-

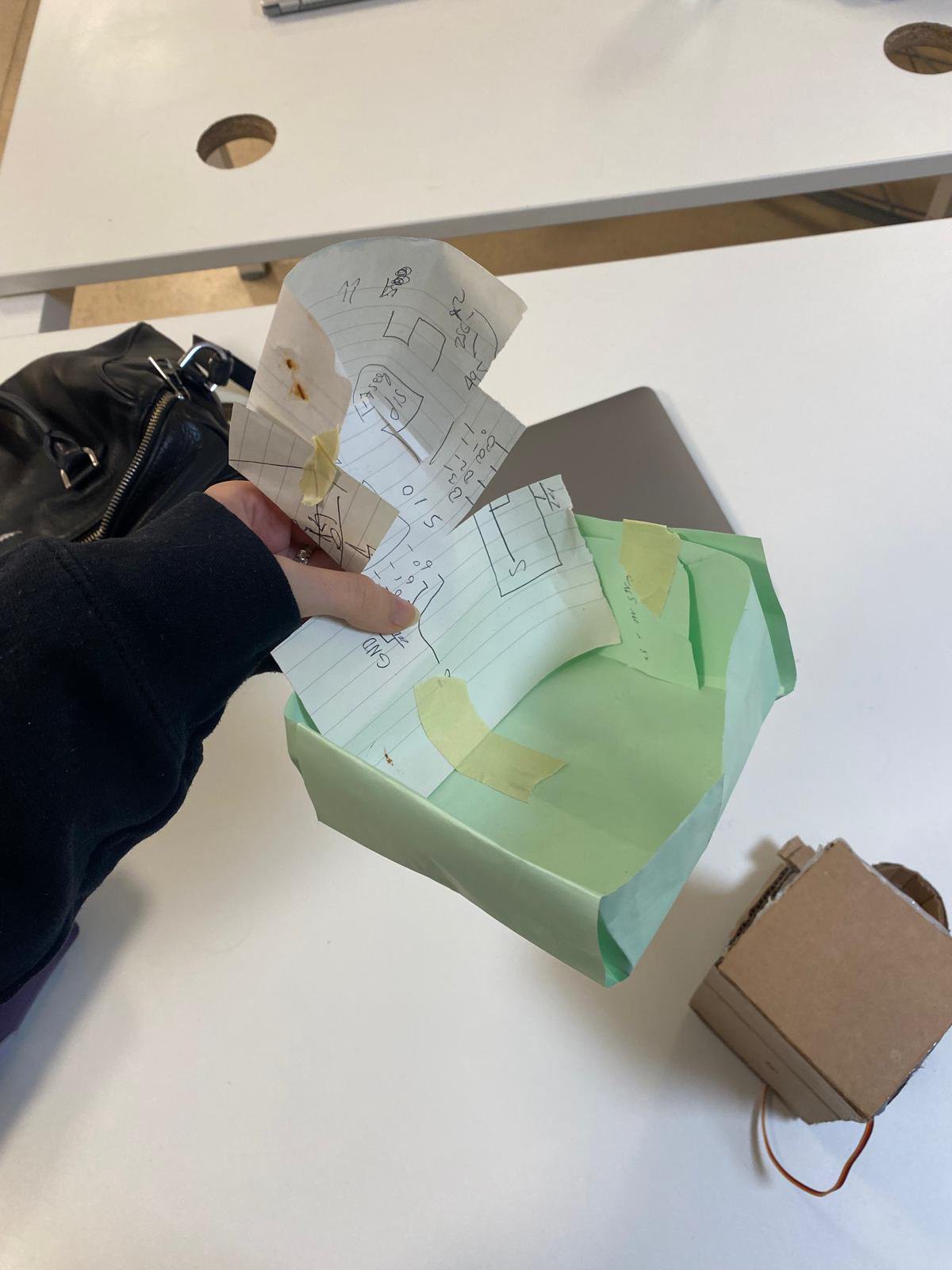

Prototype for foldable manufacturing

12/19/2024 at 11:20 • 0 commentsWe did manufacturing optimization by making again the panda box but with foldable pattern, simplifying the work. We did it with paper to test.

![]()

-

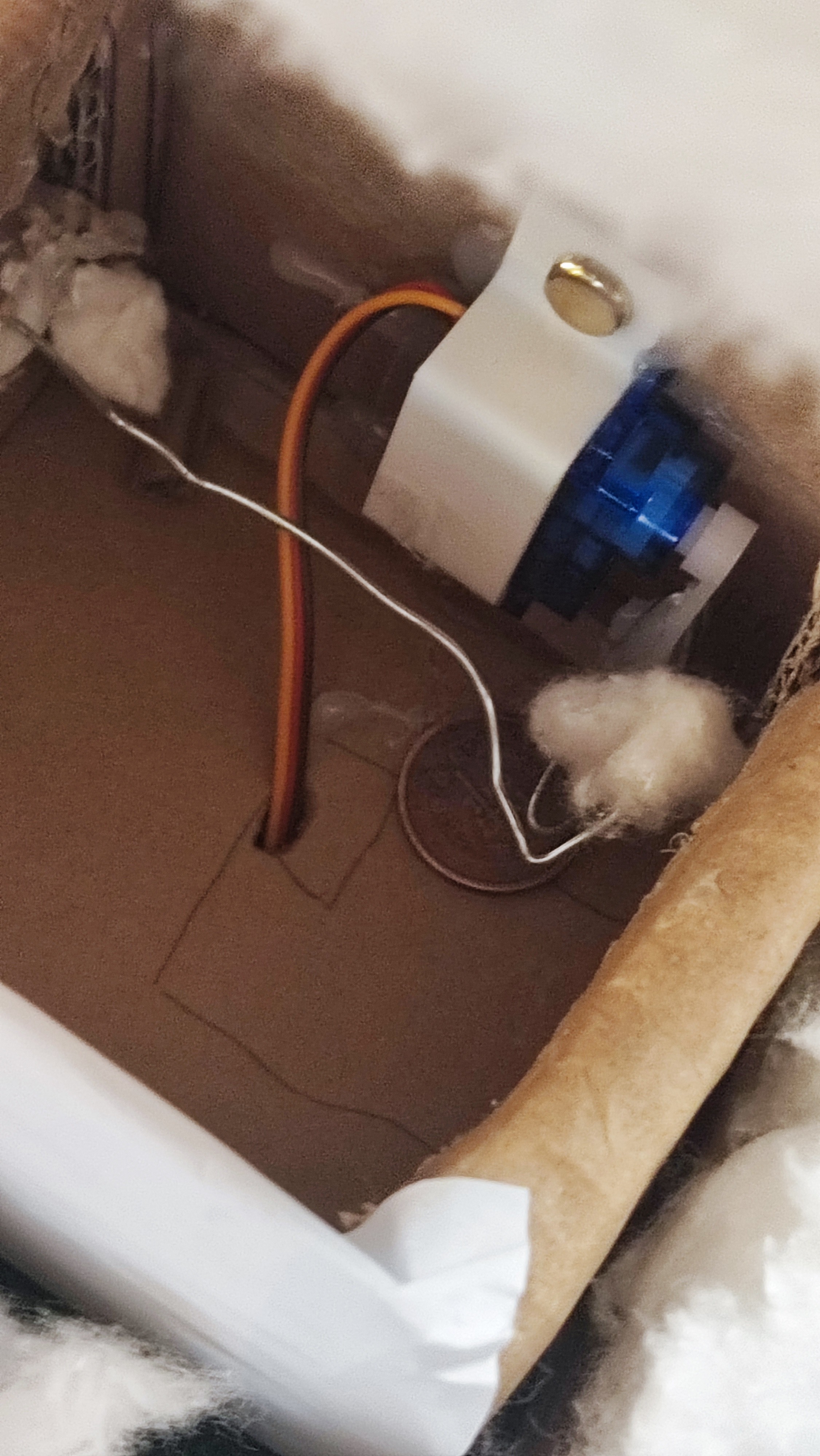

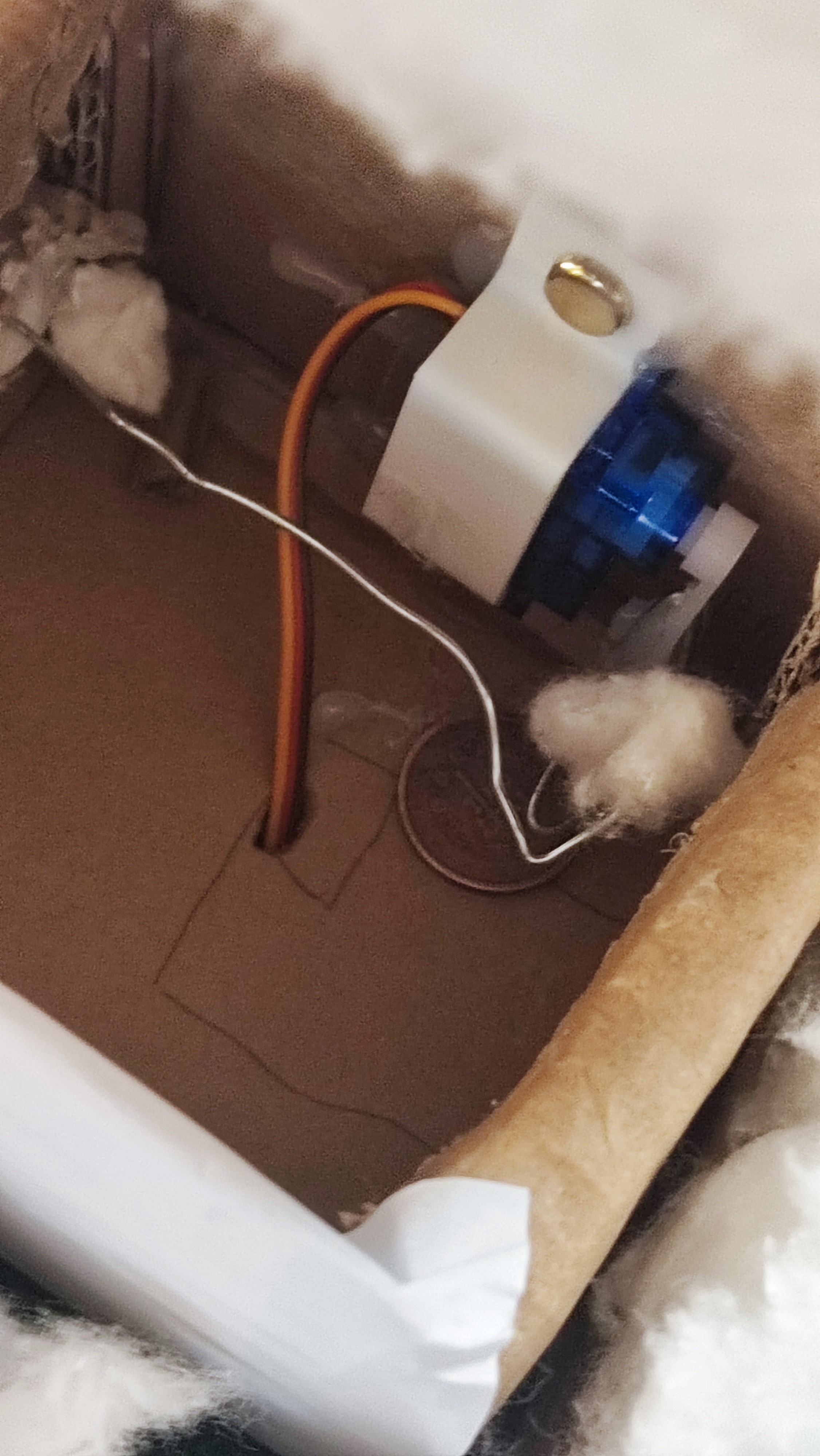

Prototyping nov 28

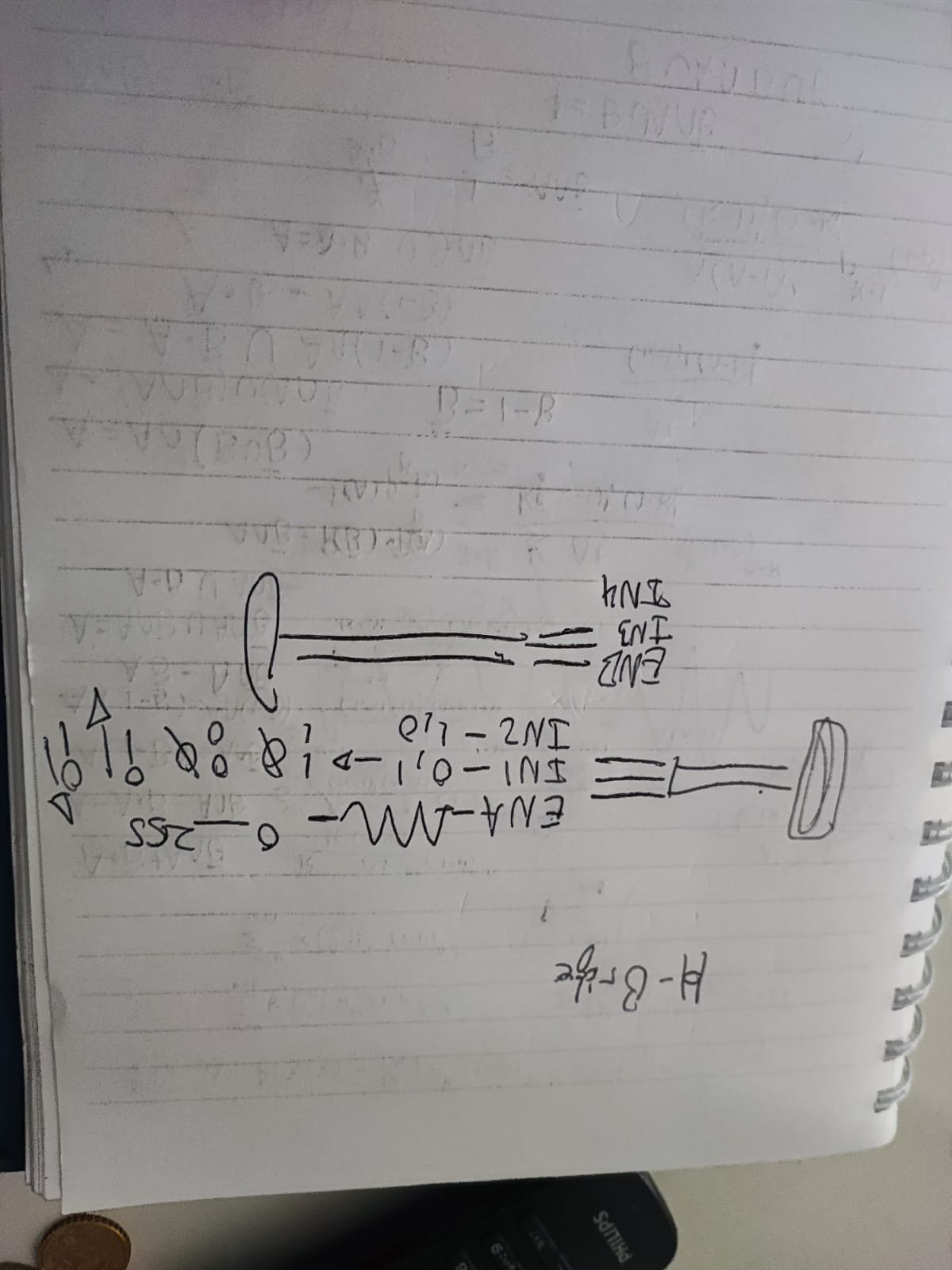

12/19/2024 at 11:18 • 0 commentsA prototype with the servomotor was generated to test the mechanism.

The servo was tested with different speeds and angles.

https://drive.google.com/drive/folders/1pN04_y27E8oay5VLukY2Znhpm0sNJt7P

![]()

-

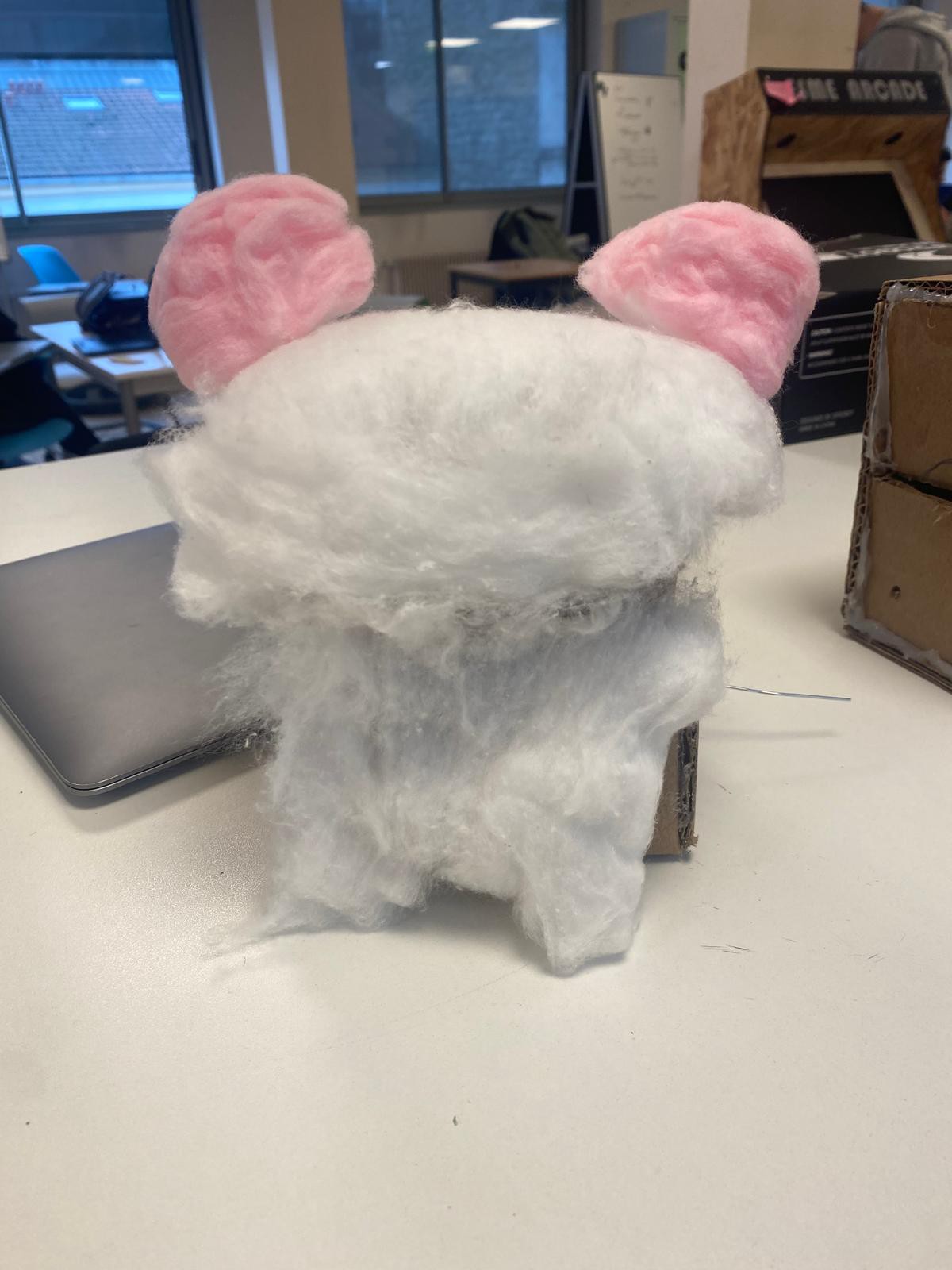

Decoration Dec 12

12/19/2024 at 11:12 • 0 commentsStarted imaginating how the panda would look like, with different materials.

![]()

-

12/12/2024

12/19/2024 at 11:10 • 0 commentswe were working on the software part, coding the esp32-cam, esp32,as well creating the web page using html, css and js.

-

Final touches

12/19/2024 at 11:09 • 0 comments![]()

![]()

The final version of the panda car was decorated with cotton, we used paper clips to complete the going up and down mechanism.

we fixed the panda with glue. The mechanism in reality turned out to be really specific, the axis had to be straight and the servomotor had to touch the pivot point on an exact area.

We also tested the range of the esp32 for the wifi of a mobile phone that was about 10 meters.

![]()

-

Final touches

12/19/2024 at 11:04 • 0 comments![]()

![]()

The final version of the panda car was decorated with cotton, we used paper clips to complete the going up and down mechanism.

we fixed the panda with glue. The mechanism in reality turned out to be really specific, the axis had to be straight and the servomotor had to touch the pivot point on an exact area.

We also tested the range of the esp32 for the wifi of a mobile phone that was about 10 meters.

![]()

-

11/12

12/19/2024 at 10:57 • 1 commentpatern of the panda in order to not see glue/ easier manufacturing.

-

3d printed parts for panda box

12/17/2024 at 21:34 • 0 commentsFor the panda box, after creating a prototype version, it was found a need for the servomotor to be fixed on one side of the box, and also a pivot for the arms and box. For this an exercise of generatenge a hinge and two circular spaces so that the arms could rotate smoothly was made and the final pieces were printed. This added a more profesional presentation to the project and mainly served as an exercise to explore complexity on the design.

Holes where made for the paper pins. -

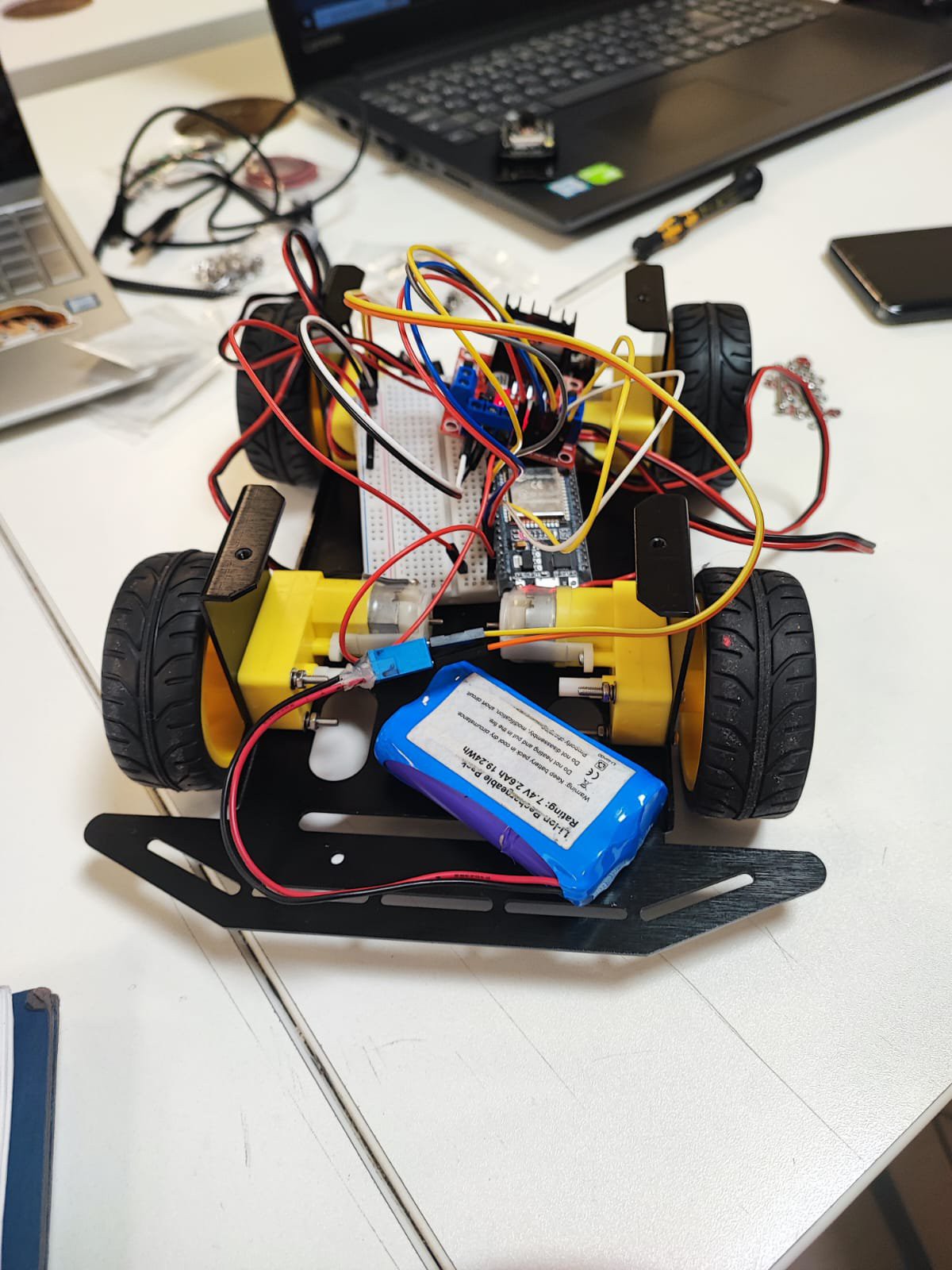

24/10/24

11/08/2024 at 12:08 • 0 commentsBuilt the car, added the motor drivers, learnt the functioning of the driver. Added a bluetooth control for the rc car and tested the functioning.

![]()

![]()

-

logs

11/07/2024 at 09:49 • 0 comments10-17/10/24: researches about the parts we can use

24/07/24 : Build our car

7/11/24 :