As we mentioned in previous logs, we decided to abandon the 5/3 spool control valve in favor of a different type of valve that would be easier to design and manufacture using 3D printing.

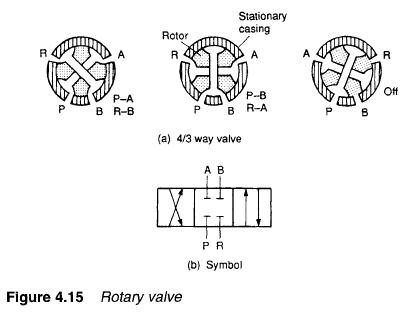

We opted for a 4/3 rotary control valve:

By rotating the piston within the valve, we can selectively connect and disconnect the channels.

We chose this type of valve because it operates using rotational motion. Since we still plan to use a 9g servo, this design eliminates the need to convert rotary motion into linear motion, simplifying both the design and manufacturing process compared to the linear 5/3 valve.

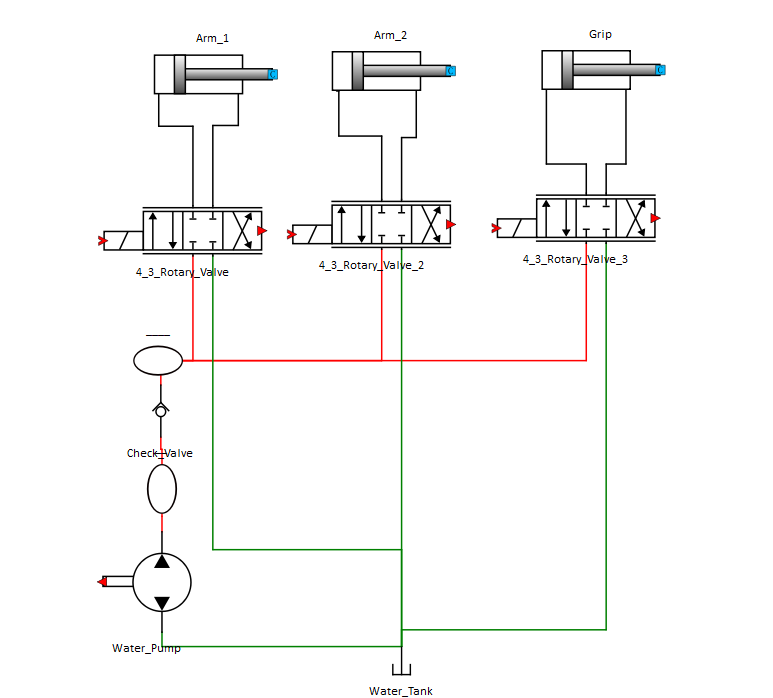

Additionally, after further discussions, we decided to switch to hydraulics for our project. This decision was driven by two key reasons:

- Precision: Hydraulic systems are much more precise and have less "jankiness" compared to pneumatic systems.

- Improved sealing: Rotational motion is inherently more difficult to seal than linear motion. Air is already challenging to seal properly, especially when using 3D printing technology. Switching to hydraulics, which uses a liquid medium, reduces the risk of leaks and makes sealing the valve more manageable.

With these considerations in mind, we are now moving on to the design and construction of the 4/3 rotary control valve.

Nasser

Nasser

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.