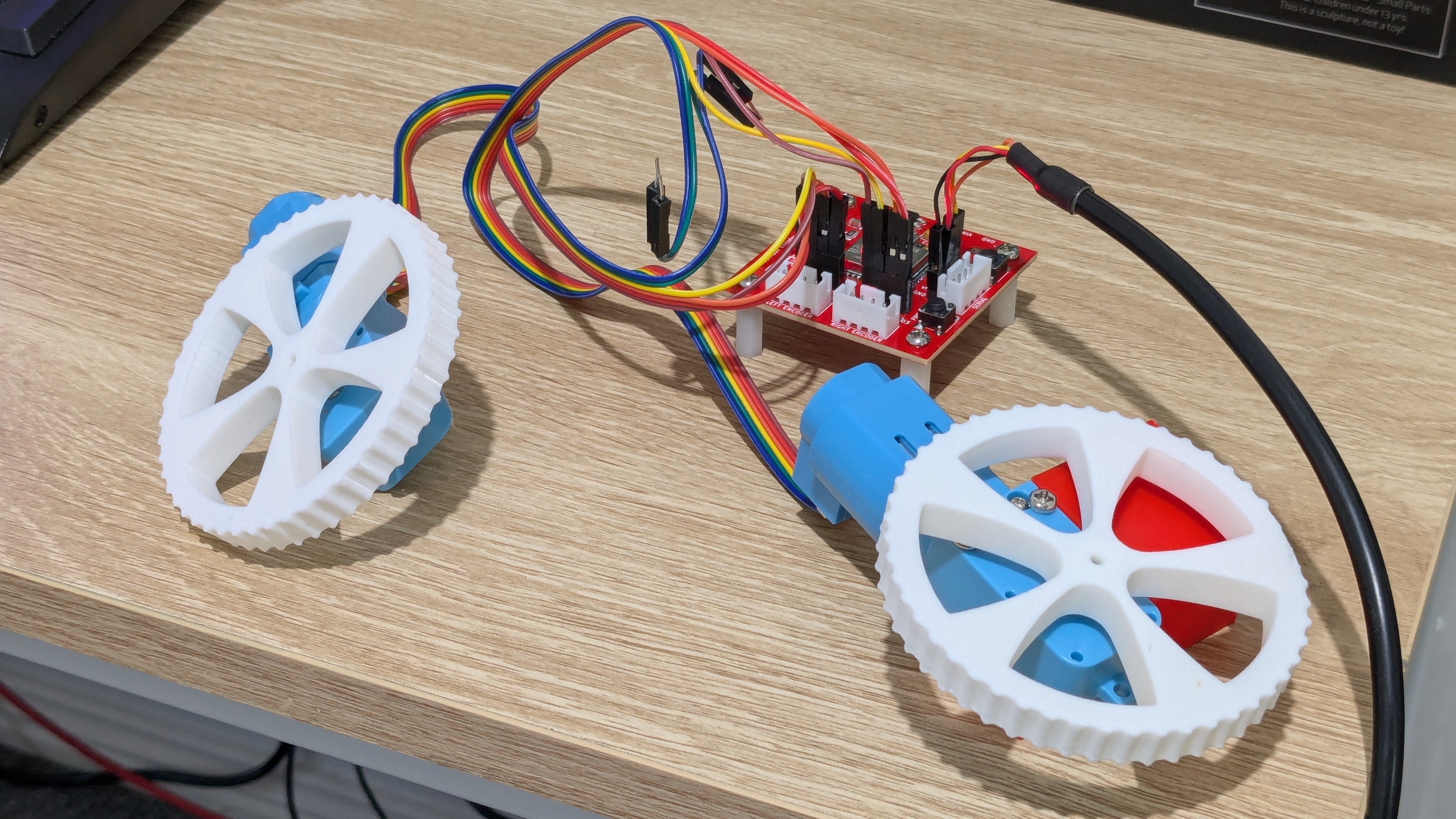

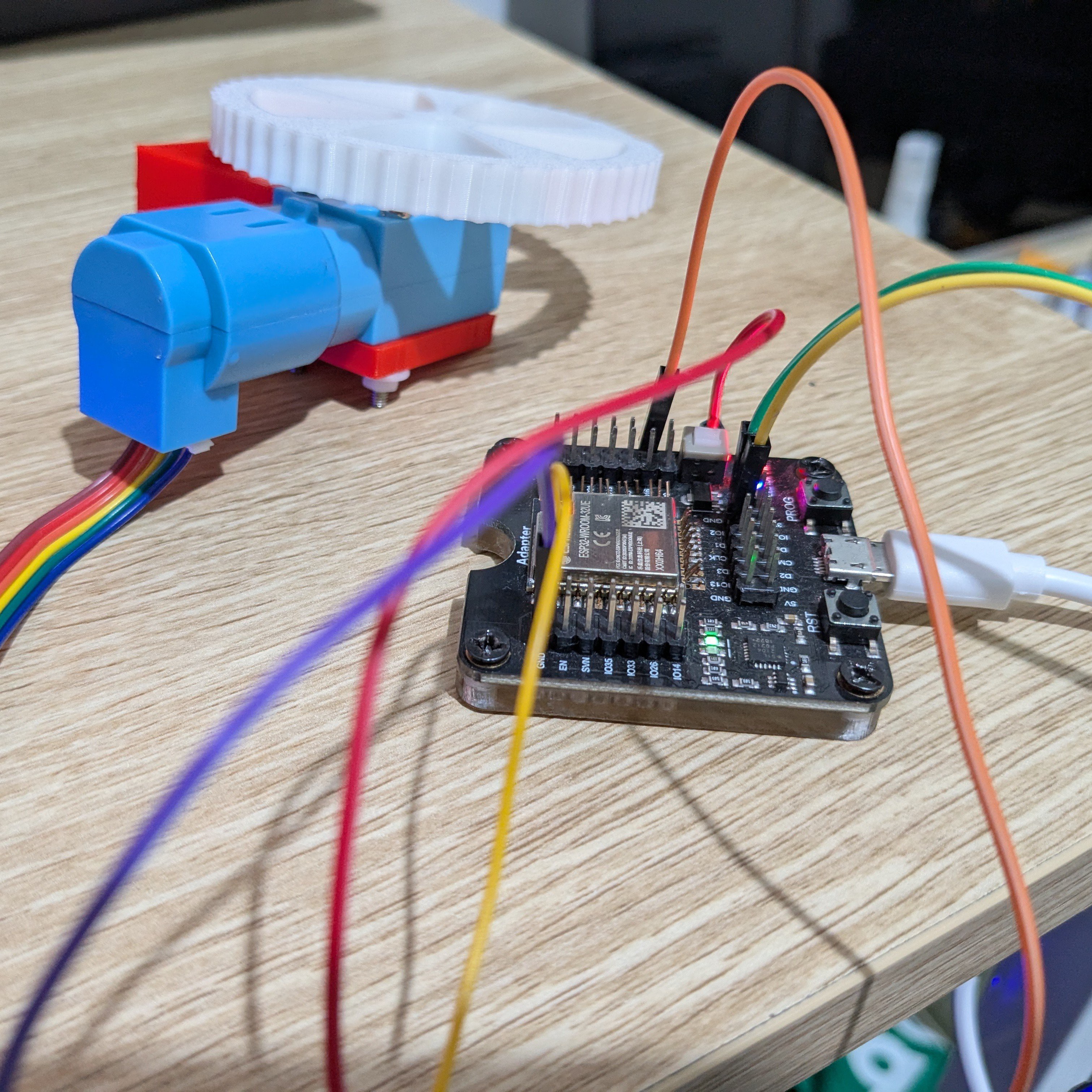

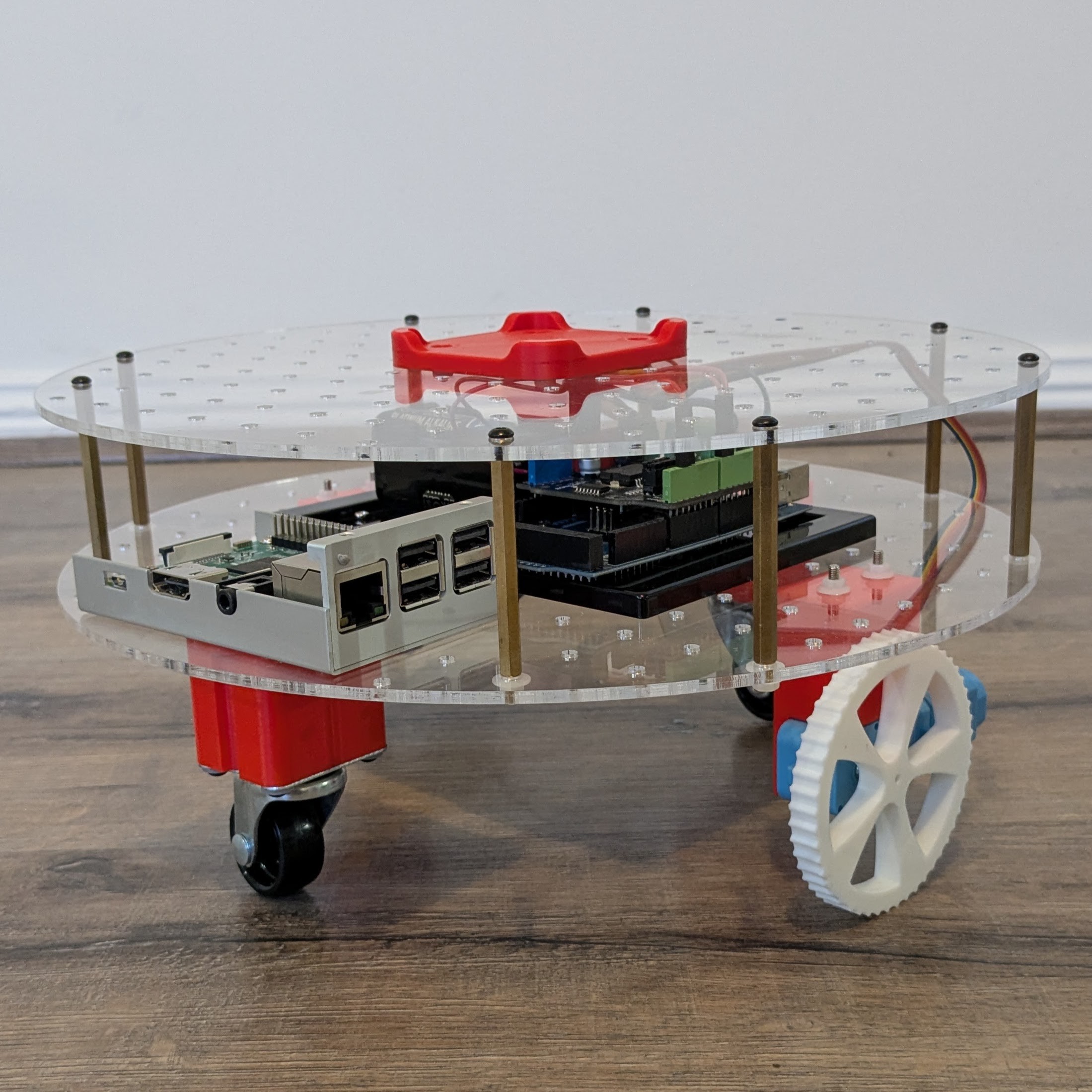

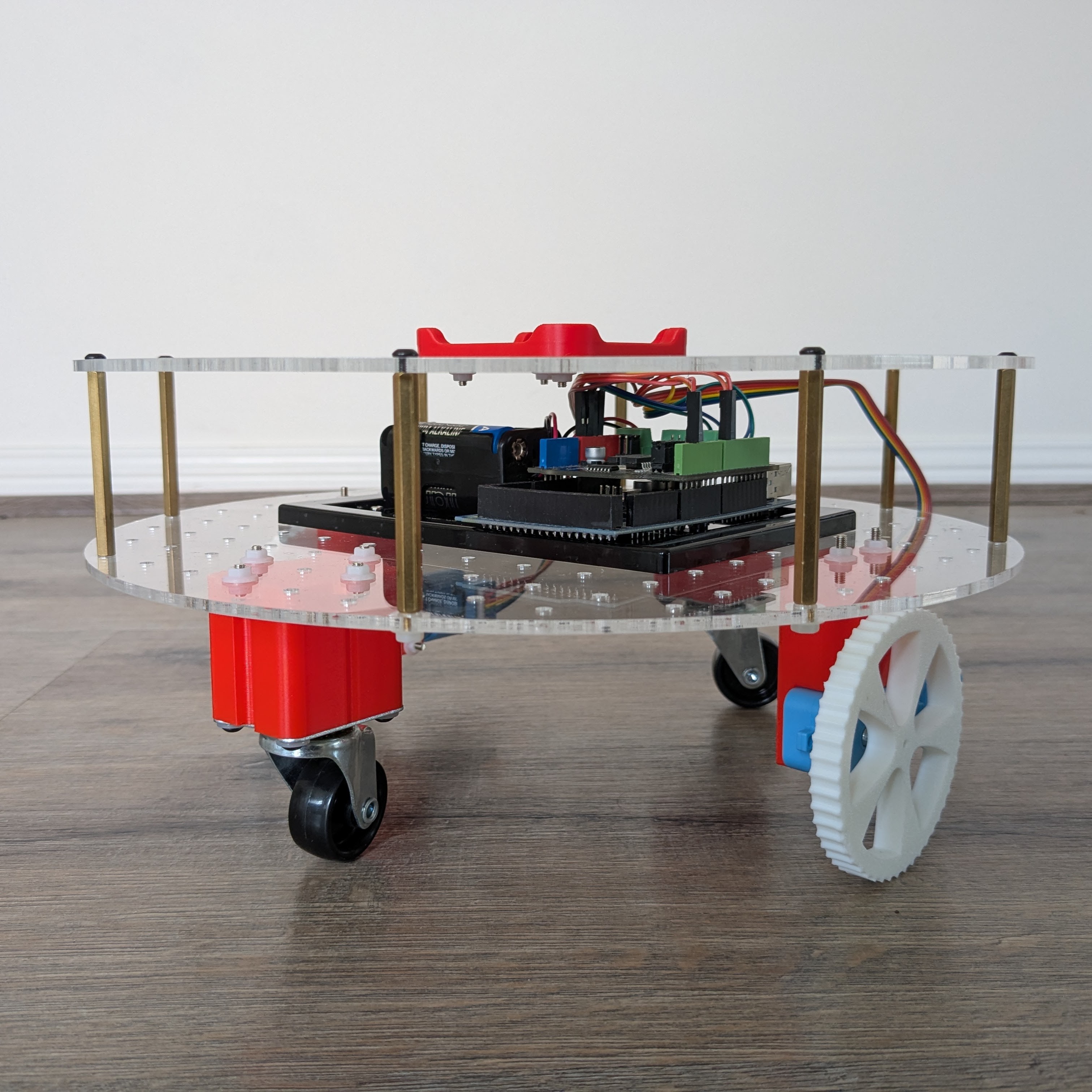

This ongoing project is assisting me to apply my recently acquired ROS 2, micro-ROS, and C learnings to a real-world application.

While this project may not be easily built as a whole by others, I hope that components of it, especially the software, can be used for ideas and inspiration.

Software repositories

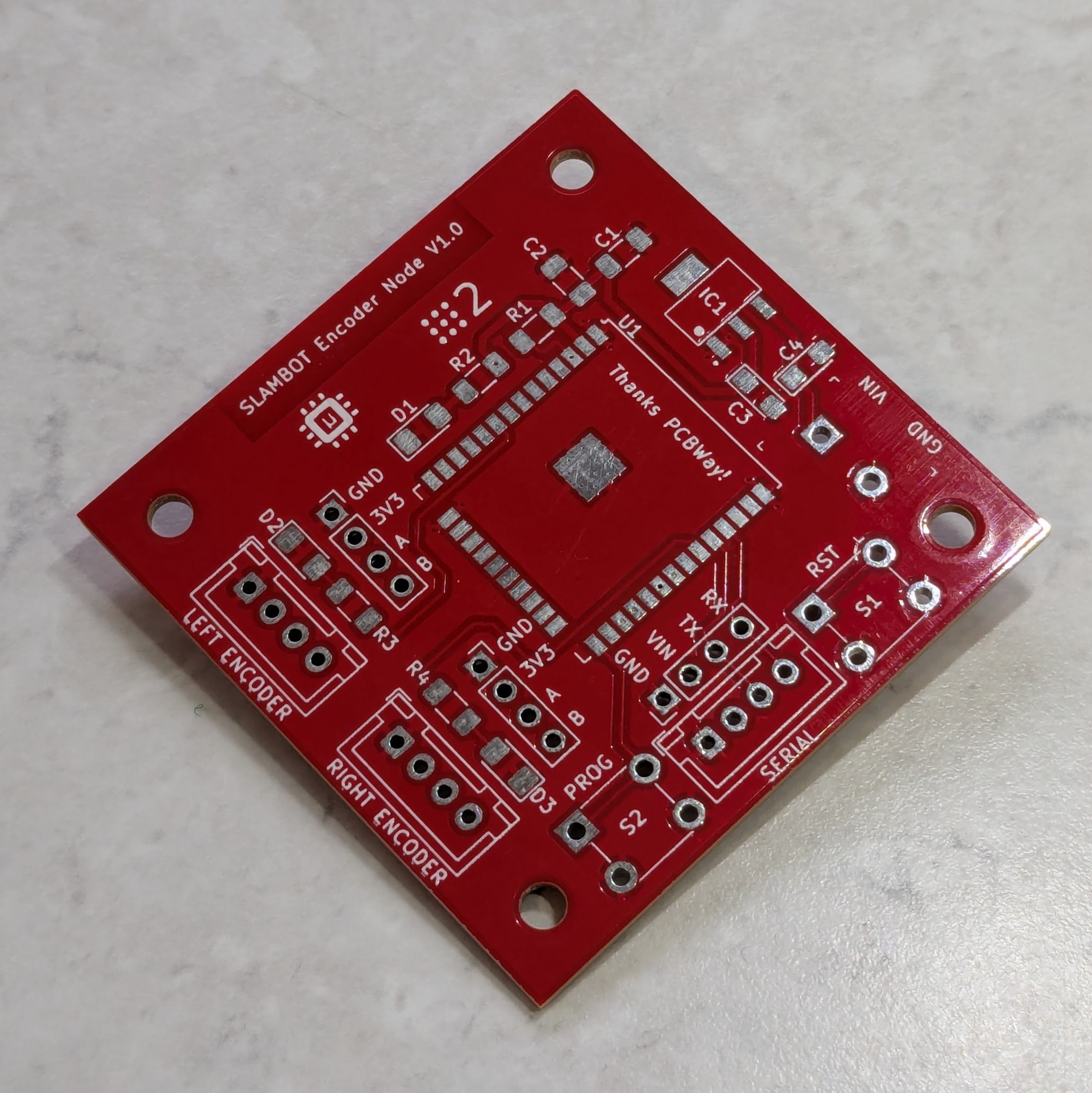

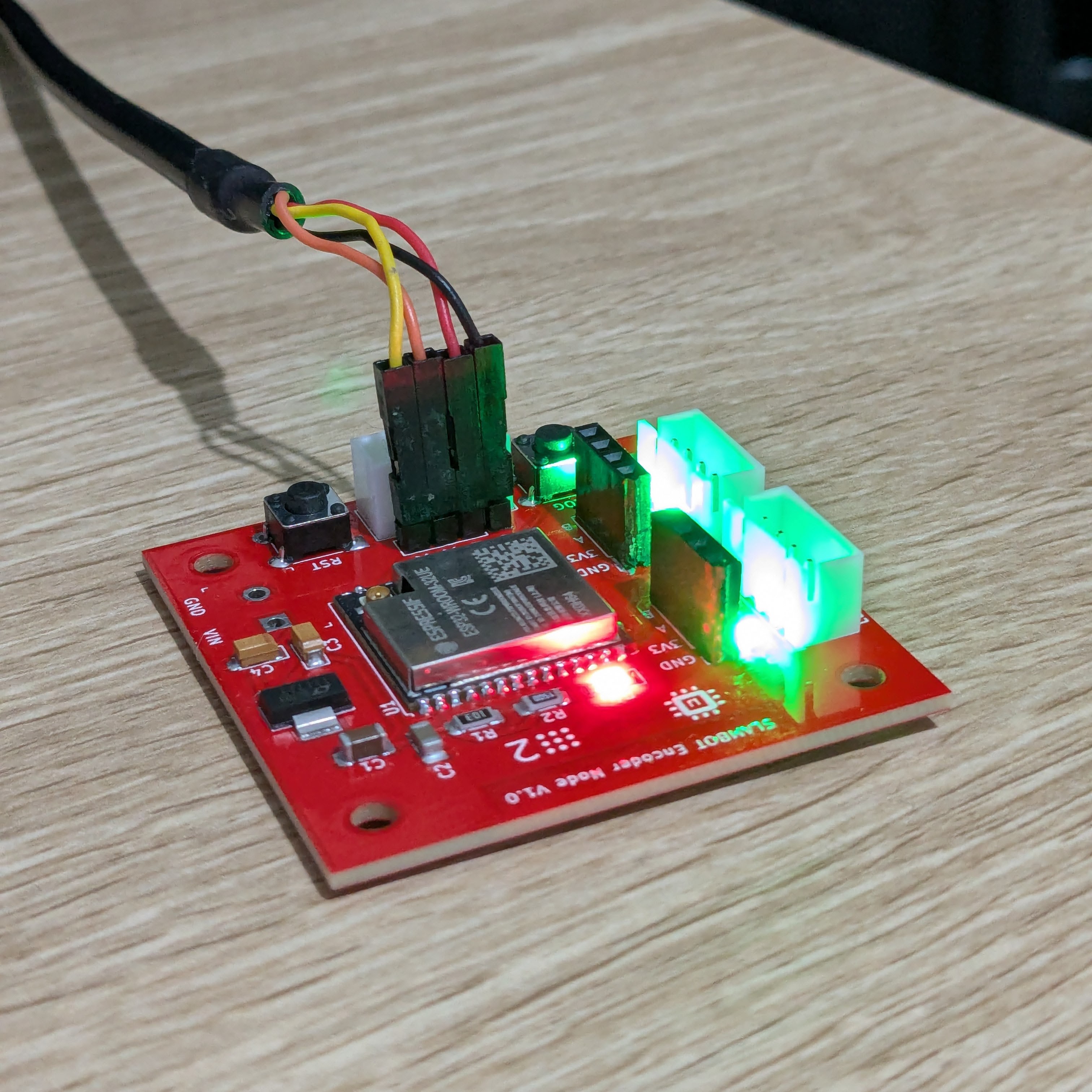

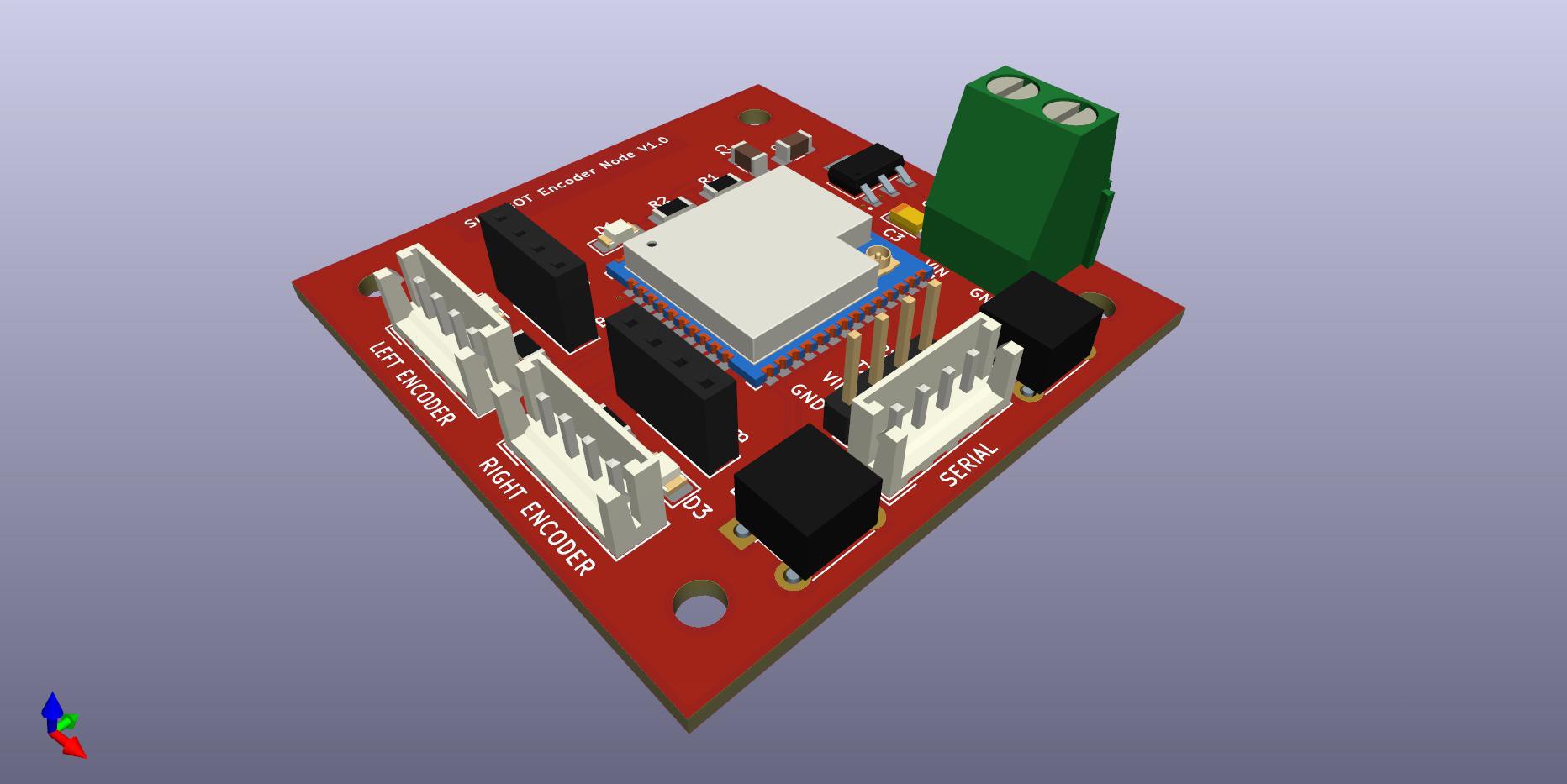

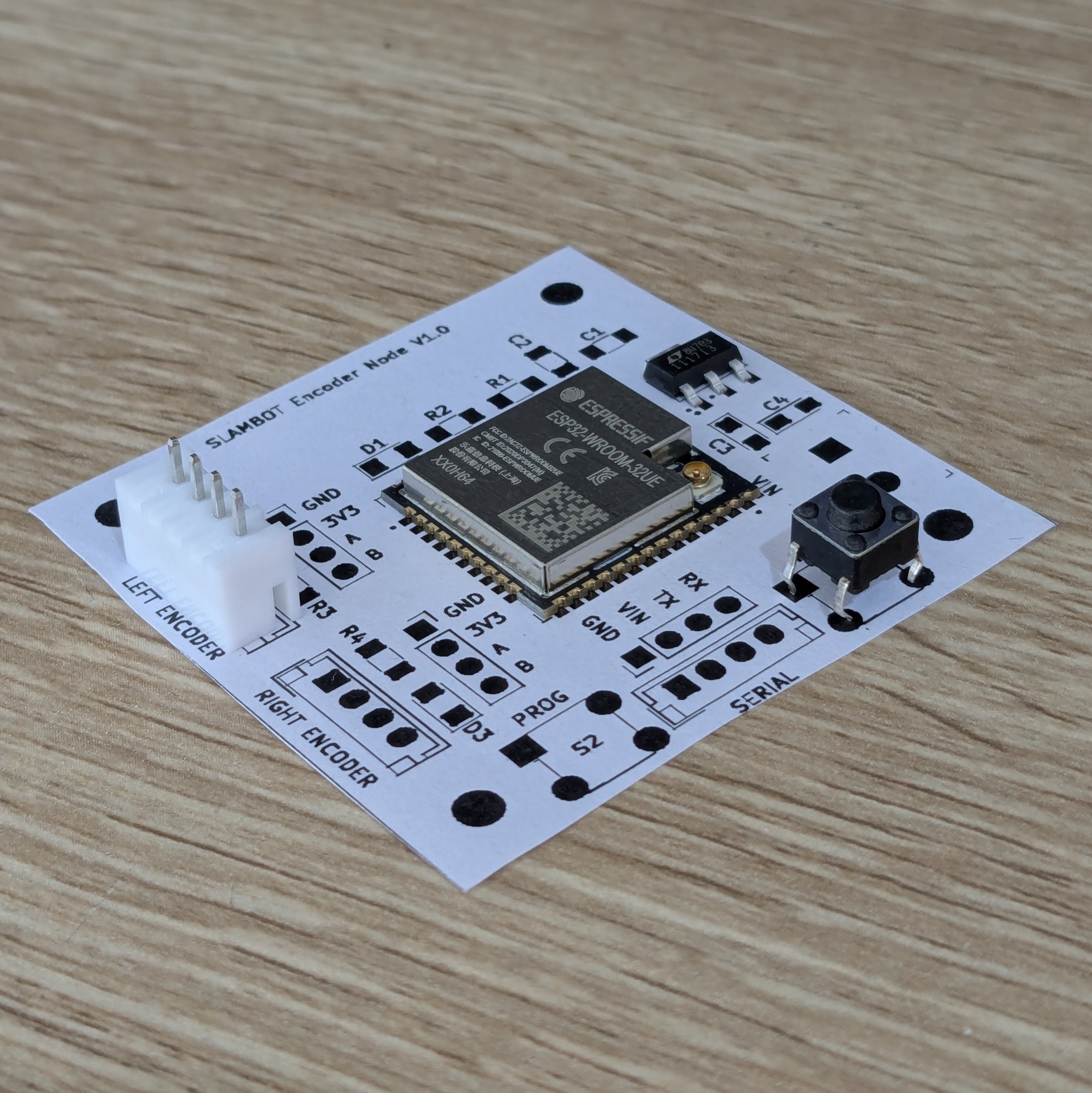

A big thank you to PCBWay for supporting a critical component of this project by printing the PCB for the Encoder Node V1.0. I genuinely appreciate their assistance with this project as their sponsorship has accelerated its development.

Peter Wallhead

Peter Wallhead