Goals to reach (updated Nov. 11th, 2018)

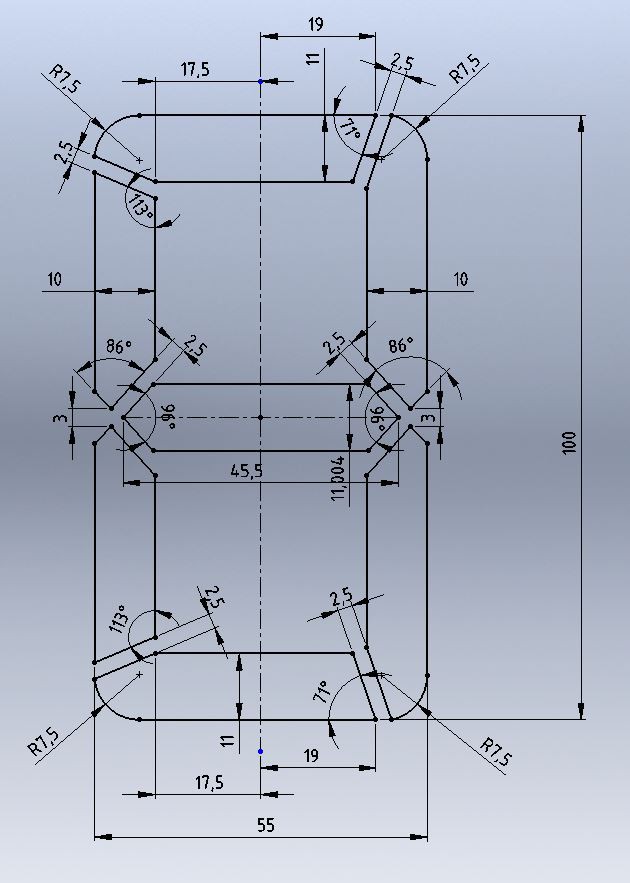

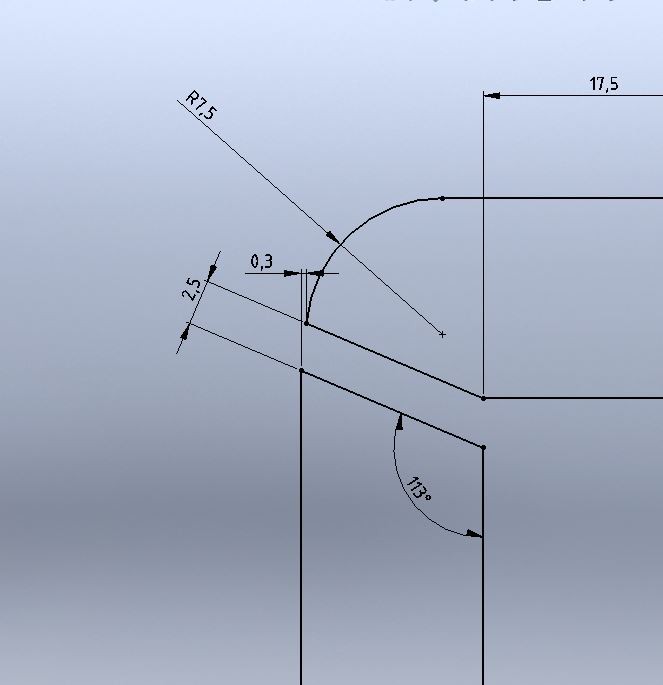

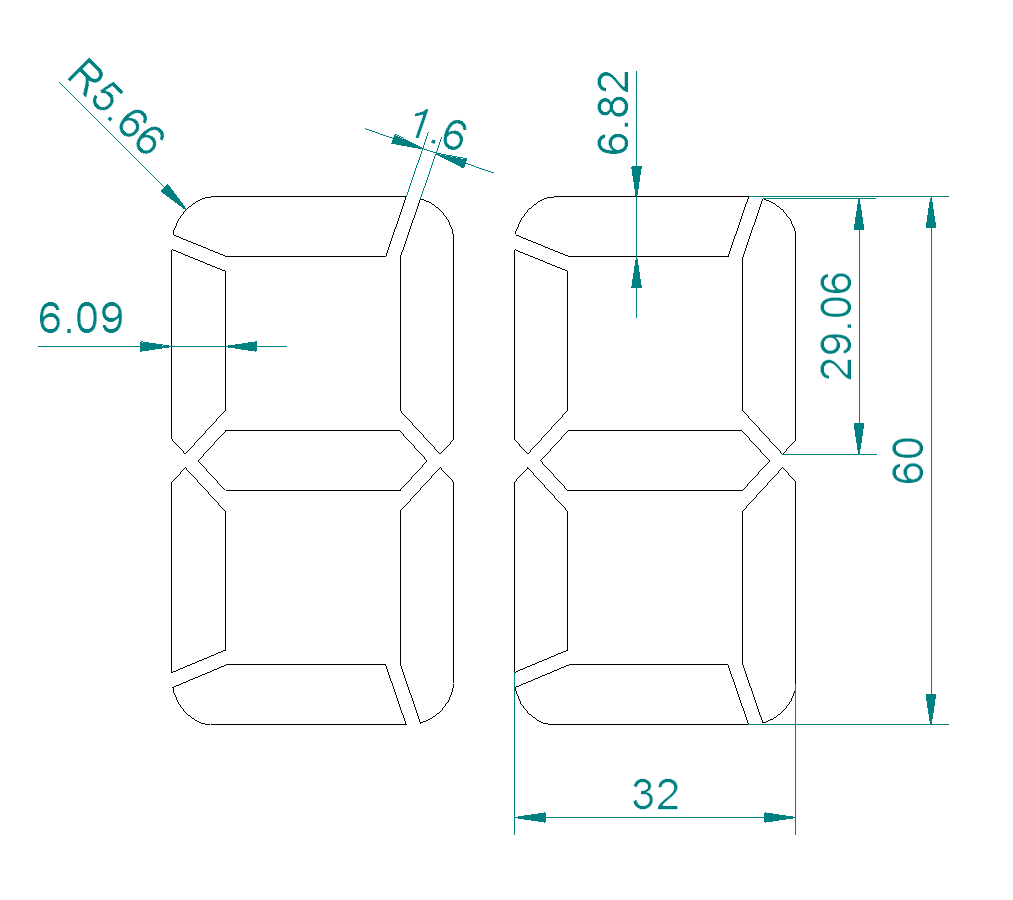

— Number-height of 100mm (approx. 4") @ 10mm thickness

See old post here: https://hackaday.io/project/20142/log/54244-obstacle-1-number-height-of-60mm

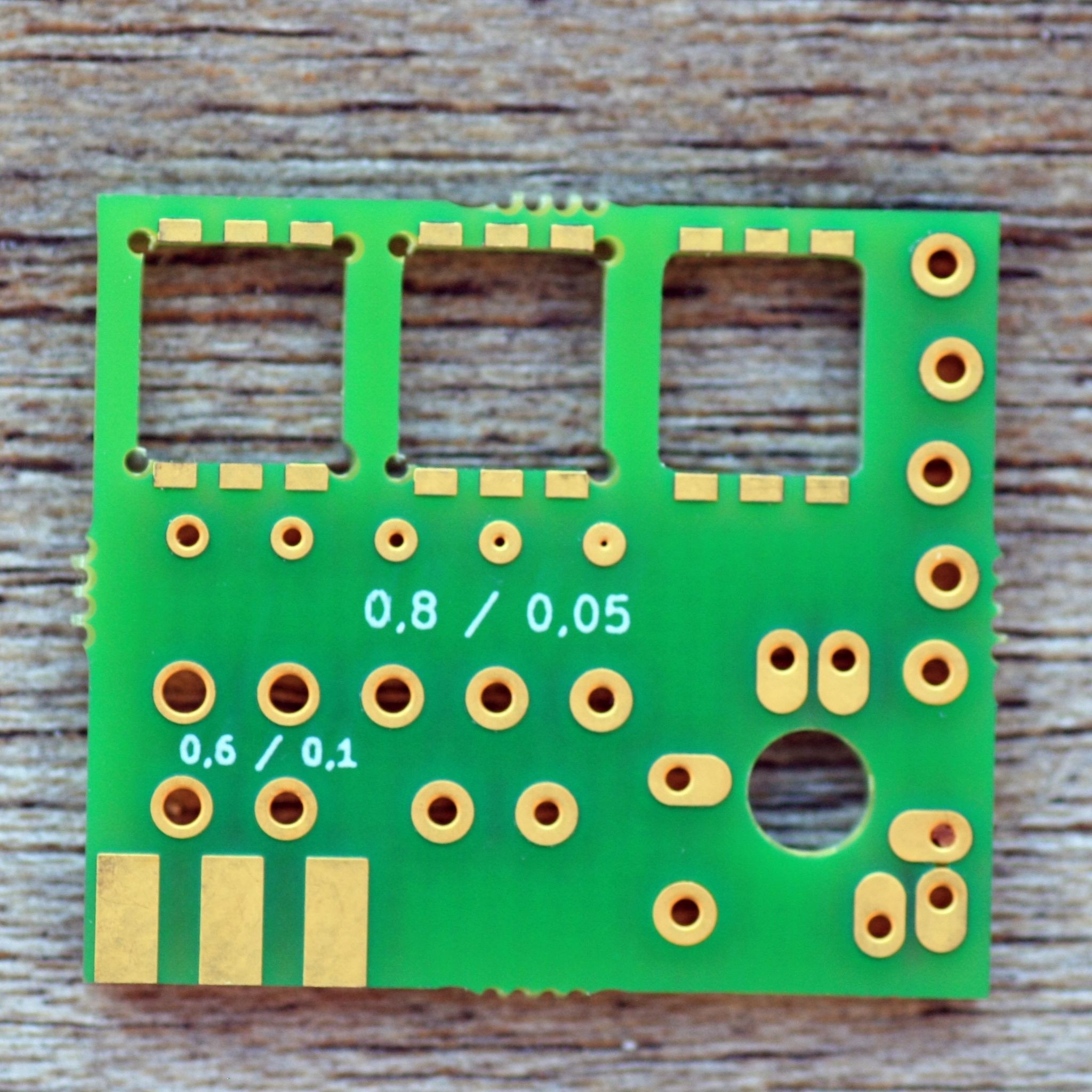

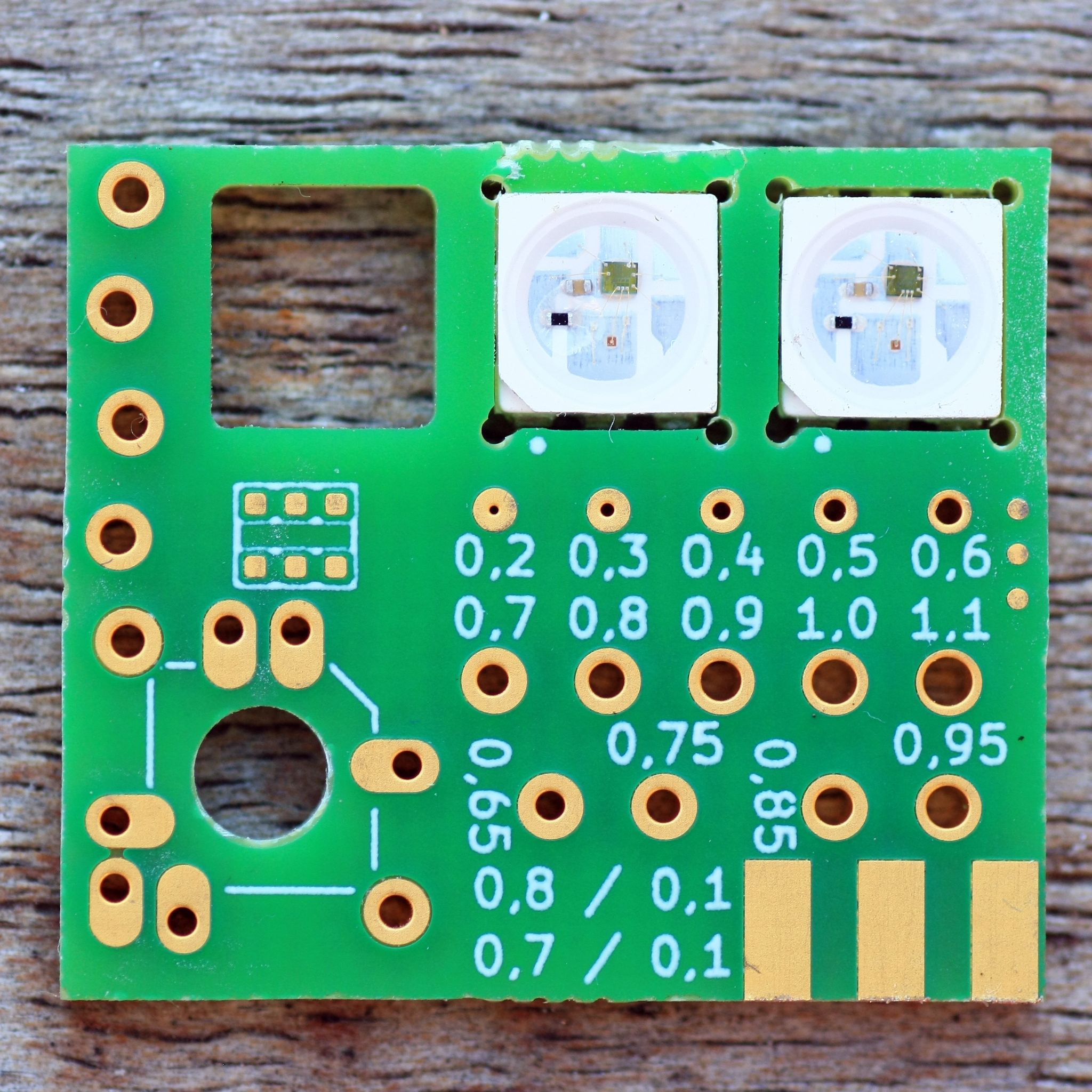

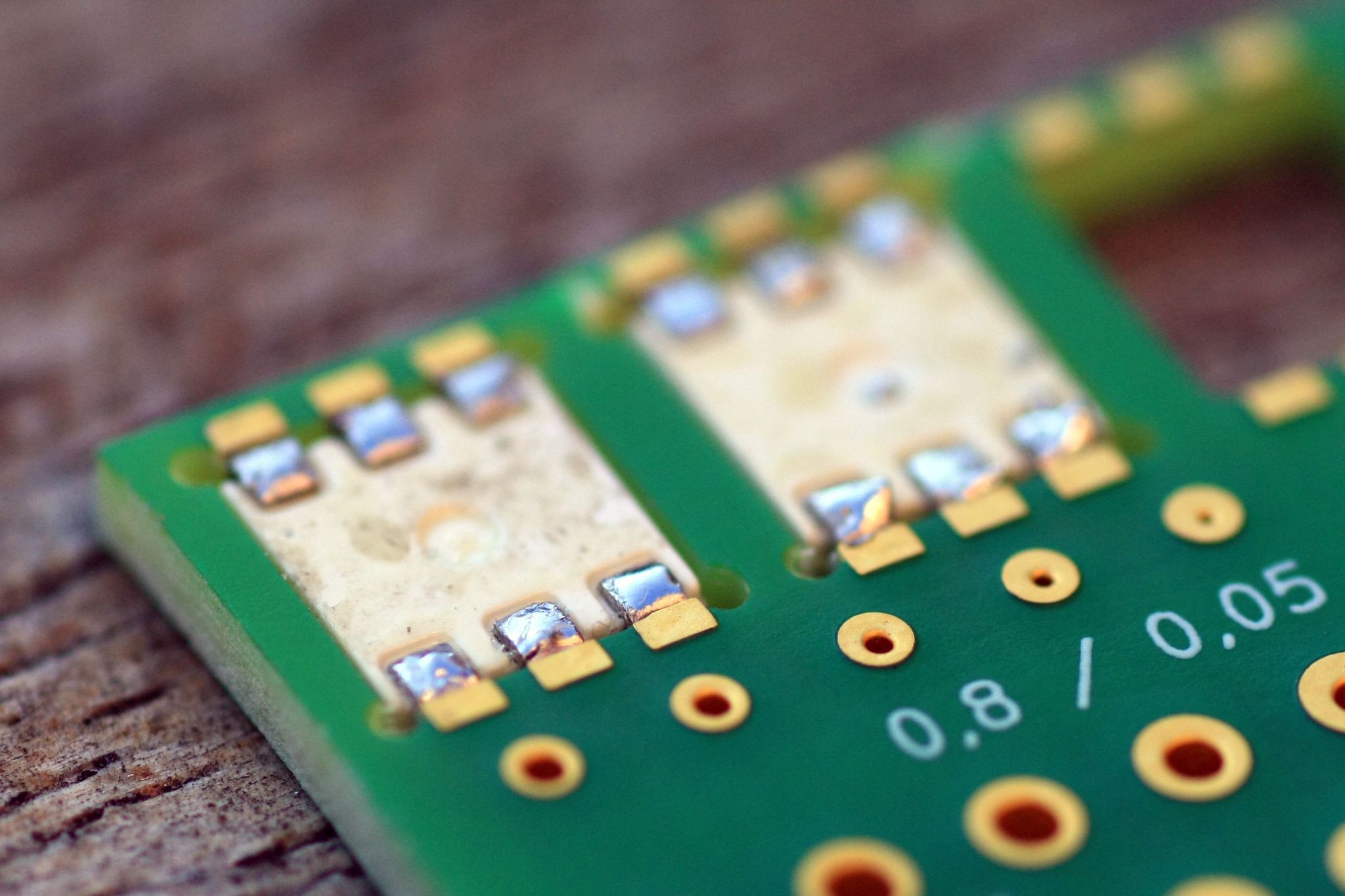

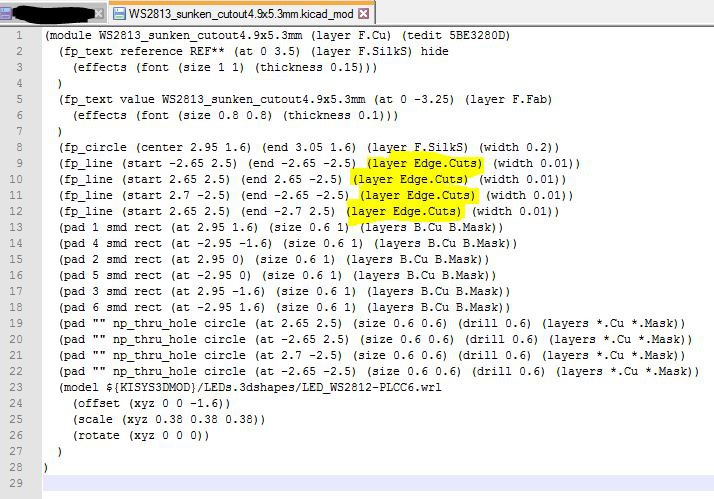

See new post here: https://hackaday.io/project/20142-rgb-seven-segment-display-rssd/log/155852-new-design-includes-special-ws2813-footprint

— Homogeneously illuminated segments

See old post here: Homogeneously illuminated segments

See new post here: to be continued (will be fancy. Promise!)

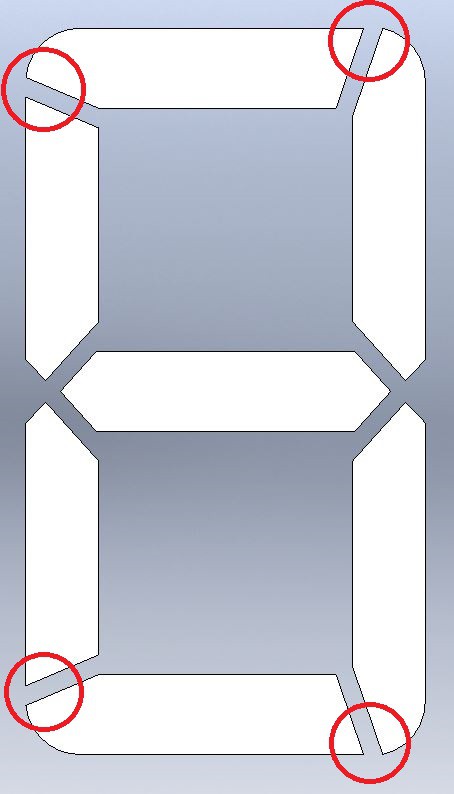

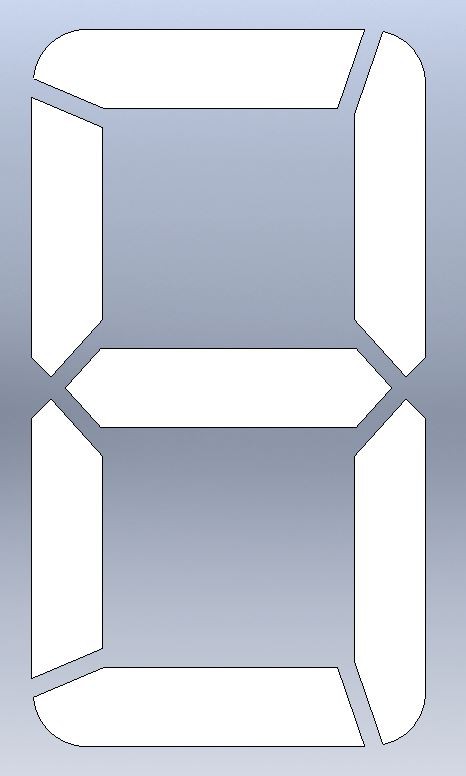

— Clean, unobtrusive design and easy to assemble

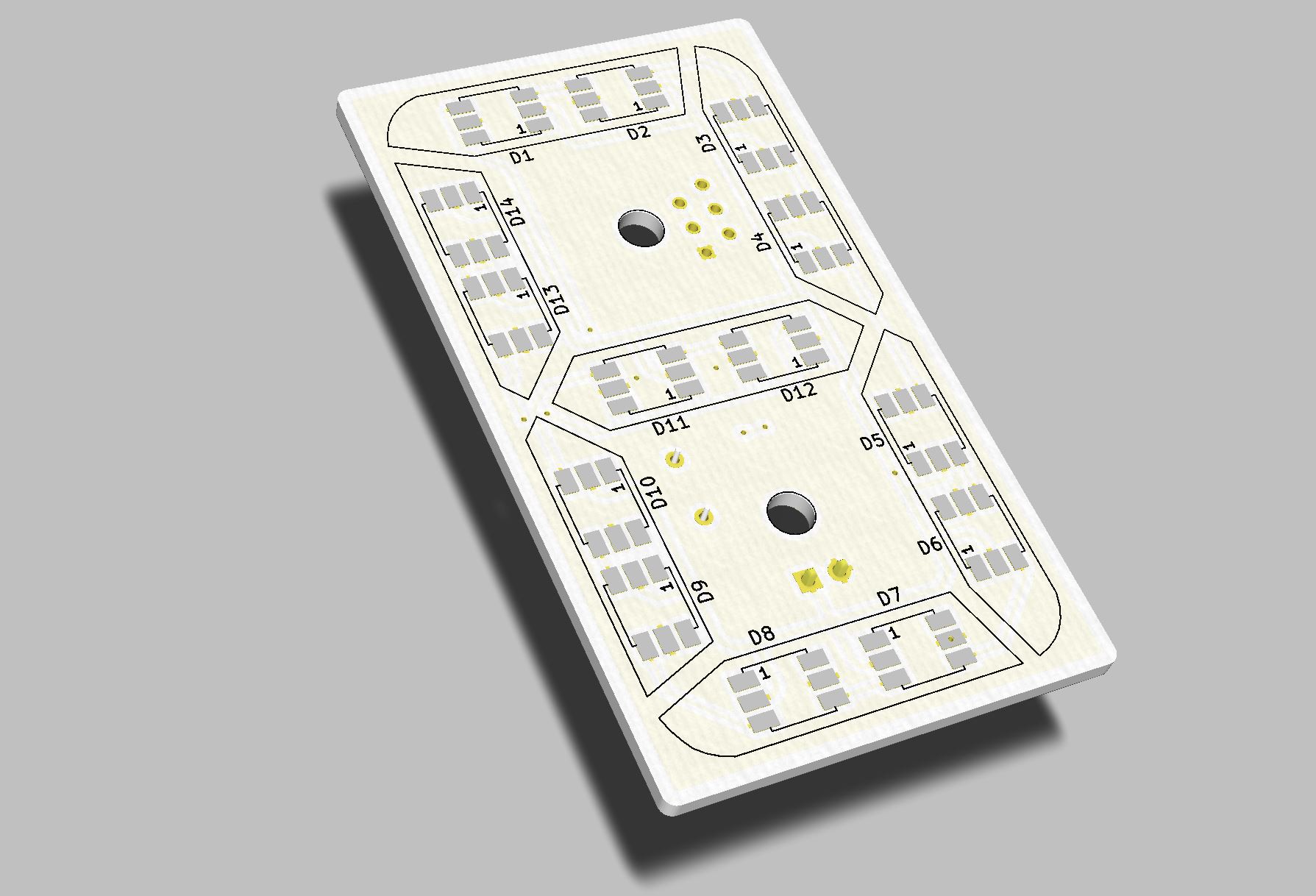

- one PCB per character

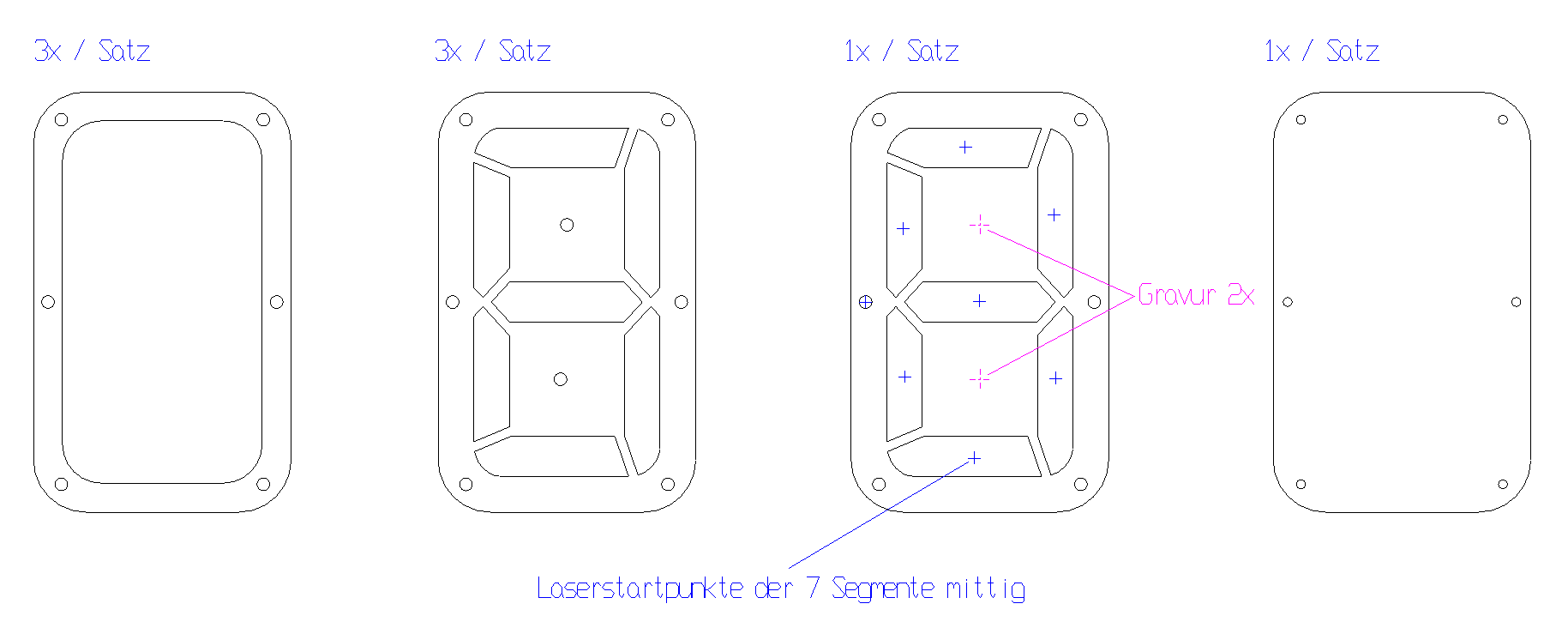

- frame laser-cut wood/steel/whatever you like

- preferably no screw or hidden screws (magnets?)

See [Blog-Entry]

— More features:

- programming and power via USB

- [...]

Jan

Jan

Stanislas Bertrand

Stanislas Bertrand

Alex

Alex

R. Scott Coppersmith

R. Scott Coppersmith

Gha, seems like you got to this project before I did!

I wanted to make a simple four-digit seven segment display countdown for New Years eve, but I'm making it a lot simpler than yours ^^'

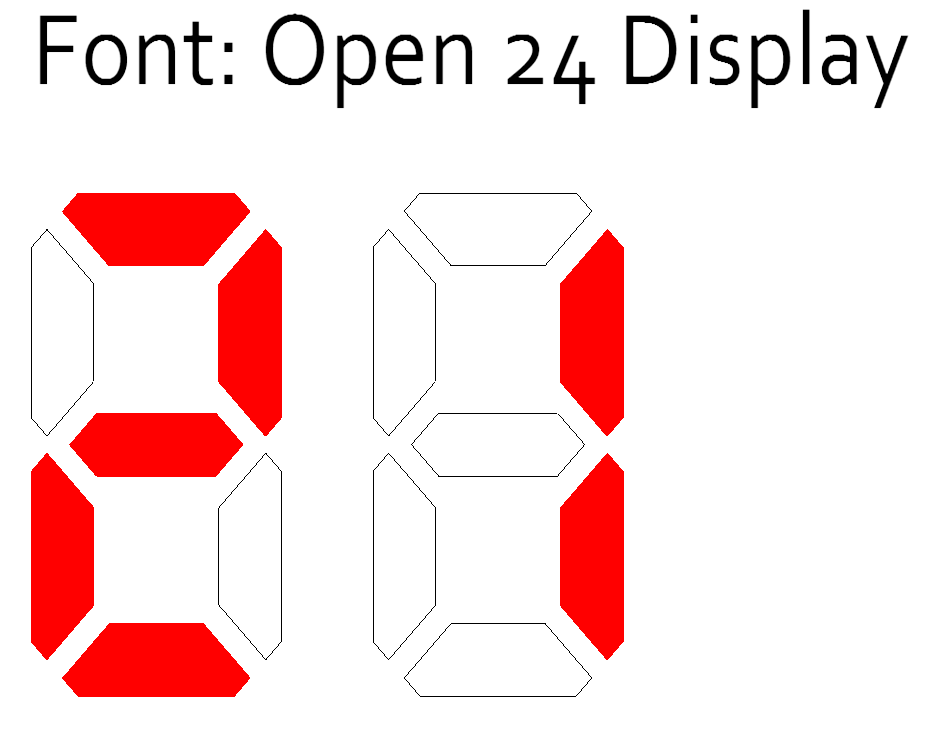

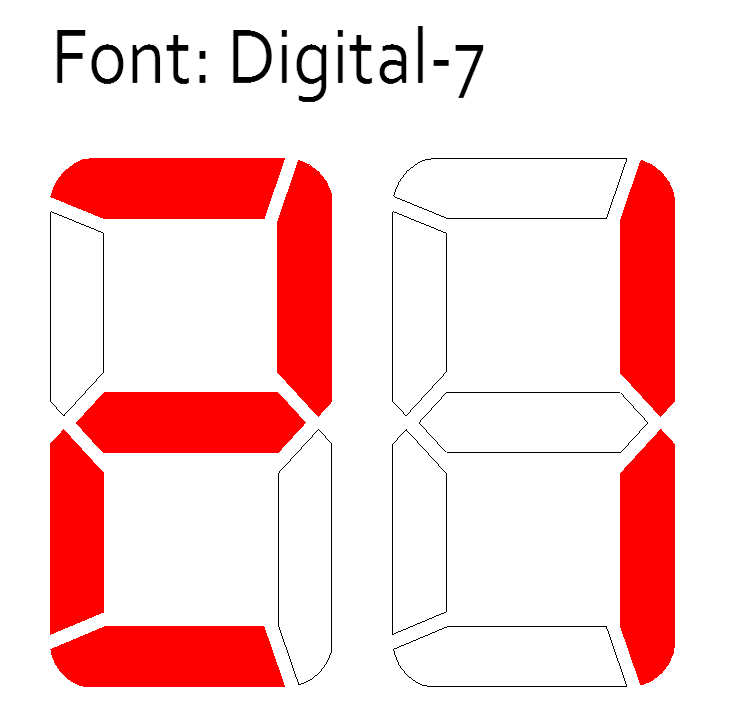

Seems like you're putting a lot of thought into this, which is nice! The font certainly looks nice :D

What will the main controller be? I can highly recommend a ESP WROOM module. Easy to solder, cheap enough, and the ESP32 has a built-in digital signal generator that can control a good number of WS2812 LEDs from hardware.

It's also got WiFi and has the processing power for smooth animations~