The experiment with ceramic fixtures made out of pottery clay failed because the clay shrinks when drying (and especially during firing) - I mounted the clay onto steel flasks to try to imprint the flask surface on the inside which meant the fixtures had no available space to shrink and blew up in the kiln.

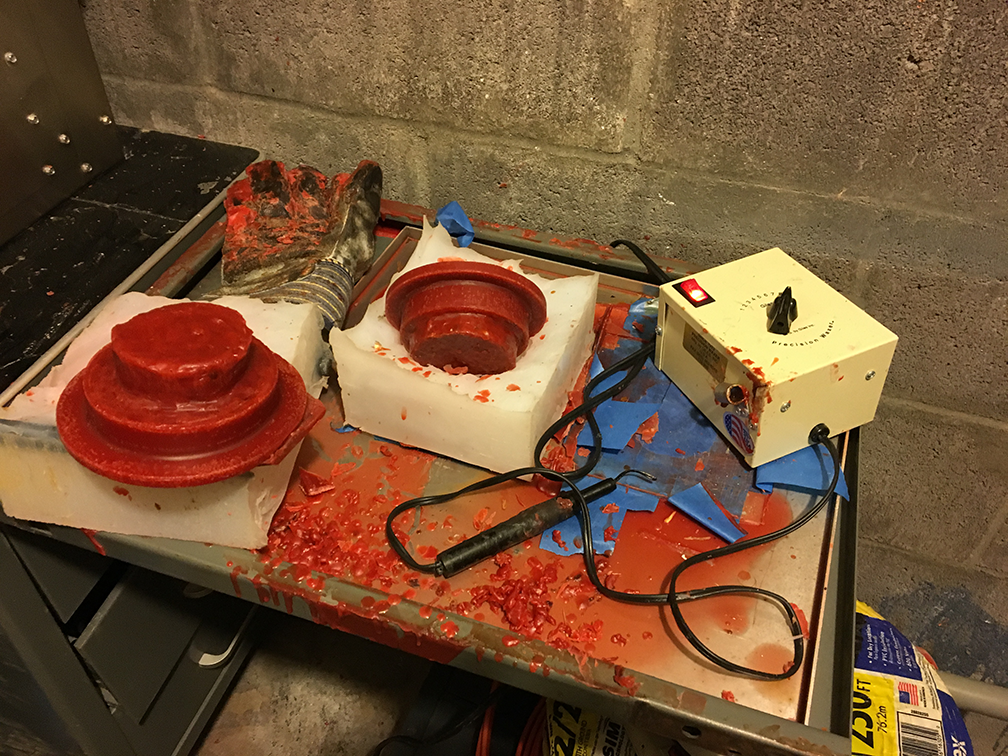

Plan B - I am going to try a quality ceramic casting compound for dense and high-detail casts with 1% shrinkage: Ceramacast. This time I will use wax cores cast from silicone molds to create the inside detail - after hardening, no firing is necessary and the wax core can be steamed out.

Val

Val

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.