1-Project Objectives

- Enable users to remotely control an RC car from a custom-built web page.

- Stream real-time video from the car’s perspective to the same interface.

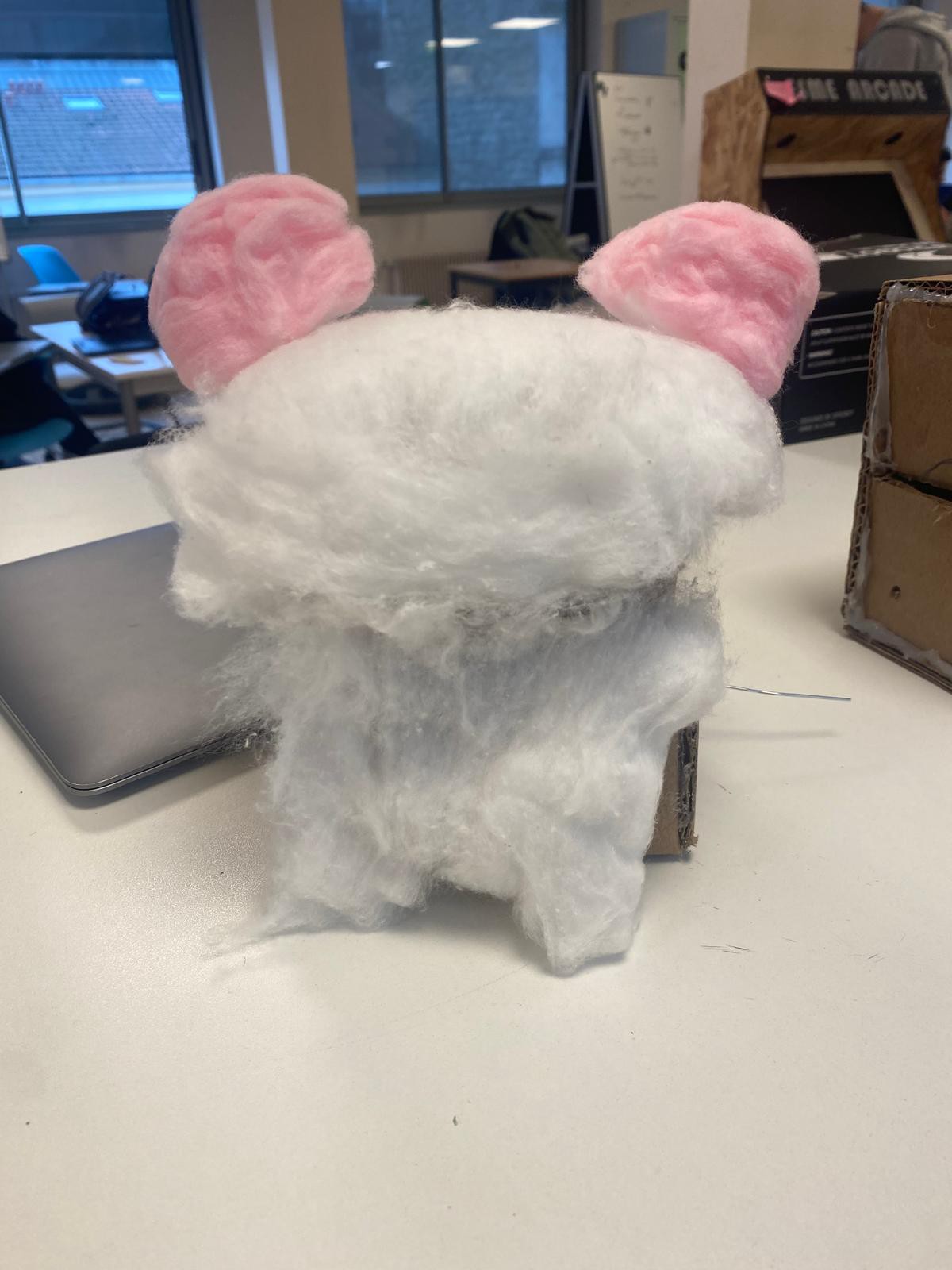

- Integrate an interactive panda coin collector mechanism.

- Utilize affordable components to create a functional, engaging system.

2-System Architecture and Design

System Overview

- ESP32-CAM: Hosts the web server, handles video streaming, and transmits control commands to the second ESP32.

- Second ESP32: Receives commands, controls motors via the L298N, and operates the servo motor for the panda box.

- Web Interface: Displays the video feed and provides a control panel for the RC car.

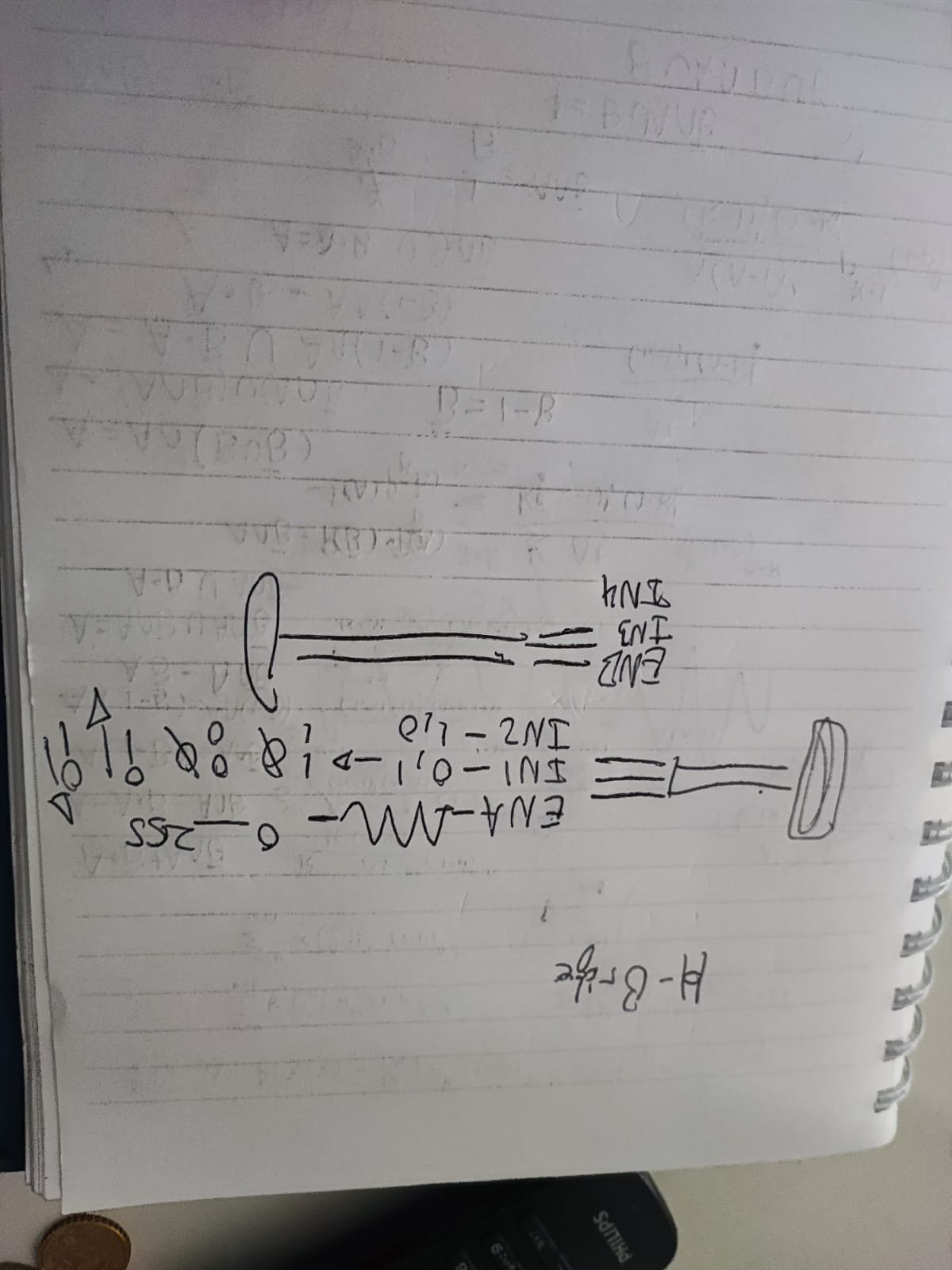

Block Diagram

- ESP32-CAM: Captures video, hosts the web server, and transmits movement commands.

- Second ESP32: Controls motor driver and servo motor based on commands.

- Web Interface: Integrates video streaming and control functionality.

3-Wiring Details

- ESP32-CAM and Second ESP32:

- GPIO 3 (TX) of the ESP32-CAM is connected to GPIO 16 (RX) of the second ESP32 for serial communication.

- Both modules share a common ground.

- Motor Driver:

- The second ESP32 controls the L298N motor driver, which powers the car’s motors.

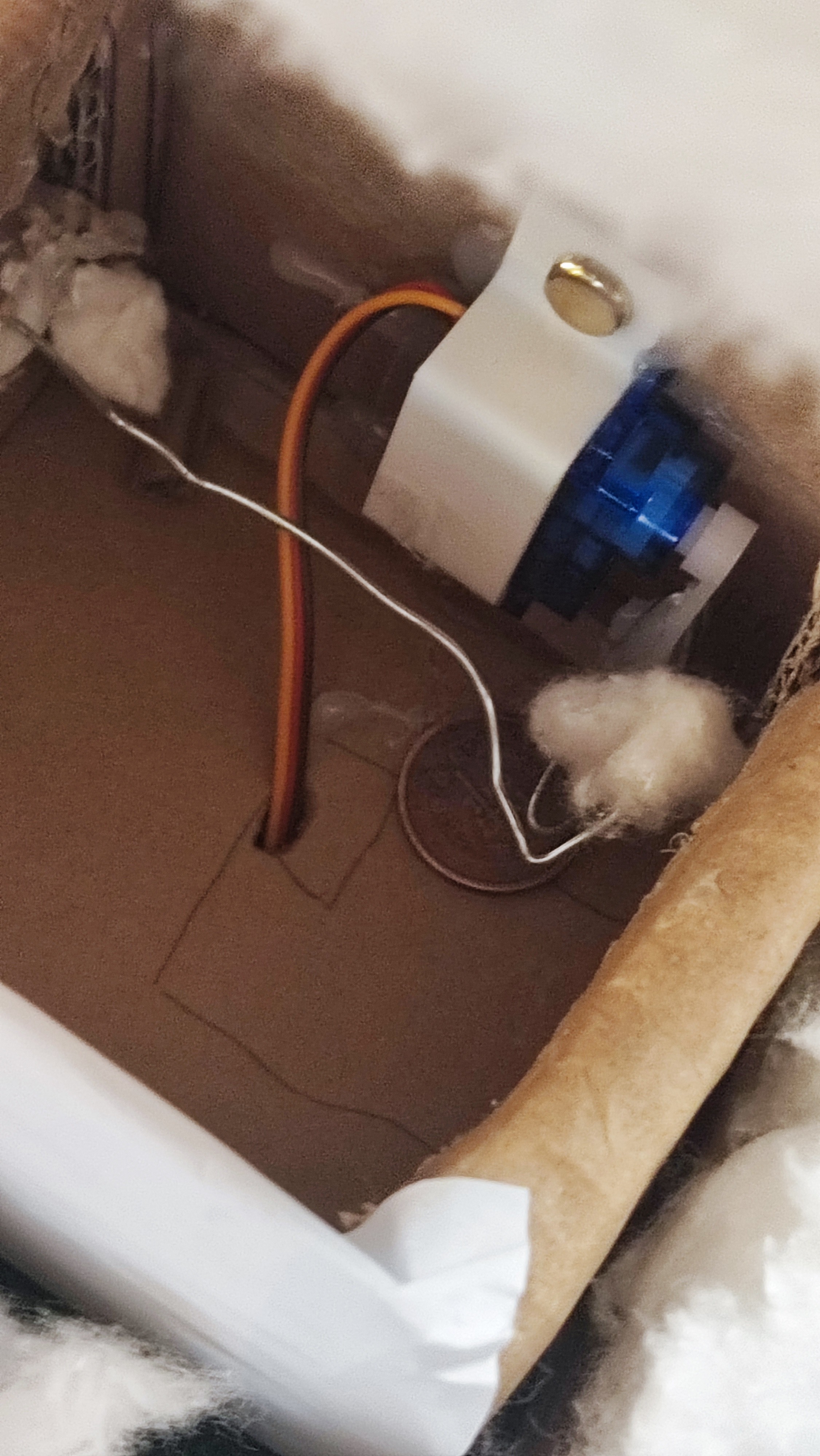

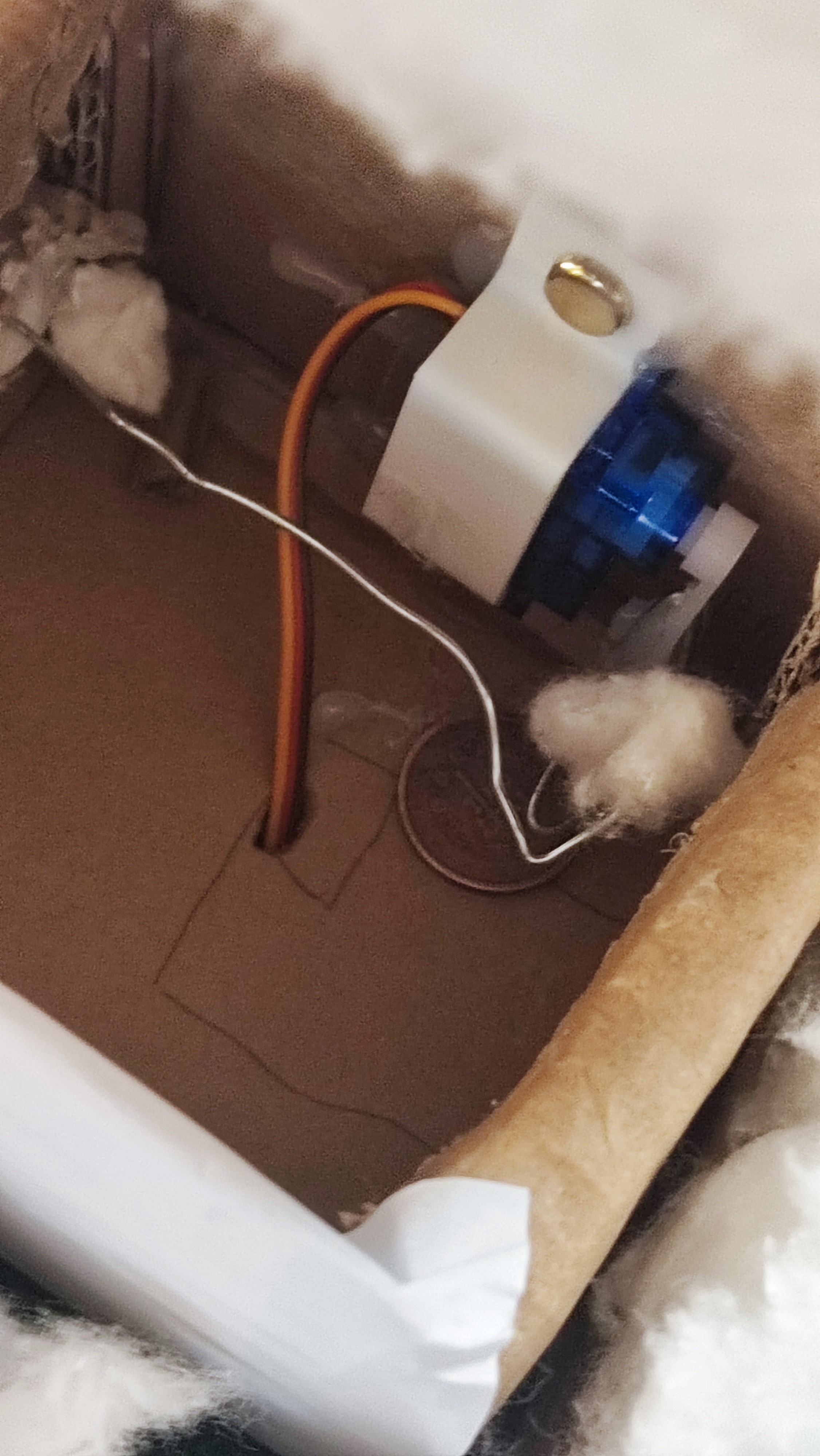

- Servo Motor:

- Connected to GPIO 12 of the second ESP32 for controlling the panda box.

- Push Button:

- Connected to GPIO 13 and ground on the second ESP32, serving as the trigger for the panda box.

Step-by-Step Build Guide

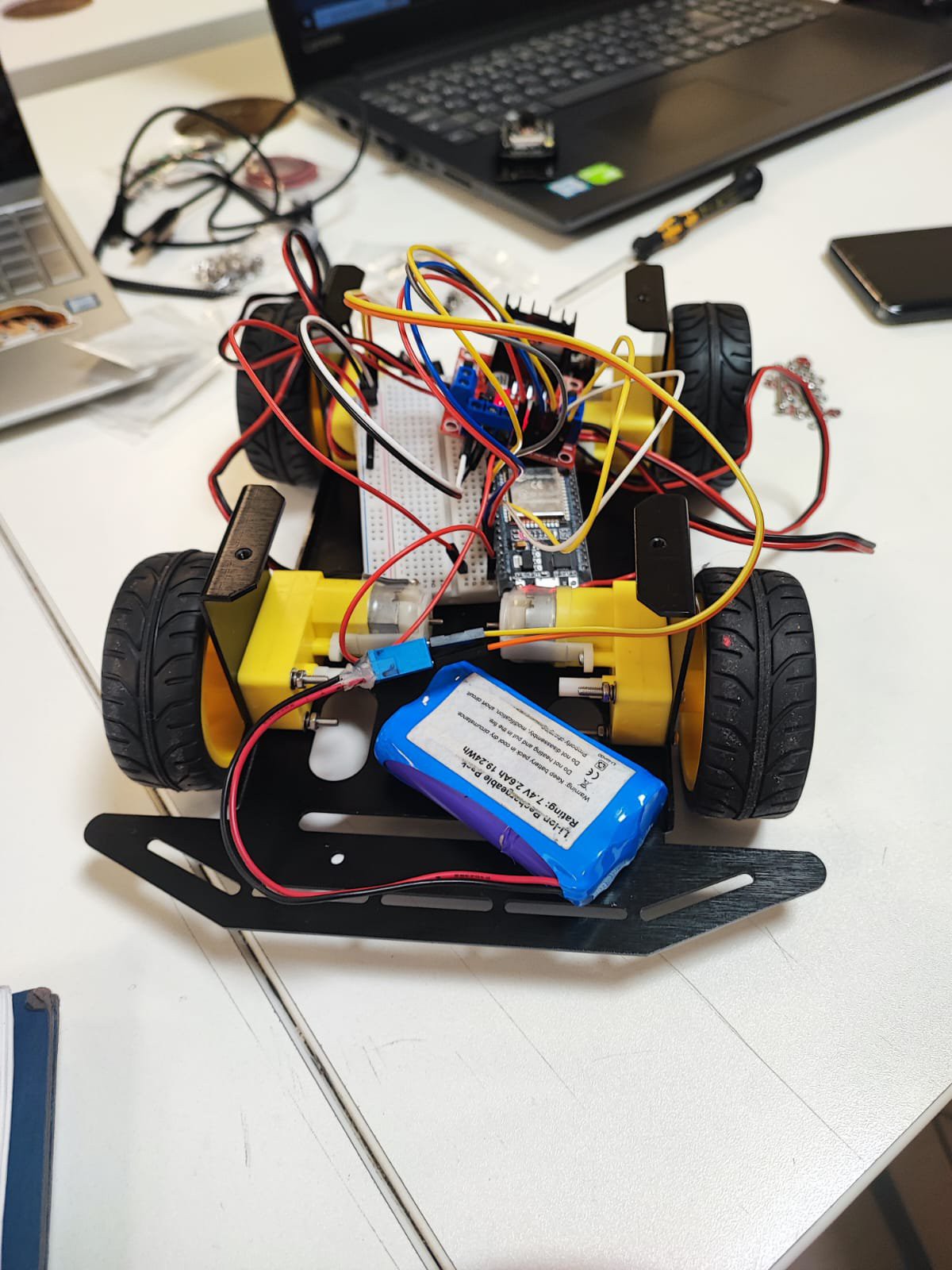

- Assemble the Chassis:

- Attach wheels, motors, and other hardware to form the car’s base.

- Set Up the ESP32-CAM:

- Connect the ESP32-CAM to a breadboard.

- Program it to stream video and transmit movement commands via UART.

- Connect the Motor Driver:

- Wire the L298N motor driver to the motors and the second ESP32.

- Test connections to ensure proper control of directional movement.

- Integrate the Servo Motor:

- Connect the servo motor to GPIO 12 of the second ESP32.

- Program the servo to respond to the button on GPIO 13.

- Build the Web Interface:

- Develop an HTML/CSS/JS webpage to stream video and provide control buttons.

- Test communication between the web interface and the ESP32-CAM.

- Test and Troubleshoot:

- Verify seamless communication between both ESP32 modules.

- Test motor control and panda coin collector functionality.

How It Works

The RC car leverages two ESP32 modules to separate tasks and optimize functionality:

-

Web Server and Video Streaming:

- An ESP32-CAM hosts a web server using mobile data from a cellphone.

- The server's webpage, developed with HTML, CSS, and JavaScript, displays the live video feed from the ESP32-CAM’s camera and includes control buttons for the car’s movement (Forward, Backward, Left, Right, and Stop).

- Button handlers send commands directly to the ESP32-CAM’s serial port, which communicates with the second ESP32.

-

Motor Control:

- Due to limited GPIO availability on the ESP32-CAM (some pins are internally used by the camera module), motor control commands are forwarded via UART to a second ESP32.

- The ESP32-CAM’s UART outputs commands like "Forward" to the second ESP32, which reads the input and triggers the motor driver to execute the corresponding movement.

-

Servo-Controlled Panda Coin Collector:

- A servo motor connected to the second ESP32 controls the panda box.

- When a button connected to the second ESP32 is pressed, the servo motor opens the panda box lid, accepts the coin, deposits it, and closes the lid.

- The second ESP32 uses the millis() function to ensure non-blocking control of both the motor driver and servo motor, avoiding conflicts between PWM signals.