I had to change my approach to this project many times as it changed phases. With investment casting, I have take the scientific approach and put the breaks on my humanity. To force myself to work only on planned tasks, not get distracted by randomly working on pieces of other tasks, and give each task the proper time it deserves I started keeping a daily log. Each day I write a mission statement and a list of tasks - I am not allowed to begin work before the plan for the day is written and it's set in stone until I leave.

Monday, February 20, 2017

Stories

- Get a perfect cast of the forearm clamp part – thin areas strengthened with sprues, perfect fill, no bubbles

- Get a perfect cast of both forearm shoulder parts

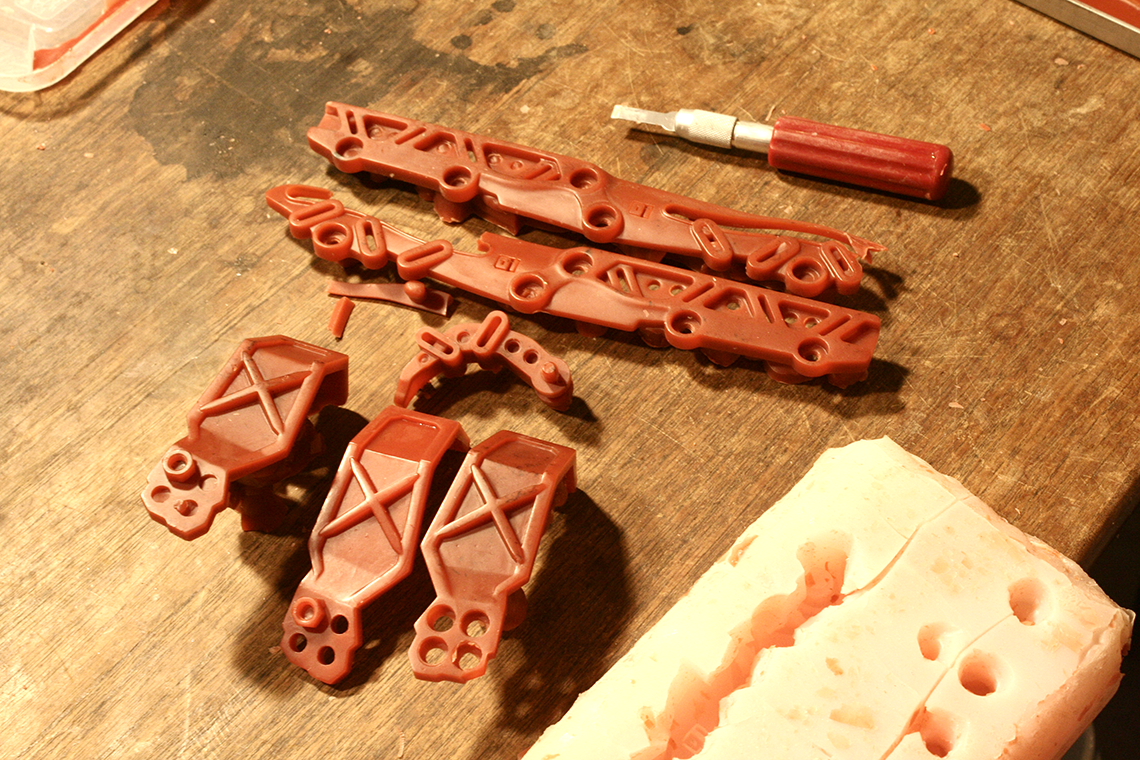

- Get a perfect cast of forearm cover parts

Tasks

2-part mold research- Clean up vacuum oven and vacuum chamber

- Continue 2-part mold research by cleaning up last night’s mold and pouring a second layer

temperature to avoid the mess?)

- Second shell layer (straight to secondary slurry, silica – fine)

- Install the new long blade on exacto knife

- Modify the forearm shoulder mold to remove thru holes and 1-3 test casts

- Modify forearm cover mold to add supports and 1-3 test casts

Tuesday, February 21, 2017

Themes (same as yesterday)

- Get a perfect cast of the forearm clamp part – thin areas strengthened with sprues, perfect fill, no bubbles

- Get a perfect cast of both forearm shoulder parts

- Get a perfect cast of forearm cover parts

Tasks

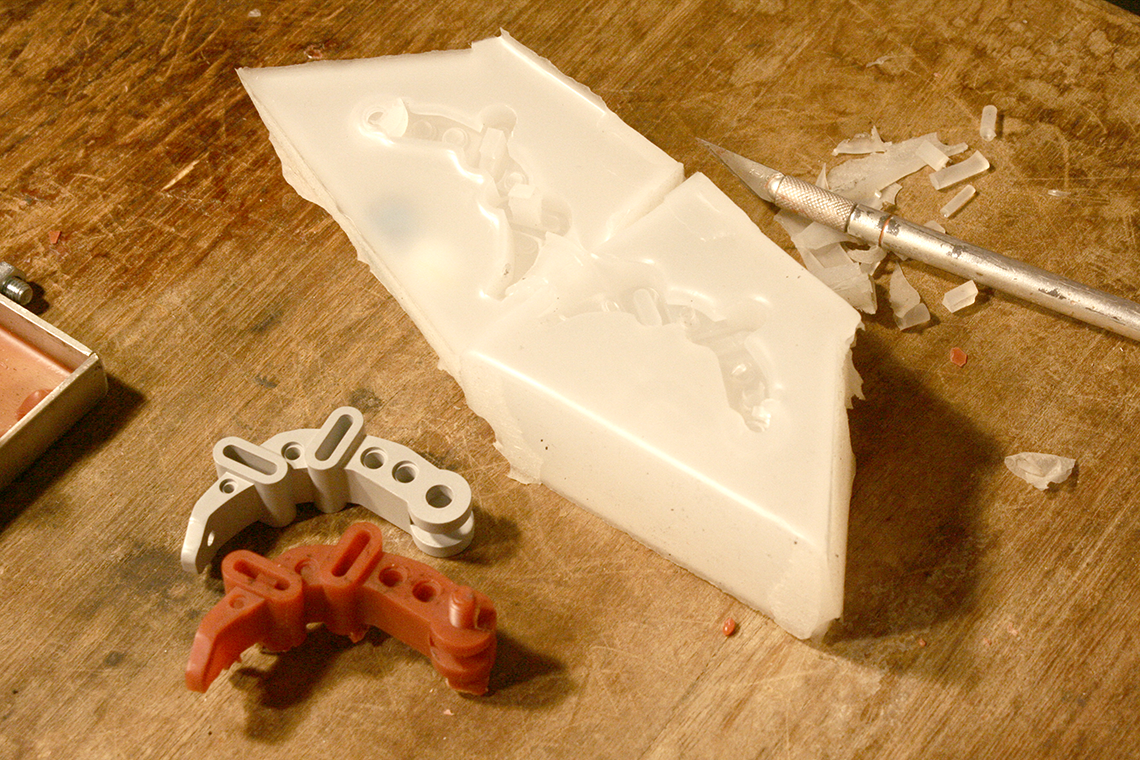

2-part mold research- Inspect the 2nd part of the 2-part mold

- If successful, perform wax test

- If not successful, research why

- Inspect the wax injected into the two-part mold with the syringe

- Iterate on the mold by cutting pieces that cause thin areas and thus fracturing of the wax model

- Third shell layer (secondary slurry, silica sand – fine)

- Stretch goal: try measuring viscosity of the secondary slurry.

- Modify the forearm shoulder mold further to remove holes (to stubs)

- Modify the forearm cover mold to allow demolding thin edge on one end

- Fourth shell layer (secondary slurry, silica sand – coarse)

- Another iteration of modifying the forearm cover mold to allow demolding thin edge on one end

- Another iteration of modifying the forearm cover mold to allow demolding thin edge on one end

Tuesday, February 22, 2017

Themes (same as yesterday)

- Get a perfect cast of the forearm clamp part – thin areas strengthened with sprues, perfect fill, no bubbles

- Get a perfect cast of both forearm shoulder parts · Get a perfect cast of forearm cover parts

Tasks

2-part mold research

- Inspect the wax injected into the two-part mold with the syringe · Iterate on the mold by cutting pieces that cause thin areas and thus fracturing of the wax model

Shell burnout research

- Fourth shell layer (secondary slurry, silica sand – coarse)

Wax fracture research (stretch goal)

- Another iteration of modifying the forearm cover mold to allow demolding thin edge on one end

Val

Val

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.