We discovered the 4/3 rotary valve through this video:

The video even provided technical drawings to recreate the valve. However, the original design relied on CNC machining to fabricate the valve from metal.

Since we only had access to 3D printing, we had to adapt the design:

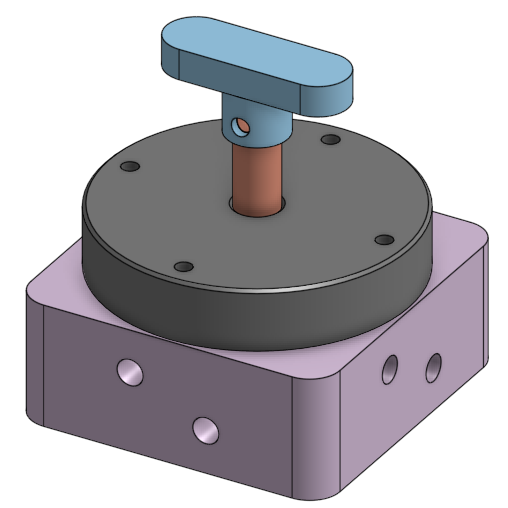

Initial Design

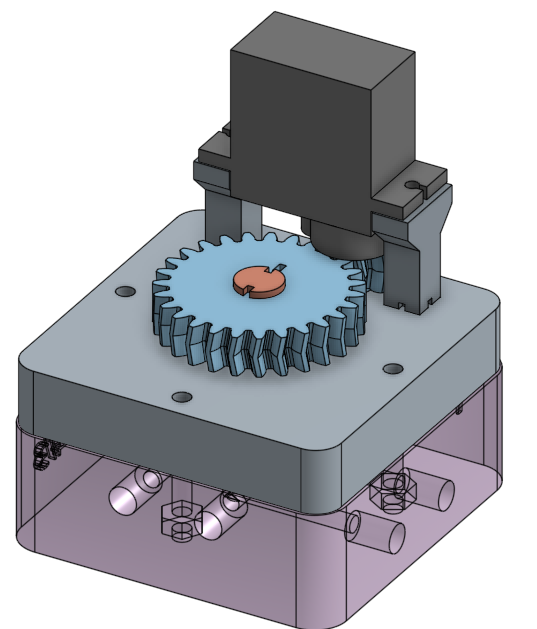

- CAD Model:

|  |

- Printed Valve:

![]()

To test the performance, we created a hand-operated version of the valve.

- Test Results:

- The valve performed well, holding pressure up to 5 bar.

- Leaks occurred at two locations:

- Through the plastic base.

- At the fittings.

Encouraged by the results, we addressed these issues and worked on making the valve servo-operated.

Addressing Issues

- Plastic Base Leak

- Switched to PETG instead of PLA, as PETG is less porous.

- Fitting Leak

- Increased clamping force by using longer screws.

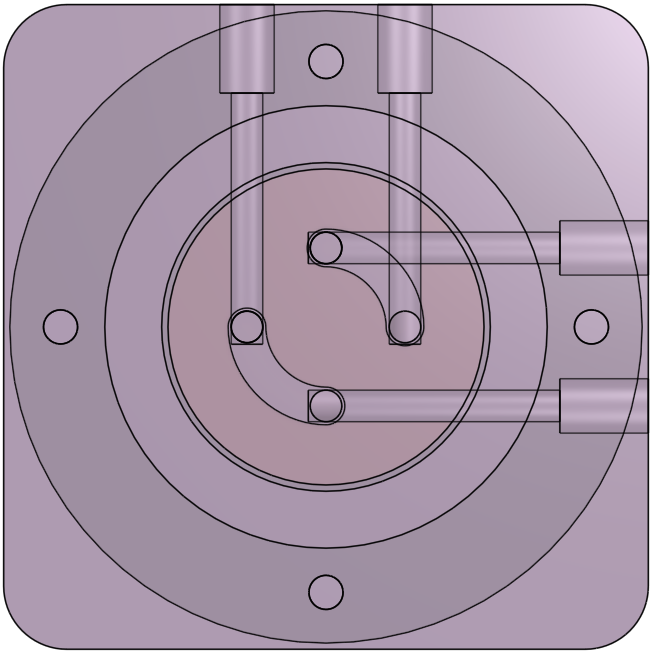

First design

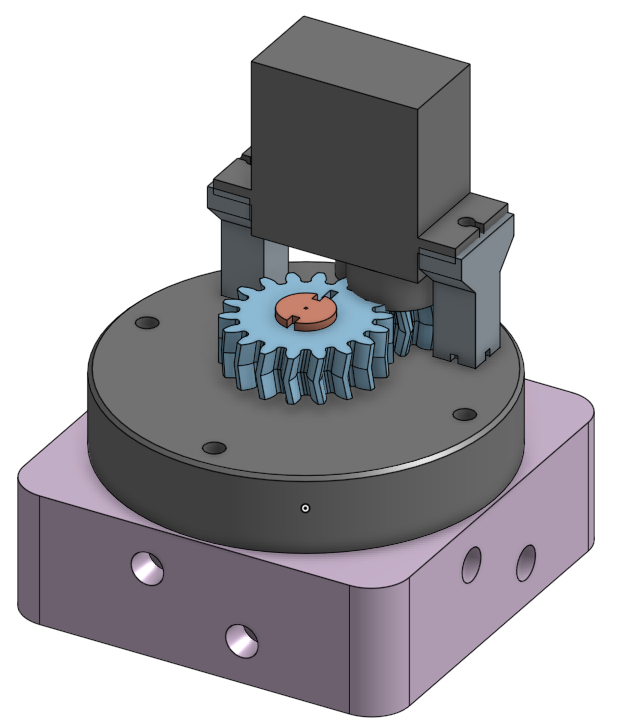

- CAD Model:

![]()

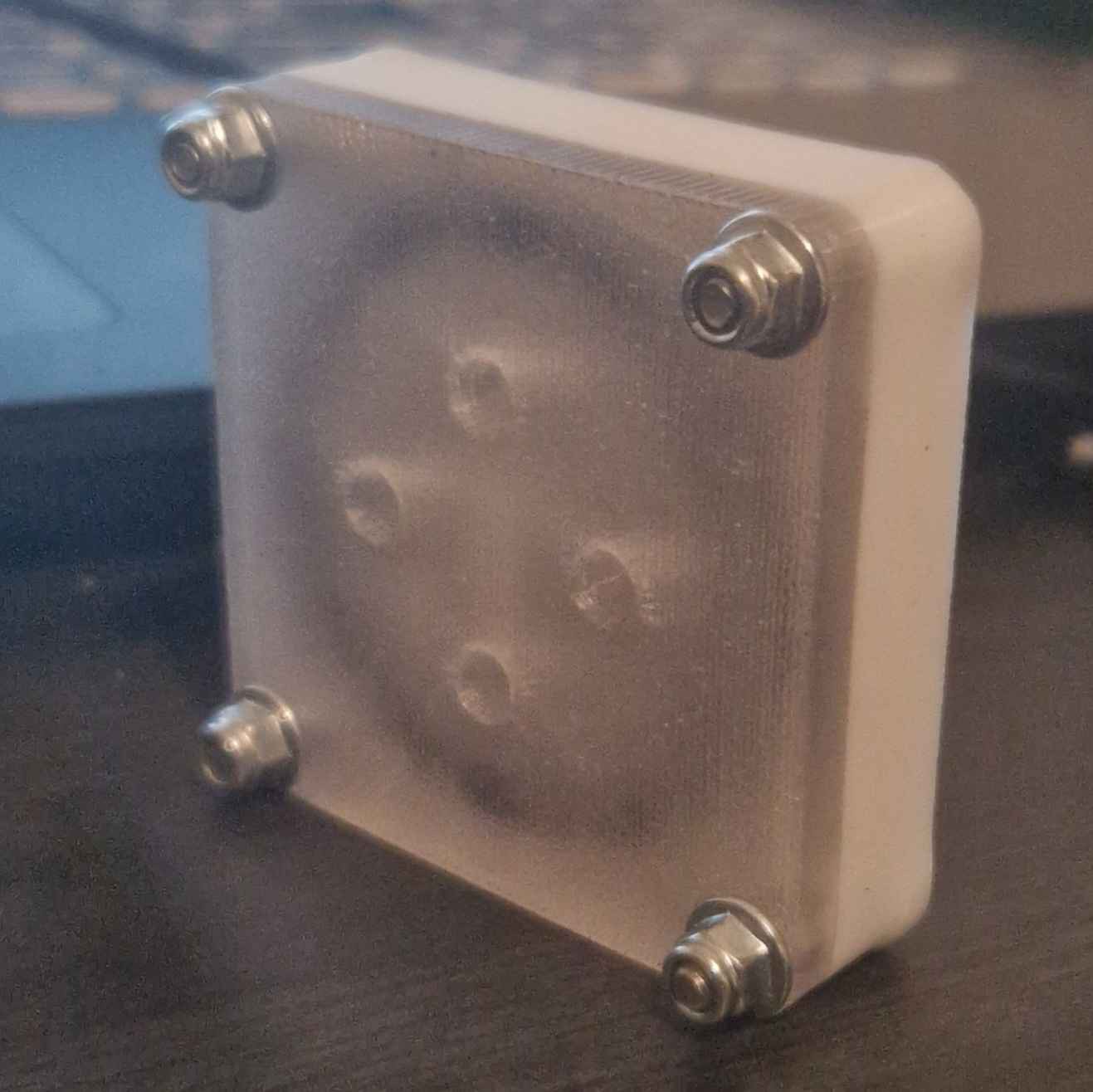

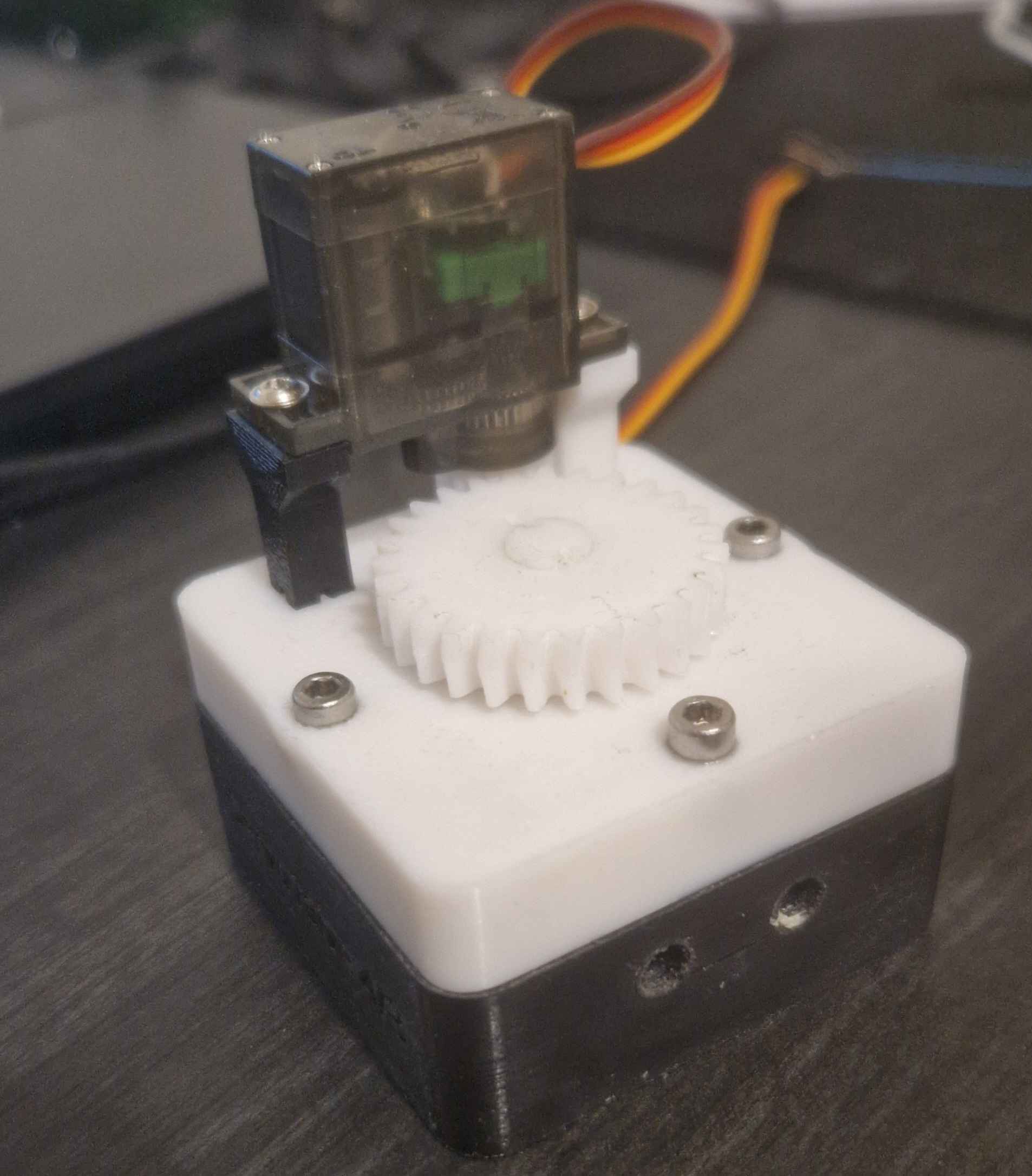

- Printed Valve:

![]()

This version featured a 1:1 gear ratio to drive the piston.

- Performance:

- Slightly worse than the first design.

- PETG proved to be more porous, leading to increased leakage.

- Clamping force was still insufficient.

Second design

To maximize clamping force, we redesigned the valve so that screws passed completely through both parts and were secured with nuts on the other side.

- Outcome:

- The valve was now too hard to turn for the 9g servo.

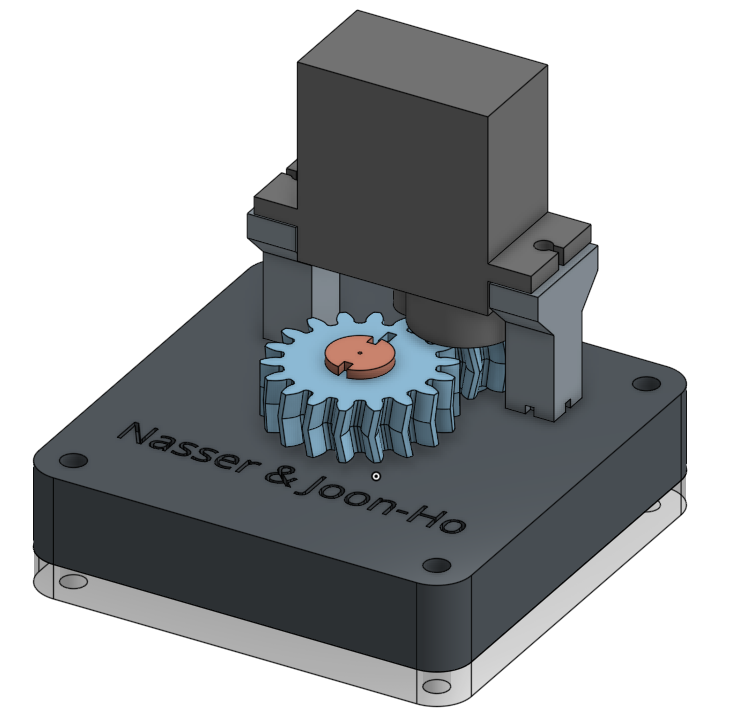

Alternative Design Attempt

We tried a new 4/3 rotary valve design inspired by another video:

- CAD Model:

|  |

- Printed Valve:

|  |

- Performance:

- Poor overall.

- Hard to turn for the 9g servo.

- Leaked more and could only hold up to 2 bar.

Realizations and Adjustments

At this point, performance was consistently declining with each new iteration. The valves we printed couldn’t hold more than 2 bar and leaked excessively.

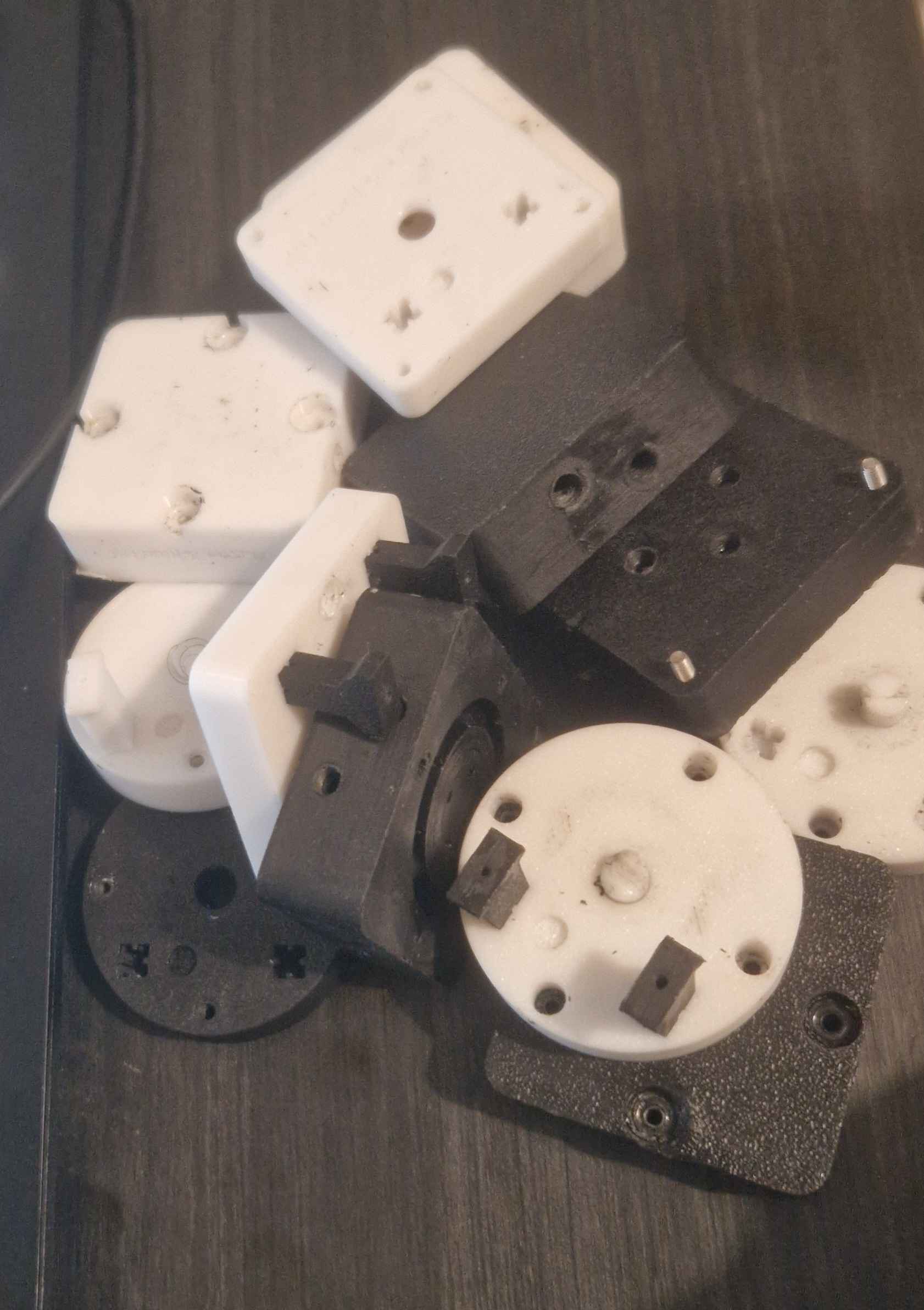

Here’s how many valves we printed during this process:

We decided to return to our first design, as it had performed the best.

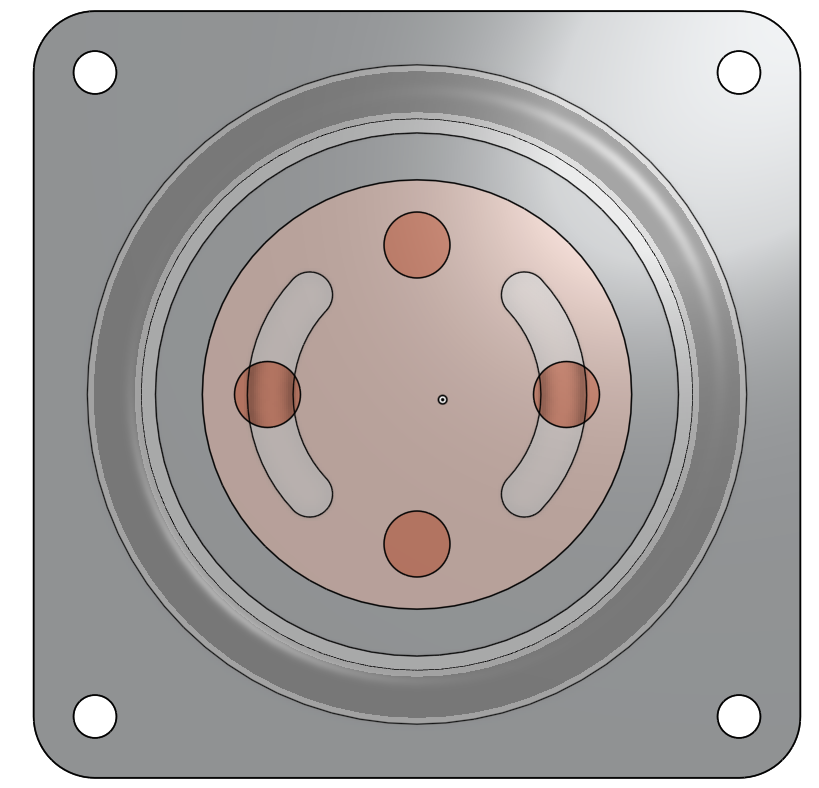

Final Adjustments

- Minor Adjustments:

- Inserted a nut mid-print to improve clamping force

- Used a larger gear ratio to compensate for higher clamping force and increased turning resistance.

- CAD Model:

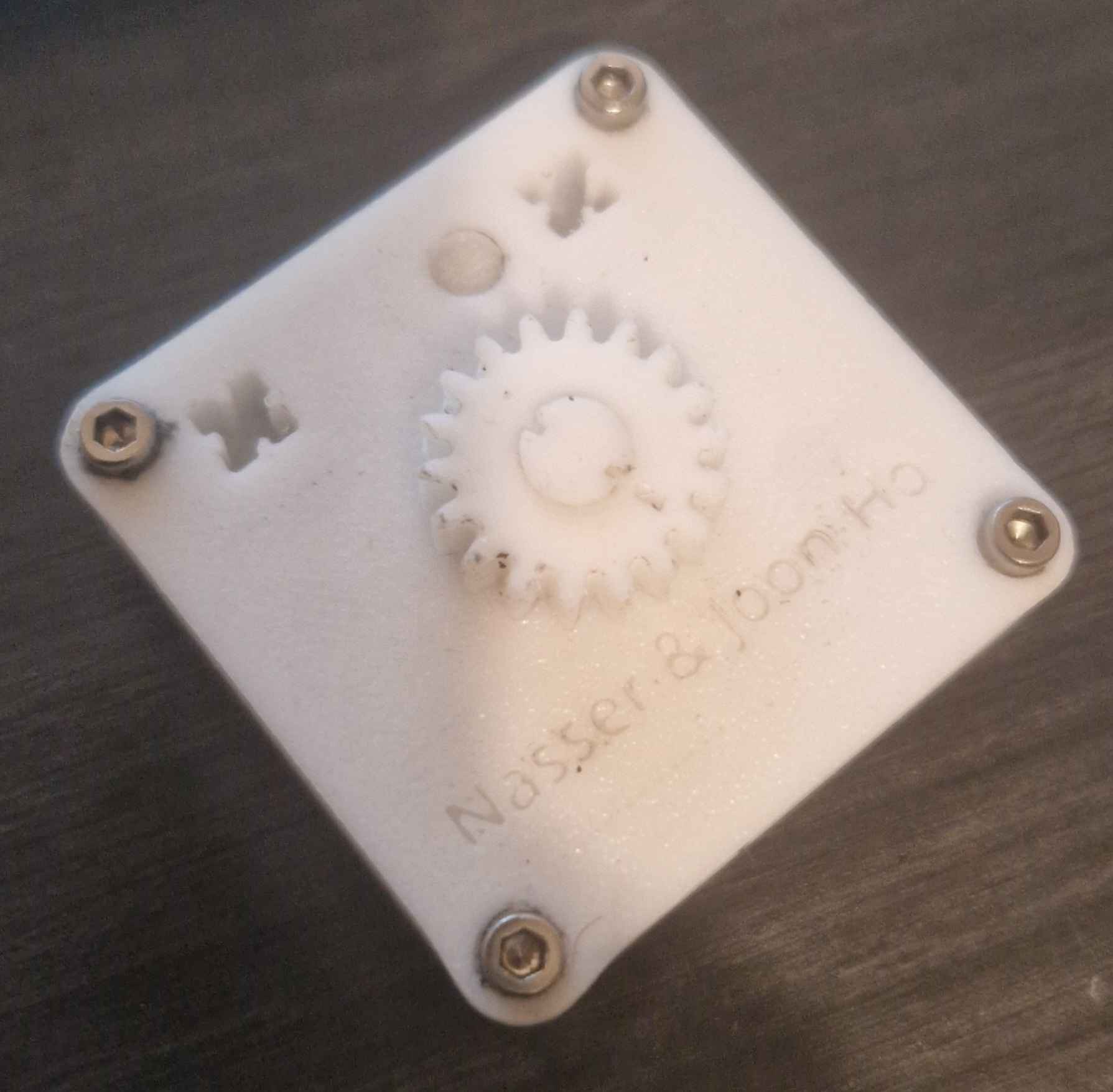

- Printed Valve:

- Performance:

- As good as the original design.

- Leaked through the plastic, but we accepted this limitation.

Final Design

To manage leaks, we devised a solution (to be explained in the next log) that minimized their impact.

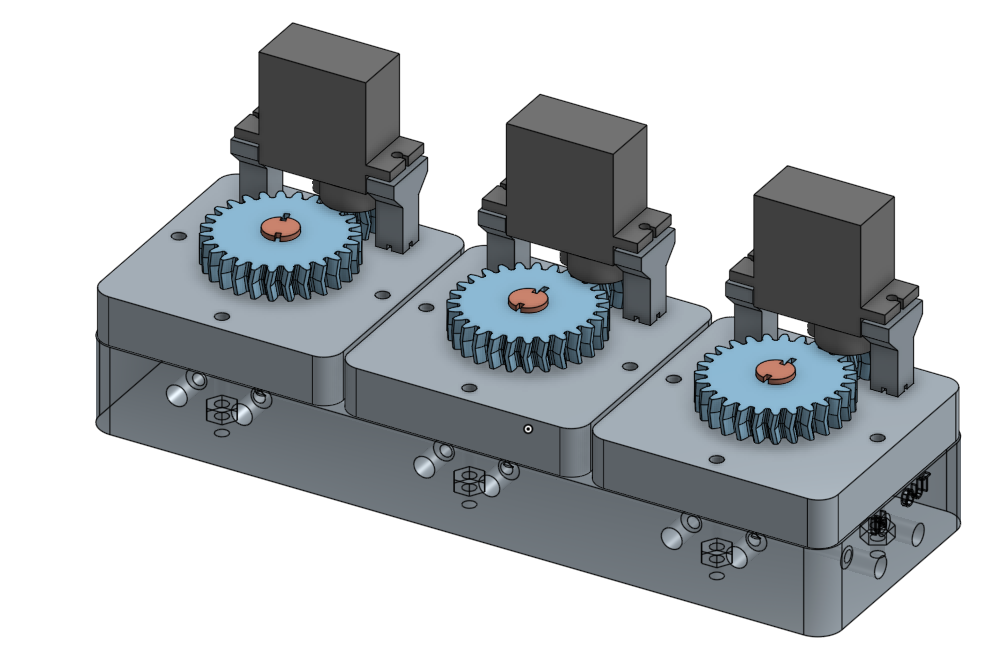

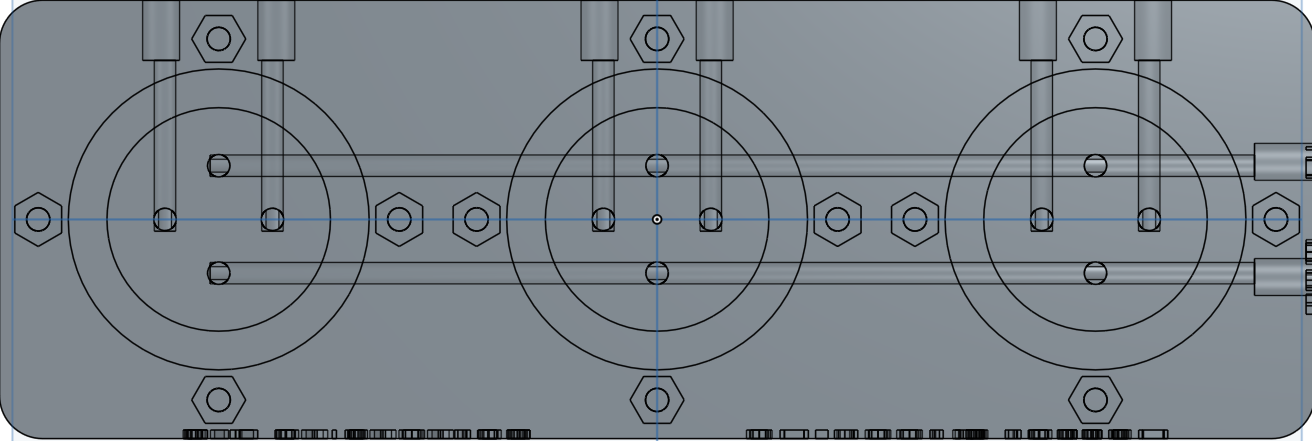

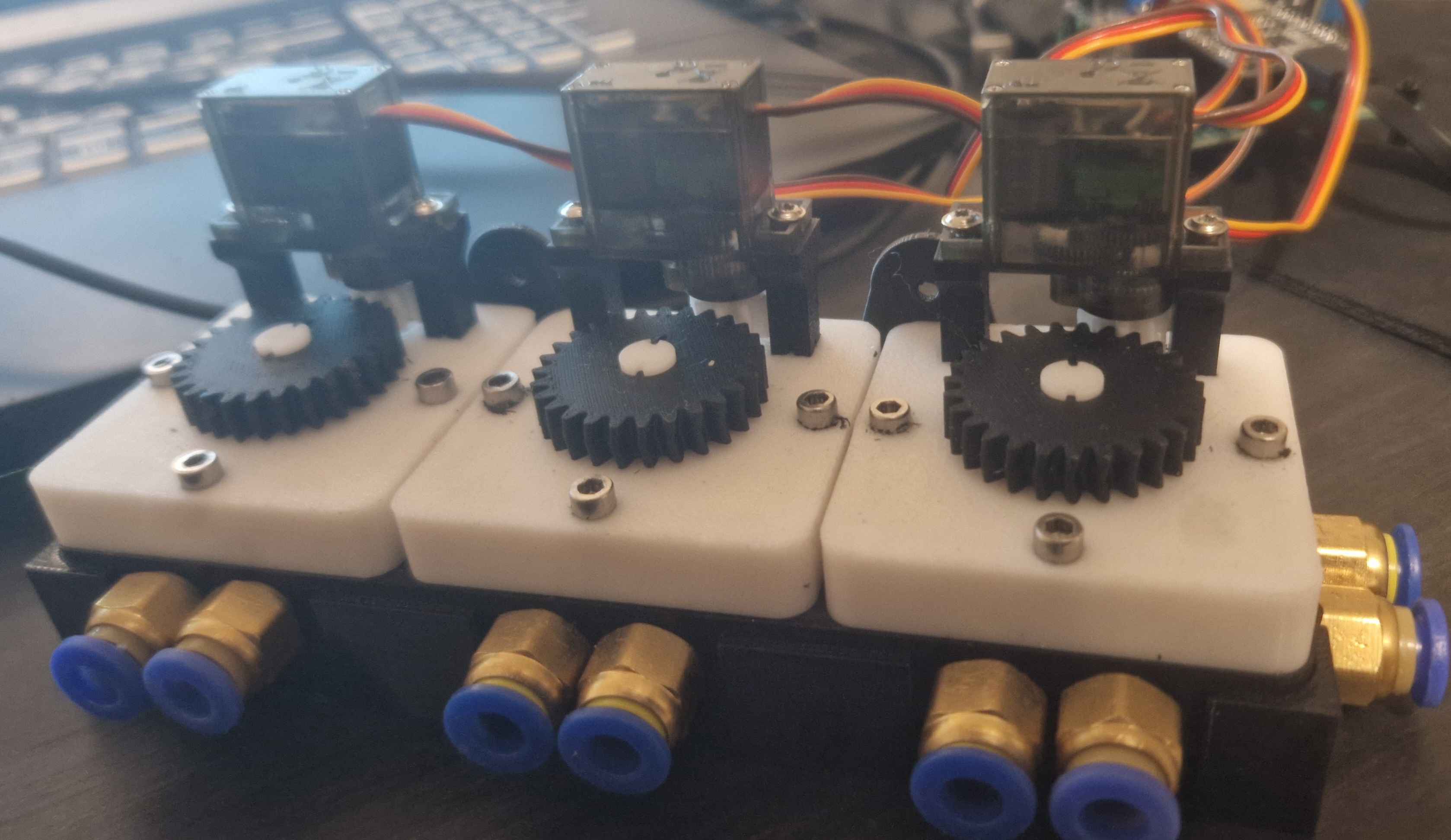

Satisfied with the results, we scaled the valve to control three actuators instead of one.

- FINAL CAD Design:

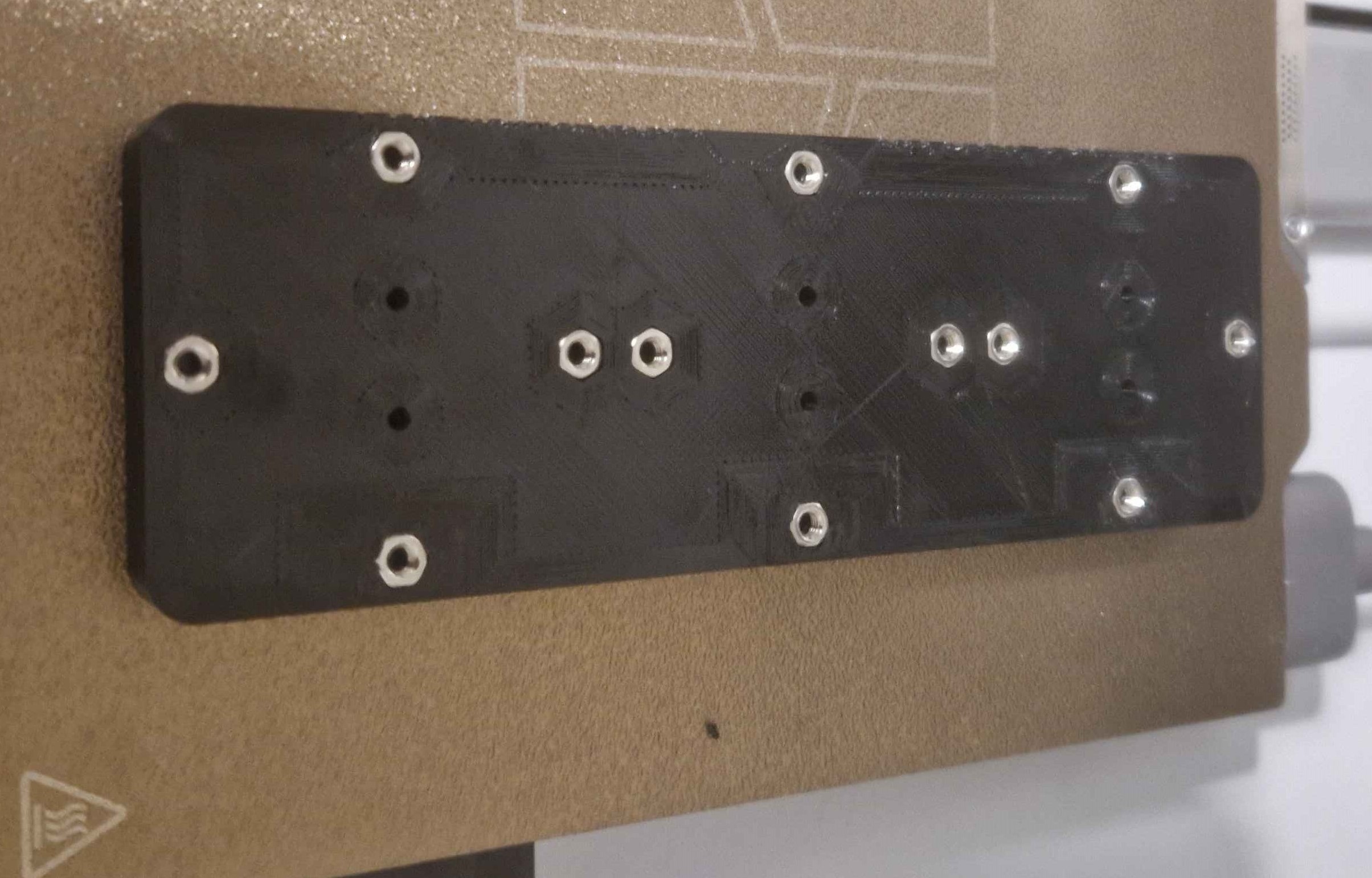

- Printed Valve:

Nasser

Nasser

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.