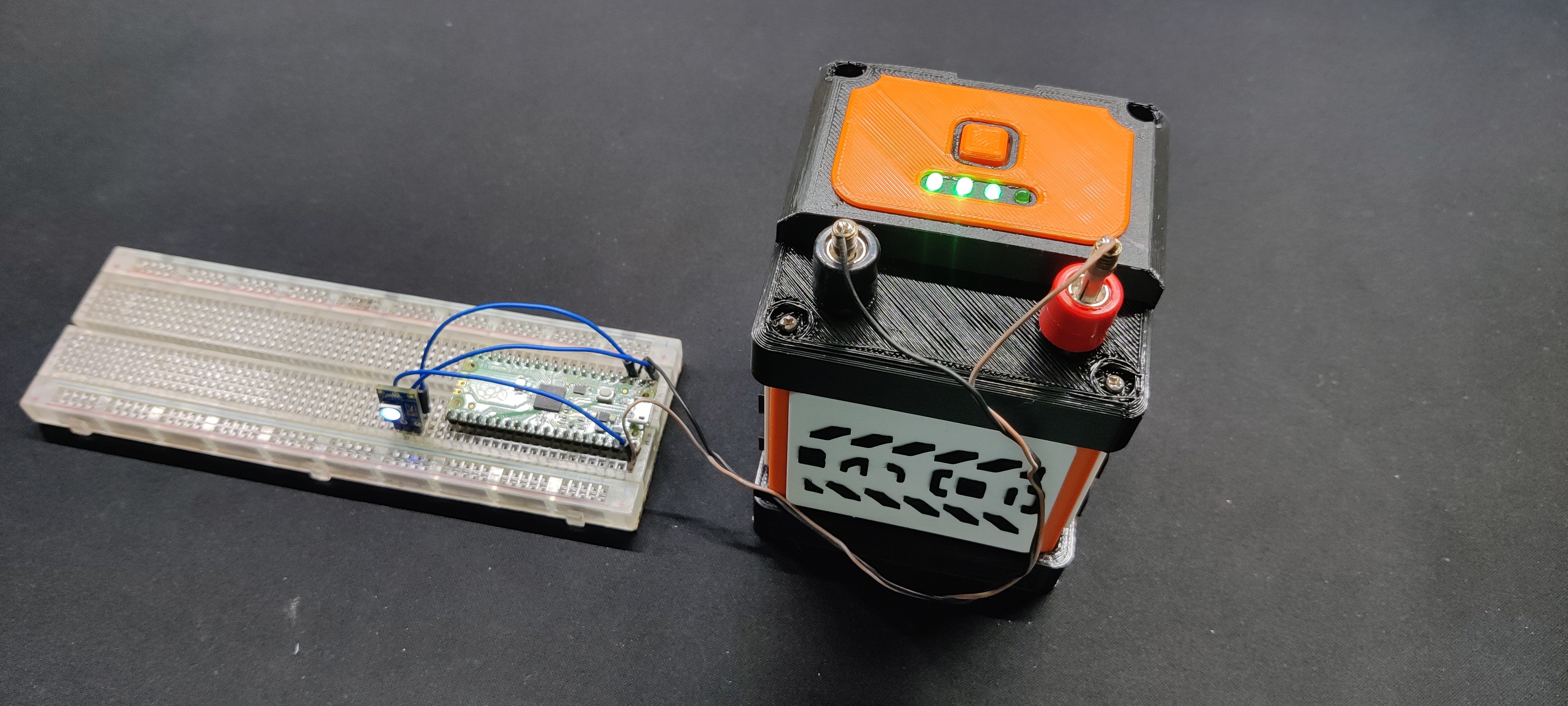

This is the result of this powerful build: a cyberpunk-themed battery pack that can supply a steady 5V/2A to power a variety of 5V devices. This battery has a 96.5Wh overall capacity, which is excellent for long-term use to power anything.

To turn this device on, press the center push button. If you press the button twice, it will switch off. After 30 seconds, it will automatically switch off if there is no load connected.

This battery pack can be charged using the type C port that is located on the back face of the top section. An indicator that indicates the battery's charge level will be provided by the battery indicator LEDs as it charges.

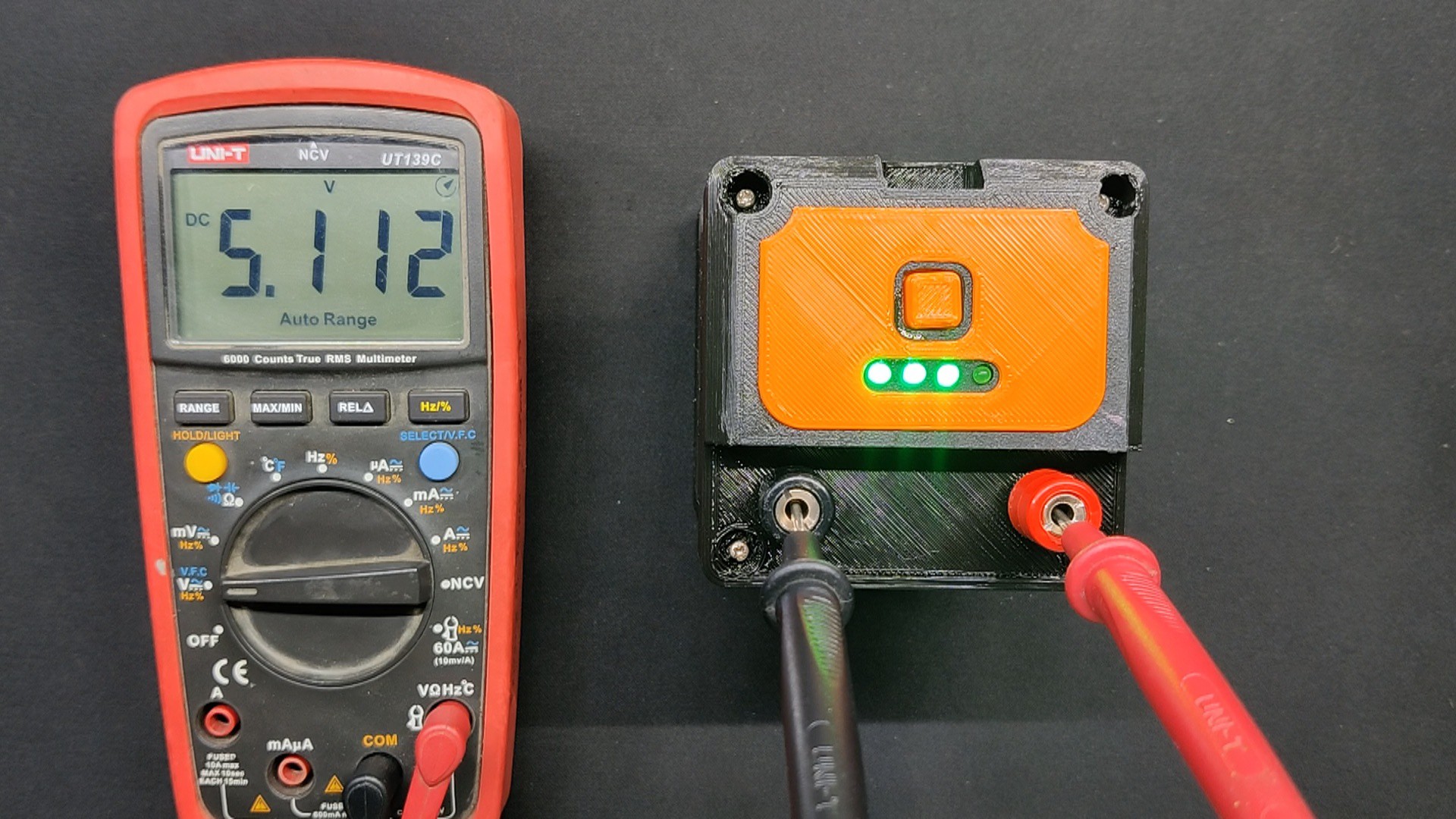

We used a multimeter to measure the output of this device to make sure it was operational, and sure enough, it delivered a steady 5V and operating as intended.

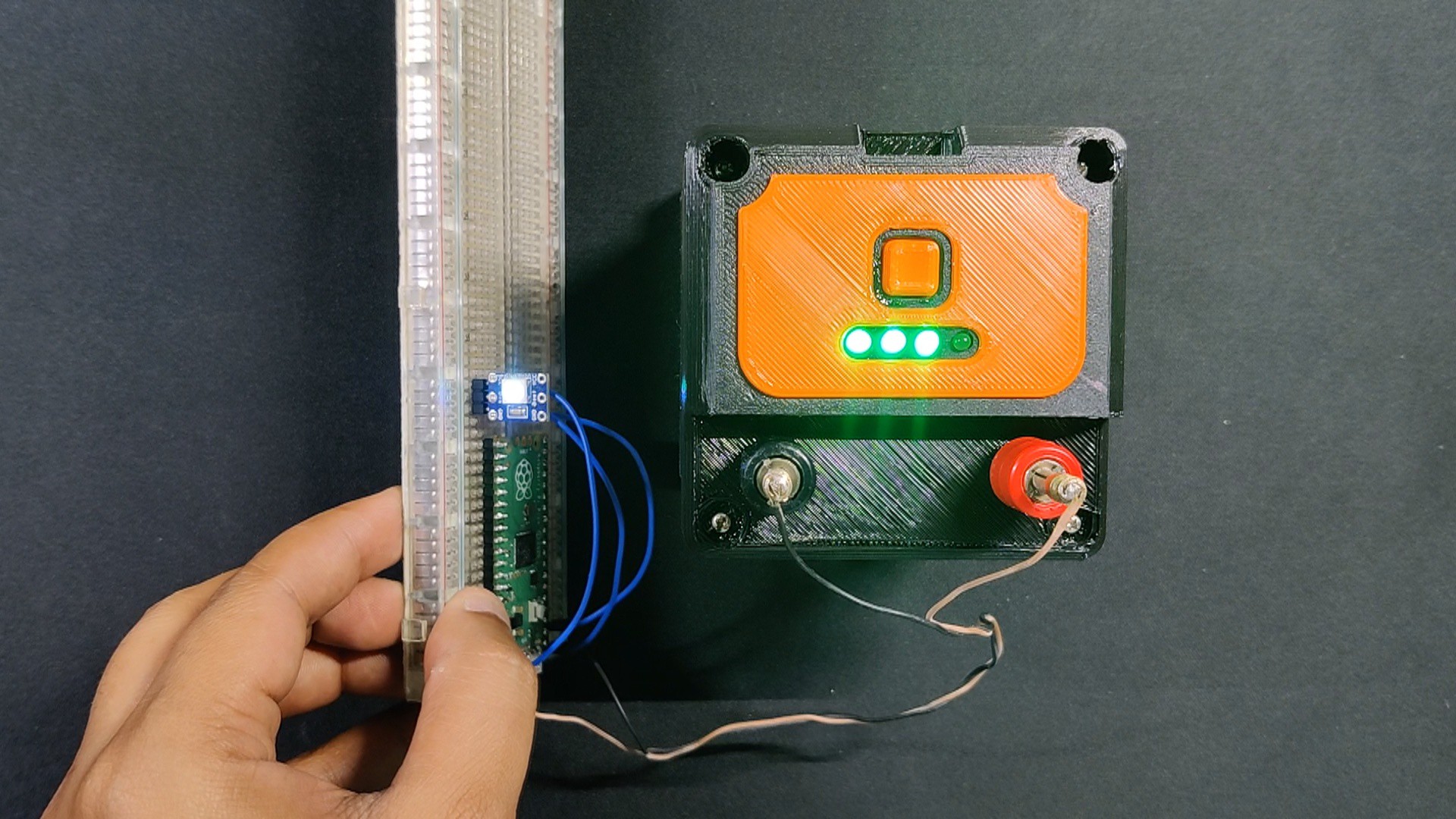

Next, in order to power the Raspberry Pi Pico Setup, we connected a WS2812B LED to the Pico's GPIO0, VCC, and GND using our Voltmaster Battery Pack.

We powered the Pico setup by adding 5V to its VBus terminal and GND to GND. This showed that the battery pack device functions and can be used to power various microelectronic setups that need a steady 5V to run.

Overall this project was completed and needed no further revisions.

Special thanks to HQ NextPCB for providing components that I've used in this project, check them out for getting all sorts of PCB or PCBA-related services for less cost.

Thanks for reaching this far, and I will be back with a new project soon.

"VOLTMASTER" the 5V Power Source

VOLTMASTER is a constant 5V power source which can be used to power a variety of 5V devices, including MCUs, SBCs and even smartphone.

Arnov Sharma

Arnov Sharma

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.