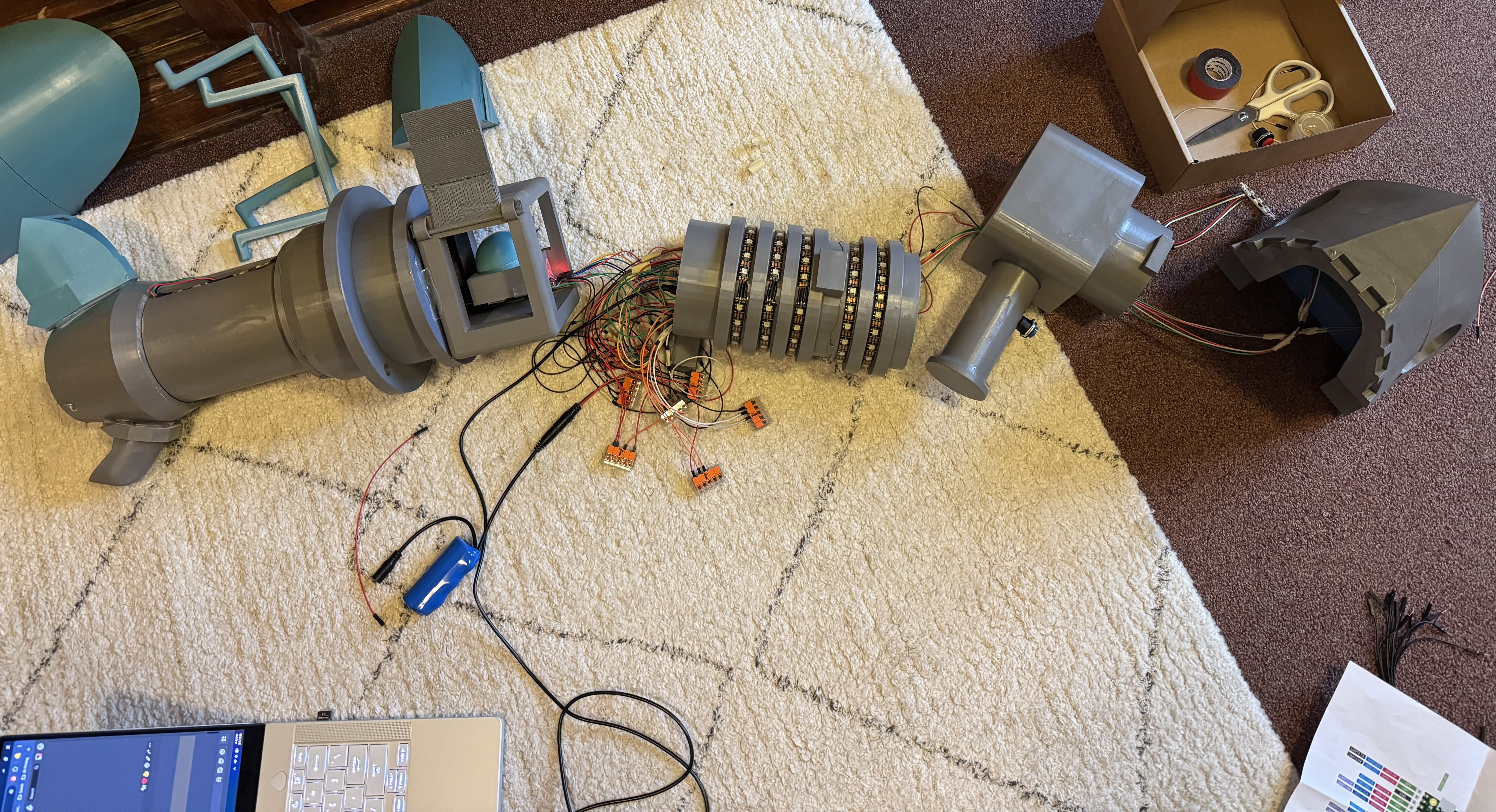

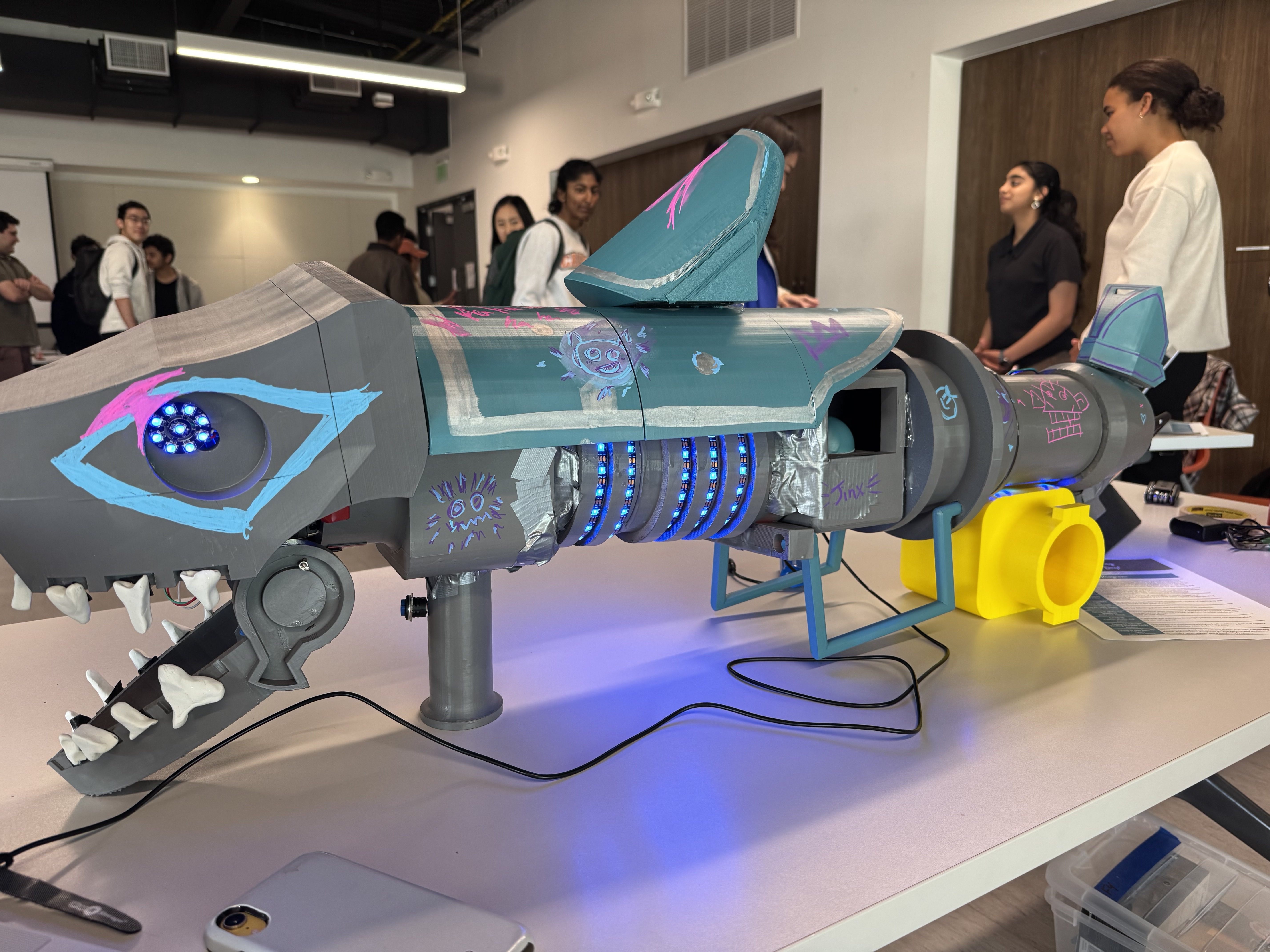

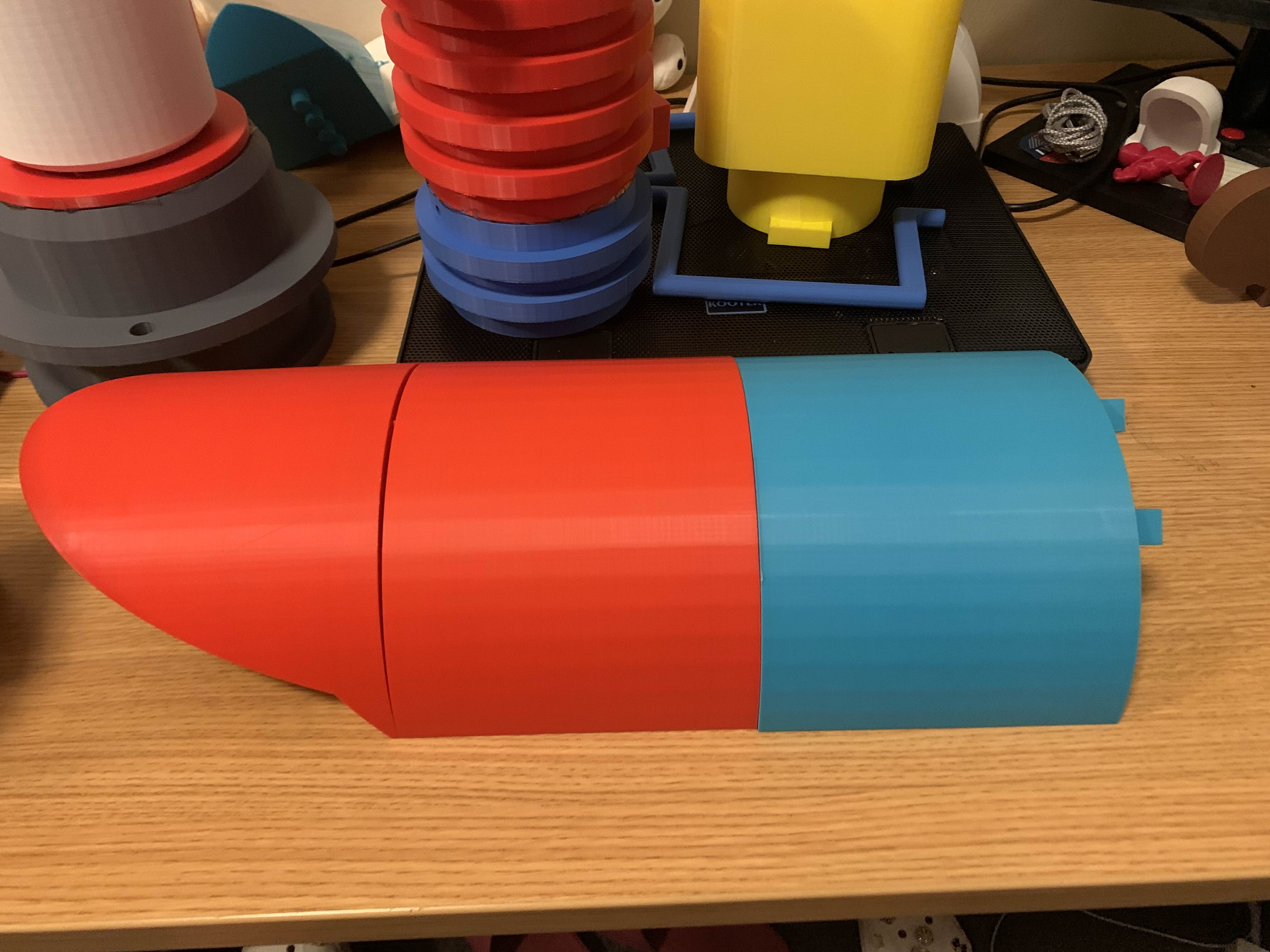

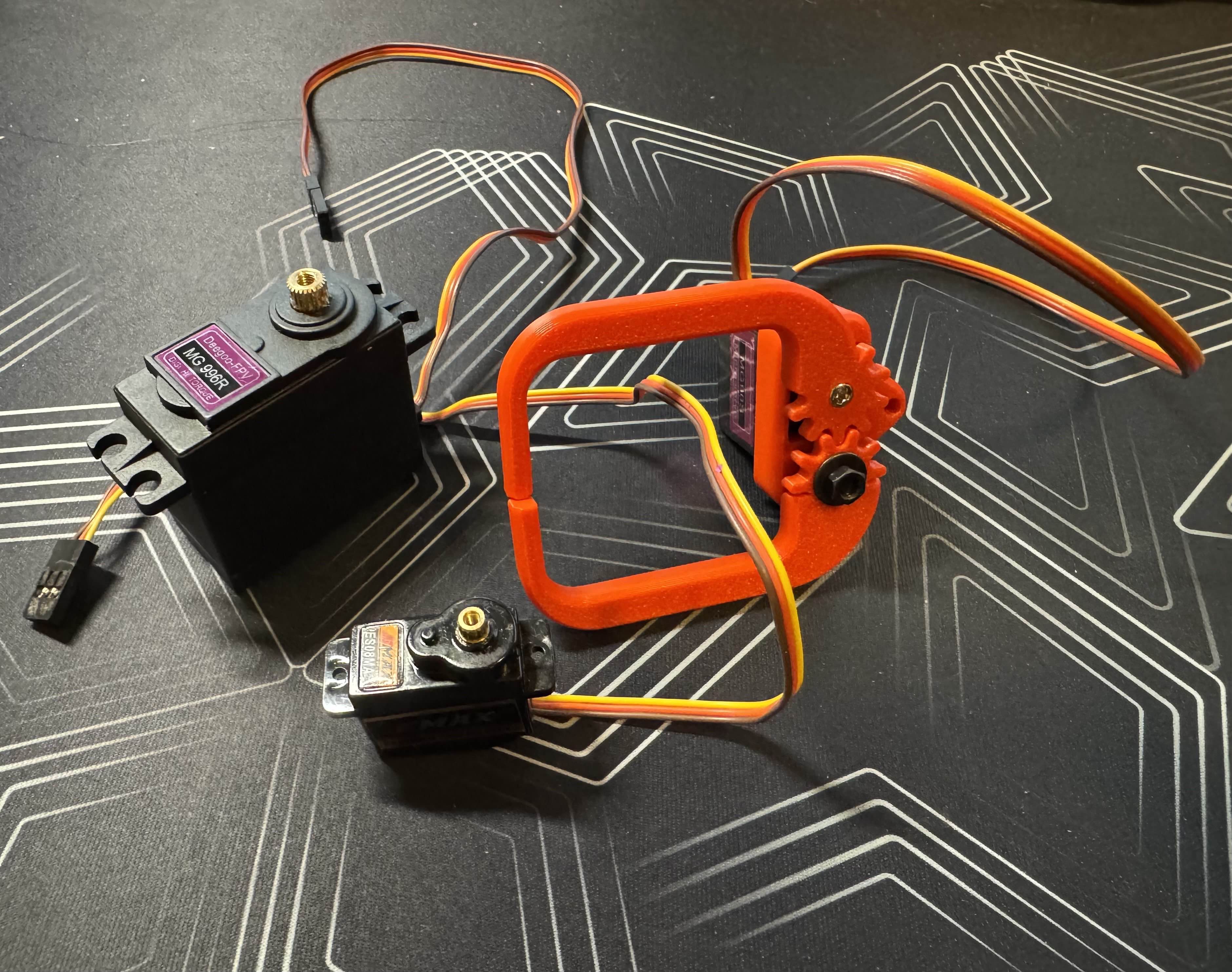

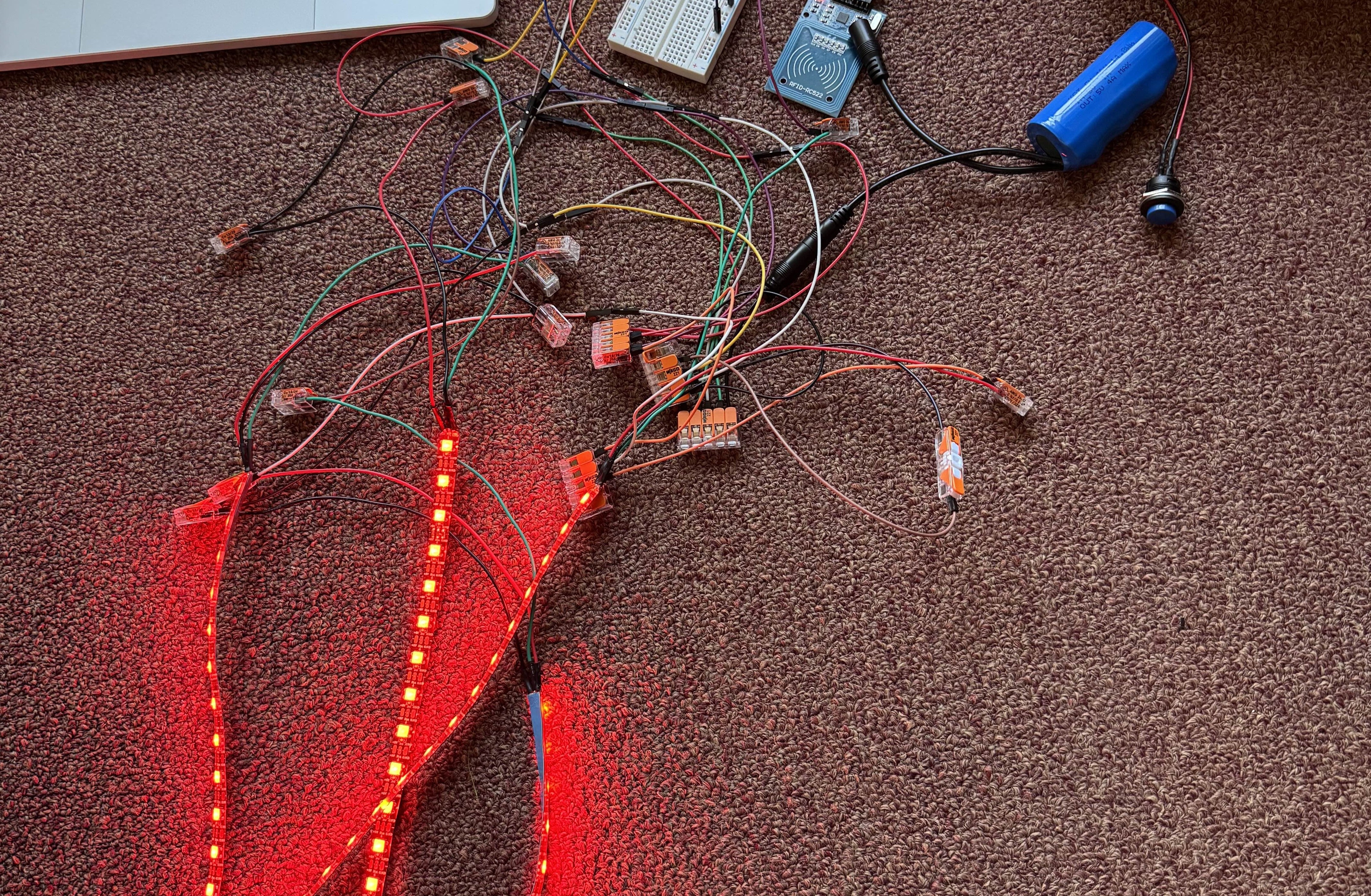

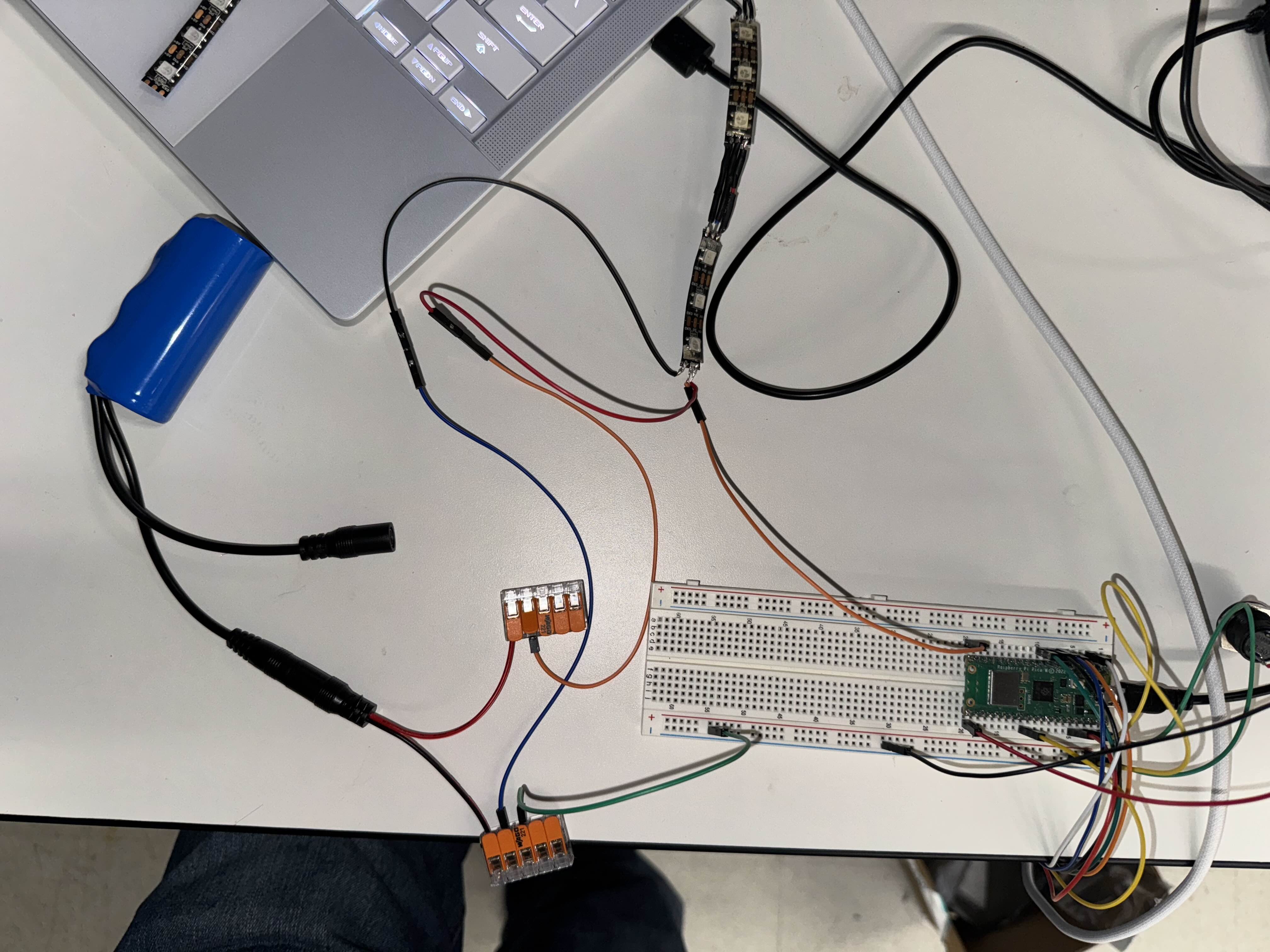

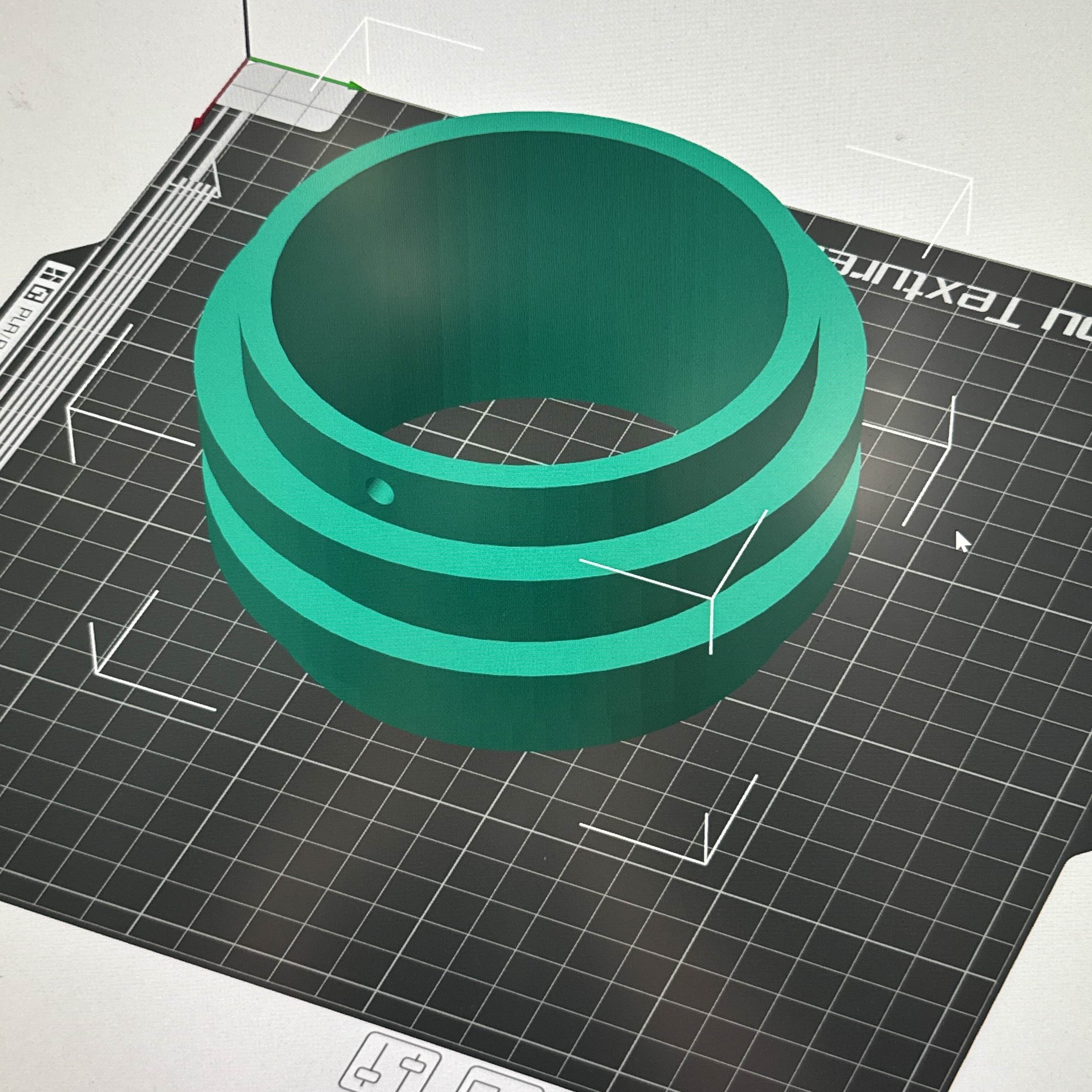

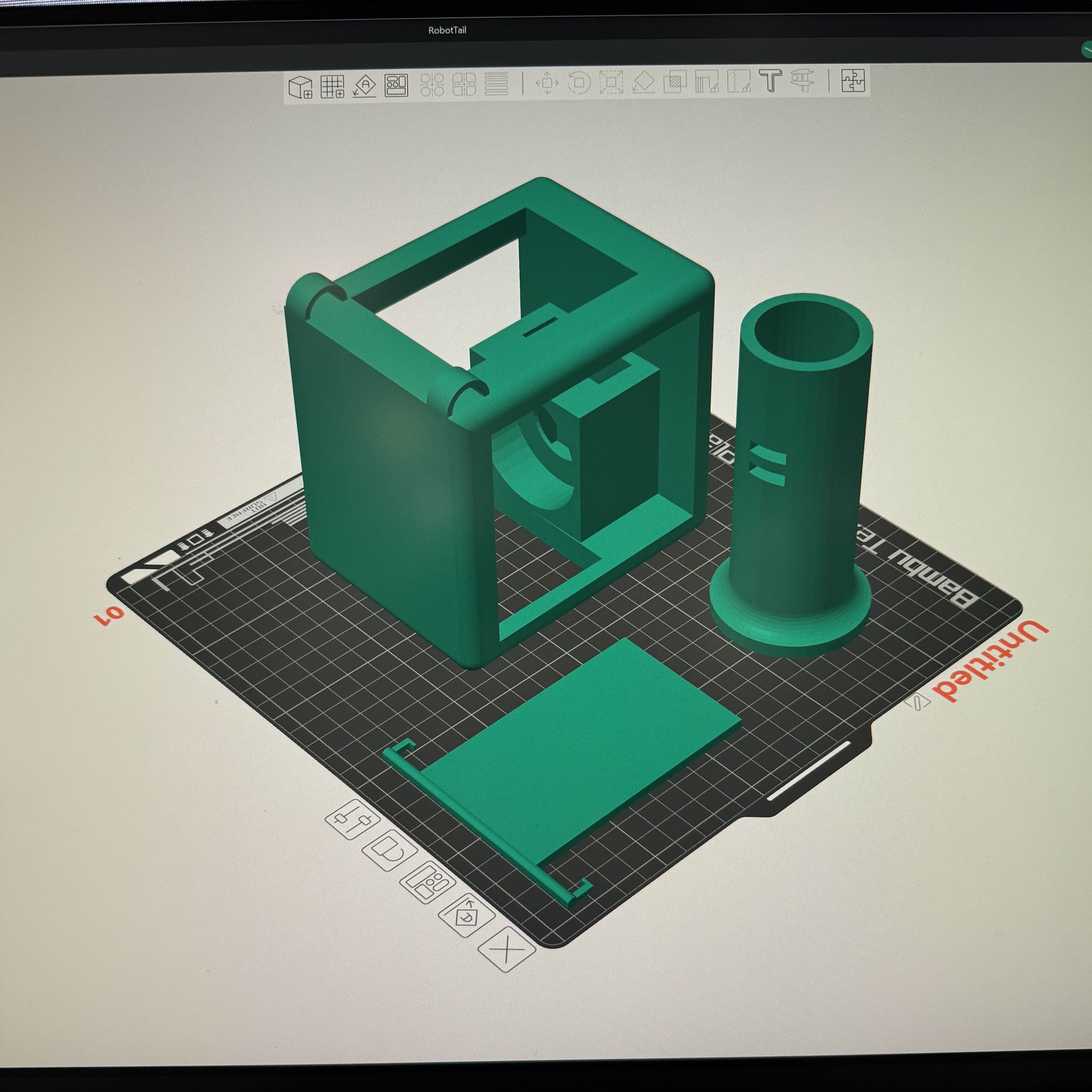

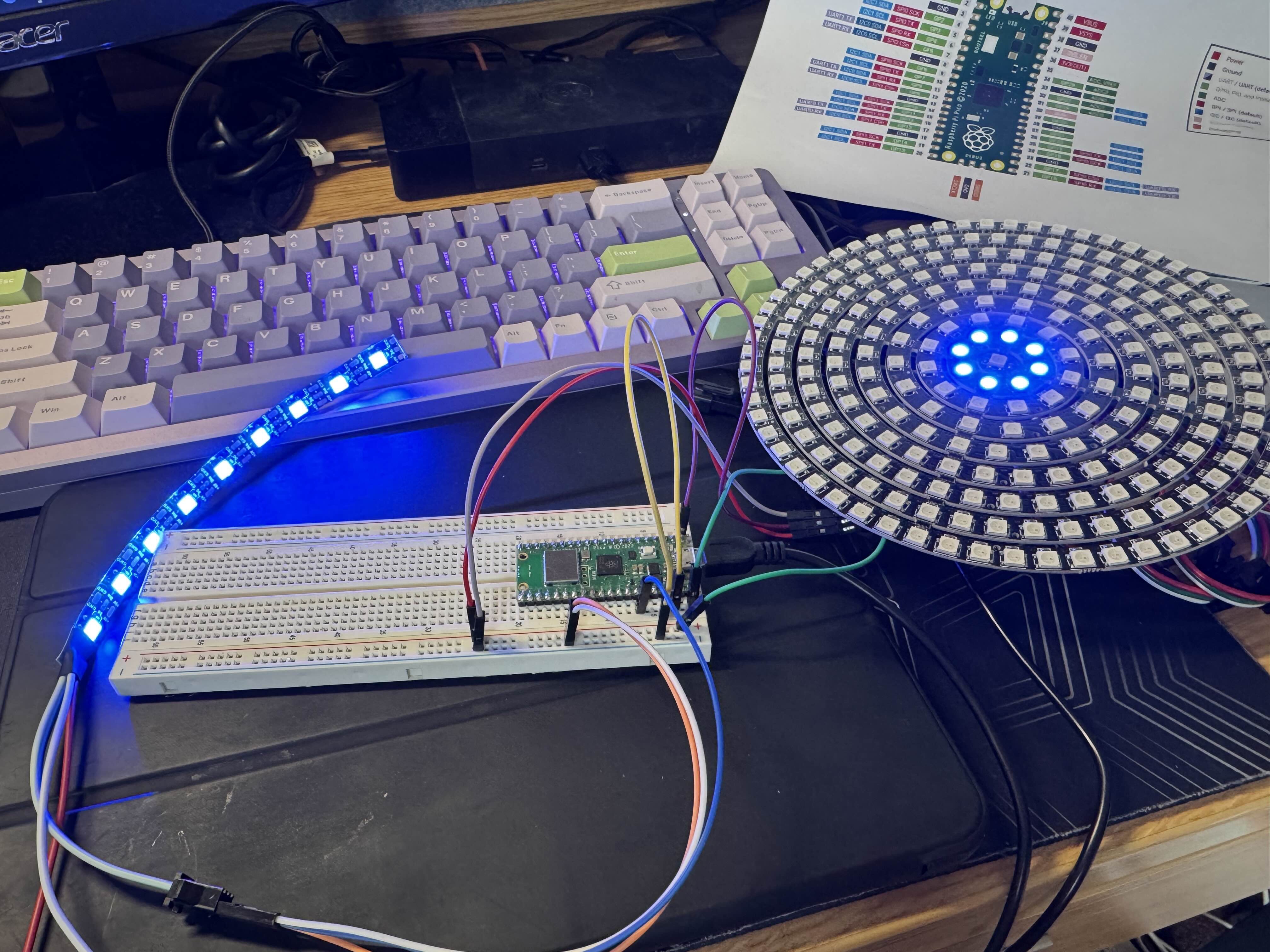

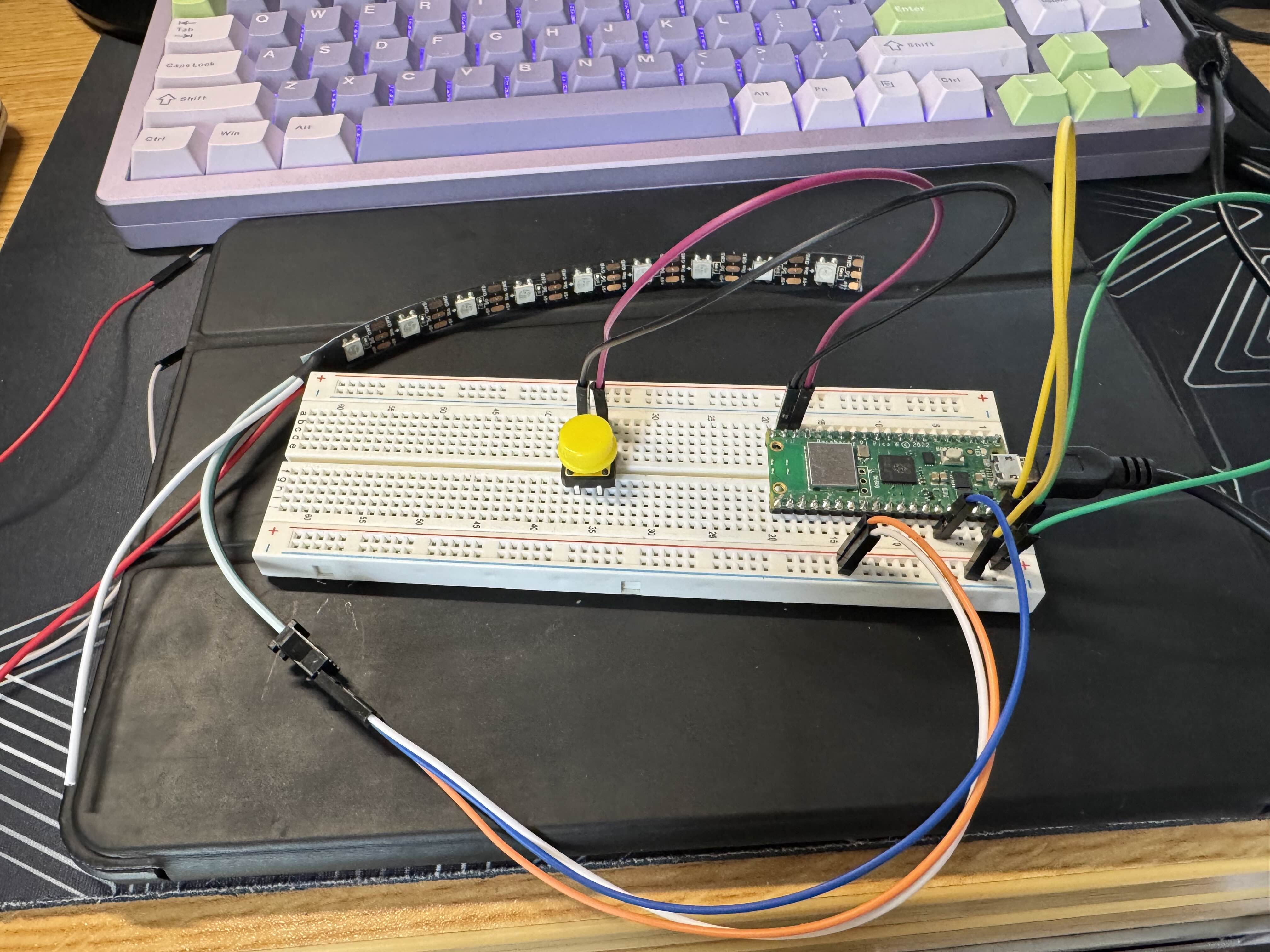

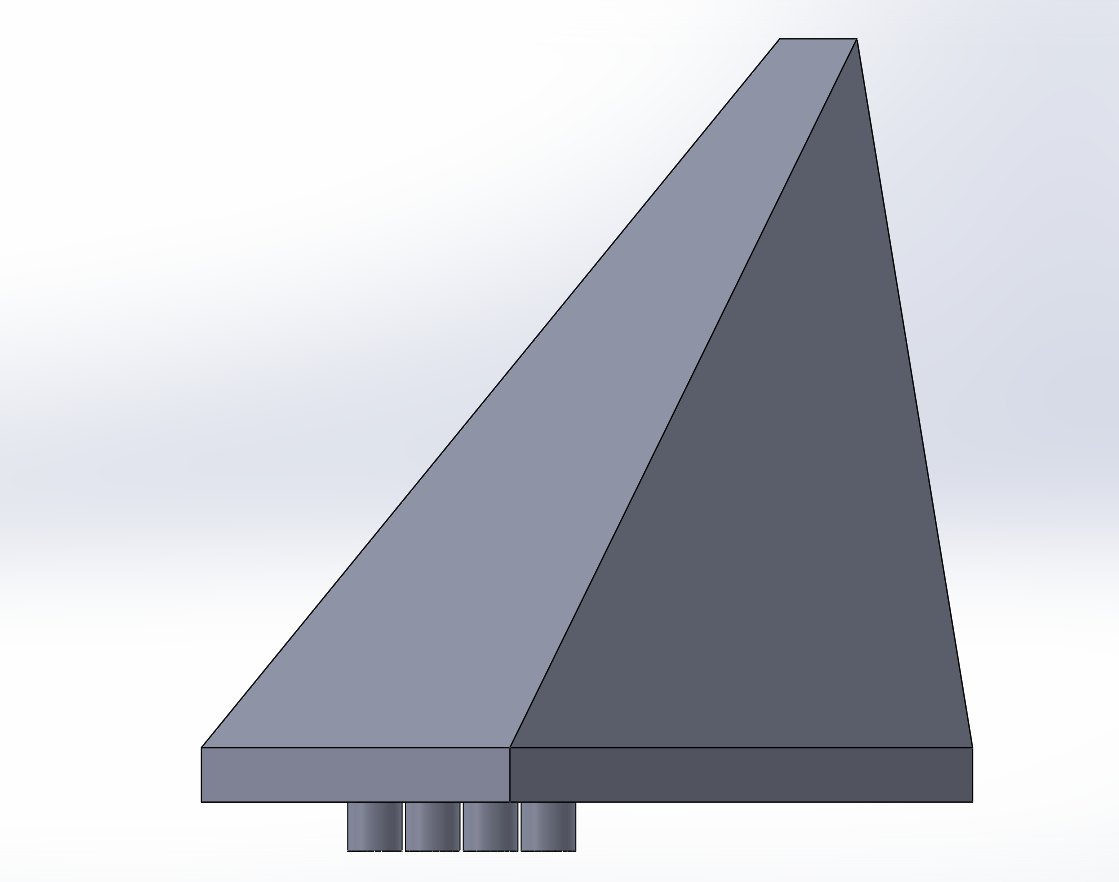

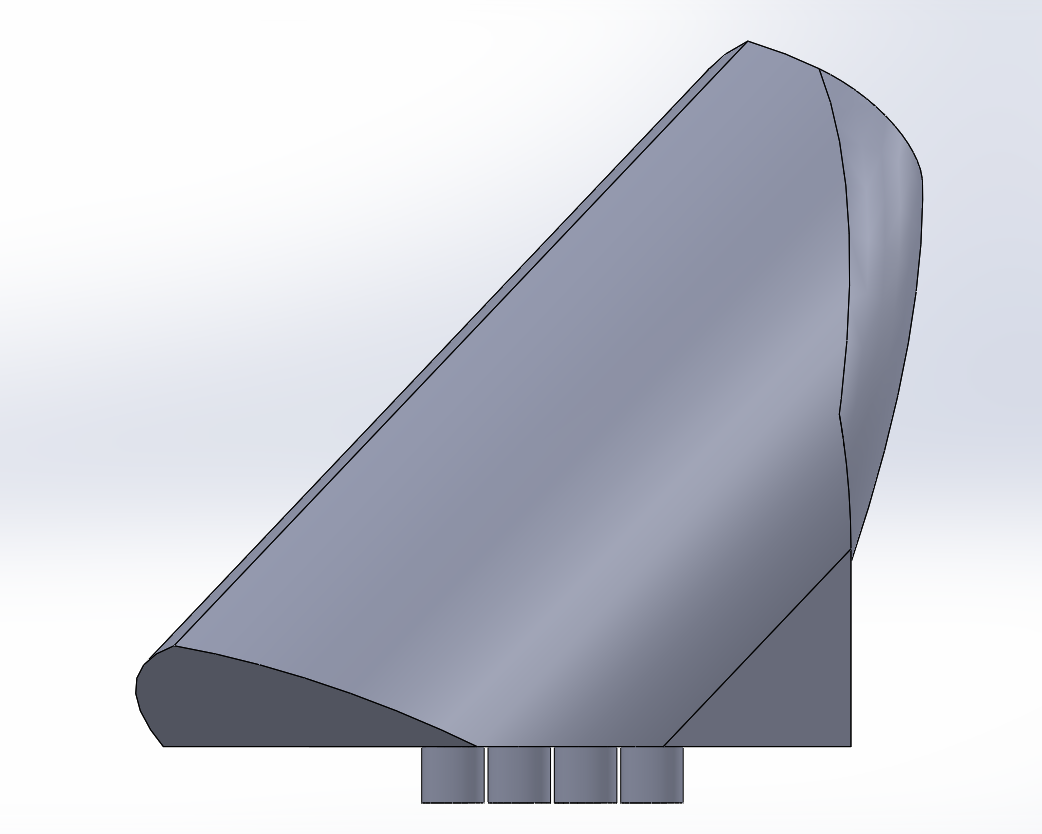

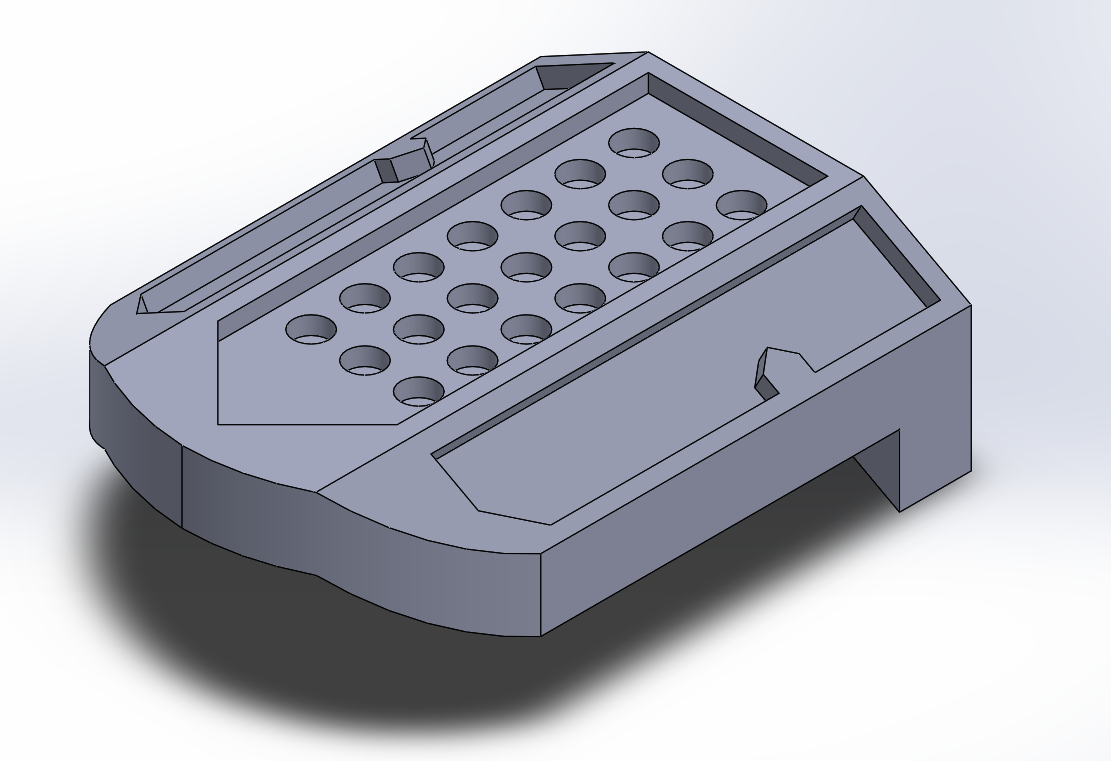

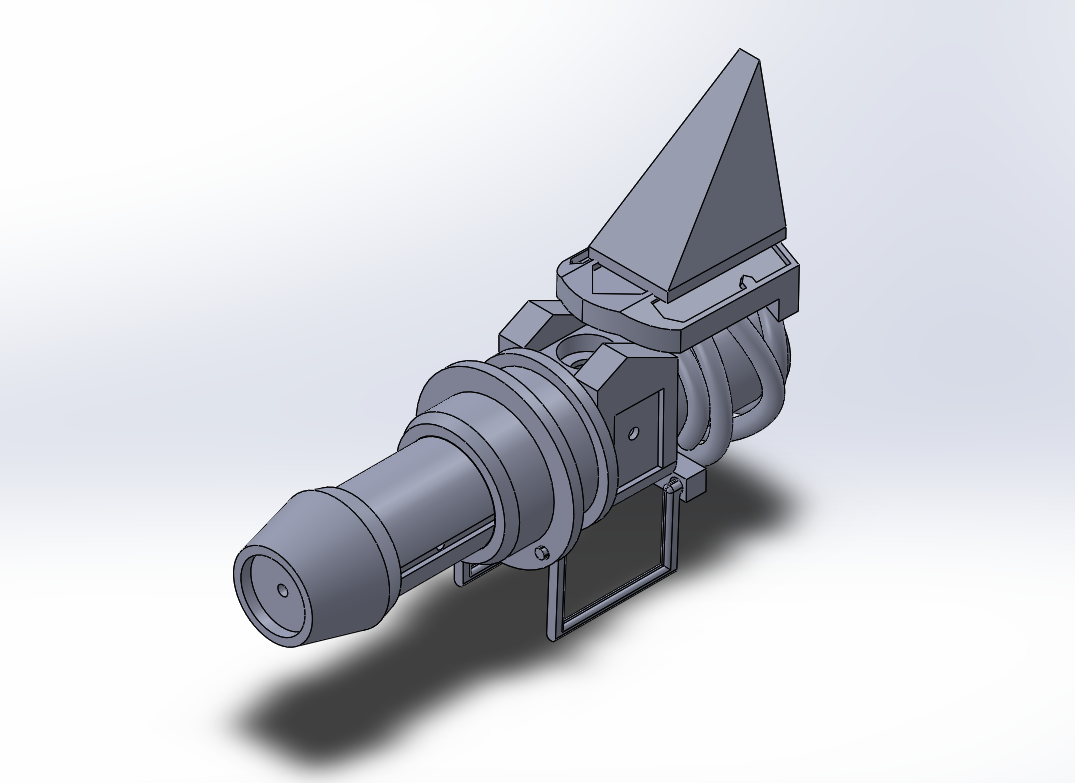

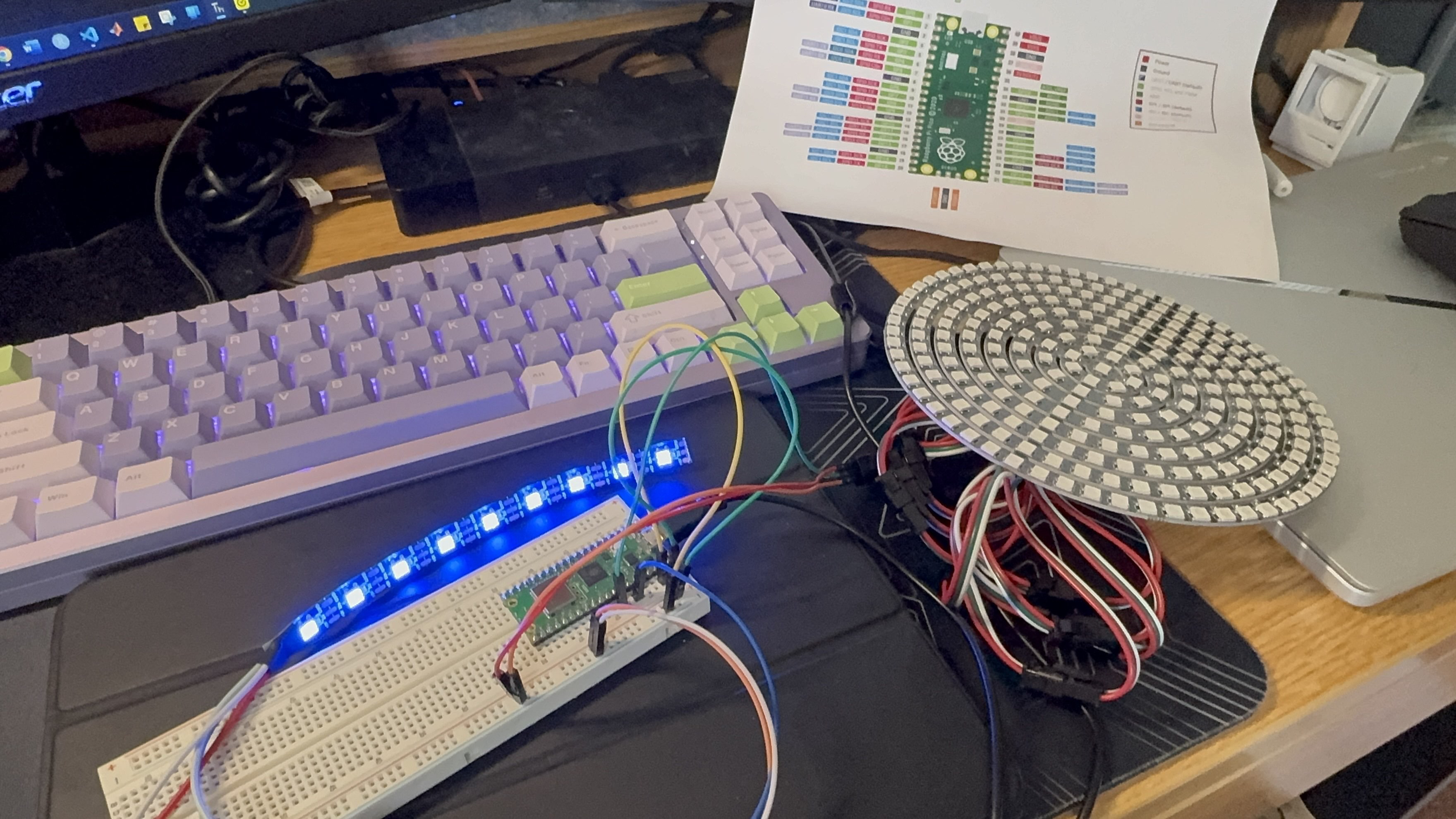

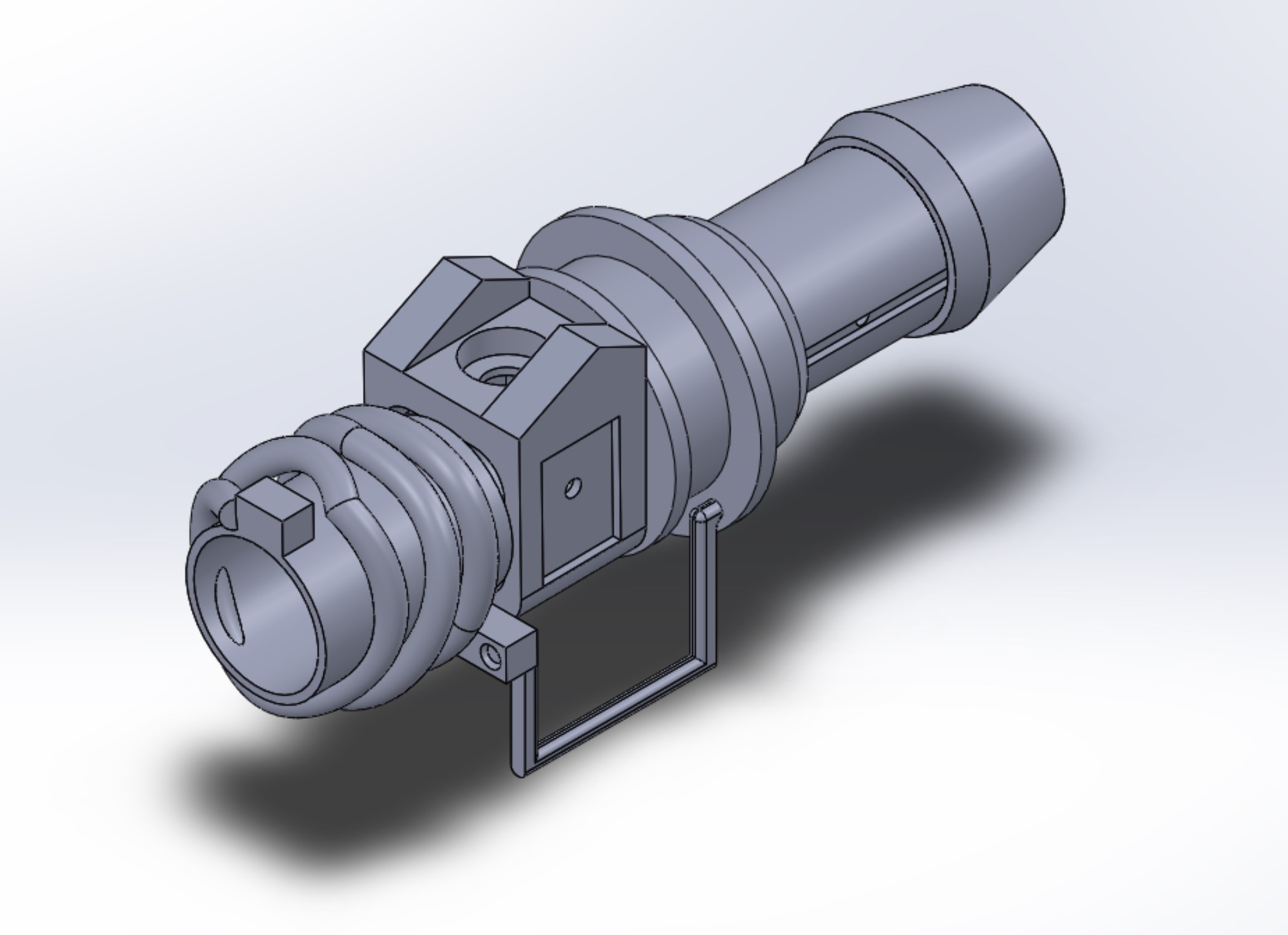

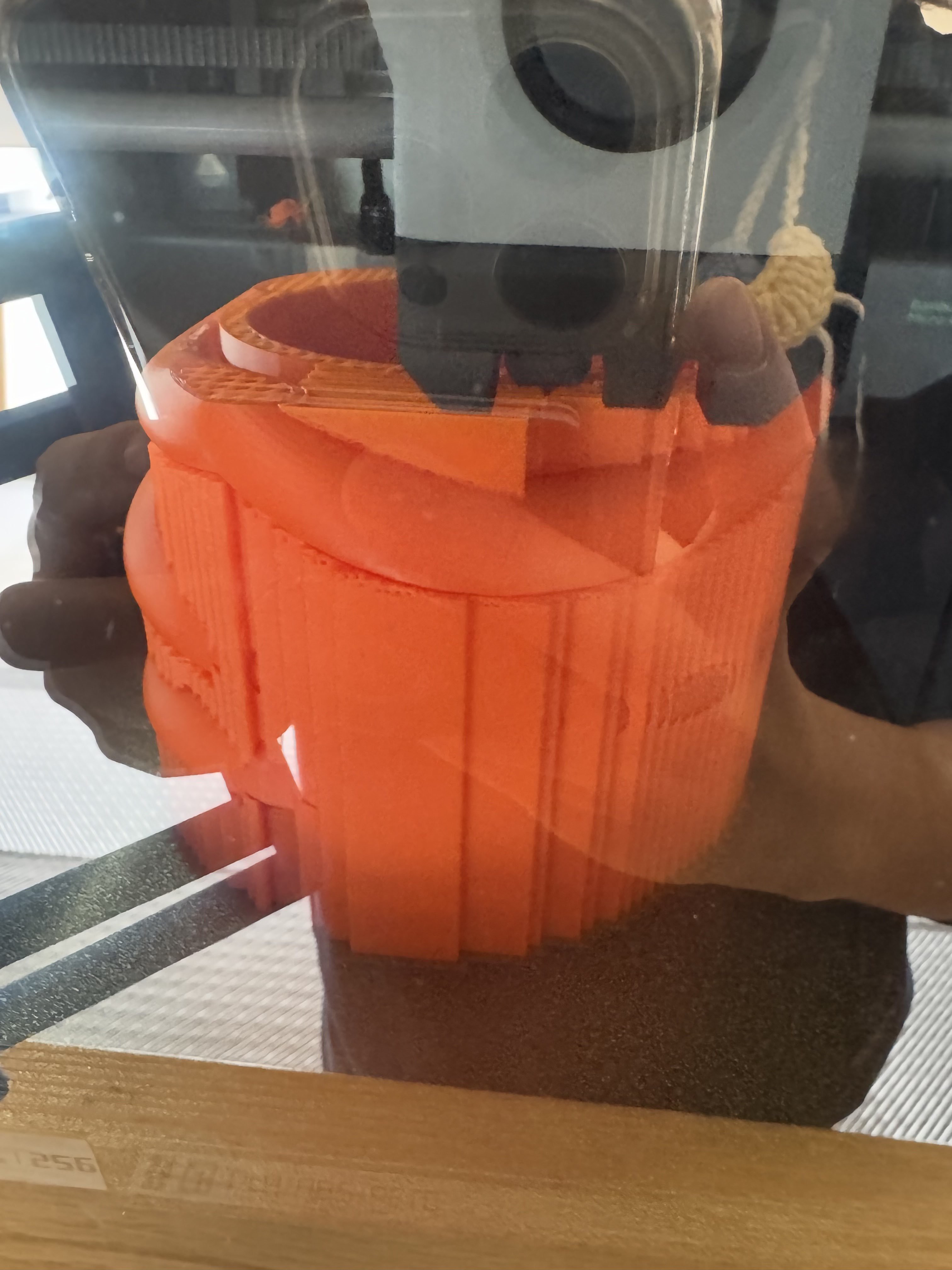

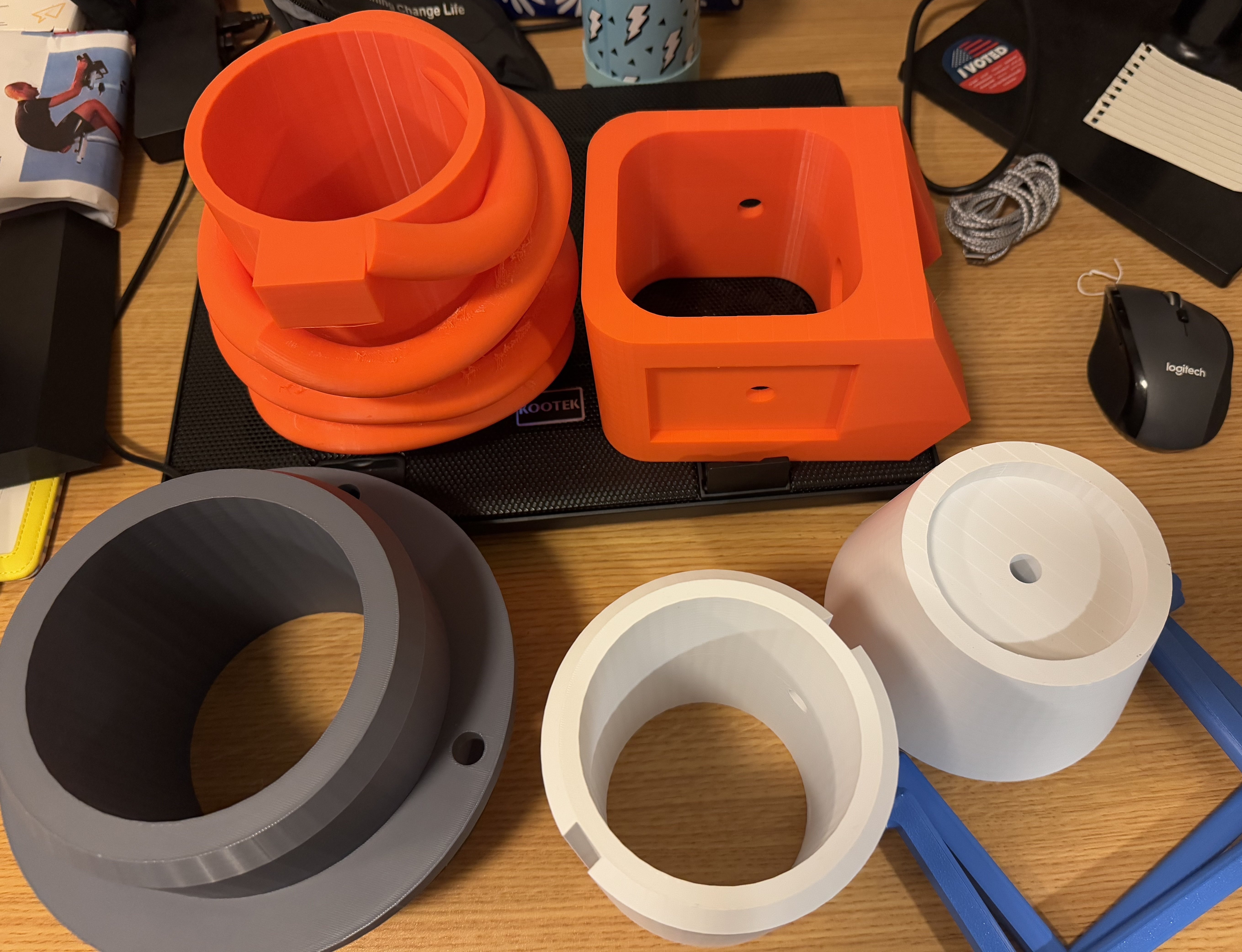

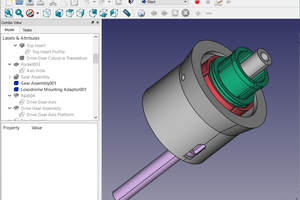

Inspired from Arcane, we decided to make a 3D-printed recreation of the Fish Bones device from the show. A sphere with RFID tags inside symbolized the Hexcore, which is a power source similar to a battery but more powerful. When the device is running all the LED strips and rings (approximately 100 individual LEDs), exhibit a red LED breathing pattern. When the RFID tags reader reads the presence of the tags, the device is being "powered," so the LEDs change to blue. Moreover, the articulate mouth can be moved upon pressing a button on the handle, which moves the jaw down with servo motors and also changes the LED pattern to cycle through as if loading. Note that all the motors and LEDs are separately powered with a lithium-ion polymer battery.

| Power State | Hexcore Detected? | Button Pressed? | Lighting | Jaw Movement |

| Off | - | - | No lighting | No movement |

| On | No | No | Red | No movement |

| On | No | Yes | Red | No movement |

| On | Yes | No | Blue | No movement |

| On | Yes | Yes | Blue | Jaw goes down |

Pat Mutia

Pat Mutia

OddDavis

OddDavis

Padfoot

Padfoot

Angela Sheehan

Angela Sheehan

marciot

marciot