-

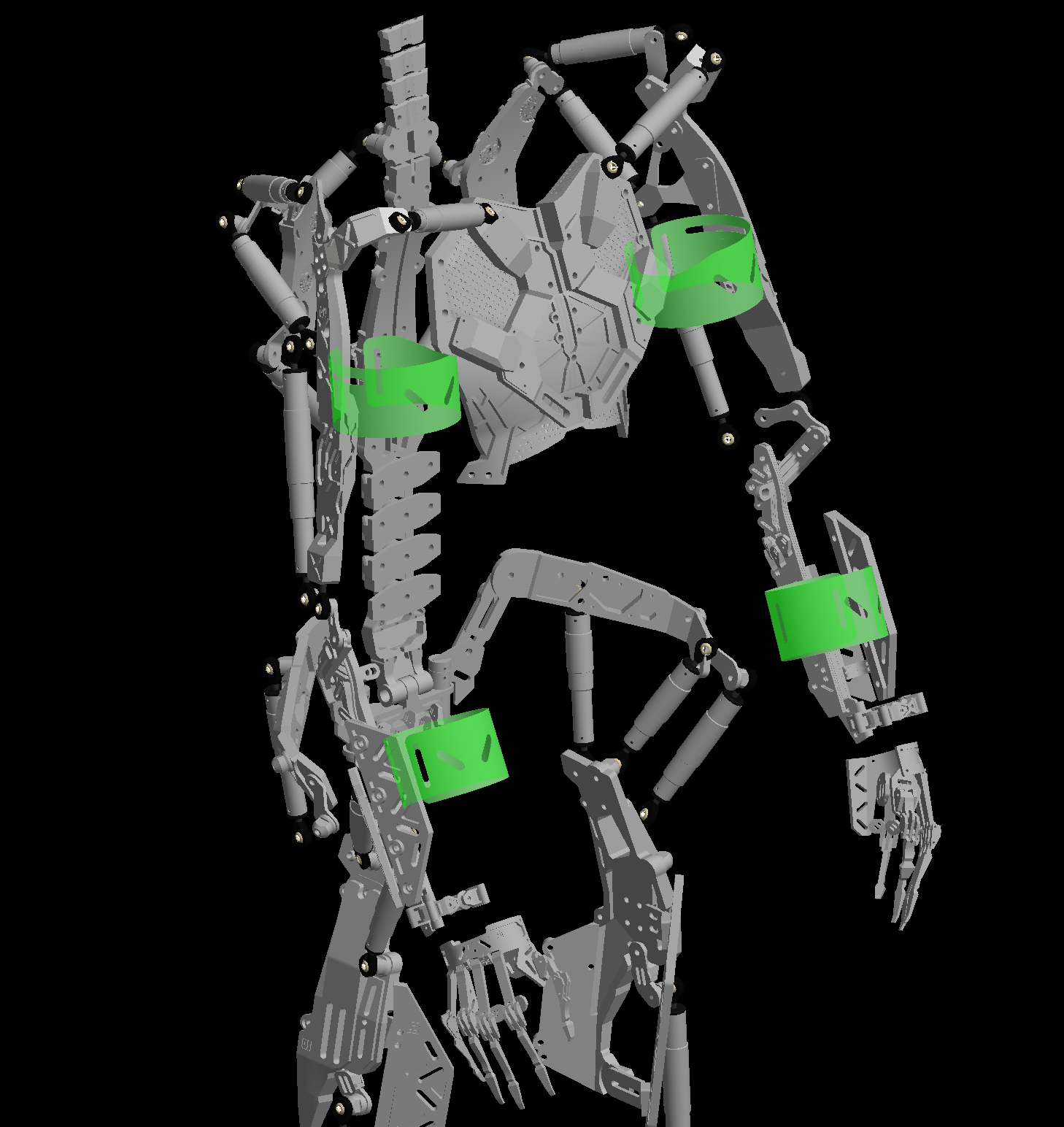

3D-printed shin guards re-cast out of rubber

05/14/2019 at 02:30 • 0 commentsThe past three weeks have been a living hell of trying to cast two large plastic parts with complex geometry and thin edges out of rubber. Today it ends!

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

I used SmoothOn Brush-On 40 to make the mold and shore 70 hardness rubber along with a black pigment to cast the parts.

-

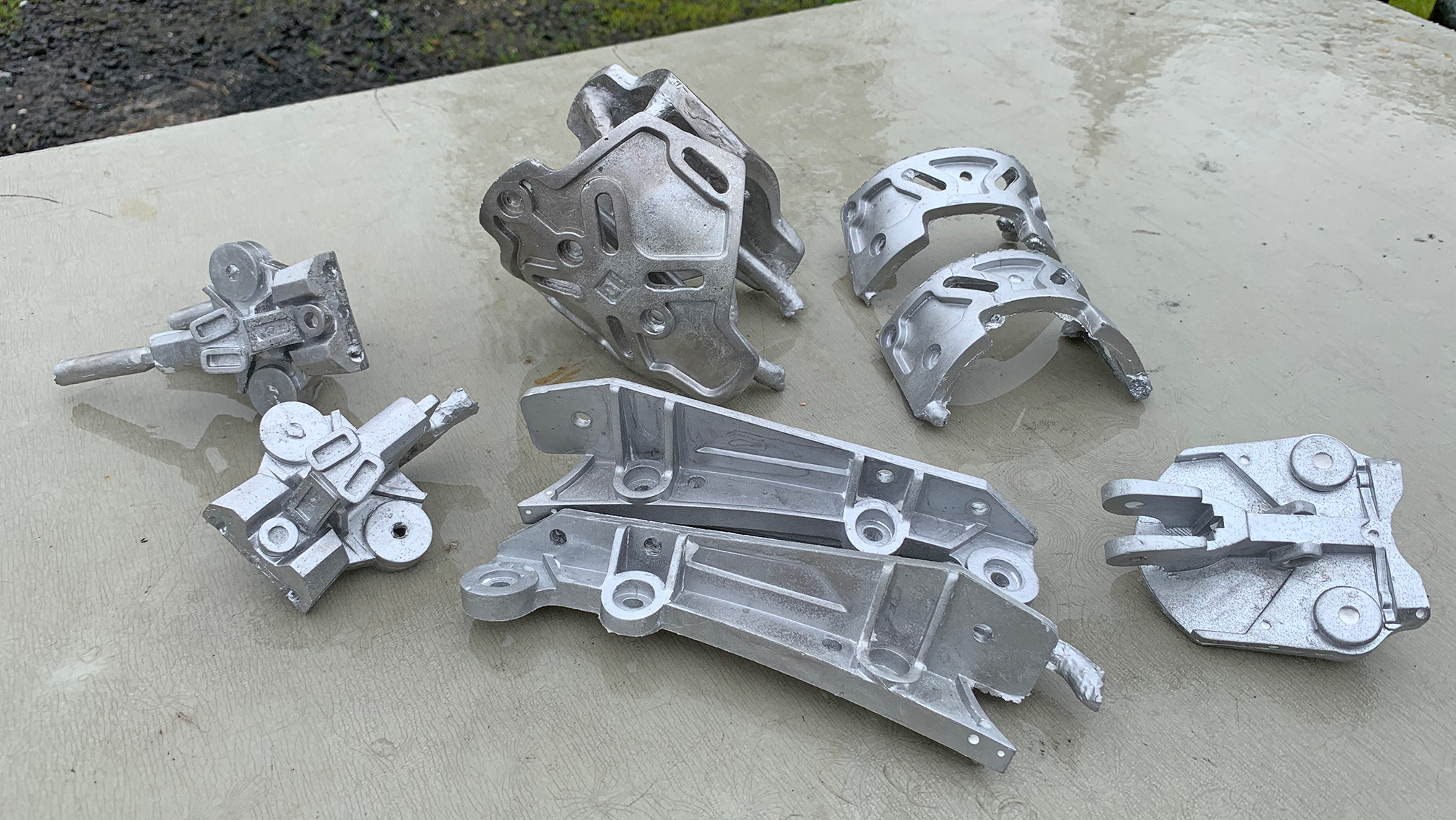

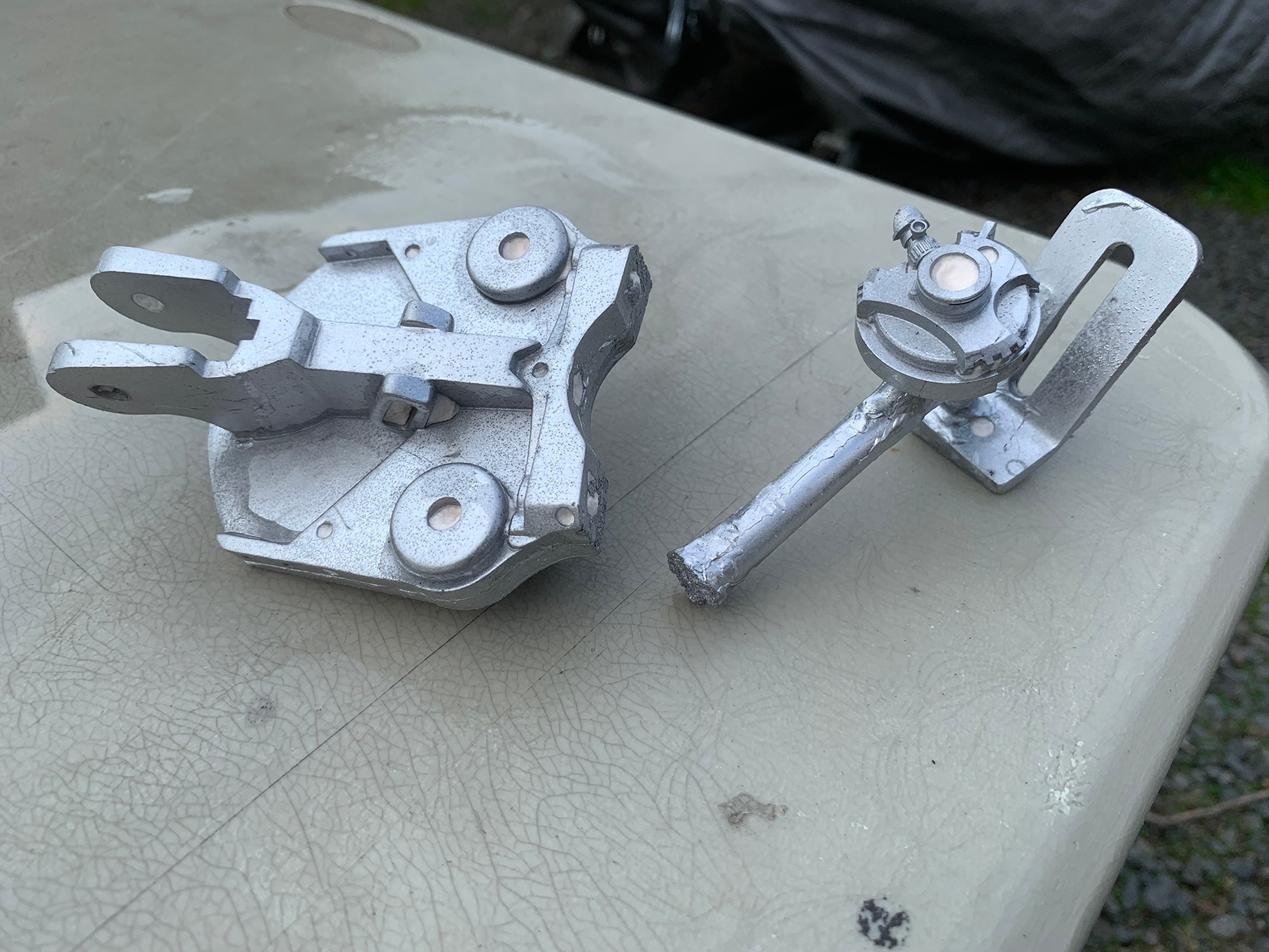

More parts cast, sheet metal order complete

04/19/2019 at 23:20 • 0 commentsIn the past 3 weeks I cast the remaining parts for the spine as well as shock plates/armor that will be attached to boots:

![]()

Just before that I cast two extra parts I was missing before, a shoulder connector with some extreme detail and an unsightly hip connector. One of the parts here is repeated above.

![]()

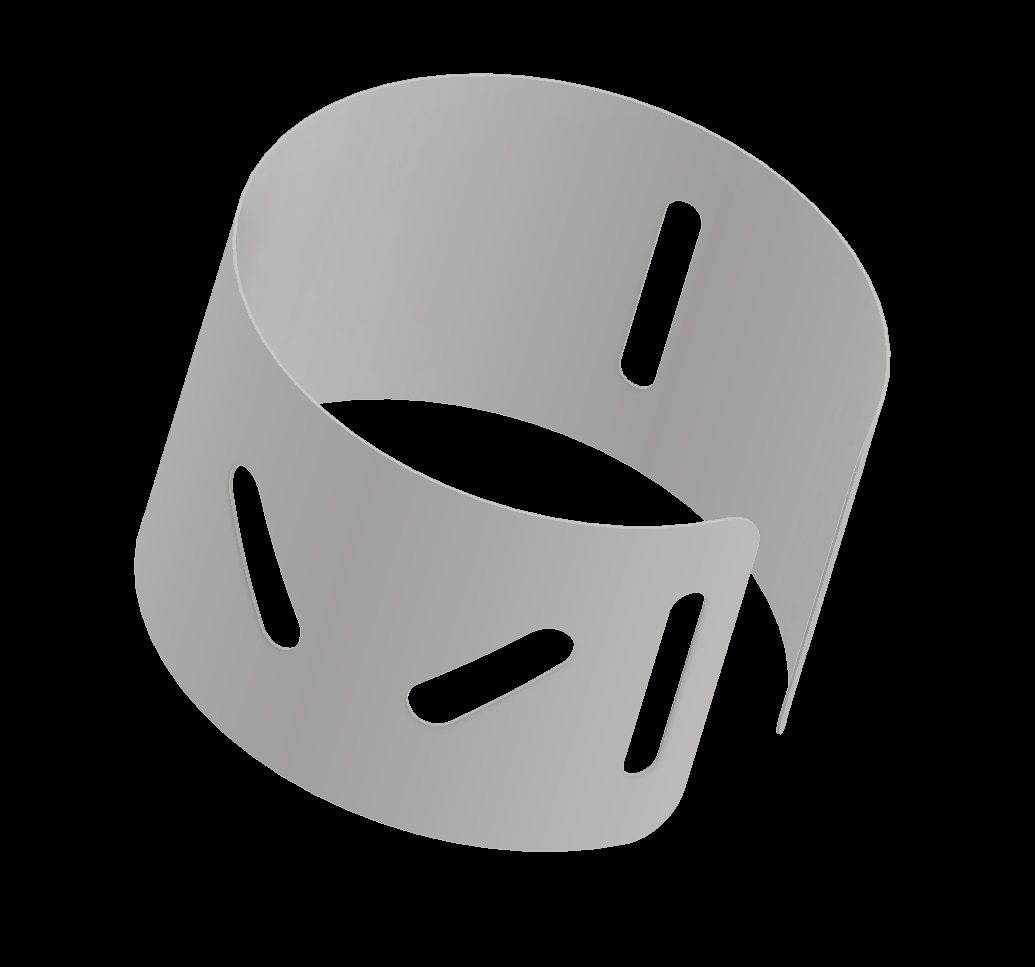

My sheet metal order of bent spine connectors and arm bracelets came in:

![]()

![]()

I decided I might as well make those in 2mm stainless steel after prototyping with paper and cardboard:

![]()

-

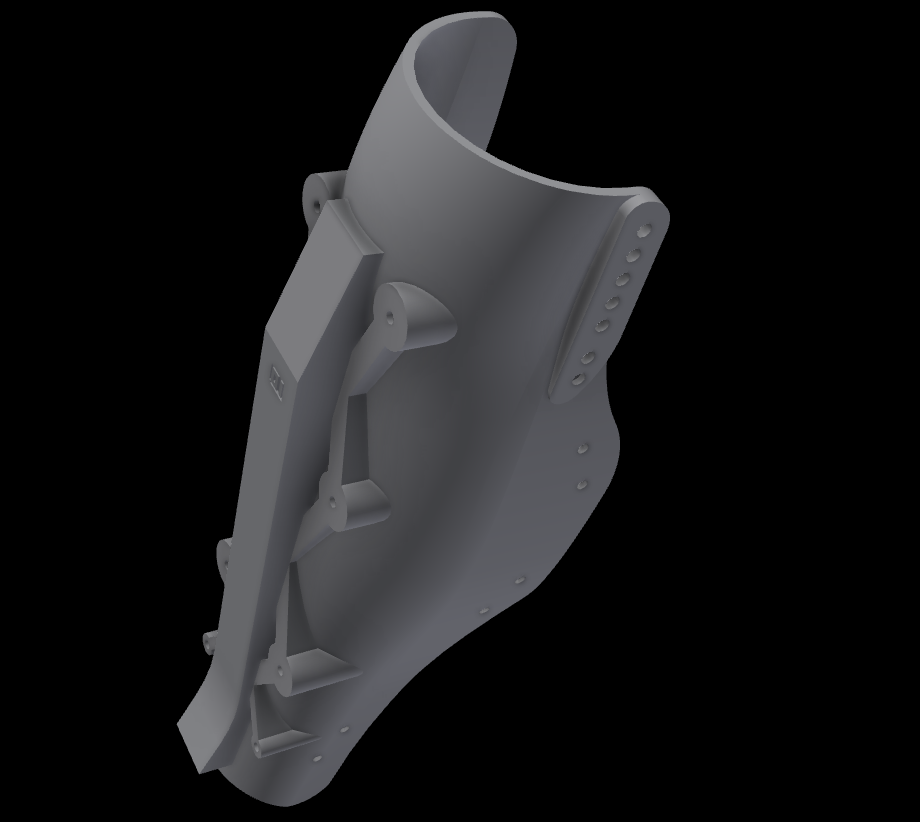

Last few molds

04/18/2019 at 15:35 • 0 commentsLast week I finished two more molds for shin shockplates. The only other "required" part left is the chest plate, one of the biggest and coolest-looking parts of the exoskeleton. There are a bunch of optional parts I would like to cast as a stretch goal, notably the tiny details placed on the hands, the vacuum tube holders with light-up tubes, and some tech gribble for the face to complete the cyber ninja look.

Fig. 1: Finished making the first part of a two-part mold with 3D-printed model suspended in clay

![]()

Fig 2: Preparing to pour the second part of both two-part molds

Fig 3: Resulting two-part molds I will use for casting wax positives

![]()

Fig. 4: Resulting wax positives that will be shell-cast by adding 10 layers of ceramic shell and melting the wax out before pouring metal

![]()

-

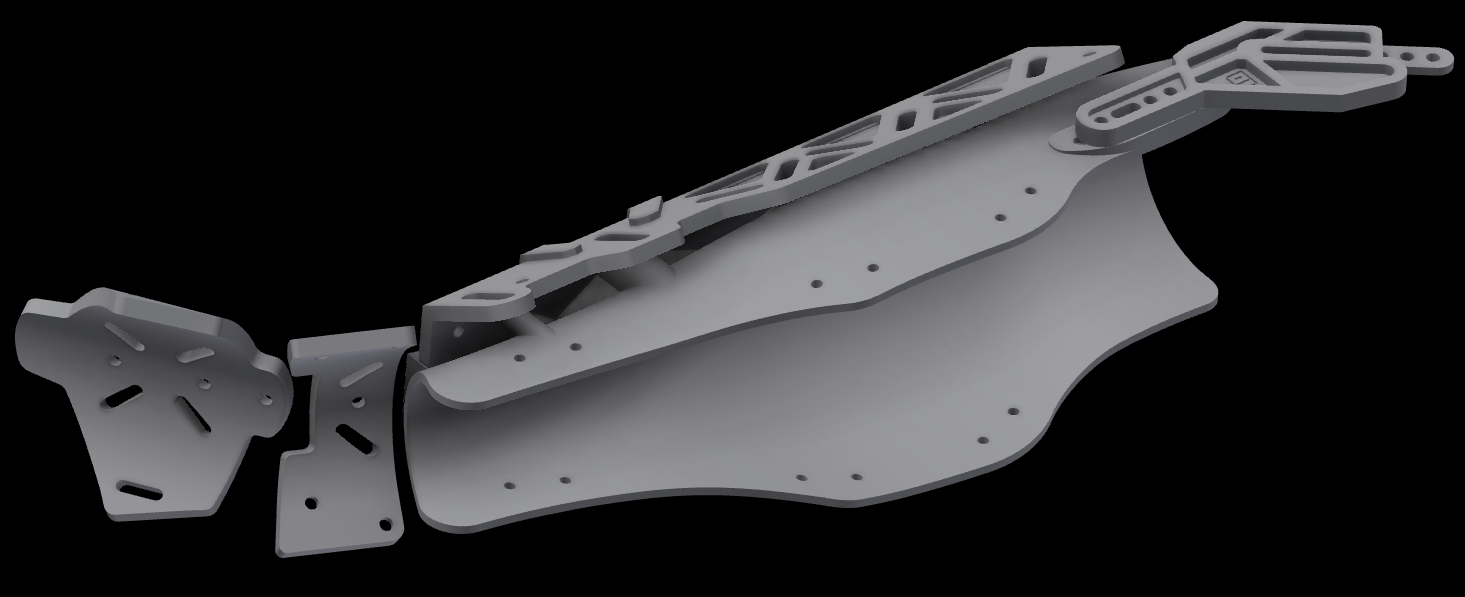

Box Casting & Sheet Metal parts

03/21/2019 at 21:00 • 0 commentsI successfully cast the chest plates this fall (see Shell Casting Success), but after many casting attempts on hip bones this winter, I finally ran out of slurry. I can't order more because it would arrive frozen, resulting in permanent chemical damage.

Issues included areas that cooled too fast, porous surface, and pieces of the mold breaking off prematurely:

![]()

So, I am switching back to box casting. Here's the breakdown of the parts I have left to cast:

Shell casting with SuspendaSlurry

- Hip Left

- Hip Right

- Chest Base

- Shin Snockplate Left

- Shin Shockplate Right

Box casting with UltraVest

- Hip Bottom Connector

- Spine Top

- Spine Bottom

- Spine Middle Left

- Spine Middle Right

- Foot Upper Shock Plate (2)

- Foot Shock Plate (2)

I also started working on polished sheet metal bracelets to attach arm bones without using elastic belts or gauze (like in the movie).

The prototyping session:

![]()

![]()

The parts I uploaded to RSM RapidQuote:

-

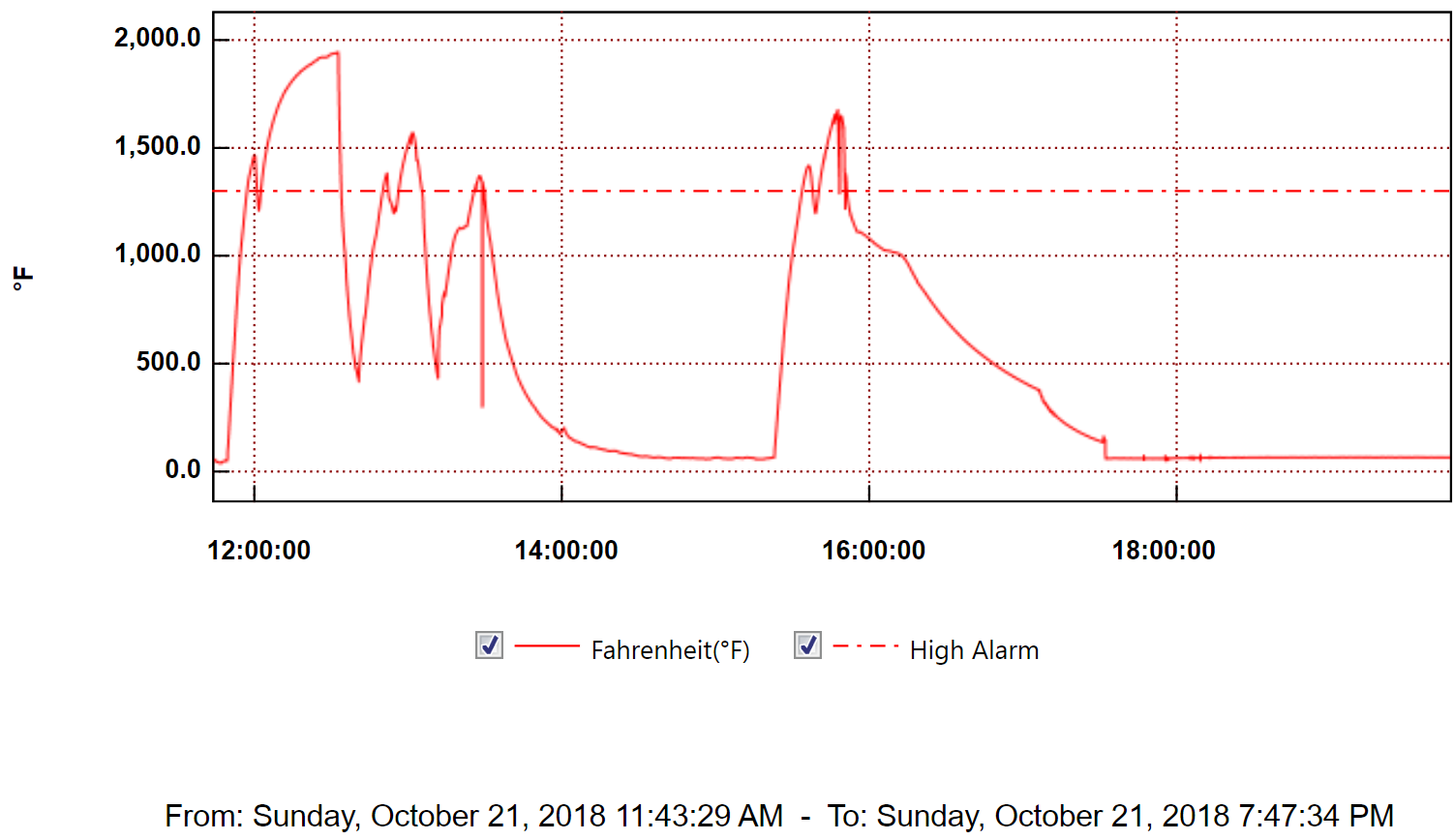

Logging temperature and more casting attempts

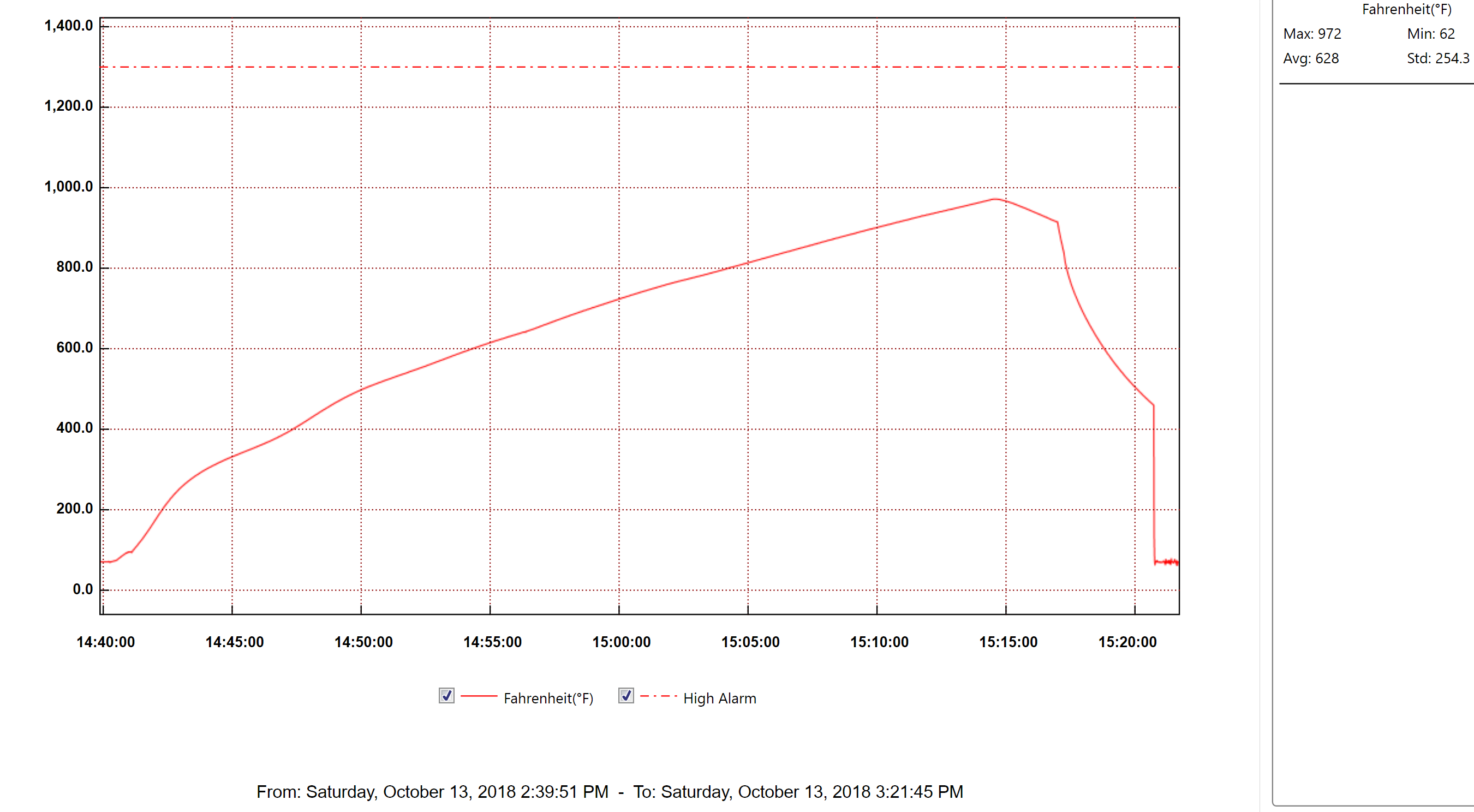

10/25/2018 at 05:48 • 0 commentsI have some mixed news from my attempt this weekend. I got all the data, but the act of observing the temperature and filming combined with more trouble from my regulator caused a decline in casting quality. I suspect it mostly came down to metal that got too hot, thus absorbing more gas from the atmosphere. I also had to move the camera and take laser temp readings, so I didn't remove the mold from the kiln as quickly as last time, and didn't pour as quickly.

![]()

First three attempts on the graph was me messing with camera and lights to try and raise "production values" so I left the crucible in the kiln for too long. The last attempt the crucible was in the kiln for about the right amount of time, but the kiln was over-fed by propane.

This week I am sick, so next week I will retry all of this and hopefully have some video worth publishing. I took some time to setup lights, and the video quality was significantly better - next time I will already have that experience so I can setup lighting quickly and before doing anything important to the casting process.

-

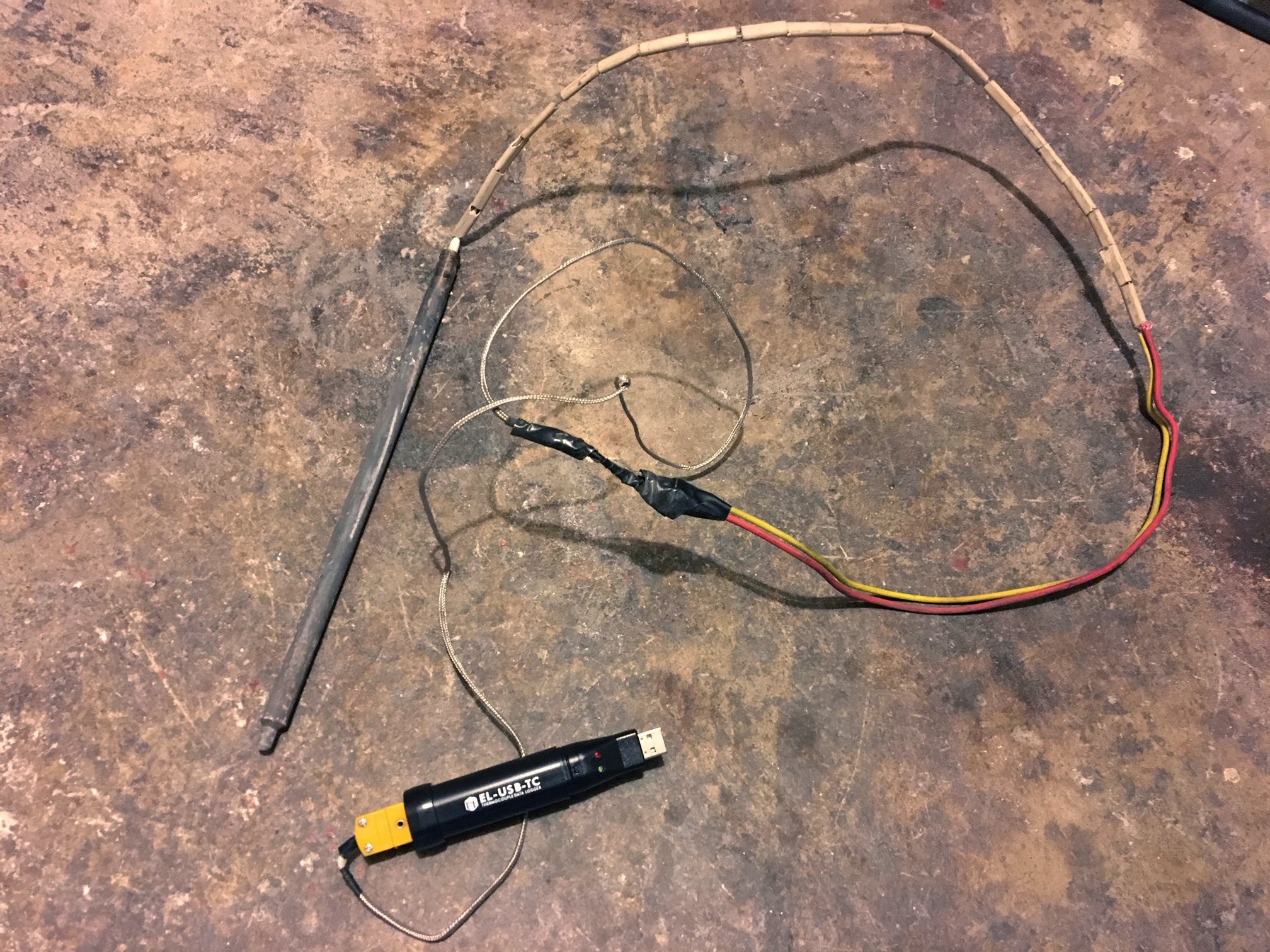

Trying out USB temperature logger

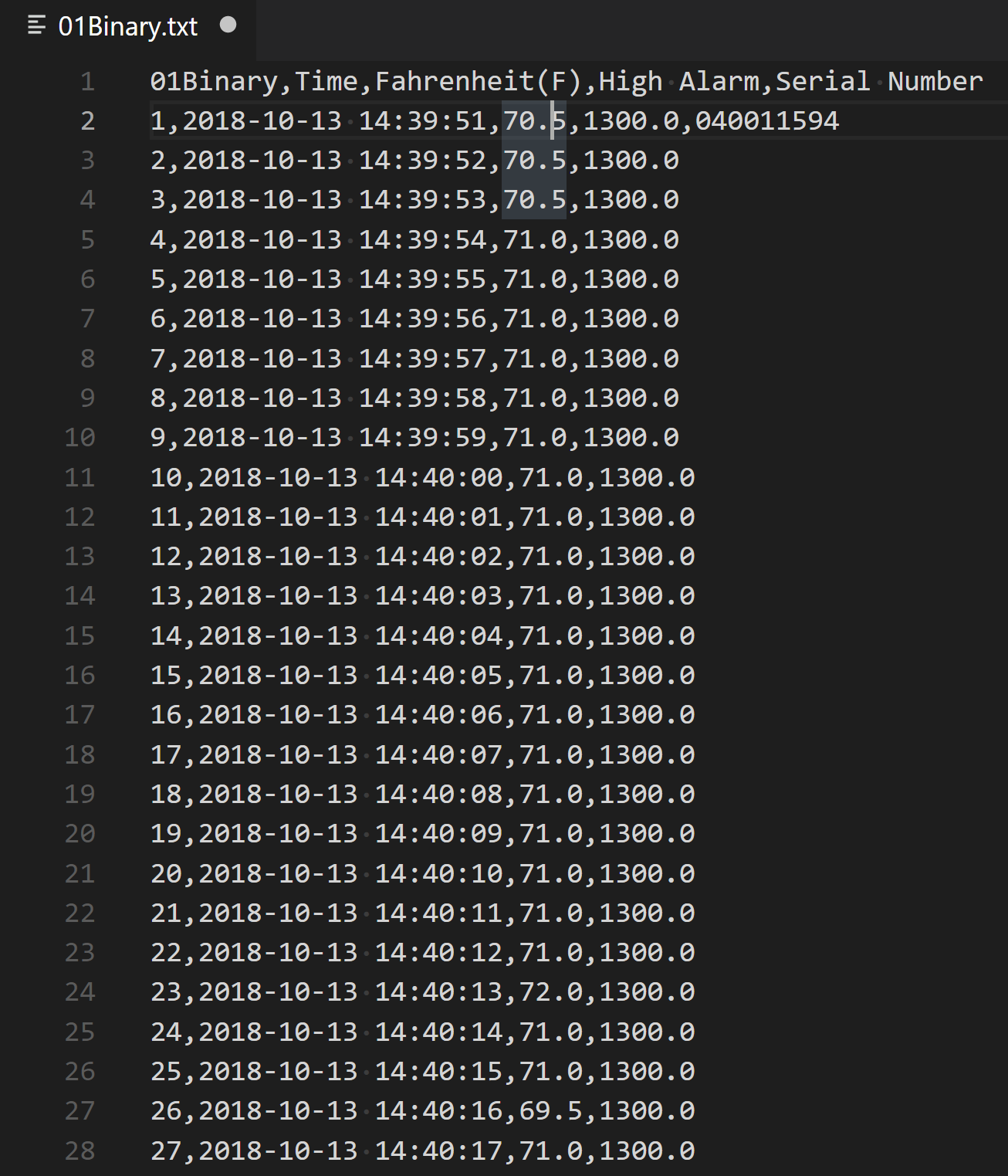

10/13/2018 at 22:36 • 0 commentsI got a USB temperature logger that works with my K-type thermocouple, so I can overlay a live temperature feed on my next metal casting video.

![]()

![]()

Here's what the output text file looks like when opened in the app that comes with the logger:

...and this is the raw output. CSV with sample ordinal, date/time, temperature in F, high alarm, and serial number

-

Shell casting success

10/05/2018 at 06:01 • 0 commentsToday I nailed down the shell casting process (with a great amount of help from The Home Foundry) I can use to finish off remaining parts.

...without pre-heating:

![]()

...with pre-heating:

![]()

-

First successful shell cast, with minor surface issues

09/04/2018 at 04:15 • 0 commentsI followed advice on building more shell layers, pre-steaming the pressure cooker before putting in the shell, steaming for a short time (30 mins instead of 2 hours) and repairing cracks /adding another shell layer after vitrification. I have one final problem with a frozen surface in parts of the cast. Here's the video of this attempt:

Here's the frozen effect. I poured at 950-970 and I skimmed a film of metal off the top, but it filmed over just as I was pouring.

-

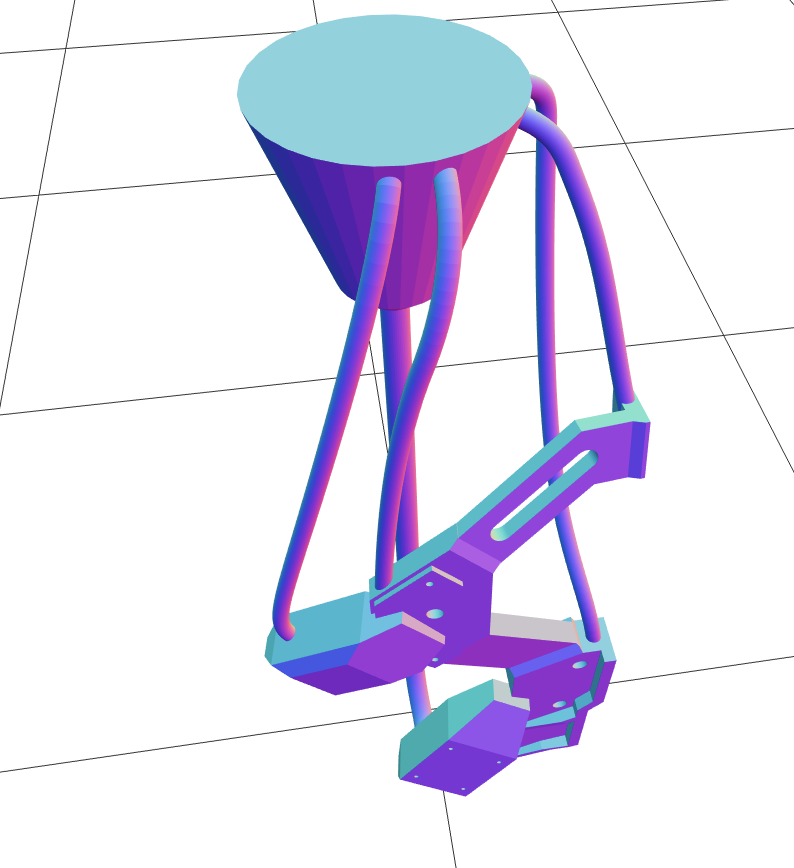

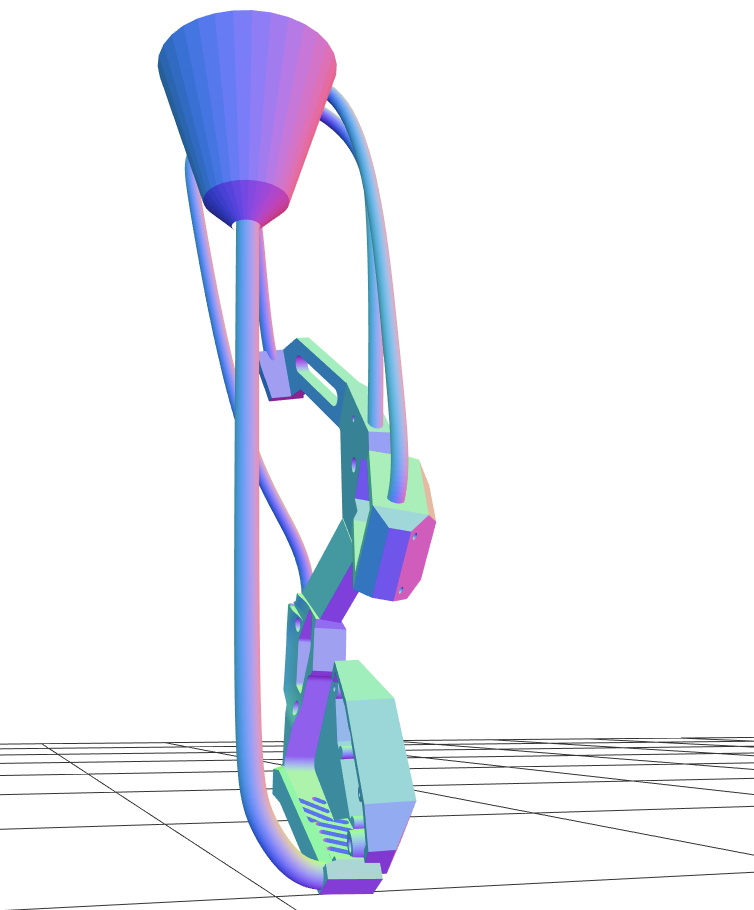

Second iteration of sprue planning

08/05/2018 at 19:05 • 0 commentsAnother iteration of sprue planning for the chest pieces: https://github.com/01binary/sprue-planning/blob/master/chest-sprues.stl

![]()

![]()

Elysium Max Exoskeleton

Exoskeleton suit replica from the movie Elysium in Autodesk Inventor, 3D printed and investment cast out of Aluminum

Val

Val