-

First dips

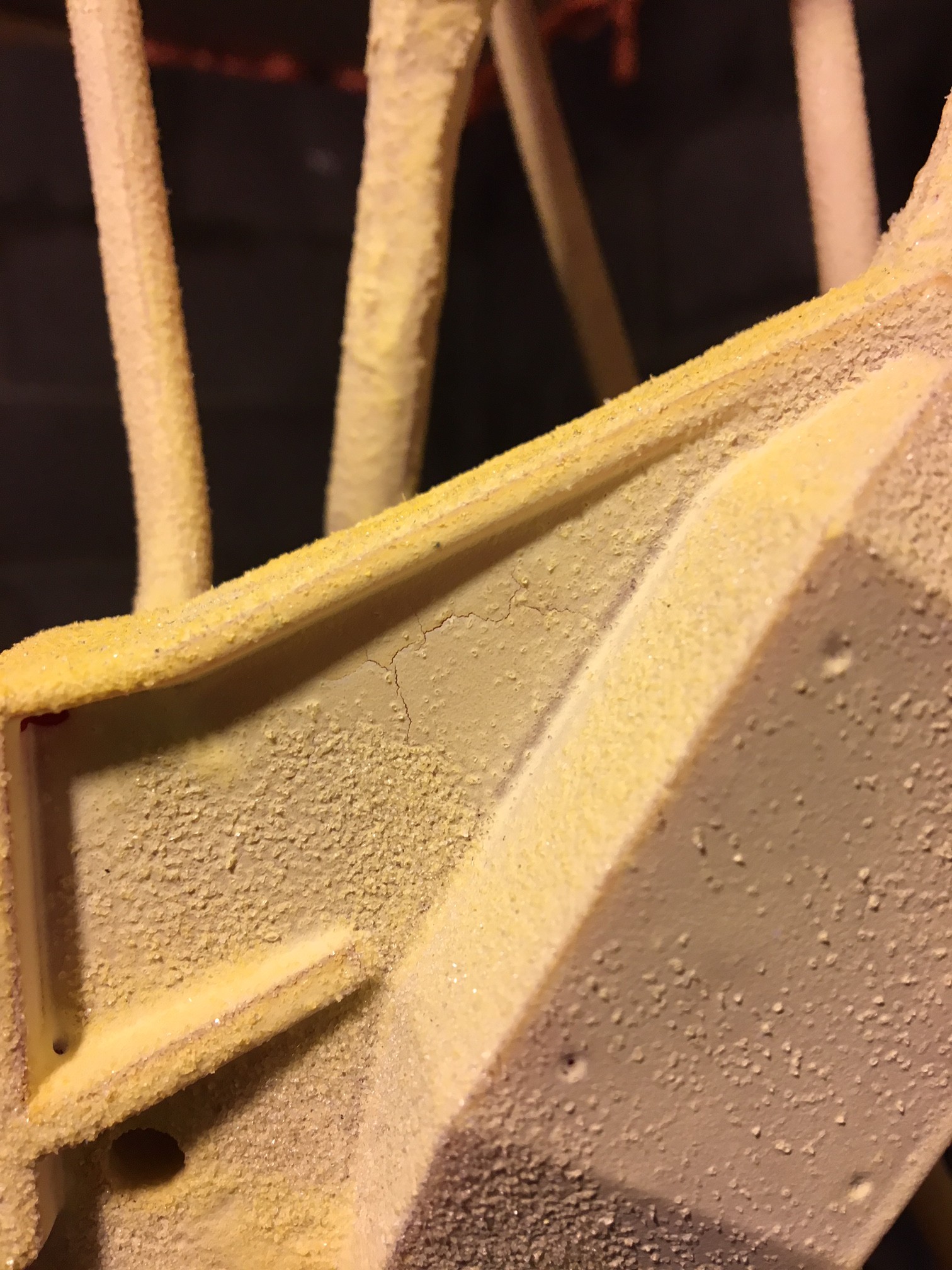

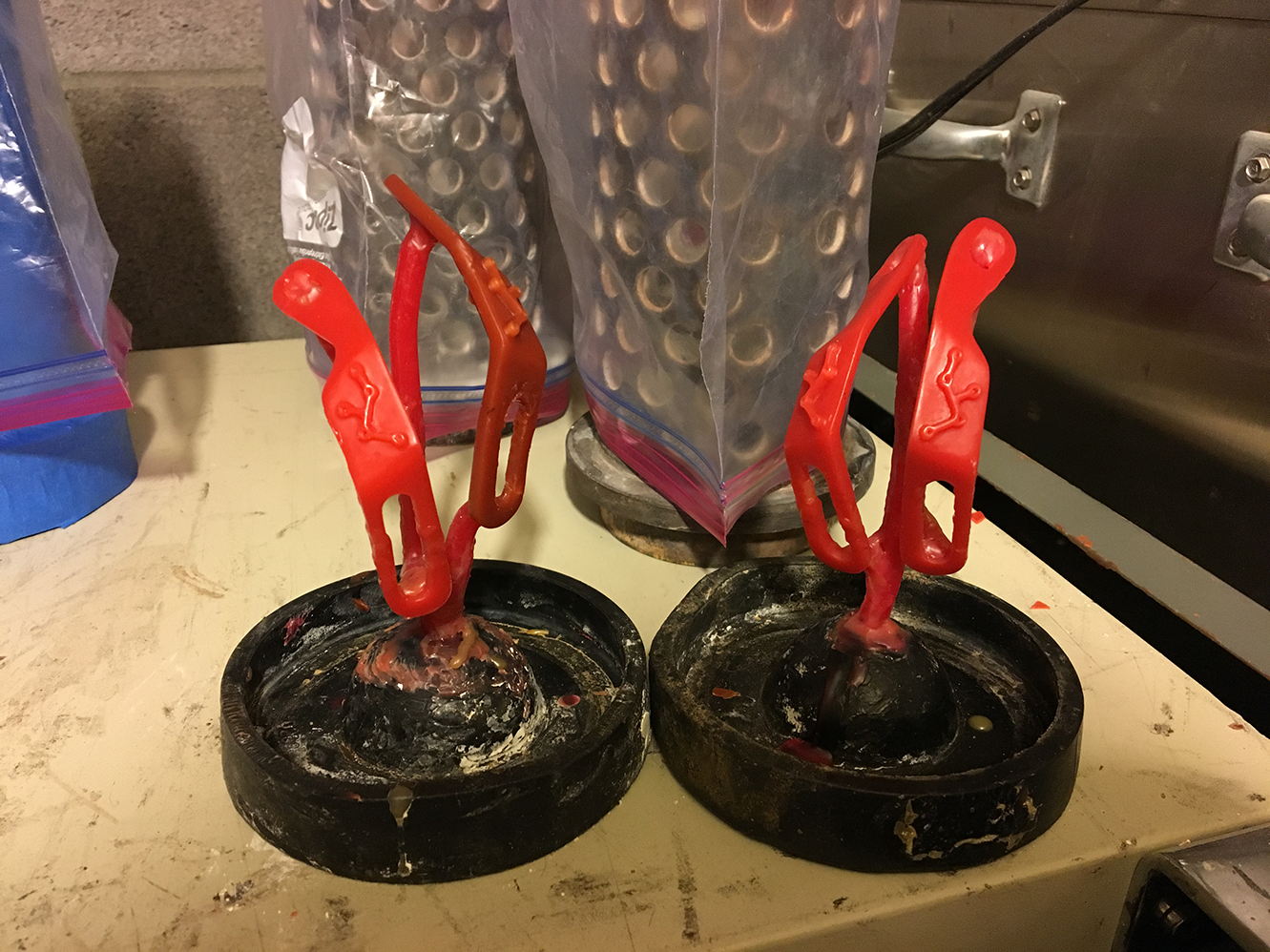

07/22/2018 at 23:31 • 0 commentsThe first attempt at shell casting with the two chest plates has started. Sprued wax model:

First dip

Already developing cracks in the fist layer - most likely because the slurry needs more water

Second dip

-

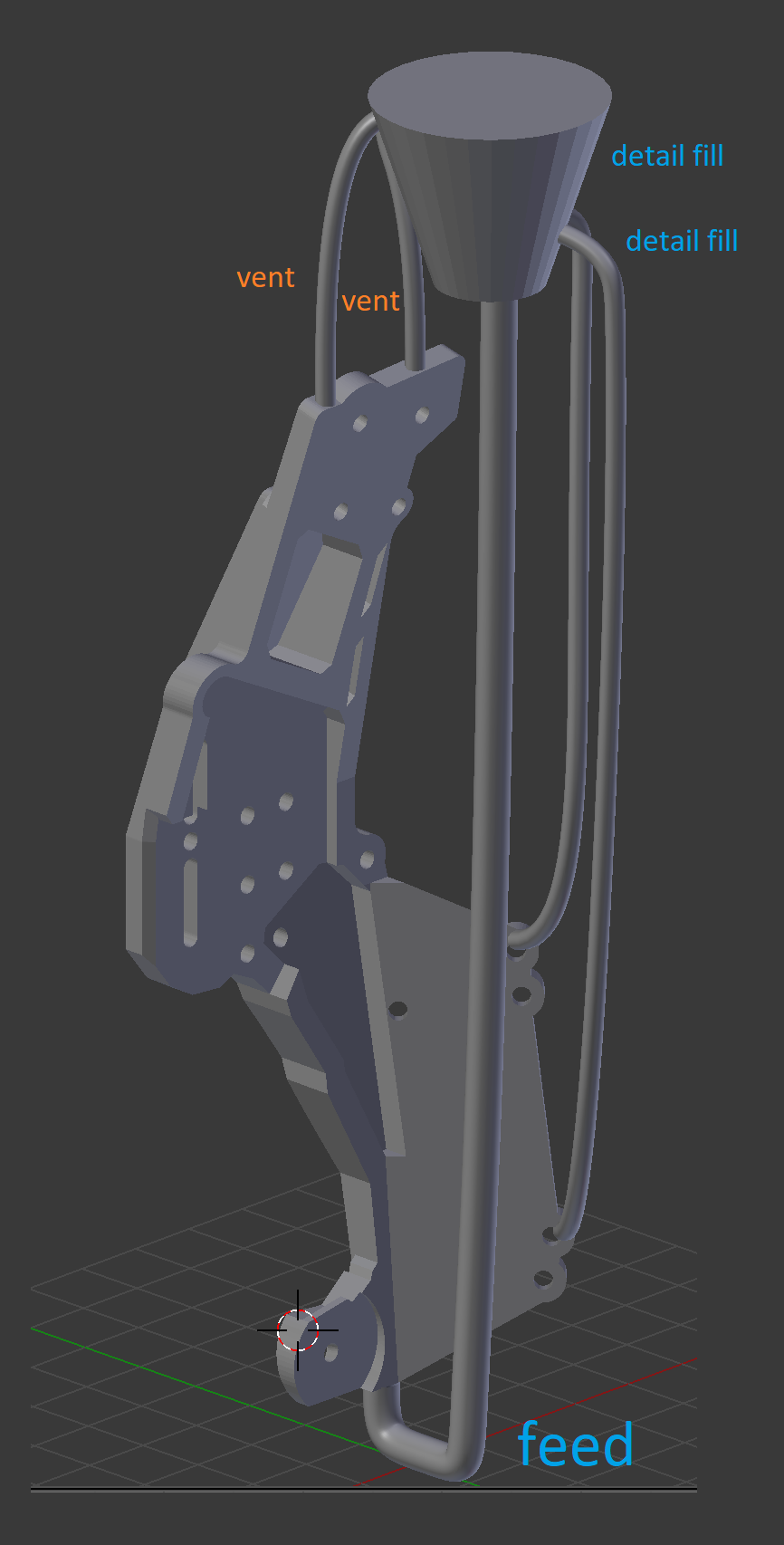

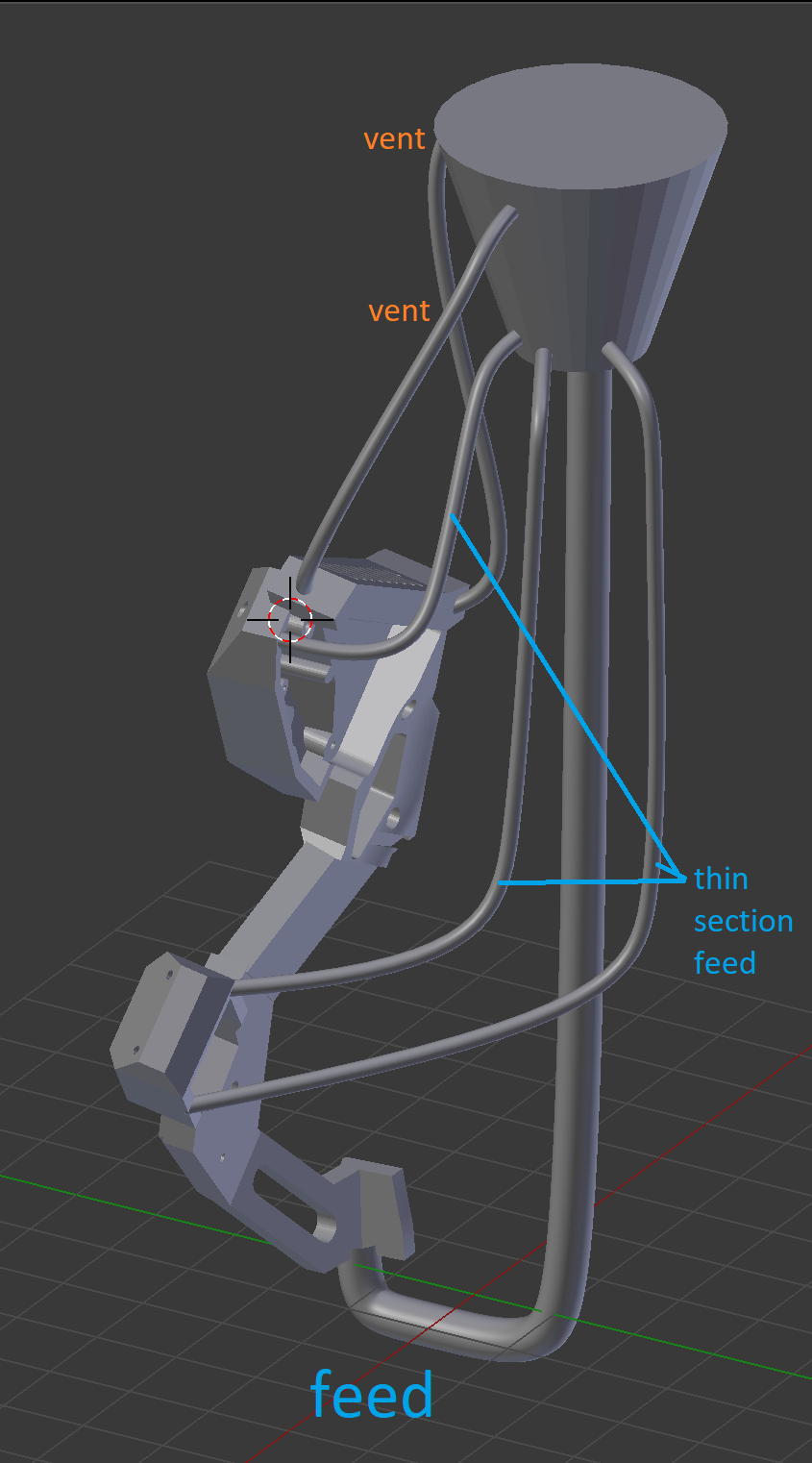

Planning sprues

07/20/2018 at 19:58 • 0 commentsSprue planning for models to be cast using the shell casting process is more serious than with vacuum-assist casting, so I am performing at least two rounds of review with metal casting experts before proceeding:

![]()

![]()

https://github.com/01binary/sprue-planning/blob/master/chest-sprues.stl

https://github.com/01binary/sprue-planning/blob/master/hip-sprues.stl

-

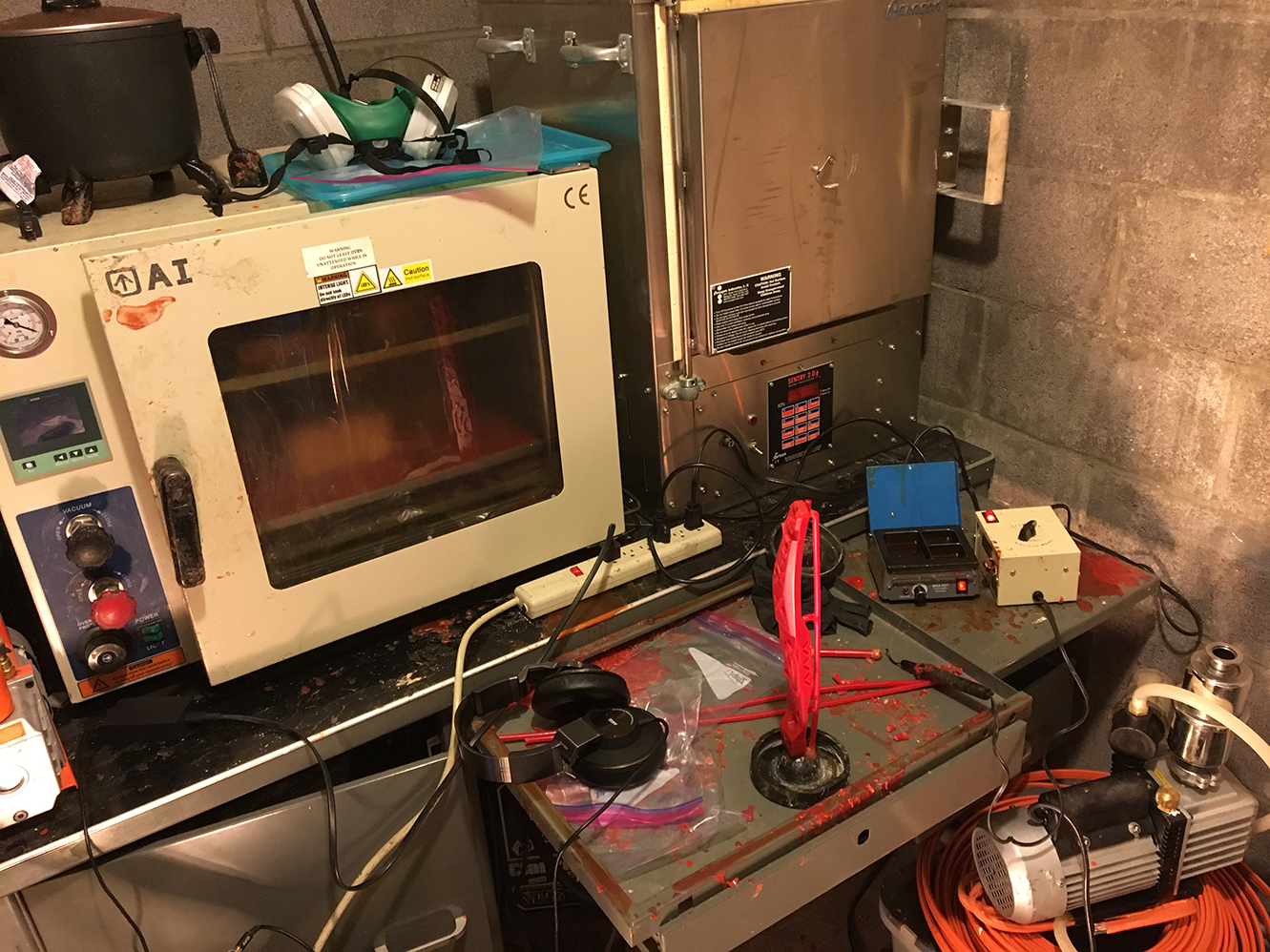

Back to shell casting

07/20/2018 at 03:03 • 0 commentsThe last 7 parts cannot be cast using the jewelry process due to geometry that requires a very heavy custom flask and tons of investment. The weight of the finished piece makes it nearly impossible to manipulate fast enough to insert into a vacuum chamber and pour metal in 20 seconds, before shell-shock.

I am going back to shell casting after some advice from The Home Foundry forums, and I will post a video after the first failed experiments.

-

Investment casting in VR

06/18/2018 at 05:17 • 0 commentsAnother 360 video of trying out the new vacuum chamber:

-

Pouring molds in VR

05/29/2018 at 01:50 • 0 commentsI exported my first long 360 video with immersive effects, transitions and composited 3D renders:

-

Custom vacuum assist chamber and more molds

05/22/2018 at 19:54 • 0 commentsI've been working on a custom vacuum assist chamber for casting large parts:

I also got a 360 camera so now I can video blog & live stream the work on this project in VR. The editing should also be fun.

![]()

Lastly, I am continuing to make rubber molds for the remaining parts:

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

-

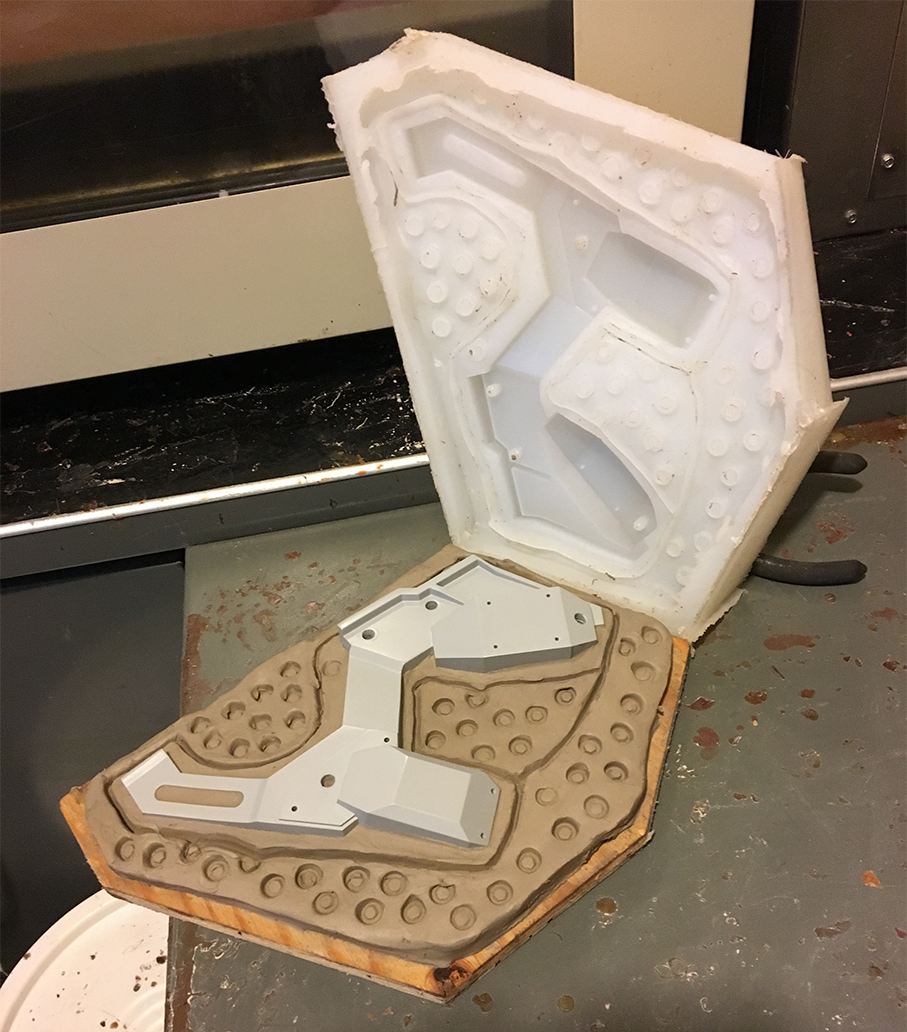

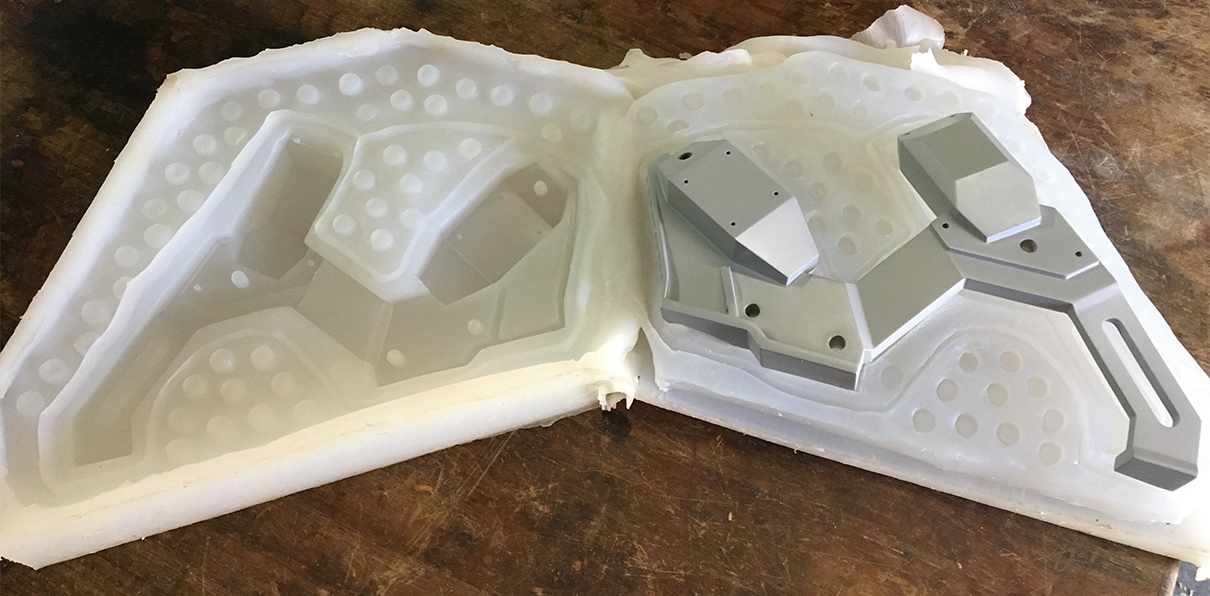

Starting on chest plates and more connectors

04/28/2018 at 17:39 • 0 commentsMore two-part molds for chest plates. Casting them in metal will require welding a custom steel flask because they are the biggest parts I will have to cast yet.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

-

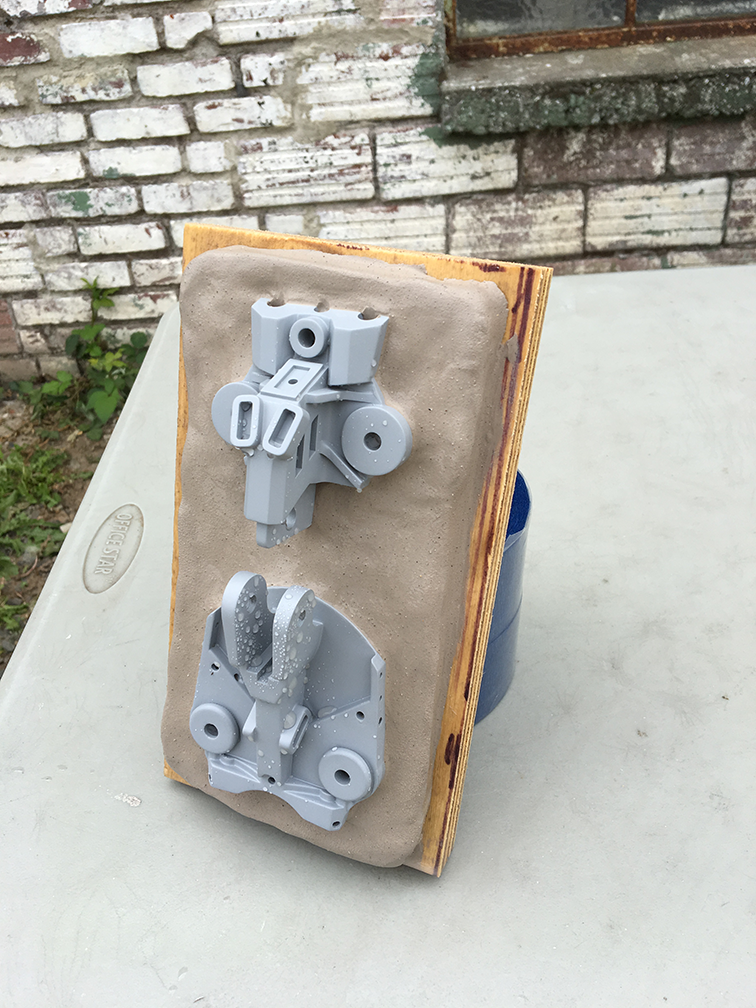

Batch of connectors and new mold

03/24/2018 at 20:38 • 0 commentsStarted a new two-part mold for shoulder connector heads:

![]()

![]()

A batch of four flasks with connectors & wrist clamps:

![]()

![]()

![]()

![]()

New vacuum setup with fixtures still working well:

![]()

-

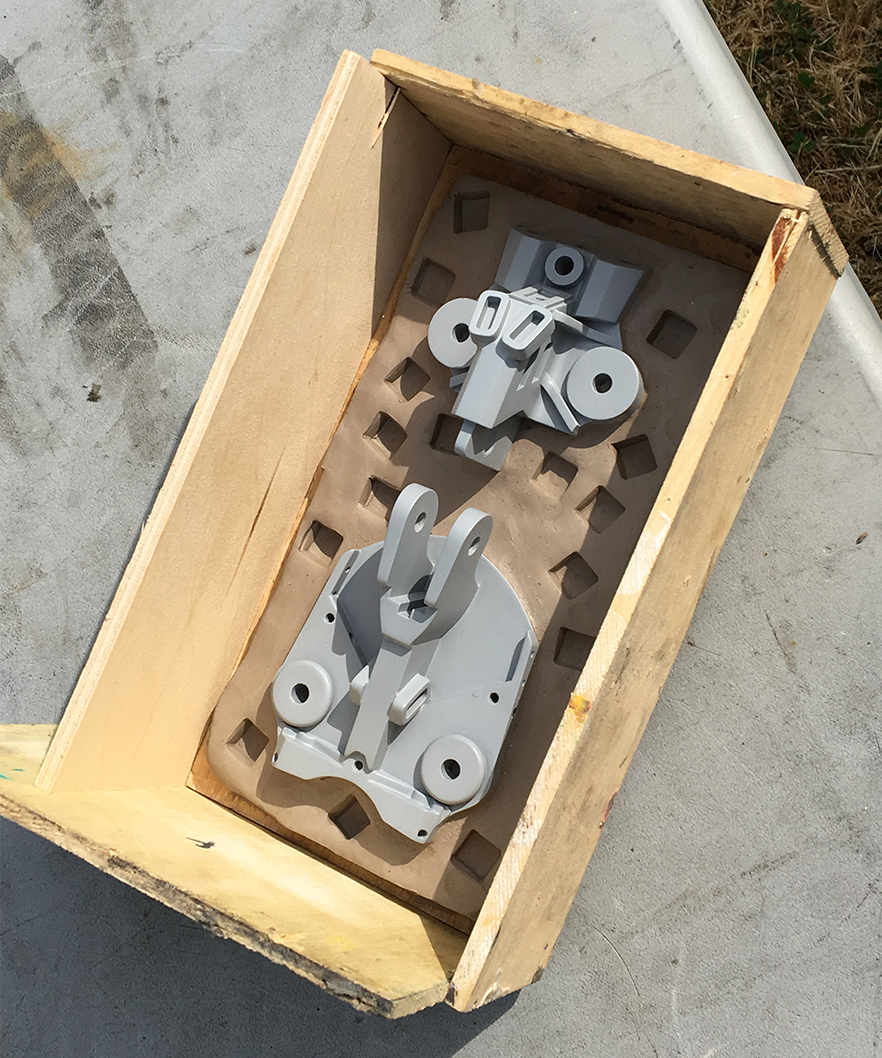

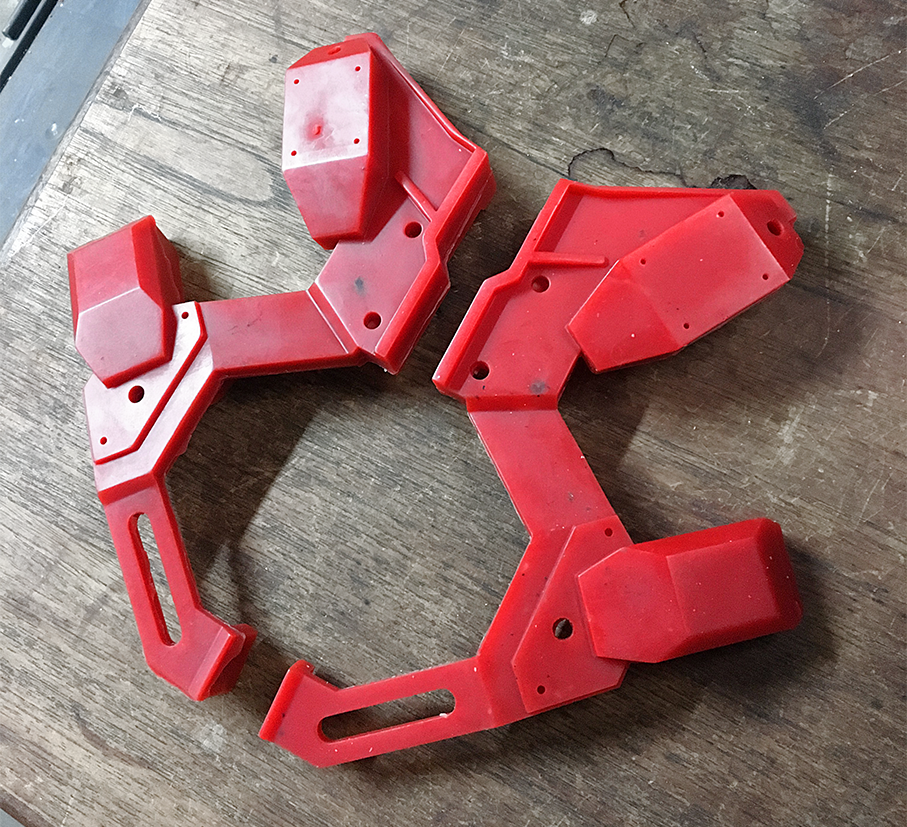

Casting parts, started working on article

03/12/2018 at 05:42 • 0 commentsLast week I re-cast two parts with better detail and completed four other parts I already had molds for.

![]()

![]()

![]()

![]()

I also started working on casting some of the largest parts: hip and chest plates

![]()

Left chest plate two part mold (probably just the first draft, as I am still learning how to make these)

![]()

I also ordered a new batch of risers with inline ceramic filters.

![]()

Finally, I started working on an investment casting article. I want it to be the best reference for DIY investment casting on the Internet, so I'm taking time with reviews, edits, and graphics. Seeking feedback from anyone here:

-

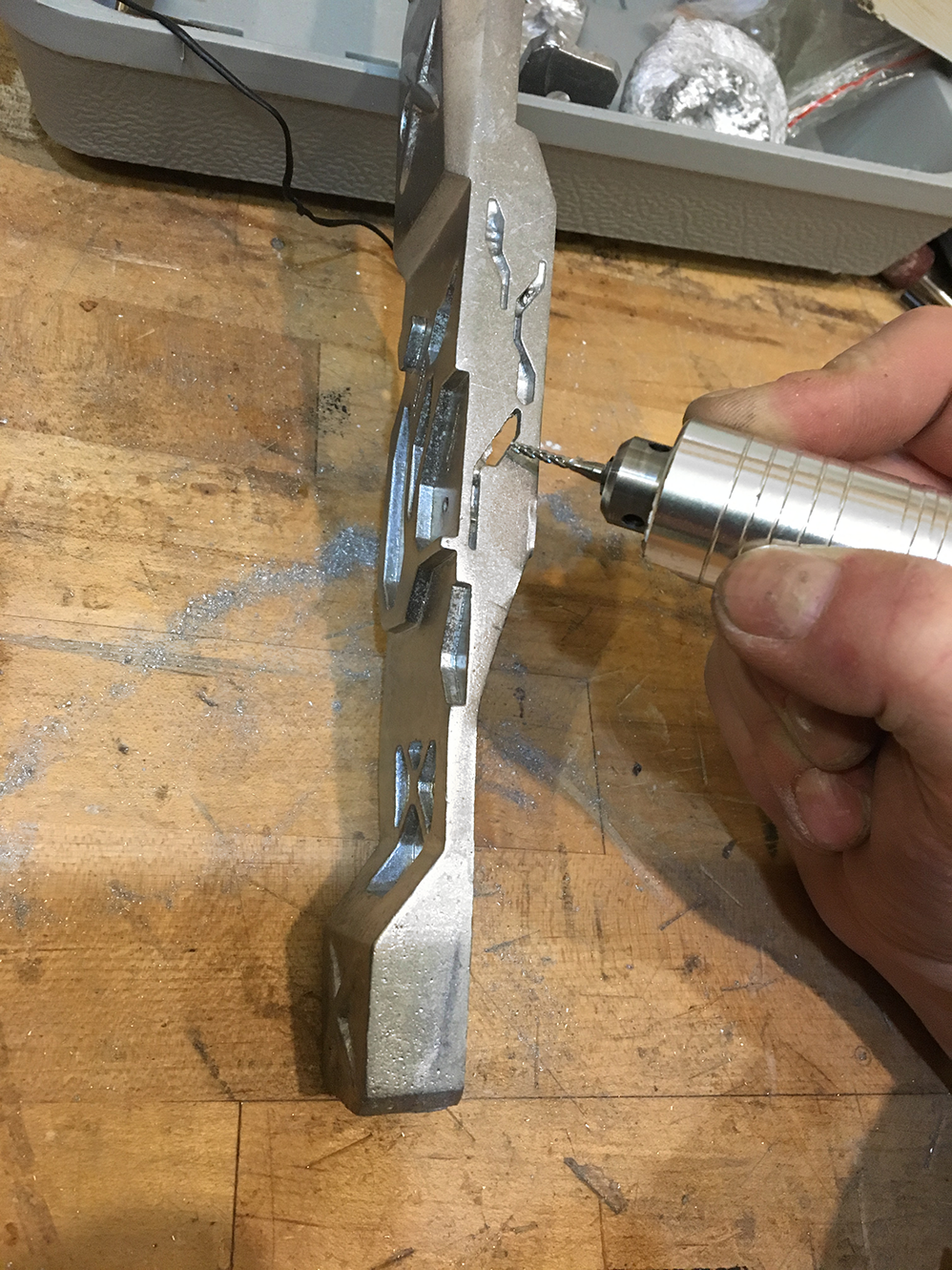

Finishing first parts

02/05/2018 at 04:19 • 0 commentsI've achieved the highest quality casting results possible with my setup, so I am learning how to use a FlexShaft this weekend to finish parts after cutting them off the sprues:

![]()

![]()

![]()

Also casting wax parts to begin another metal casting batch:

![]()

Elysium Max Exoskeleton

Exoskeleton suit replica from the movie Elysium in Autodesk Inventor, 3D printed and investment cast out of Aluminum

Val

Val