3D-Printed Version Stringing Demo

This video provides a real-world example of how the machine operates and handles stringing efficiently. If you have any questions or feedback, feel free to leave a comment!

Functions

- LB/KG display and setting

- Pre-Stretch function

- Constant-Pull system

- Knot function

- Tension adjustment manually during tensioning

- Tension calibration

- Stringing timer

- Tension timer

- Tension counter and boot counter

- Detailed recording of tensioning logs

- Pull speed with 9-speed selection

3D-Printed Parts Download

PicoBETH HW 3D Printed Version

Caution: Avoid using PLA for printing as its strength may degrade over time.

3D Viewing Model (Non-Printable)

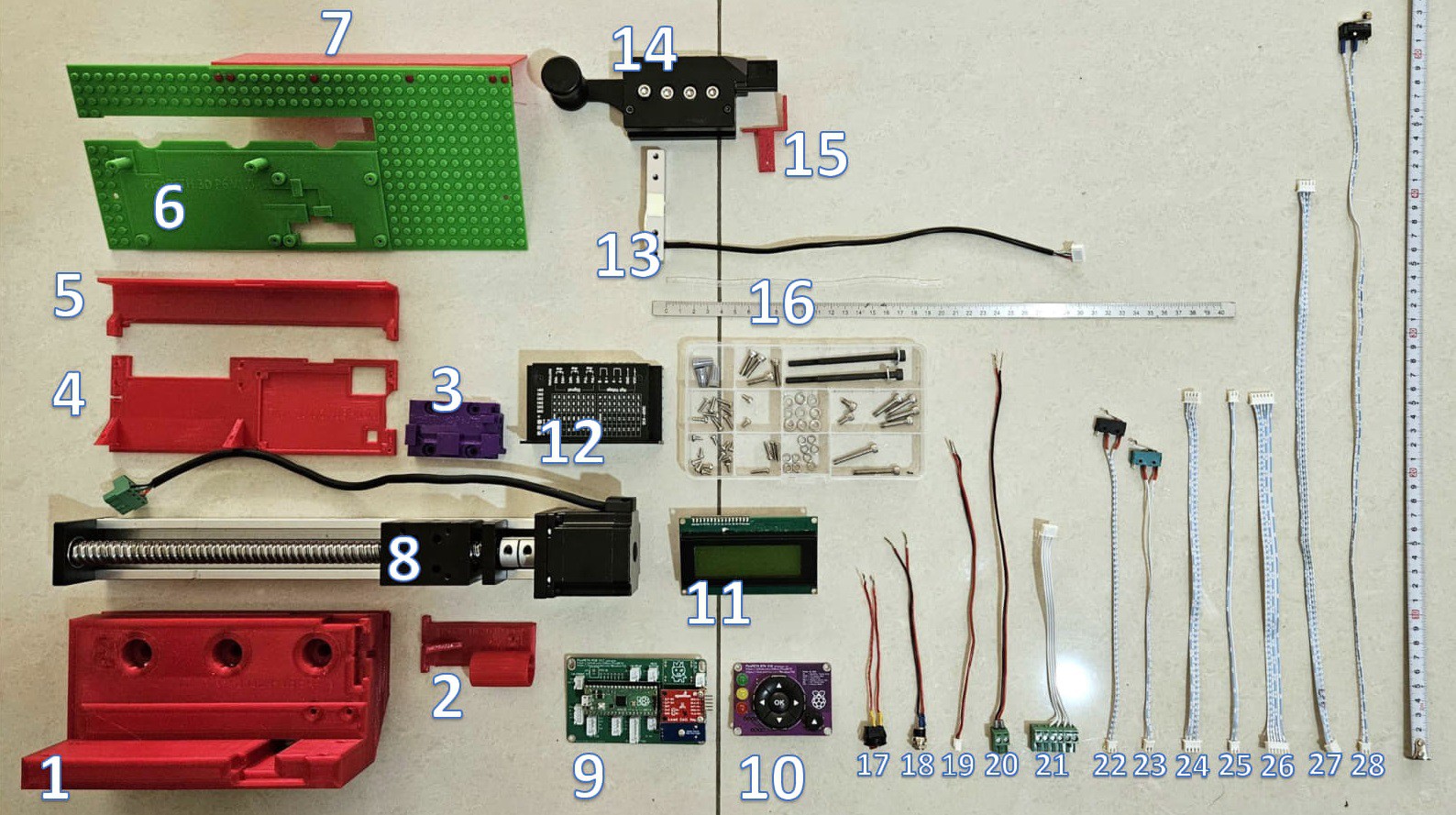

Parts List

Main Components

| No. | Name |

|---|---|

| 1 | Part-1 Main Body |

| 2 | Part-2 Rear Limit Mount |

| 3 | Part-3 Load Cell Bracket |

| 4 | Part-4 PCB and TB6600 Mount |

| 5 | Part-5 Power and Switch Cover |

| 6 | Part-6 LCD and Button Mount |

| 7 | Part-7 Rear Cover |

| 8 | SGX 1610 200mm Sliding Table |

| 9 | PCB Mainboard, Raspberry Pico, SparkFun HX711, Buzzer |

| 10 | PCB Button Board |

| 11 | 2004 i2c LCD |

| 12 | TB6600 Stepper Motor Driver |

| 13 | NJ5 20kg Load Cell (YZC-133) |

| 14 | WISE 2086 Clip Head |

| 15 | Activation Switch Mount |

| 16 | Ø4 20cm Wire Wrap |

| 17 | Power Switch 12cm |

| 18 | DC Jack Cable 15cm |

| 19 | Mainboard Power Cable 20cm |

| 20 | TB6600 Power Cable 28cm |

| 21 | XH2.54mm 4P Stepper Motor Signal Cable 15cm |

| 22 | XH2.54mm 2P Front Limit Switch Cable 20cm |

| 23 | XH2.54mm 2P Rear Limit Switch Cable 20cm |

| 24 | XH2.54mm 4P LED Signal Cable (Same Direction) 25cm |

| 25 | XH2.54mm 2P Cancel Button Cable (Same Direction) 25cm |

| 26 | XH2.54mm 6P Five-Way Button Cable (Same Direction) 25cm |

| 27 | XH2.54mm 4P LCD Signal Cable 40cm |

| 28 | XH2.54mm 2P Clip Activation Switch Cable 50cm |

Warning: Power cables must not be thinner than 22 AWG.

Screw List

| No. | Name | Quantity |

|---|---|---|

| A | Gray Spring Wire Connectors | 3 |

| B | M3 × 10mm Self-Tapping Screws | 8 |

| C | M3 × 6mm Self-Tapping Screws | 15 |

| D | M2.6 × 10mm Self-Tapping Screws | 4 |

| E | M3 × 6mm Round-Head Screws | 2 |

| F | M4 × 16mm Hex Screws | 4 |

| G | M4 × 20mm Hex Screws | 4 |

| H | M4 × 30mm Hex Screws | 2 |

| I | M4 × 8mm Hex Screws | 2 |

| J | M4 Spring Washers | 10 |

| K | M4 Flat Washers | 10 |

| L | M5 × 80mm Hex Screws + Washers | 2 |

Assembly Steps

Follow the YouTube Tutorial Video for detailed assembly instructions.

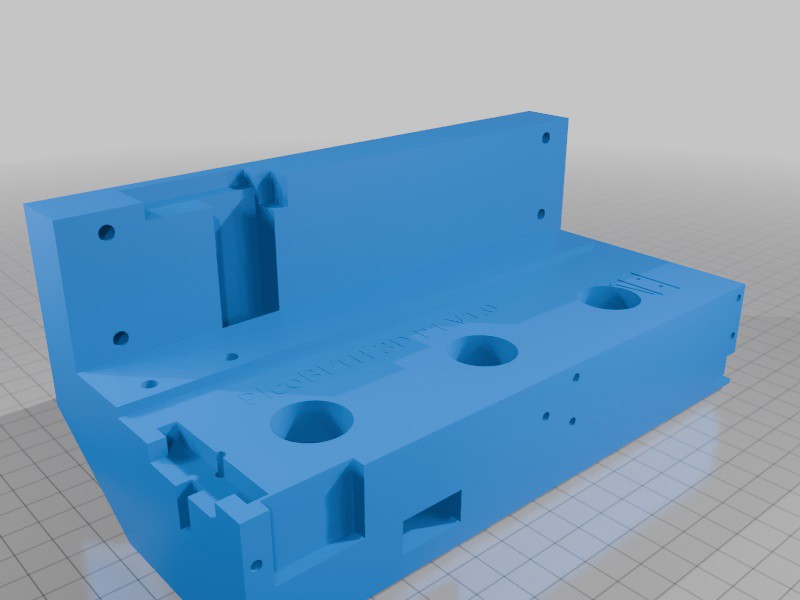

Step 1: 3D-Printed Parts

Main Body (PART-1)

- The main body must withstand significant deformation forces. Recommended print settings:

- Wall Thickness: At least 5mm

- Infill: At least 30%

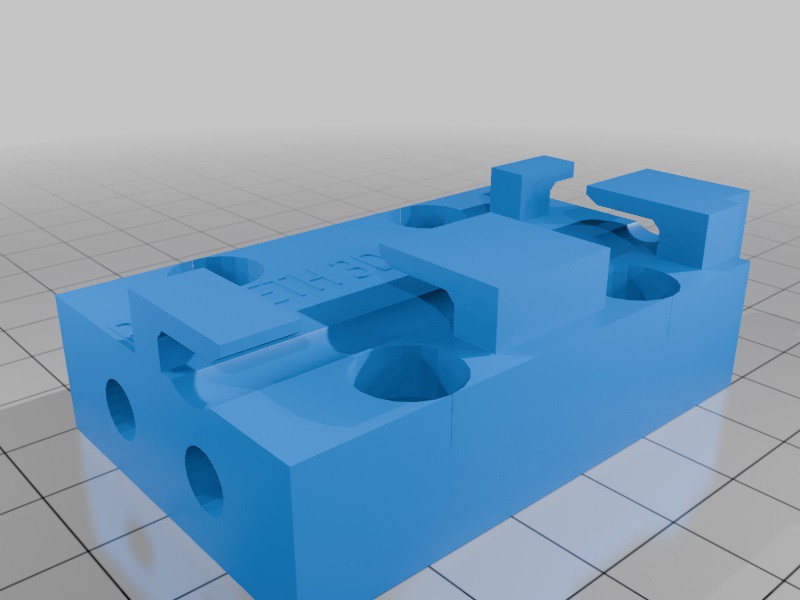

Load Cell Bracket (PART-3)

This part serves as the mounting bracket for the Load Cell and the sliding table. Recommended print settings:

- Infill: 100%

Step 2: Assembling the Main Body (Part-1)

- Attach the bottom of the main body to the sliding table using M4 x 30mm screws + spring washers + flat washers x2 (keep them slightly loose for adjustment).

- Attach the sides of the main body to the sliding table using M4 x 20mm screws + spring washers + flat washers x4 (keep them slightly loose for adjustment).

- Align the main body with the sliding table.

- Tighten the bottom M4 x 30mm screws x2 to a torque of 1.5 Nm.

- Tighten the side M4 x 20mm screws x4 to a torque of 1.5 Nm.

Caution: Ensure washers are installed, and tighten screws to the recommended torque to prevent damage to the 3D-printed parts.

Step 3: Assembling the PCB and TB6600 Mount (Part-4)

- Secure the TB6600 to the mount using M3 x 10mm self-tapping screws x4.

- Secure the PCB using M3 x 10mm self-tapping screws x2 and M3 x 6mm self-tapping screws x2.

- Connect the TB6600 power cables, control signal cables, and motor signal cables.

- Secure the TB6600 mount to the frame using M3 x 10mm self-tapping screws x2.

Step 4: Wiring the Power Cables

- Install the power switch and DC jack onto the Power Cover (Part-5).

- Insert the mainboard power cable into the mainboard.

- Use gray spring wire connectors to connect the DC jack positive wire to...

kuokuo702

kuokuo702

BoboPL

BoboPL

Becky Stern

Becky Stern

Greg Zumwalt

Greg Zumwalt

Micahel Guerero

Micahel Guerero