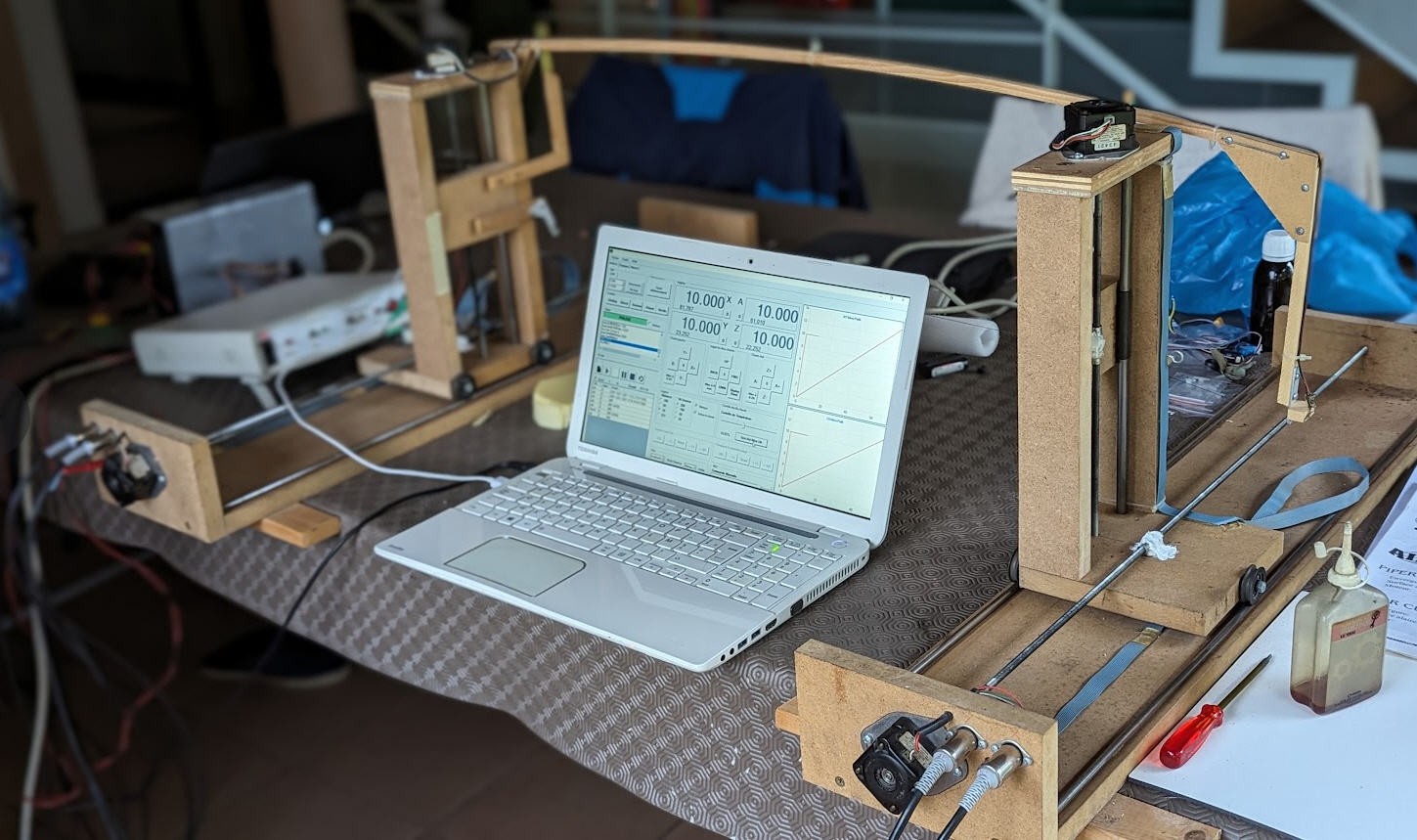

A few months ago I retrofitted an old foam cutter based on a MM2001 hardware.

This system works quite well, but the unipolar stepper motors are very weak and prevent any fast motion... which is "annoying" when the hot wire is at one end of the machine and you want to go to the opposite side...

So why not building a brand new controller with the following requirements :

- able to drive a hot wire

- equiped with 4 bipolar steppers

- driven by standard polulu shields

- and with an ESP32 MCU

- FluidNC driven

- able to "eat" gcode produced by any "foam cutter" software

Let's go it's an easy project which shouldn't cost more than 20$ (without motors) !

Electronics

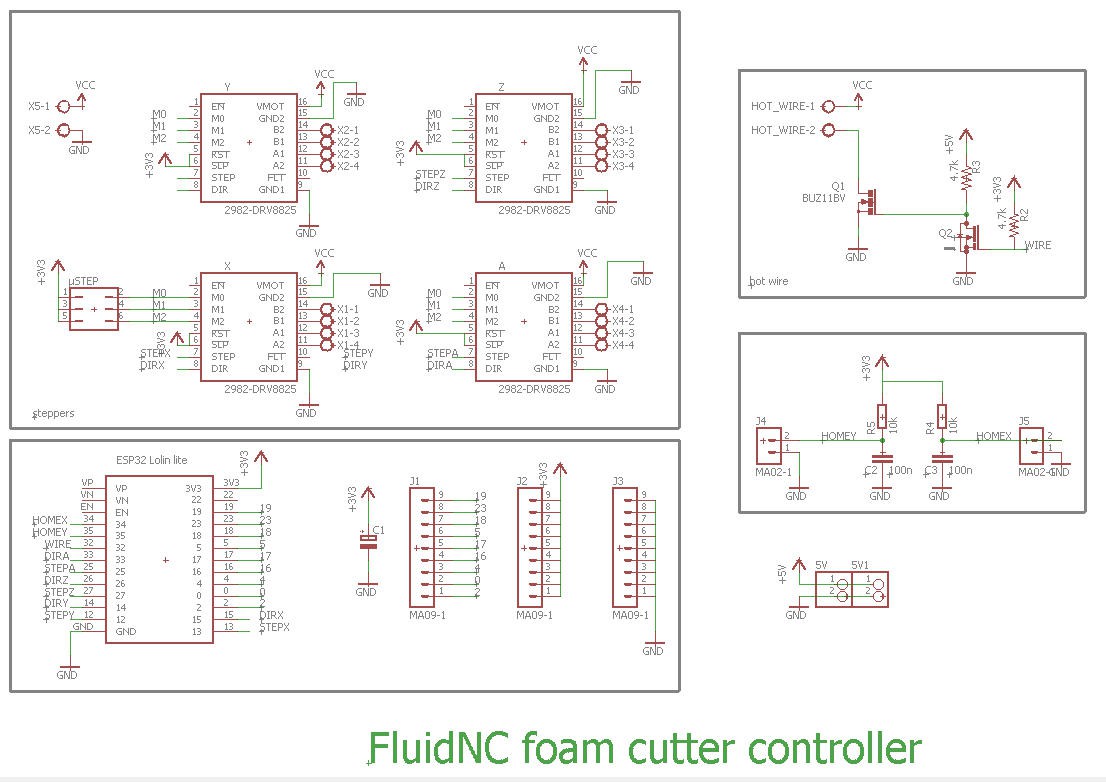

Schematics

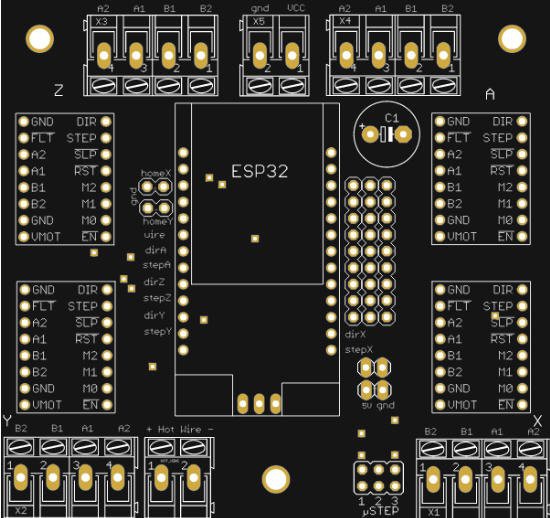

This schematics is extremly simple as it implements 4 times the basic way to use a polulu driver

Apart from the steppers, the only useful part is the hotwire. It's a 1m long 0.3mm nichrome wire which is fine tuned powered by a PWM under 40V (same PSU for the steppers).

- PWM is produced by a two stages mosfets setup

- the big BUZ11 takes care of the power line

- the small 2N7000 is powered at 5V and its gate is triggered by GPIO32 of the ESP32

- 5V supply is delivered by the USB cord plugged into the ESP32 and by an external supply for polulus and hotwire

Finally I have added two home switches inputs (homeX and homeY) although they are useless for a foam cutter!

And exposed a few more pins of the ESP32 to be used (or not) for future projects!

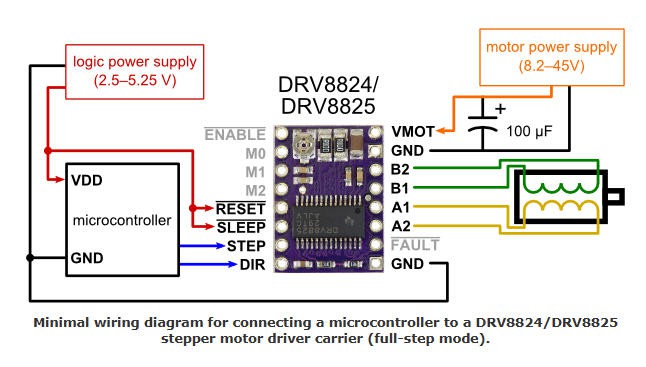

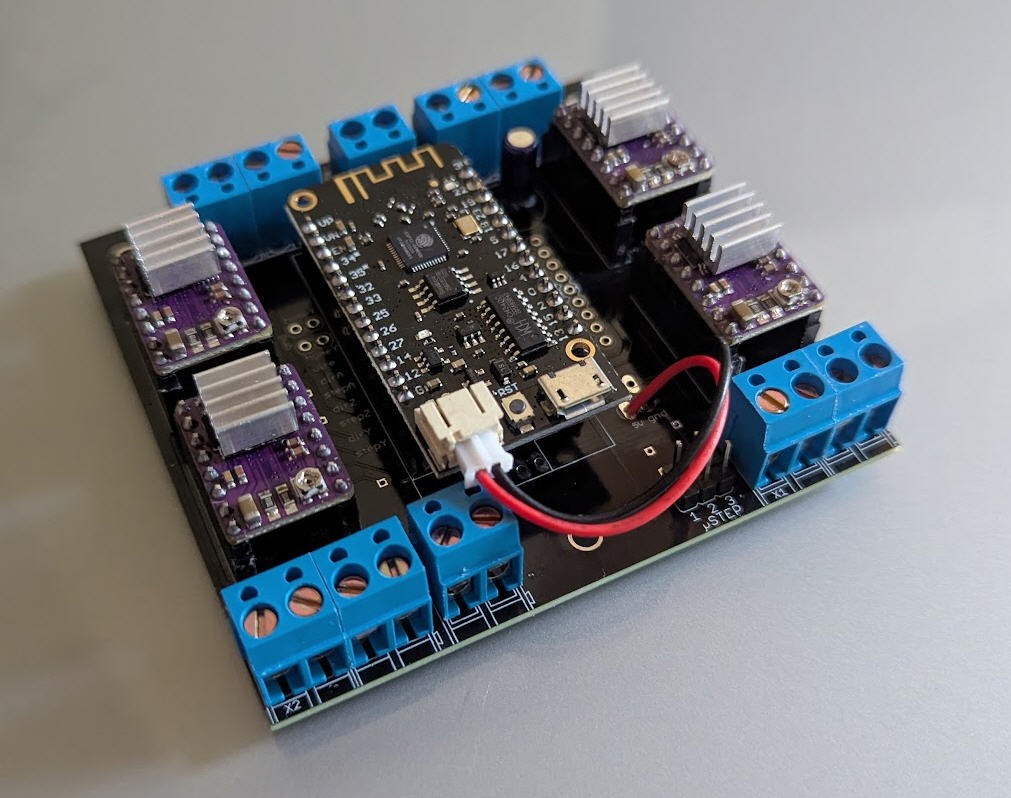

PCB

I have designed a nice and compact PCB allowing to "shield" the drivers and the ESP32 modules.

The PCB was kindly sponsored by PCBWay and is as usual of excellent quality.

You can order it here: PCBWay shared project. It's cheap, delivered very fast and so professional looking!

and if you are new to PCBWay please use this affiliated link : https://pcbway.com/g/o35z4O

Soldering this board is fairly simple.

Here is the result:

Software

This board is directly compatible with FluidNC firmware. So we will only focus on FluidNC configuration.

If you don't know how to install FluidNC, please refer to this log : https://hackaday.io/project/193659-lets-convert-a-dc-motor-into-a-stepper-one/log/225300-installing-fluidnc

Configuring FluidNC is not totally simple but if you follow the documentation it is feasible without too much difficulties.

Here is the config.yaml file for my machine.

name: 4 axis hot wire cutter

start:

must_home: false

axes:

x:

steps_per_mm: 200

max_rate_mm_per_min: 1000

acceleration_mm_per_sec2: 10

max_travel_mm: 1000

motor0:

limit_all_pin: NO_PIN

limit_neg_pin: NO_PIN

limit_pos_pin: NO_PIN

hard_limits: false

pulloff_mm: 1

standard_stepper:

step_pin: gpio.13

direction_pin: gpio.15:low

disable_pin: NO_PIN

y:

steps_per_mm: 200

max_rate_mm_per_min: 1000

acceleration_mm_per_sec2: 10

max_travel_mm: 1000

motor0:

limit_all_pin: NO_PIN

limit_neg_pin: NO_PIN

limit_pos_pin: NO_PIN

hard_limits: false

pulloff_mm: 1

standard_stepper:

step_pin: gpio.12

direction_pin: gpio.14:low

disable_pin: NO_PIN

z:

steps_per_mm: 200

max_rate_mm_per_min: 1000

acceleration_mm_per_sec2: 10

max_travel_mm: 1000

motor0:

limit_all_pin: NO_PIN

limit_neg_pin: NO_PIN

limit_pos_pin: NO_PIN

hard_limits: false

pulloff_mm: 1

standard_stepper:

step_pin: gpio.27

direction_pin: gpio.26:low

disable_pin: NO_PIN

a:

steps_per_mm: 200

max_rate_mm_per_min: 1000

acceleration_mm_per_sec2: 10

max_travel_mm: 1000

motor0:

limit_all_pin: NO_PIN

limit_neg_pin: NO_PIN

limit_pos_pin: NO_PIN

hard_limits: false

pulloff_mm: 1

standard_stepper:

step_pin: gpio.25

direction_pin: gpio.33:low

disable_pin: NO_PIN

stepping:

engine: RMT

idle_ms: 250

pulse_us: 20

dir_delay_us: 0

disable_delay_us: 0

user_outputs:

digital0_pin: NO_PIN

digital1_pin: NO_PIN

digital2_pin: NO_PIN

digital3_pin: NO_PIN

PWM:

output_pin: gpio.32:low

enable_pin: NO_PIN

direction_pin: NO_PIN

disable_with_s0: false

s0_with_disable:...

Read more »

JP Gleyzes

JP Gleyzes

t.oster92

t.oster92