I generally get stencils for all projects, and use the interactive HTML BOM for assembly, combined with a camera based microscope to check orientation and proper placement.

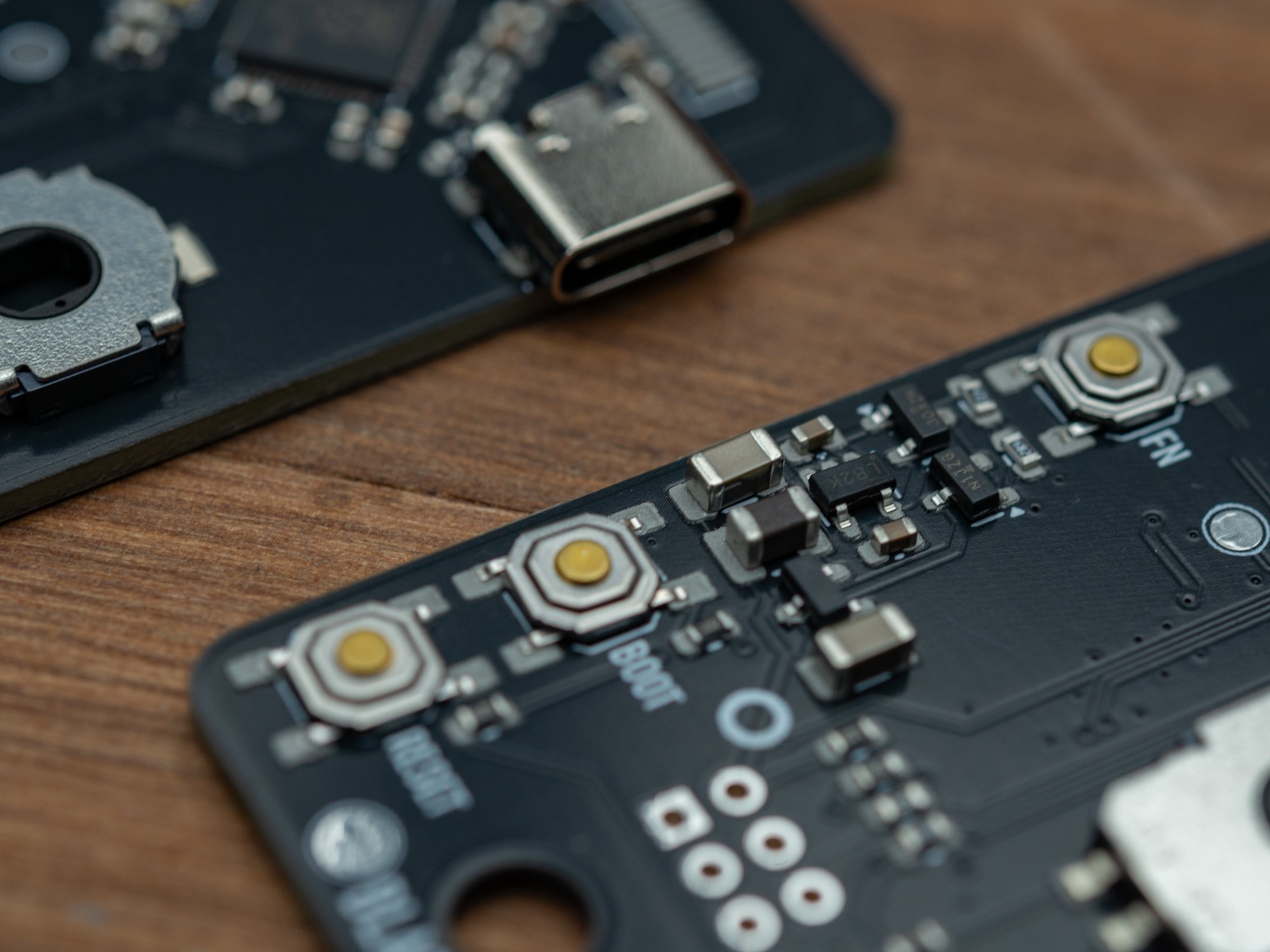

For the majority of the parts, I use a small curved tweezer (Erem), and some of the larger ones could simply be positioned by hand (rotary encoder and USB-C connector), as there are alignment holes for those.

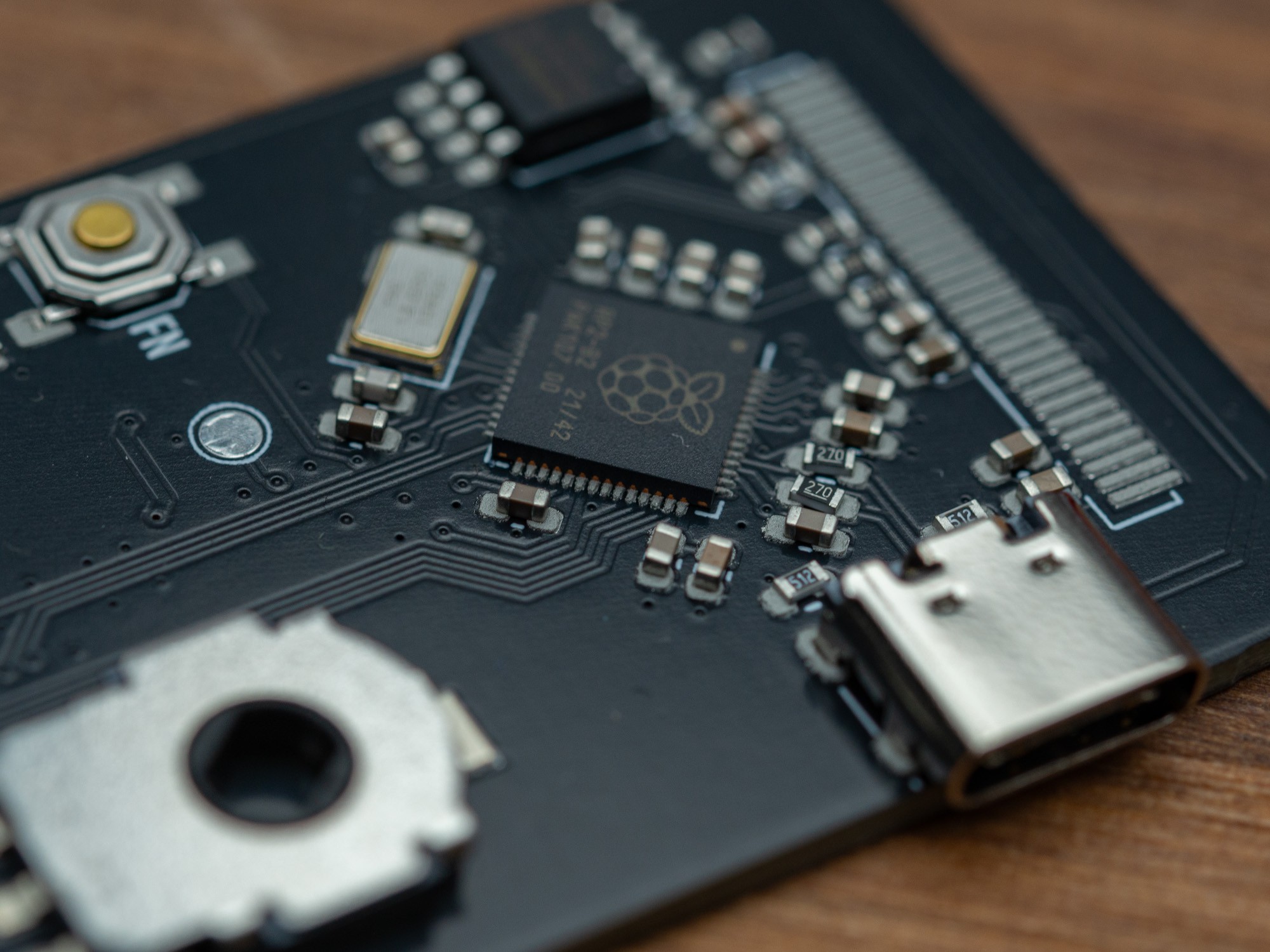

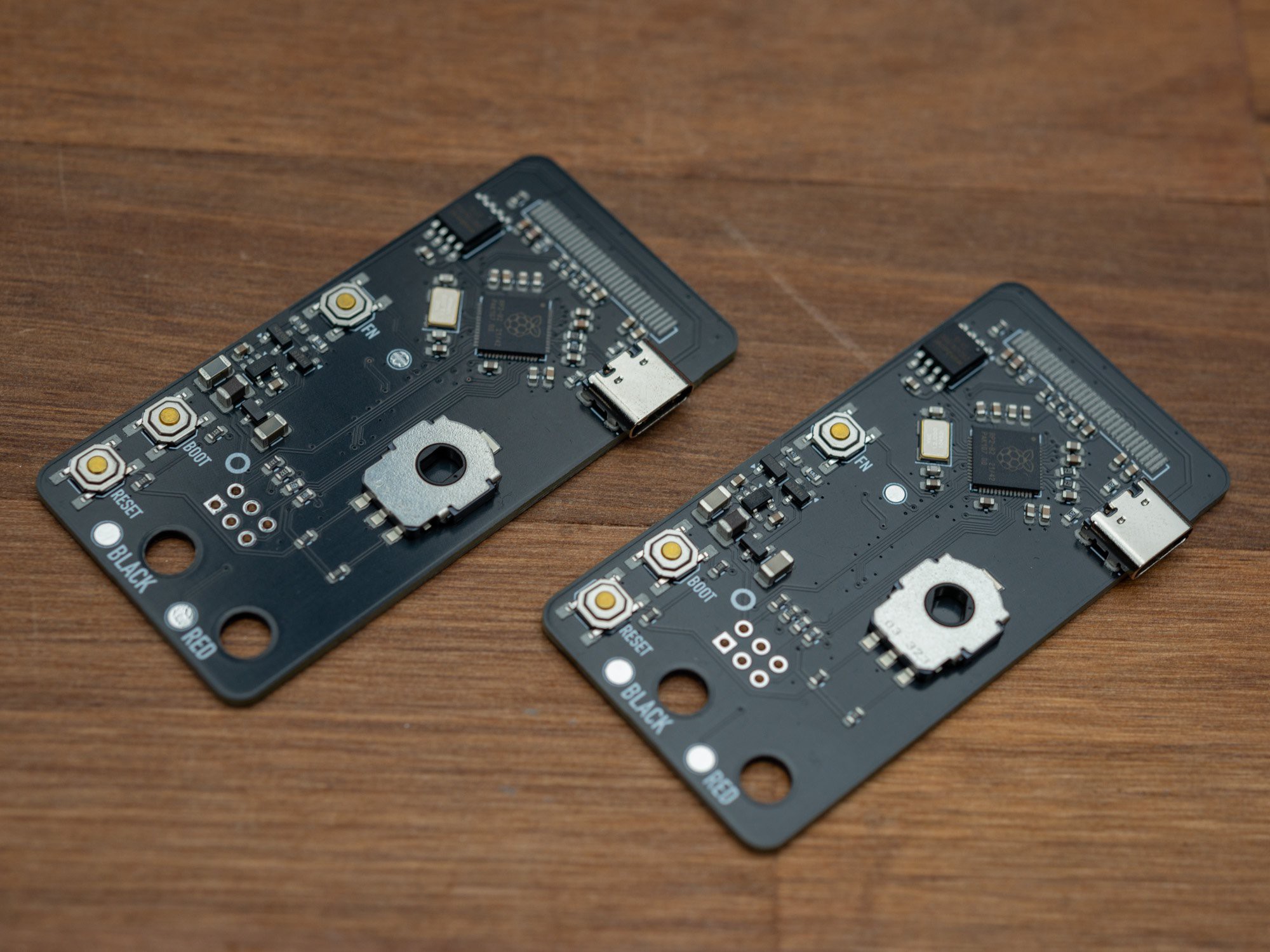

Two base boards ready for baking

I use one of these small hotplates... it a bit on the small size for this, but moving the PCB a little made sure all got soldered. Compared to the regular cooking hotplate I was using before, this is MUCH more stable with the temperature, and stays at 210°C only dips a little when I put on a new PCB (probably not the best thing to do, but I'm to impatient to wait for it to cool down)

The OLED displays are soldered on with a soldering iron and the solder that was applied during pasting. It might have been a little too much solder, as I had to redo it on one of them due to a short.

Thomas Flummer

Thomas Flummer

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.