Introduction

The power button of my bladeless fan had stopped working. It first began acting up and being difficult to press few months back. However it was still completely usable by pressing firmly or using the remote control.

Today it gave up all signs of life. This week is the time for Chinese New Year. So in this project, I attempt a repair just in time during the Chinese New Year holidays.

Repairing the push button is a cost-effective solution, saving it from contributing to e-waste. Aside from the power button, the rest of the fan is still working perfectly since it was first bought 3 years ago in 2022.

Understanding the Hardware

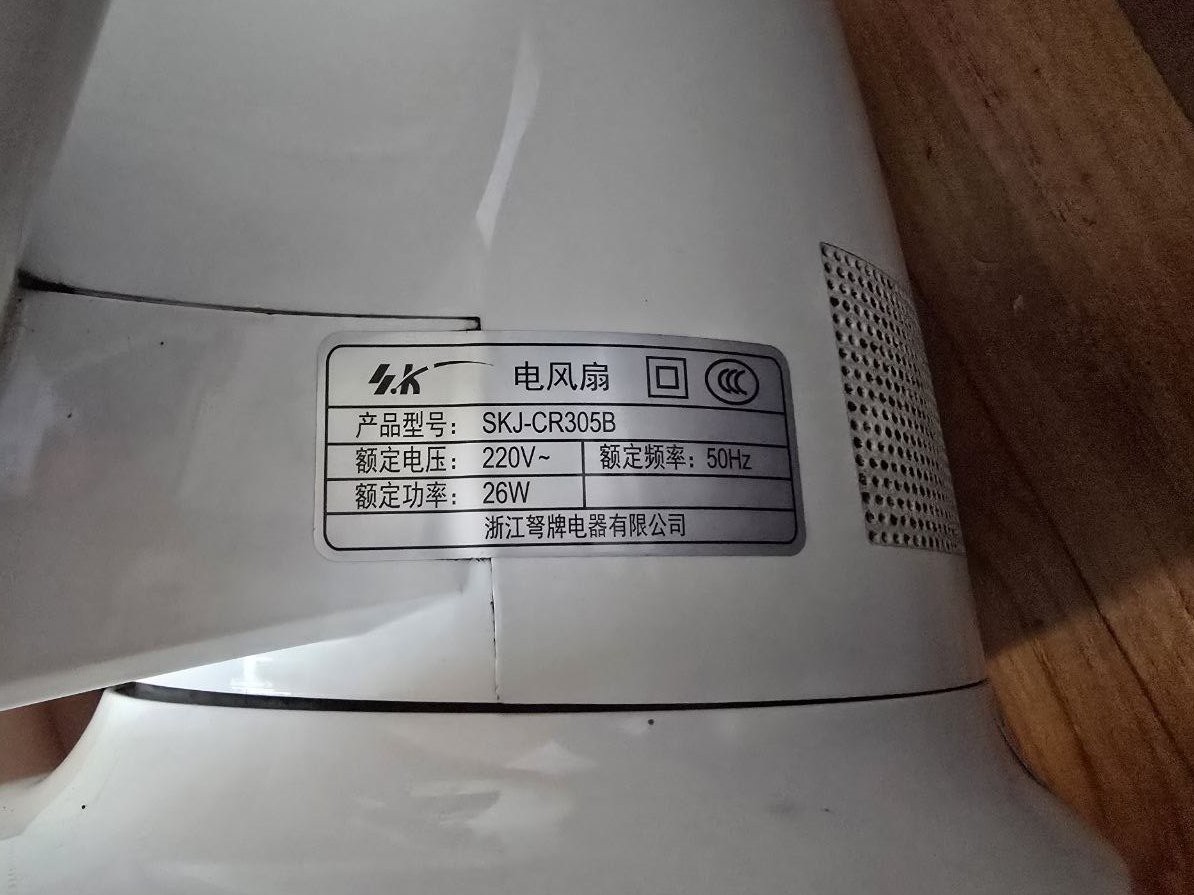

We will be repairing the following bladeless-style fan. At the side of the fan, the model specs are printed in Chinese text.

Here we see that the model number is "SKJ-CR305B" and the brand logo is "SK Japan". I believe it is a Japanese design and the company name of the Chinese OEM is printed at the bottom of the label.

The item was originally bought on e-commerce website for around US$80. Externally, the quality appears to be decently made. Searching online as of writing, we see newer models with similar-looking designs. These include the SKJ-CR305WD, SKJ-CR309WD and SKJ-CR310WD.

However, there are still no documentations available on how to disassemble or repair them.

Hardware Teardown

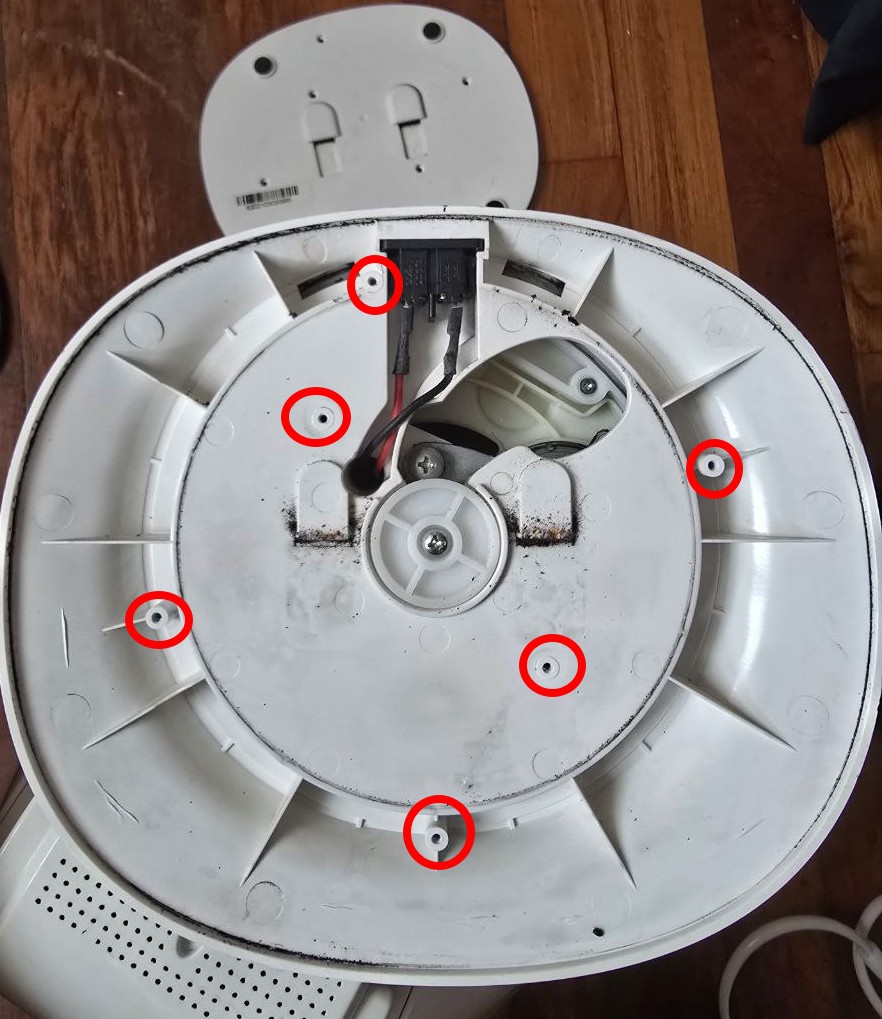

Since I want to access the power button panel, I need to remove the screws holding the front plastic cover. Looking around the body, we identify 4 Phillips-head screws. Sadly, the bottom 2 screws are blocked by the base and we cannot remove it right now.

Let's open up the base first. There are 6 screws on this panel.

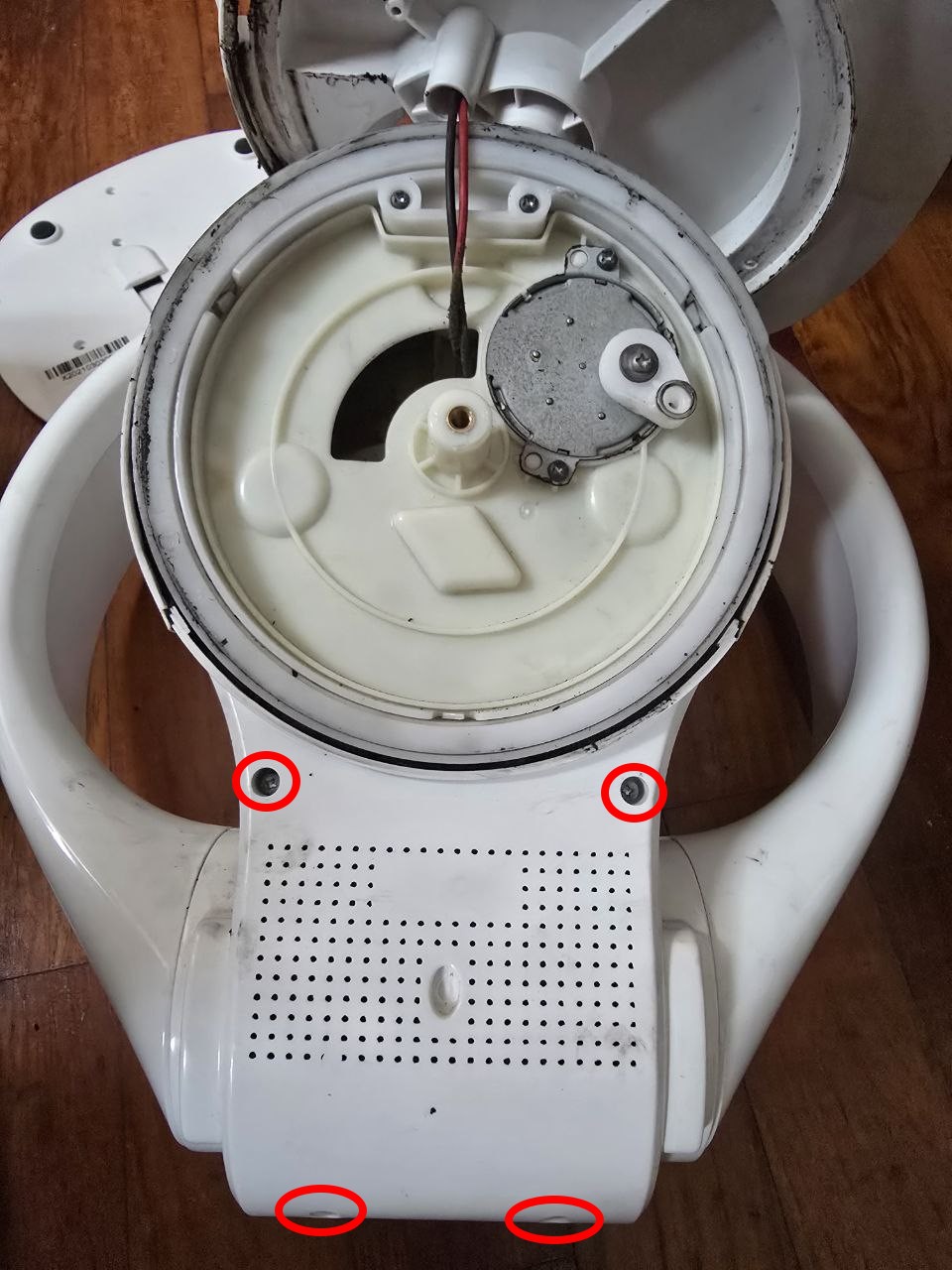

With the panel removed, we now need to detach the base from the main body. Rotate the base such that you are able to access the inner metal arm. Remove these 2 screws minimally to decouple the base.

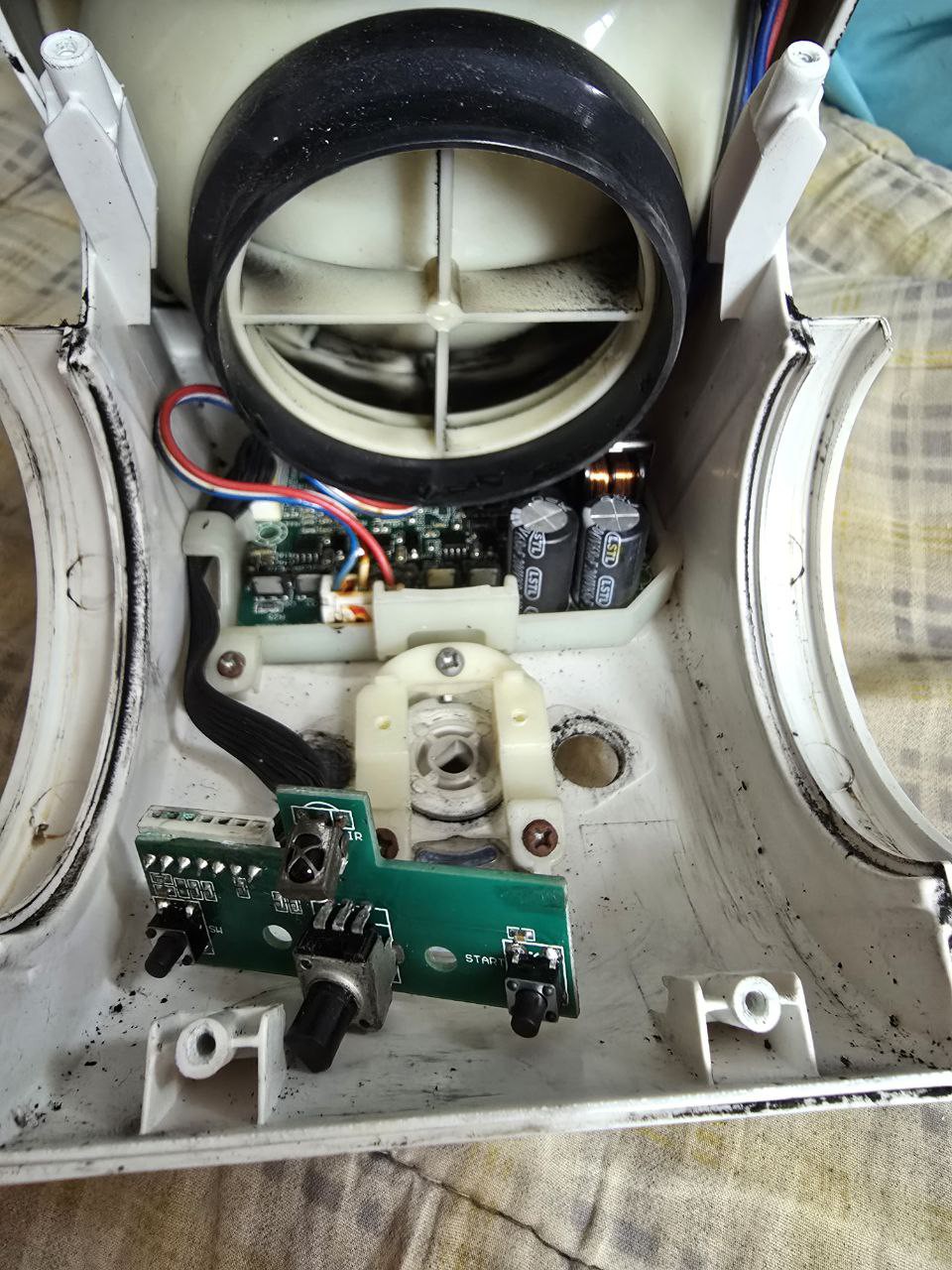

Be very careful as the white plastic bearing will fall out as you pull apart the base. Take note that there is a lot of grease here which has trapped a lot of dust.

Now we can access the original 4 screws we had identified earlier.

Be very careful as the middle T-structure has rubber seals which will fall out.

Circuit Board Repair

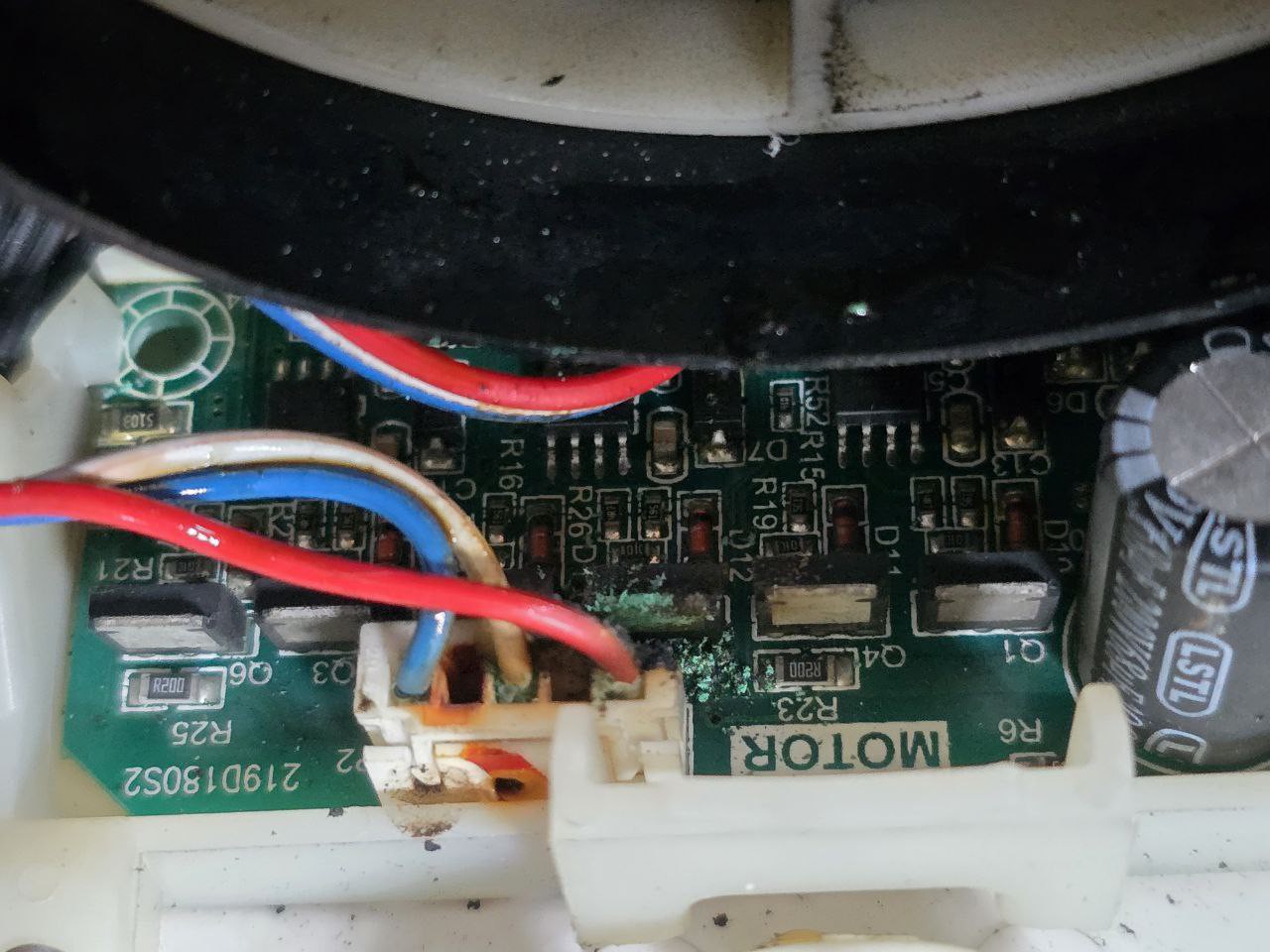

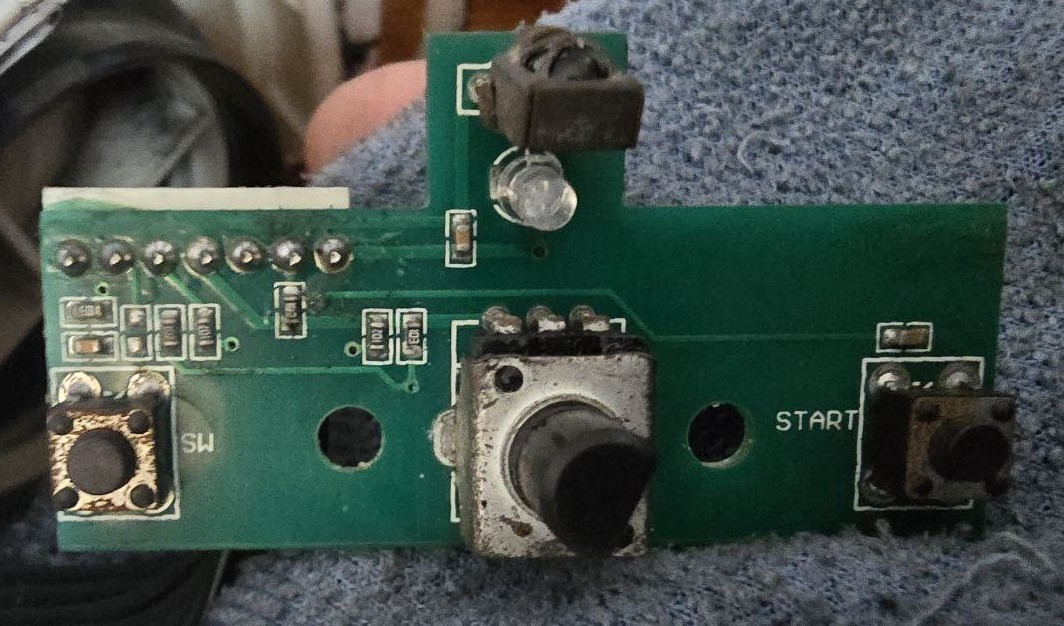

With that out of the way, we can now access the circuit board containing the user buttons. Looking around, there is a lot of visible corrosion. It appears that there is a poor seal around the fan output.

For T-structure that was just removed, the sealing ring is actually made out of plastic and does not form a tight seal. Isolation is poor between the electronics and mechanical parts.

Especially in humid environments, the leaked air may contain moisture which can accumulate on the metal components. This is a close up of the motor driver board.

Especially in humid environments, the leaked air may contain moisture which can accumulate on the metal components. This is a close up of the motor driver board.

After a quick cleaning, let's finally repair the power button.

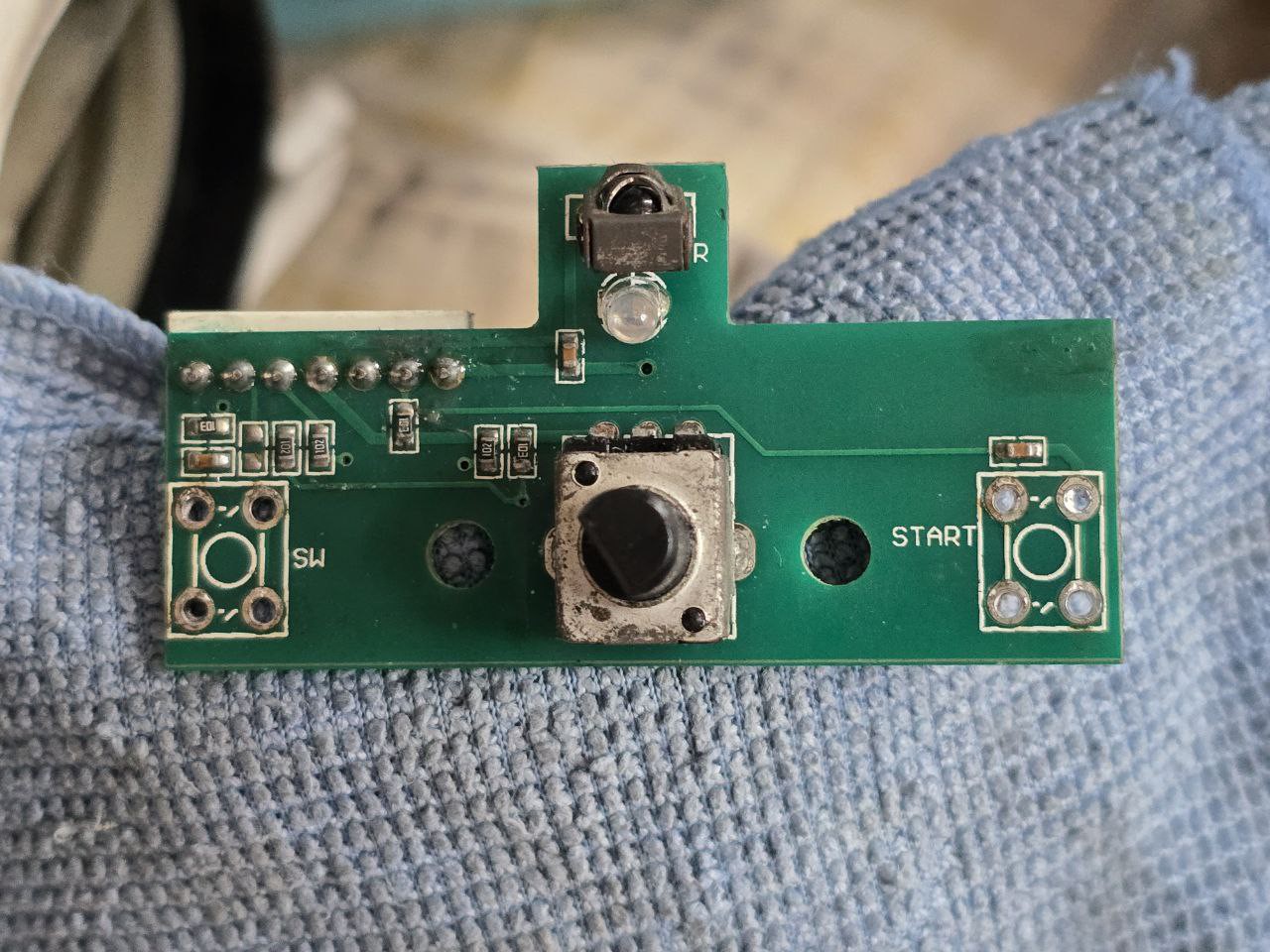

The front PCB is held by 2 screws. Unfortunately, the wiring is directly soldered on.

This is a close-up of the PCB. The buttons appear to be corroded internally too. Using a multimeter, the buttons register about 100kΩ when it is pressed lightly, and about 10kΩ when pressed firmly.

Here is the PCB with the buttons desoldered. Desoldering was complex as the buttons are through-hole. Working with the desoldering pump is a clumsy procedure, especially with wires still hanging onto the board. Be extra careful not to melt the insulation of the wires.

These are the replacement new buttons ready to be soldered in.

Now, let's do some final cleaning before assembling everything back together

Hardware Assembly

Putting back everything was straightforward. These are some photos of the process.

In particular, my hands got very grimy when due to the grease around the sealing rings and the plastic bearing. The dusty grease quickly transferred over to the white body.

As...

Read more » zst123

zst123

bryan.lowder

bryan.lowder

Miroslav Zuzelka

Miroslav Zuzelka

Emilio P.G. Ficara

Emilio P.G. Ficara

Doubleyou

Doubleyou